Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

297results about How to "Improves carbonation resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lightweight high-strength cement based composite material

InactiveCN103896527AMeet the requirements of construction mobilityThe material surface is denseSolid waste managementChemical admixtureUltimate tensile strength

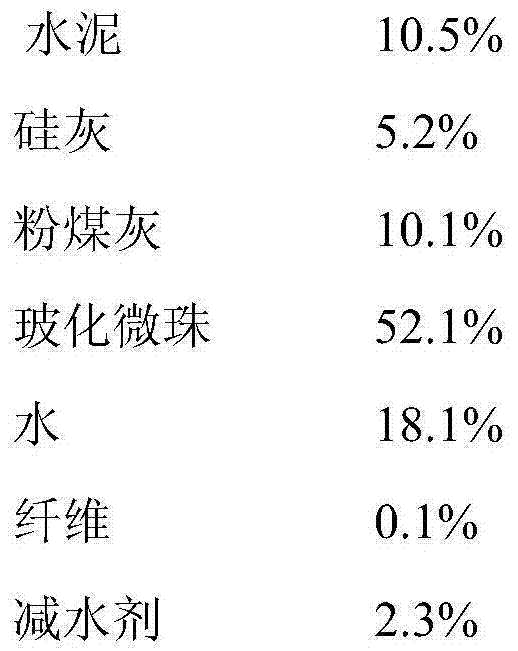

The invention relates to a lightweight high-strength cement based composite material. The grain composition of a multivariate cementing material and grain composition of aggregate are optimized, anddue to use of additives such as water reducing agent and thickener, the material can obtain high compressive strength of over 20MPa while obtaining the unit weight which is significantly lower than that of common concrete. The material has the technical advantages that the compressive strength of 28d standard curing is greater than or equal to 20MPa when the unit weight is smaller than or equal to 1650kg / m<3>; the requirements of the construction liquidity can be met by grain composition of the optimized gel material and the grain composition of the aggregate; the hardened material has a dense surface, and has excellent endurance performances such as anti-permeability, carbonation resistance, resistance to chloride ion erosion and the like.

