Method for preparing polycarboxylic acid water reducer by itaconic acid waste liquid

A technology of itaconic acid and polycarboxylic acid, which is applied in the field of preparing polycarboxylate water reducing agent, can solve the problems of high price, large effect and low dosage, and achieves improvement of conversion rate, retention capacity and retardation time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

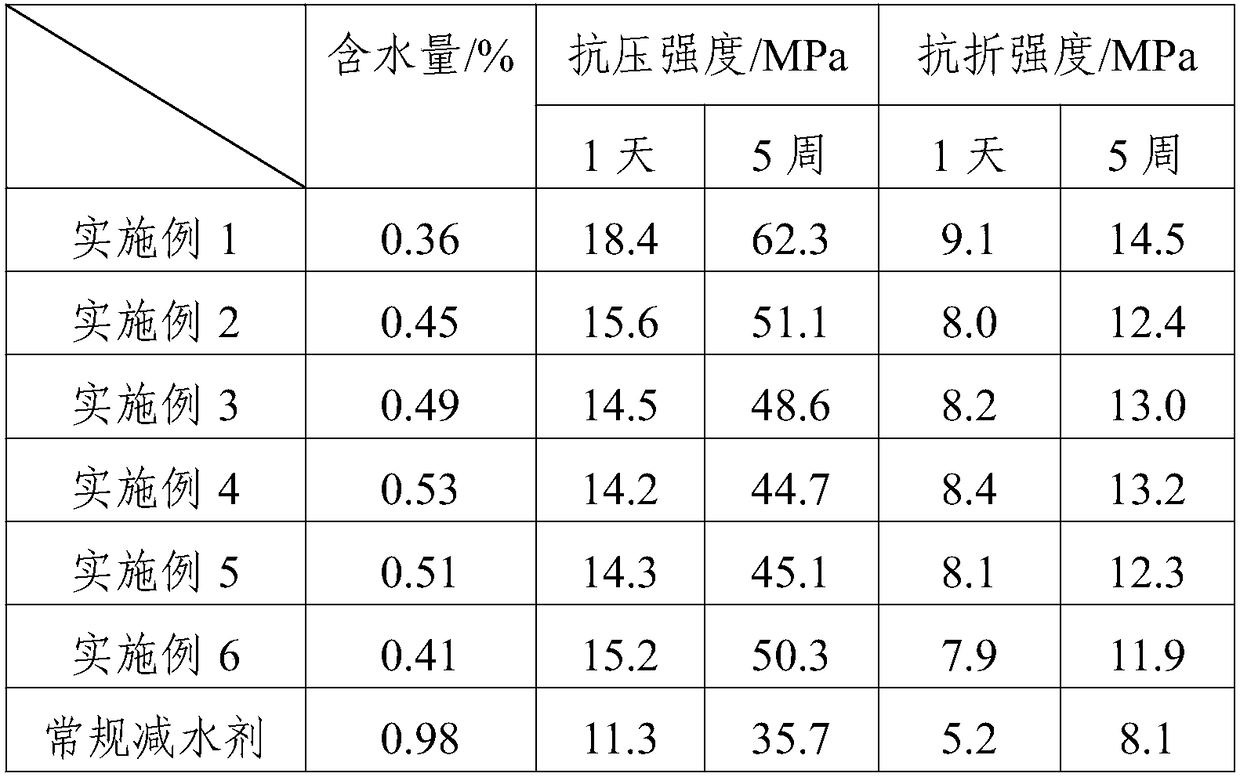

Examples

Embodiment 1

[0019] A kind of method utilizing itaconic acid waste liquid to prepare polycarboxylate water reducer, comprises the following steps:

[0020] (1) Evenly mix 23 parts of acrylic acid and 2 parts of mercaptopropionic acid, and add 50 parts of deionized water to it, stir and dissolve to obtain solution A; add 3.2 parts of deionized water to 1.6 parts of vitamin C, stir and mix to obtain Solution B;

[0021] (2) 320 parts of methallyl polyoxyethylene ether, 3.7 parts of mass concentration are 27.5% hydrogen peroxide and 647.4 parts of deionized water as base materials and 65 parts of itaconic acid waste liquid are dropped into the reactor simultaneously, Stir until completely dissolved to obtain mixed liquid A;

[0022] (3) Add solution A and solution B dropwise to mixed solution A. Solution A is added dropwise in 2 hours, and solution B is added dropwise in 2.5 hours. After solution B is added dropwise, continue to stir and react for 50 minutes to obtain a mixed solution B;

...

Embodiment 2

[0026] A kind of method utilizing itaconic acid waste liquid to prepare polycarboxylate water reducer, comprises the following steps:

[0027] (1) Evenly mix 22 parts of acrylic acid and 2.5 parts of mercaptopropionic acid, and add 36.75 parts of deionized water to it, stir and dissolve to obtain solution A; add 1.8 parts of deionized water to 1.2 parts of vitamin C, stir and mix to obtain Solution B;

[0028] (2) 310 parts of methallyl polyoxyethylene ether, 4 parts of mass concentration are 25% hydrogen peroxide and 471 parts of deionized water as base materials and 50 parts of itaconic acid waste liquid are dropped into the reactor simultaneously, Stir until completely dissolved to obtain mixed liquid A;

[0029] (3) Add solution A and solution B dropwise to mixed solution A. Solution A is added dropwise in 2 hours, and solution B is added dropwise in 2.5 hours. After solution B is added dropwise, continue to stir and react for 40 minutes to obtain a mixed solution B;

...

Embodiment 3

[0033] A kind of method utilizing itaconic acid waste liquid to prepare polycarboxylate water reducer, comprises the following steps:

[0034] (1) Evenly mix 24 parts of acrylic acid and 2.2 parts of mercaptopropionic acid, and add 65.5 parts of deionized water to it, stir and dissolve to obtain solution A; add 5 parts of deionized water to 2 parts of vitamin C, stir and mix to obtain Solution B;

[0035] (2) 300 parts of methallyl polyoxyethylene ether, 3 parts of mass concentration are 26.5% hydrogen peroxide and 757.5 parts of deionized water as base materials and 75 parts of itaconic acid waste liquid are dropped into the reactor simultaneously, Stir until completely dissolved to obtain mixed liquid A;

[0036] (3) Add solution A and solution B dropwise to mixed solution A. Solution A is added dropwise in 2 hours, and solution B is added dropwise in 2.5 hours. After solution B is added dropwise, continue to stir and react for 60 minutes to obtain a mixed solution B;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com