Arginine-terminated polyethylene glycol methacrylate, and preparation method and application thereof

A technology of polyethylene glycol methacrylate and arginine, which is applied in the preparation of sulfonates, the preparation of organic compounds, chemical instruments and methods, etc., can solve problems such as obvious side effects, and achieve the effect of improving retardation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Table 1 105℃, 7h

[0033] material

Arg-(p-TSA):PEG

p-TSA

Yield

Proportion

1:1.1

1%

49%

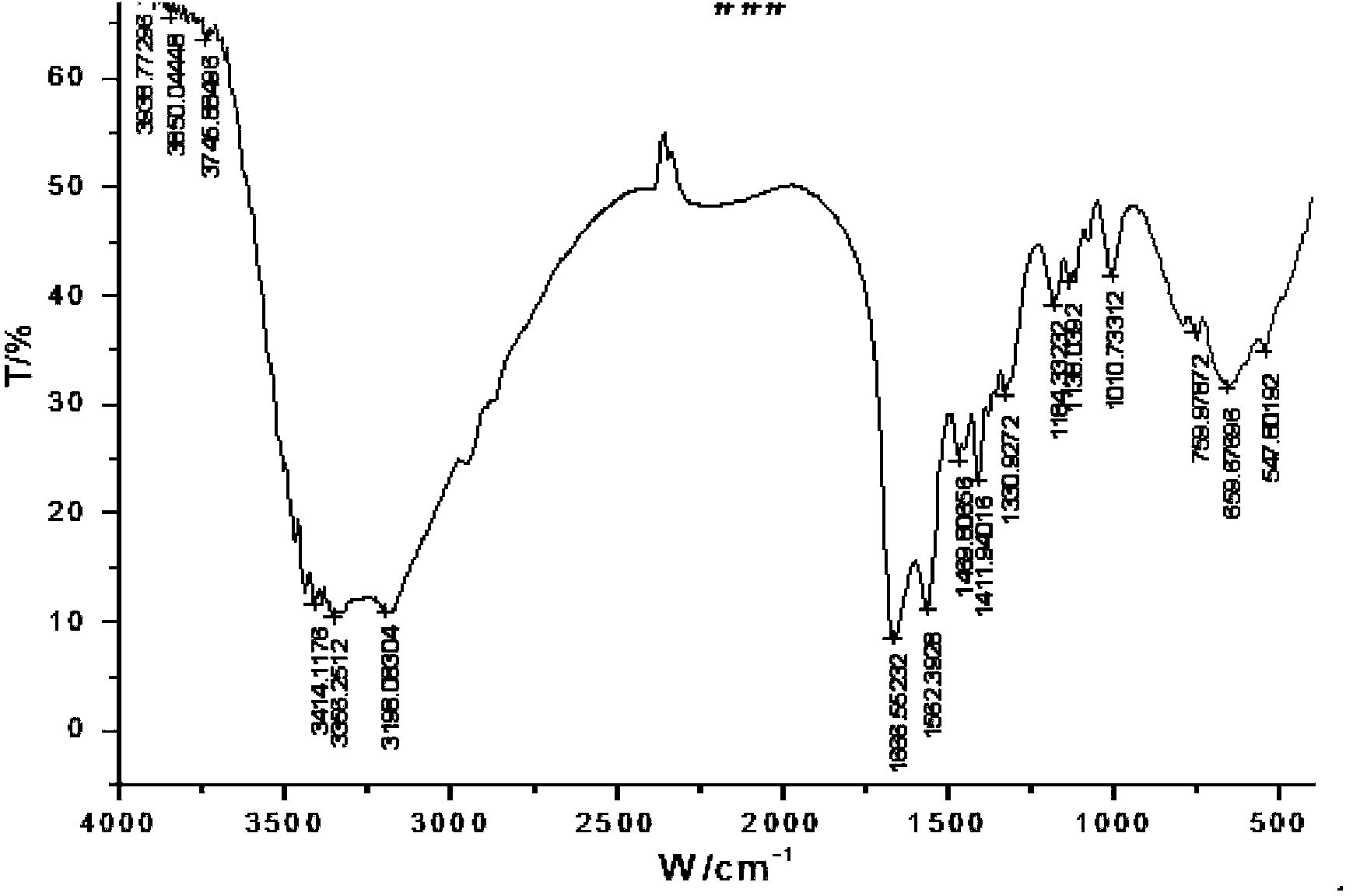

[0034] 1) Weigh 2.61 g of Arg and 5.7 g of p-TSA according to the molar ratio Arg:p-TSA=1:2, and place them in a conical flask and mix them thoroughly. Heat and stir until the mixture is in a transparent state to obtain the product Arg-(p-TSA), the reaction formula is as follows Figure 8 (a);

[0035] 2) Weigh Arg-(p-TSA) 8.31g and PEG 16.5g by molar ratio Arg-(p-TSA):PEG=1:1.1, p-TSA accounts for the total mass of Arg-(p-TSA) and PEG 1%, ie 0.25g;

[0036] 3) Arg-(p-TSA) solution was added dropwise to the mixed solution of PEG and p-TSA at 105°C, and kept for 7 hours to obtain the product APA. The reaction formula is as follows: Figure 8 (b).

Embodiment 2

[0038] Table 2 110℃, 9h

[0039] material

Arg-(p-TSA):PEG

p-TSA

Yield

Proportion

1:1.3

2%

77%

[0040] 1) Weigh 2.61 g of Arg and 5.7 g of p-TSA according to the molar ratio Arg:p-TSA=1:2, and place them in a conical flask and mix them thoroughly. Heat and stir until the mixture is in a transparent state to obtain the product Arg-(p-TSA), the reaction formula is as follows Figure 8 (a);

[0041] 2) Weigh Arg-(p-TSA) 8.31g and PEG 19.5g in molar ratio Arg-(p-TSA):PEG=1:1.3, p-TSA accounts for the total mass of Arg-(p-TSA) and PEG 2%, or 0.56g;

[0042] 3) Add the Arg-(p-TSA) solution dropwise to the mixed solution of PEG and p-TSA at 110°C, and keep it warm for 8 hours to obtain the product APA. The reaction formula is as follows Figure 8 (b).

Embodiment 3

[0044] Table 3 115℃, 8h

[0045] material

Arg-(p-TSA):PEG

p-TSA

Yield

Proportion

1:1.5

3%

93%

[0046] 1) Weigh 2.61 g of Arg and 5.7 g of p-TSA according to the molar ratio Arg:p-TSA=1:2, and place them in a conical flask and mix them thoroughly. Heat and stir until the mixture is in a transparent state to obtain the product Arg-(p-TSA), the reaction formula is as follows Figure 8 (a);

[0047] 2) Weigh 8.31 g of Arg-(p-TSA) and 22.5 g of PEG according to the molar ratio Arg-(p-TSA):PEG=1:1.5, and p-TSA accounts for the total mass of Arg-(p-TSA) and PEG 3%, or 0.92g;

[0048] 3) Arg-(p-TSA) solution was added dropwise to the mixed solution of PEG and p-TSA at 115°C, and kept for 9 hours to obtain the product APA. The reaction formula is as follows: Figure 8 (b).

[0049] The preparation method of AMAP:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com