Owner:SHANGHAI LUOYANG NEW MATERIAL TECH

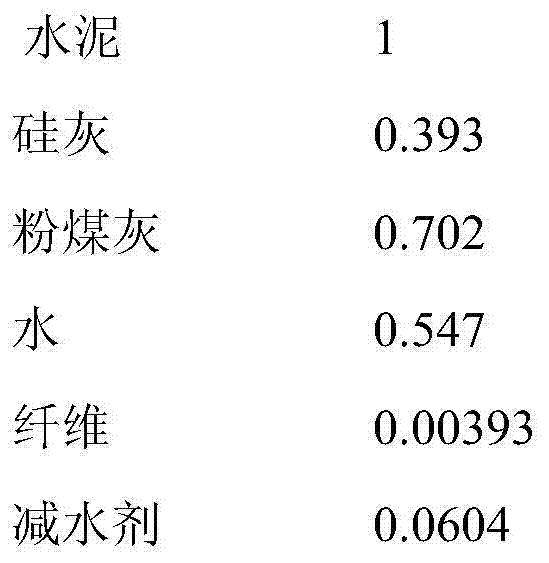

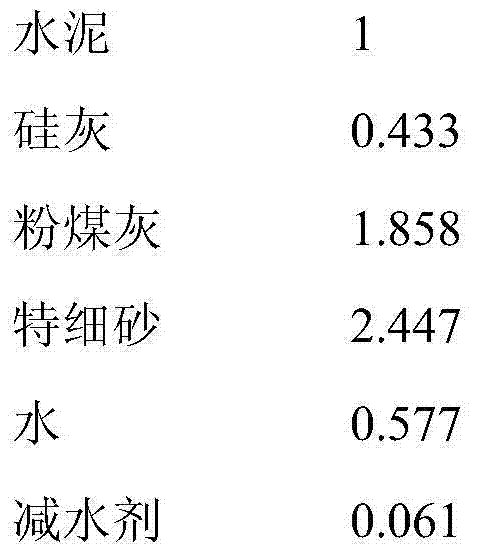

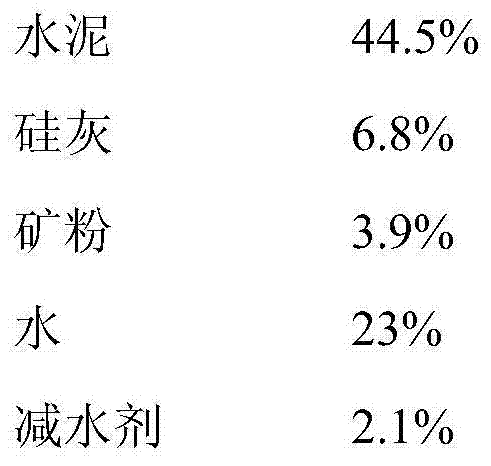

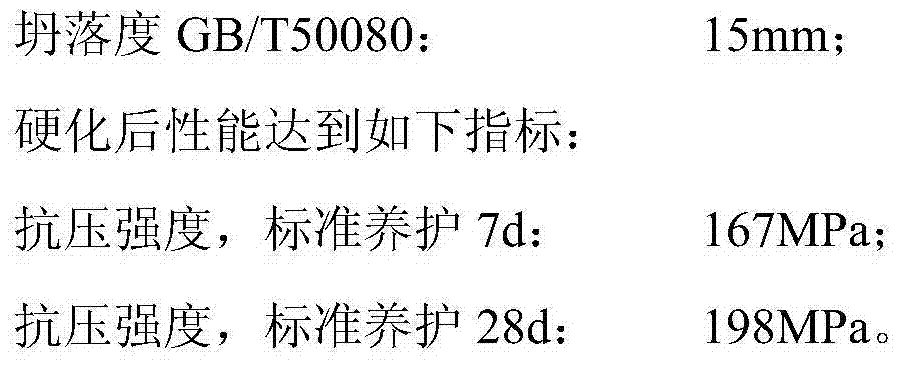

Ultrahigh-performance cement-based composite material

InactiveCN105198339AMeet the requirements of construction mobilityHigh strengthFreezing thawingHigh intensity

The invention relates to an ultrahigh-performance cement-based composite material. Particle gradation of a polynary gelling material and particle gradation of aggregates are optimized, and a water reducer and other additives are used, so the compressive strength under 28d standard curing reaches 170MPa or above on the premise that concrete has good fluidity. The material has the following technical advantages: construction fluidity requirements are met under a low water-binder ratio; under standard curing conditions, the strength of the concrete in 7d age reaches 120MPa or above, and the strength of the concrete in 28d age reaches 170MPa or above; compared with RPC which only can be used to produce prefabricated parts, the composite material can be stirred and constructed in any occasions without hot curing or pressure forming; the impermeability, the carbonization resistance, the chloride ion penetration resistance and the freeze thaw cycle resistance of the composite material are better than those of common concrete; and the composite material can be used to produce member products with the cross section being 50% (or more) than the common concrete member products.

Owner:浙江宏日泰耐克新材料科技有限公司

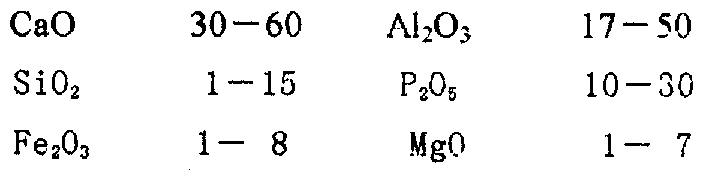

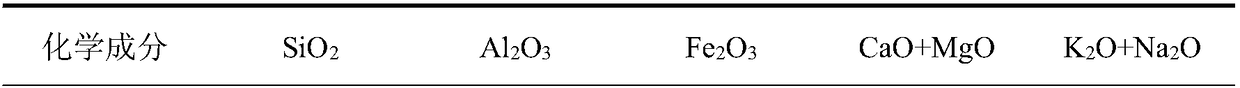

Gelatinization material of phosphoaluminic salt system

InactiveCN1498870AIncreased durabilityIncreased hydration rateCalcium biphosphateChemical composition

A cementing material is a cement whose main components are calcium phosphoaluminate, calcium aluminate and calcium phosphate. Its clinker contains such chemical components (wt%) as CaO (30-60), Al2O3 (17-50), SiO2 (1-15), P2O5 (10-30), Fe2O3 (1-8) and MgO (1-7). Its advantages are high and early strength, high refractory nature, and high compatibility with existing cement.

