Preparation method of high mud-resistant concrete water reducer with graft copolymerized cationic side chains

A concrete water-reducing agent and cation technology, which is applied in the field of high-mud-resistance concrete water-reducing agent to achieve the effects of expanding theoretical connotation, broad application prospects and less side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

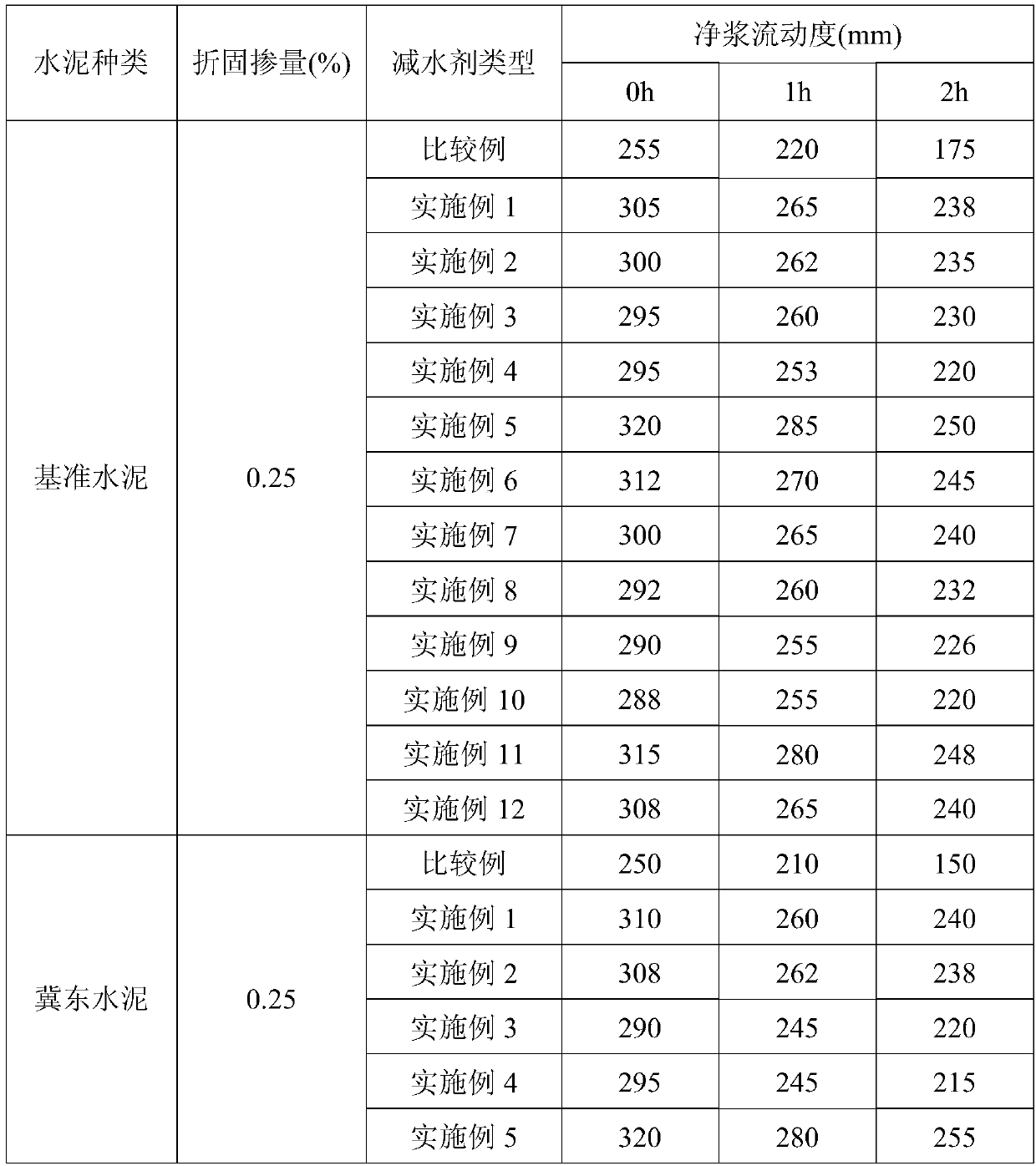

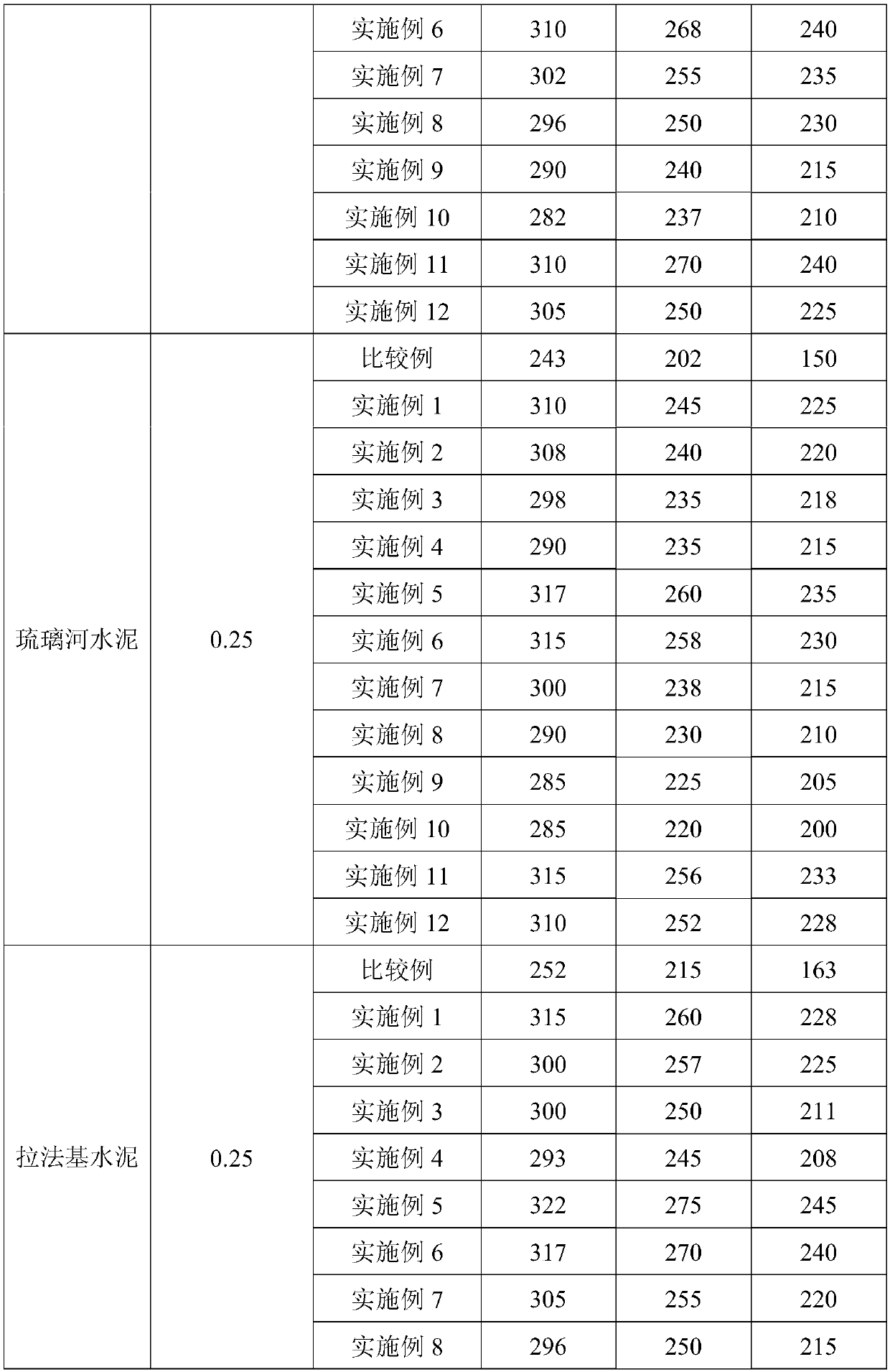

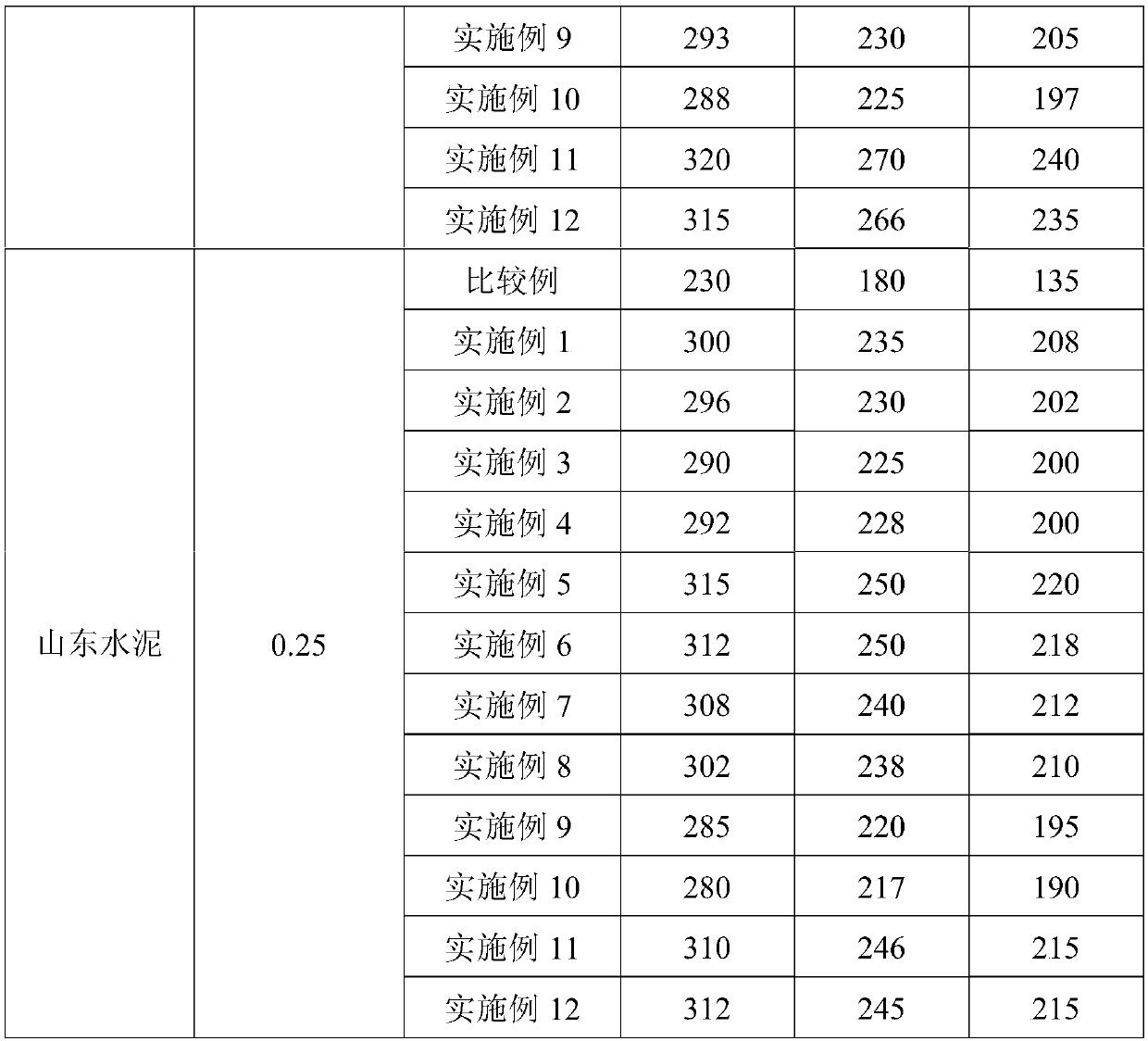

Examples

Embodiment 1

[0027] First, 26.19g of dimethyl diallyl ammonium chloride and 0.72g of isopropanol were added to the reactor, and then 699.2g of water was added to be mixed with a 4% aqueous solution, and the reactor was filled with nitrogen and deoxygenated repeatedly 4 times for 15 After 10 minutes, seal it, add 6.44g of ammonium cerium sulfate, stir for 25 minutes until it is