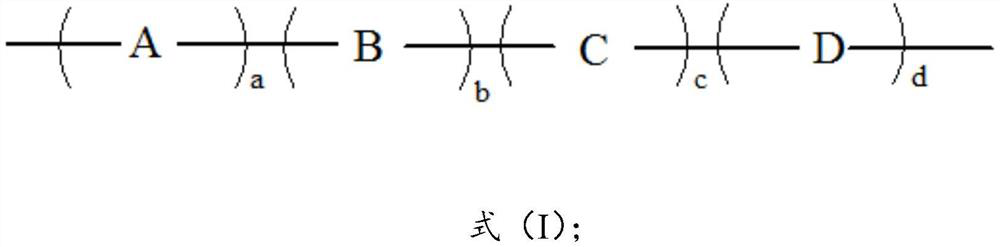

Low-sensitivity water-reducing slump-retaining polycarboxylic acid water reducer and preparation method thereof

A polycarboxylic acid, low-sensitivity technology, applied in the field of concrete admixtures, can solve the problems of large slump loss, unsatisfactory slump retention effect and adaptability improvement, unable to meet construction requirements, etc., and achieves good mud and weather resistance characteristics, The effect of high water reduction and slump retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] An embodiment of the present invention, the preparation method of the low-sensitivity water-reducing and slump-retaining polycarboxylate superplasticizer described in this embodiment, the preparation method includes the following steps:

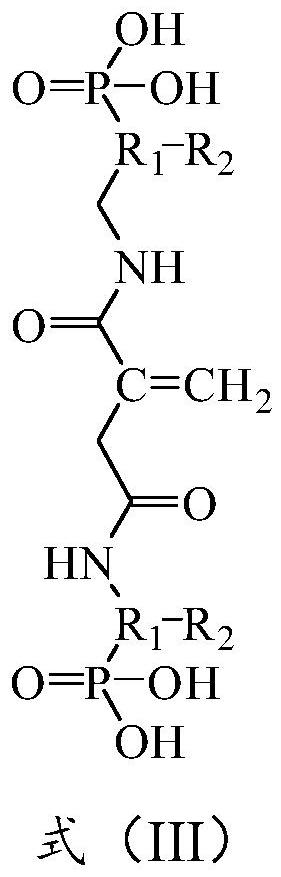

[0058] (1) Preparation of unsaturated phosphoric acid monomer C

[0059] Add itaconic acid, 1-aminopropyl phosphoric acid, and hydroquinone (polymerization inhibitor) in a molar ratio of 1:1.5:0.003 in sequence in a flask equipped with a stirring device, and react under nitrogen blowing at 115°C for 8 hours. Unsaturated phosphoric acid monomers are obtained.

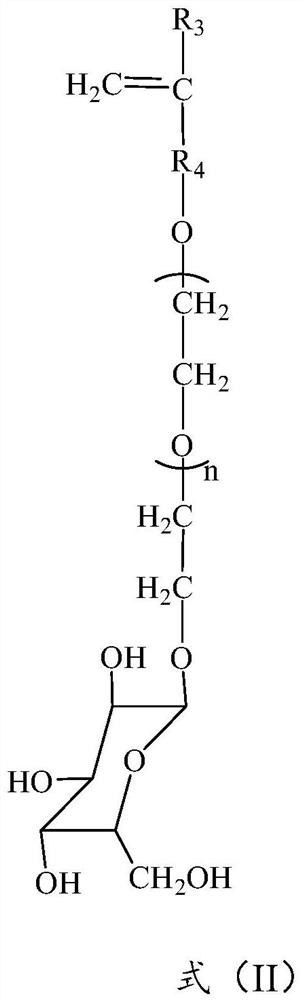

[0060] (2) Preparation of terminal glucosidation polyether macromonomer B

[0061] Adding polyoxyethylene ether macromonomer (HPEG2400) and glucose at a molar ratio of 1:1.05 in a flask equipped with a stirring device, adding hydroquinone ( Inhibitor), after heating up to 80°C, add p-toluenesulfonic acid (catalyst) equal to 0.2% glucose weight; keep in vacuum state (-0.080~-0.0...

Embodiment 2

[0066] An embodiment of the present invention, the preparation method of the low-sensitivity water-reducing and slump-retaining polycarboxylate superplasticizer described in this embodiment, the preparation method includes the following steps:

[0067] (1) Preparation of unsaturated phosphoric acid monomer C

[0068] Add itaconic acid, 1-amino-2-methylpropyl phosphoric acid, and hydroquinone (polymerization inhibitor) in a molar ratio of 1:1.5:0.003 in sequence in a flask equipped with a stirring device, and blow with nitrogen at 115°C After reacting for 8 hours, an unsaturated phosphoric acid monomer was obtained.

[0069] (2) Preparation of terminal glucosidation polyether macromonomer B

[0070] Adding polyoxyethylene ether macromonomer (TPEG2400) and glucose with a molar ratio of 1:1.05 in a flask equipped with a stirring device, adding hydroquinone ( Inhibitor), after heating up to 80°C, add p-toluenesulfonic acid (catalyst) equal to 0.2% glucose weight; keep in vacuum ...

Embodiment 3

[0075] An embodiment of the present invention, the preparation method of the low-sensitivity water-reducing and slump-retaining polycarboxylate superplasticizer described in this embodiment, the preparation method includes the following steps:

[0076] (1) Preparation of unsaturated phosphoric acid monomer C

[0077] Add itaconic acid, 1-amino-2-methylpropyl phosphoric acid, and hydroquinone (polymerization inhibitor) in a molar ratio of 1:1.5:0.003 in sequence in a flask equipped with a stirring device, and blow with nitrogen at 115°C After reacting for 8 hours, an unsaturated phosphoric acid monomer was obtained.

[0078] (2) Preparation of terminal glucosidation polyether macromonomer B

[0079] Add polyoxyethylene ether macromonomer (TPEG2400) and glucose at a molar ratio of 1:1.05 into a flask equipped with a stirring device, and add polyoxyethylene ether macromonomer (TPEG2400) equal to 0.002%

[0080] Weight of hydroquinone (polymerization inhibitor), after heating up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com