Owner:胡佳山

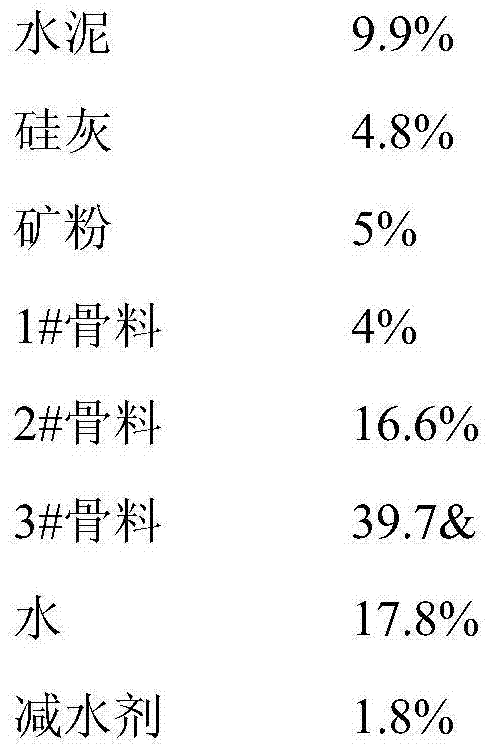

Large-admixing-amount-fly-ash C40 self-compacting concrete

The invention discloses large-admixing-amount-fly-ash C40 self-compacting concrete.The concrete comprises cementitious materials, aggregates, an admixture and water, the cementitious materials comprise cement and blending materials, the blending materials comprise fly ash and mineral powder, the aggregates include the coarse aggregates and the fine aggregates, and the admixture is a self-compacting special polycarboxylic-type water reducing agent.Per cubic meter of the concrete comprises 200 kg-280 kg of cement, 0 kg- 90 kg of mineral powder, 125 kg-200 kg of fly ash, 700 kg-1,000 kg of sand, 800 kg-950 kg of stone, 0.3 kg-10 kg of water reducing agent and 110 kg-170 kg of water.According to the large-admixing-amount-fly-ash C40 self-compacting concrete, as the fly ash and the mineral powder are combined and mixed, and the large amount of fly ash is admixed, the content of the cement is decreased, the production cost of the concrete is reduced, hydration heat of the cement can be further reduced, the workability of the concrete is improved, and the durability of the concrete is improved.

Owner:WUHAN YUANJING READY MIXED CONCRETE CO LTD

Lightweight high-strength ceramsite concrete and concrete pole

The invention relates to the technical field of concrete and more concretely relates to lightweight high-strength ceramsite concrete and a concrete pole. The lightweight high-strength ceramsite concrete is prepared from raw materials including the following ingredients in parts by mass: 380-420 parts of silicate cement, 45-53 parts of silica fume, 75-85 parts of slag powder, 560-620 parts of stone powder sand with the grain diameter of 0.16-4.75mm, 650-715 parts of shale ceramsite with the grain diameter of 5-20mm, 2.8-3.4 parts of efficient water reducing agent with the water reducing ratio higher than 30%, 115-126 parts of water and 0.4-0.6 part of polypropylene fiber. The concrete pole is formed through uniformly distributing the lightweight high-strength ceramsite concrete on a reinforcing steel bar net. According to the lightweight high-strength annular ceramsite concrete pole, the material source is wide, and a large amount of mineral waste is doped; and the weight is light, the carbonization resistance is good, the freeze-thaw resistance is good, the compressive strength is high, and the crack resistant strength is good.

