Retarder and application thereof in preparation of modified cassava starch-polycarboxylic acid composite water reducing agent

A composite water reducing agent and tapioca starch technology, which is applied in the field of building materials, can solve the problems of large pollutant discharge, increased construction cost and energy consumption, and reduced later strength of concrete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

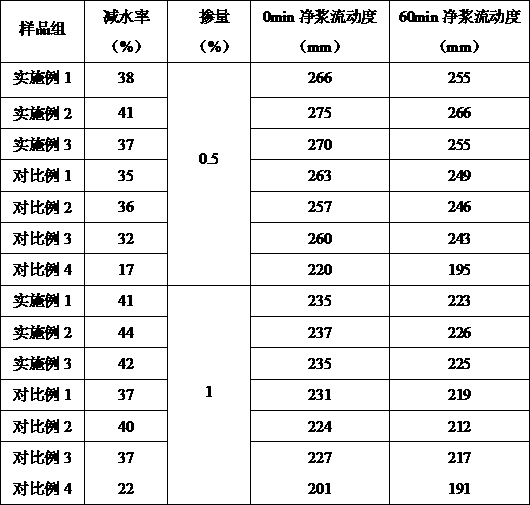

Image

Examples

Embodiment 1

[0043] A retarder, comprising the following components in parts by weight: 60 parts of sodium gluconate, 30 parts of sodium citrate, 29 parts of sodium tripolyphosphate, 19 parts of sodium pyrophosphate, 3 parts of ammonium borate, 2 parts of ferrous sulfate parts, 5 parts of magnesium sulfate.

[0044] The preparation method of described setting retarder, comprises the following steps:

[0045] S1: Mix sodium gluconate, sodium citrate, sodium tripolyphosphate, sodium pyrophosphate, ammonium borate and water evenly, and adjust the pH of the solution to 5.5 to obtain a mixed solution A;

[0046] S2: Add the mixed solution A into the reaction vessel, add magnesium sulfate, and nitrogen gas at the same time, add ferrous sulfate at 60°C to carry out free radical polymerization; observe the reaction temperature, start timing when the temperature is the highest, and obtain the retarded setting after 2 hours agent.

[0047] A modified tapioca starch-polycarboxylic acid composite wa...

Embodiment 2

[0057] A retarder, comprising the following components in parts by weight: 48 parts of sodium gluconate, 32 parts of sodium citrate, 25 parts of sodium tripolyphosphate, 16 parts of sodium pyrophosphate, 5.5 parts of ammonium borate, 3 parts of ferrous sulfate part, 2.5 parts of magnesium sulfate.

[0058] The preparation method of described setting retarder, comprises the following steps:

[0059] S1: Mix sodium gluconate, sodium citrate, sodium tripolyphosphate, sodium pyrophosphate, ammonium borate and water evenly, and adjust the pH of the solution to 6.5 to obtain a mixed solution A;

[0060] S2: Add the mixed solution A into the reaction vessel, add magnesium sulfate, and nitrogen gas at the same time, add ferrous sulfate at 60°C to carry out free radical polymerization; observe the reaction temperature, start timing when the temperature is the highest, and obtain the retarded setting after 2 hours agent.

[0061] A modified tapioca starch-polycarboxylic acid composite...

Embodiment 3

[0071] A retarder, comprising the following components in parts by weight: 43 parts of sodium gluconate, 37 parts of sodium citrate, 22 parts of sodium tripolyphosphate, 13 parts of sodium pyrophosphate, 8 parts of ammonium borate, 4 parts of ferrous sulfate 1 part, 1 part of magnesium sulfate.

[0072] The preparation method of described setting retarder, comprises the following steps:

[0073] S1: Mix sodium gluconate, sodium citrate, sodium tripolyphosphate, sodium pyrophosphate, ammonium borate and water evenly, and adjust the pH of the solution to 5.5 to obtain a mixed solution A;

[0074] S2: Add the mixed solution A into the reaction vessel, add magnesium sulfate, and nitrogen gas at the same time, add ferrous sulfate at 60°C to carry out free radical polymerization; observe the reaction temperature, start timing when the temperature is the highest, and obtain the retarded setting after 2 hours agent.

[0075] A modified tapioca starch-polycarboxylic acid composite wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com