Polycarboxylic acid water reducing agent preparation method, and retarder and preparation method thereof

A technology of water reducing agent and polycarboxylic acid, which is applied in retarder and its preparation, and in the field of preparing polycarboxylate superplasticizer, which can solve the problems of serious retarding effect and affecting the strength of gypsum, and achieve good retarding effect and prolong The effect of retarding time and strength loss is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

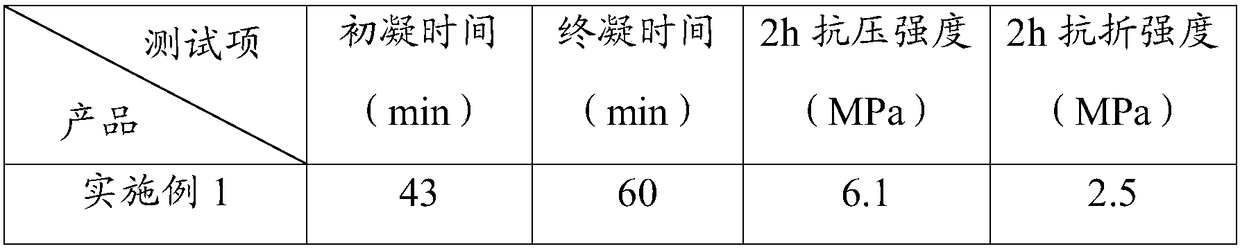

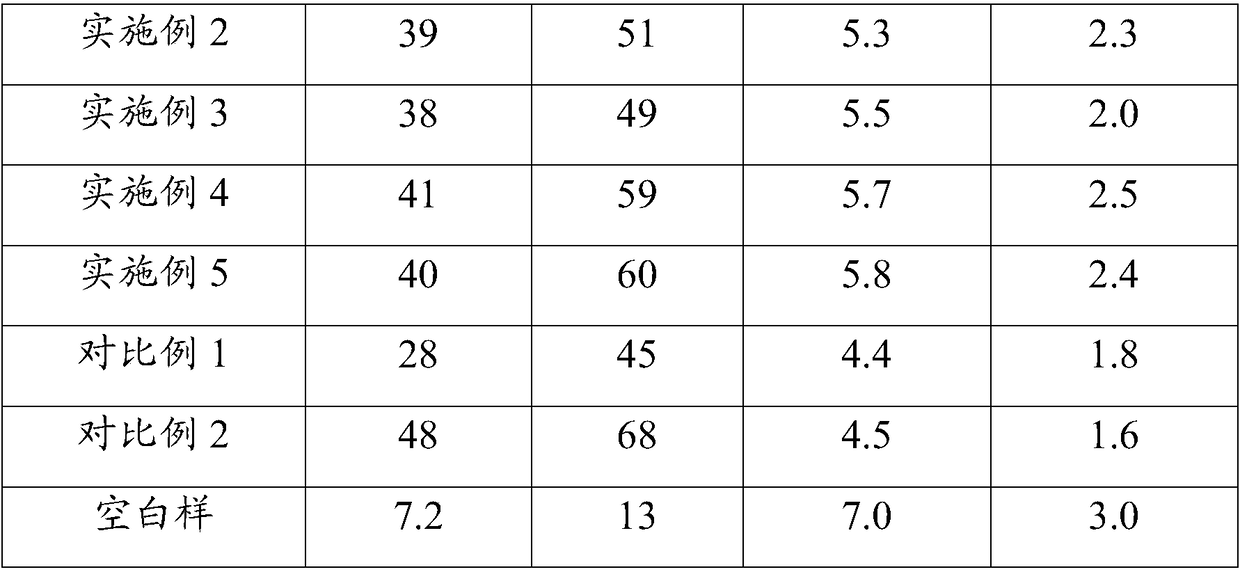

Examples

Embodiment 1

[0035] Preparation of polycarboxylate water reducer: Add 395g of water, 27g of acrylic acid, 240g of isobutylene alcohol polyoxyethylene ether with a molecular weight of 2400, 2g of ammonium persulfate and 1.6g of thioglycolic acid into a 1000ml four-necked flask, heat up to 60°C, Stir the reaction for 4h, stop stirring, keep warm for 1h, and cool. After the reaction solution was cooled to a temperature lower than 30°C, it was neutralized to a pH of 7 with a 30% NaOH aqueous solution. The prepared polycarboxylate water reducer has a solid content of about 40 wt%.

[0036] The preparation of retarder: take by weighing 5g sodium tripolyphosphate, 10g citric acid and 5g calcium enhancer (the weight ratio of calcium hydroxide, calcium oxide, calcium carbonate is 35:45:10) and put into the mixer, through fully Mix well and pour out. Slowly add the above mixture into 200 g of the prepared polycarboxylate superplasticizer with a solid content of 40 wt%, and stir evenly until there ...

Embodiment 2

[0038] Weigh 7g of sodium tripolyphosphate, 10g of citric acid and 7g of calcium enhancer (the weight ratio of calcium hydroxide, calcium oxide, and calcium carbonate is 35:45:10) and put them into a mixer, mix well and pour out. Slowly add the above mixture into 190 g of the polycarboxylate superplasticizer with a solid content of 40 wt% prepared in Example 1, stir evenly until there is no powdery material in the slurry, and let it stand for 10 minutes.

Embodiment 3

[0040] Weigh 5g of sodium tripolyphosphate, 12g of citric acid and 5g of calcium enhancer (the weight ratio of calcium hydroxide, calcium oxide, and calcium carbonate is 35:45:10) and put them into a mixer, mix well and pour out. Slowly add the above mixture into 195g of the polycarboxylate superplasticizer with a solid content of 40wt% prepared in Example 1, stir evenly until there is no powdery material in the slurry, and let it stand for 10 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com