Owner:佛冈龙清电力器材有限公司

Compounding process of concrete hydration reducer

InactiveCN1810703AReduce heat of hydrationAdiabatic temperature rise is beneficialSolid phasesChemistry

The concrete hydration heat reducer is compounded with one kind of material selected from starch grafted polyacrylate, hydroxyl acetic acid-lactic acid copolymer, modified starch, polymethylamide, polymethyl formacrylate, polyalkyl acrylonitrile and ethyl cellulose, and through dissolving in water, reaction at 5-55 deg.c, water phase-solid phase separation after reaction to obtain the solid phase concrete hydration heat reducer. The material has molar ratio to water of 1 to 1-50. The product can reduce hydration heat of cement obviously, reduce the early adiabatic temperature raise of concrete, reduce temperature raise rate to lag the peak temperature time by about 6 days, make the concrete possess excellent heat stability, less initial stage temperature stress and less cracks.

Owner:CCCC SECOND HARBOR ENG +1

Concrete anti-cracking and anti-permeability special additive and preparation method thereof

ActiveCN105819733AReduce temperature shrinkage cracksImprove affinitySodium carboxymethylcelluloseActive carbon

The invention relates to a concrete anti-cracking and anti-permeability special additive, which is composed of the following components in parts by weight: 9 to 11 parts of carboxyl material that is prepared by mixing sodium carboxymethyl cellulose and carboxylated graphene according to a mass ratio of 1:7.2-8.2, wherein sodium carboxymethyl cellulose and carboxylated graphene are both powder with a particle size of 500 to 600 meshes; 4 to 6 parts of zinc oxide with a particle size of 300 to 400 meshes; 4 to 5 parts of active carbon powder with a particle size of 200 to 300 meshes; 40 to 42 parts of nano level light heavy calcium carbonate powder with a particle size of 1000 to 1200 meshes, and 65 to 68 parts of polyester fiber with a length of 10 to 15 mm and a diameter of 20 to 25 [mu]m. The provided concrete special additive can largely improve the anti-cracking and anti-permeability performance of concrete, and thus the waterproof protection period of building is largely prolonged.

Owner:不二新材料科技有限公司

Ultra-high performance cement-based impact wear resistant material

The invention relates to an ultra-high performance cement-based impact wear resistant material. By optimizing the grain gradation of a multi-element cementing material and the grain gradation of an aggregate, and using a water reducing agent and other chemical admixtures, the material provided by the invention can be employed to perform surface coating on a newly constructed concrete structure or an impact wear damaged old concrete structure, and the impact wear resistance of a hydraulic structure can be improved by means of the high impact wear resistance of the material itself and the good adhesion of a concrete substrate. The material has the technical advantages that: the impact wear resistance is significantly superior to that of ordinary concrete; the weatherability and durability are significantly superior to those of an organic impact wear resistant coating material; by optimizing the grain gradation of the cementing material and the grain gradation of the aggregate, the material can meet the construction liquidity requirements under a low water-binder ratio; under standard curing conditions, the material can reach high strength of more than 150MPa after 28 days; and the anti-permeability, carbonization resistance, chloride ion penetration resistance, freezing-thawing cycle resistance and other properties are superior to those of ordinary concrete.

Owner:SHANGHAI LUOYANG NEW MATERIAL TECH

Ultra-high performance cement base composite material

InactiveCN103922662AMeet the requirements of construction mobilityHigh strengthChemical admixtureCarbonization

The present invention relates to a light weight and high strength cement base composite material. According to the present invention, particle size distribution of a multi-component cementing material and particle size distribution of an aggregate are optimized, and a reducing agent, a thickener and other chemical admixtures are used to make the material can concurrently achieve bulk density of significantly lower than bulk density of the ordinary concrete and a compressive strength of more than 20 MPa; the technical advantages of the material comprise that: in the case of the bulk density of less than or equal to 1650 kg / m<3>, the 28 d standard maintenance compressive strength of more than or equal to 20 MPa is achieved, and the construction fluidity requirements can be met in the case of the low water-binder ratio by optimizing the particle size distribution of the cementing material and the particle size distribution of the aggregate; and the hardened material has characteristics of compact surface, excellent impermeability, excellent carbonization resistance, chloride ion erosion resistance, and other durable performances.