mixed evenly, continue to heat up to 52°C for polymerization reaction, and react for 10 hours to obtain an aqueous solution of hydroxyl-terminated cation side chains; Mix the aqueous solution with 12.91g of methacrylic acid, then add 36g of polyethylene glycol monomethyl ether (molecular weight = 2000), raise the temperature to 65°C, wait until the polyethylene glycol monomethyl ether (molecular weight = 2000) is in a liquid state, and remove it by vacuuming Water in the system, add 5.4g of phosphoric acid, stir for 18 minutes, add 11.37g of benzene when the temperature rises to 80°C, continue to heat up to 135°C for ...

Embodiment 2

[0029] After storing the 40% concrete water reducer solution obtained in Example 1 at 5° C. for 300 days, its implementation effect was measured.

Embodiment 3

[0031] First, 52.98g of methacryloxyethyl dimethyl butyl ammonium bromide and 1.2g of cyclohexanol were added to the reactor, and then 487.62g of water was added to prepare an aqueous solution with a mass concentration of 10%, and the reactor was filled with nitrogen repeatedly After 20 minutes of deoxygenation for 3 times, seal it, add 2.86g of ammonium cerium sulfate, stir for 23 minutes until it is evenly mixed, continue to heat up to 10°C for polymerization reaction, and react for 14.5 hours to obtain an aqueous solution of hydroxyl-terminated cation side chains; the obtained product Hydroxyl-terminated cation side chain aqueous solution is mixed with 9.3g of methacrylic acid, then 72g of polyethylene glycol monomethyl ether (molecular weight=1200) is added, and the temperature is raised to 70°C, until polyethylene glycol monomethyl ether (molecular weight=1200) is Liquid state, vacuumize to remove moisture in the system, add 5.76g of sulfamic acid, stir for 8 minutes, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com