Owner:SHANGHAI LUOYANG NEW MATERIAL TECH

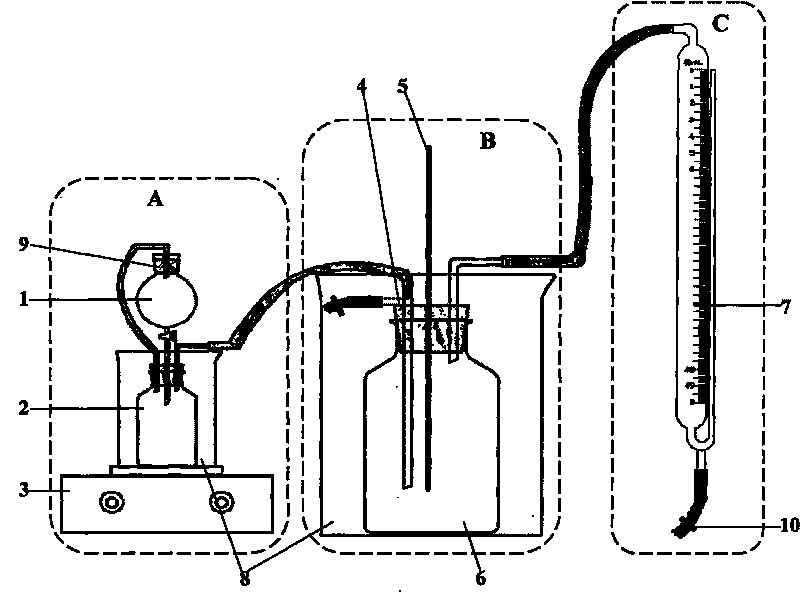

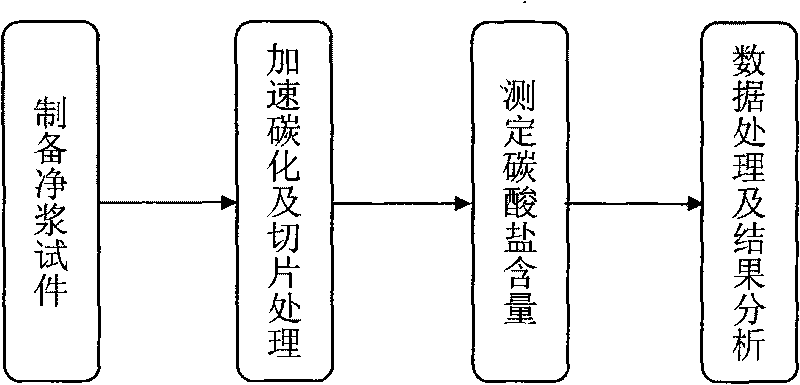

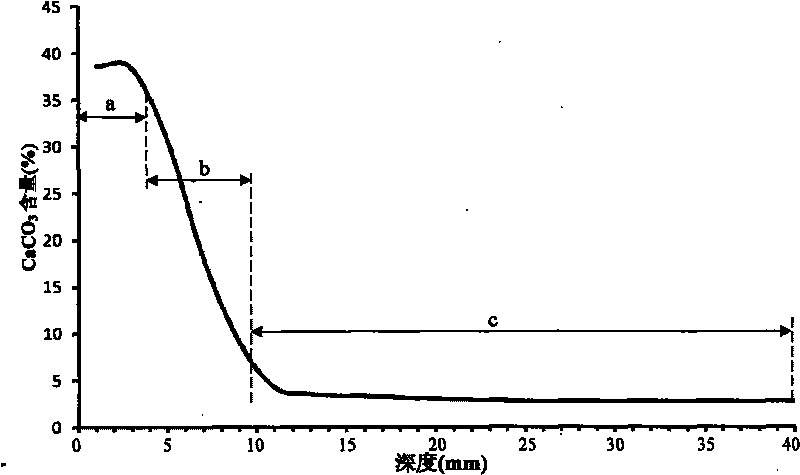

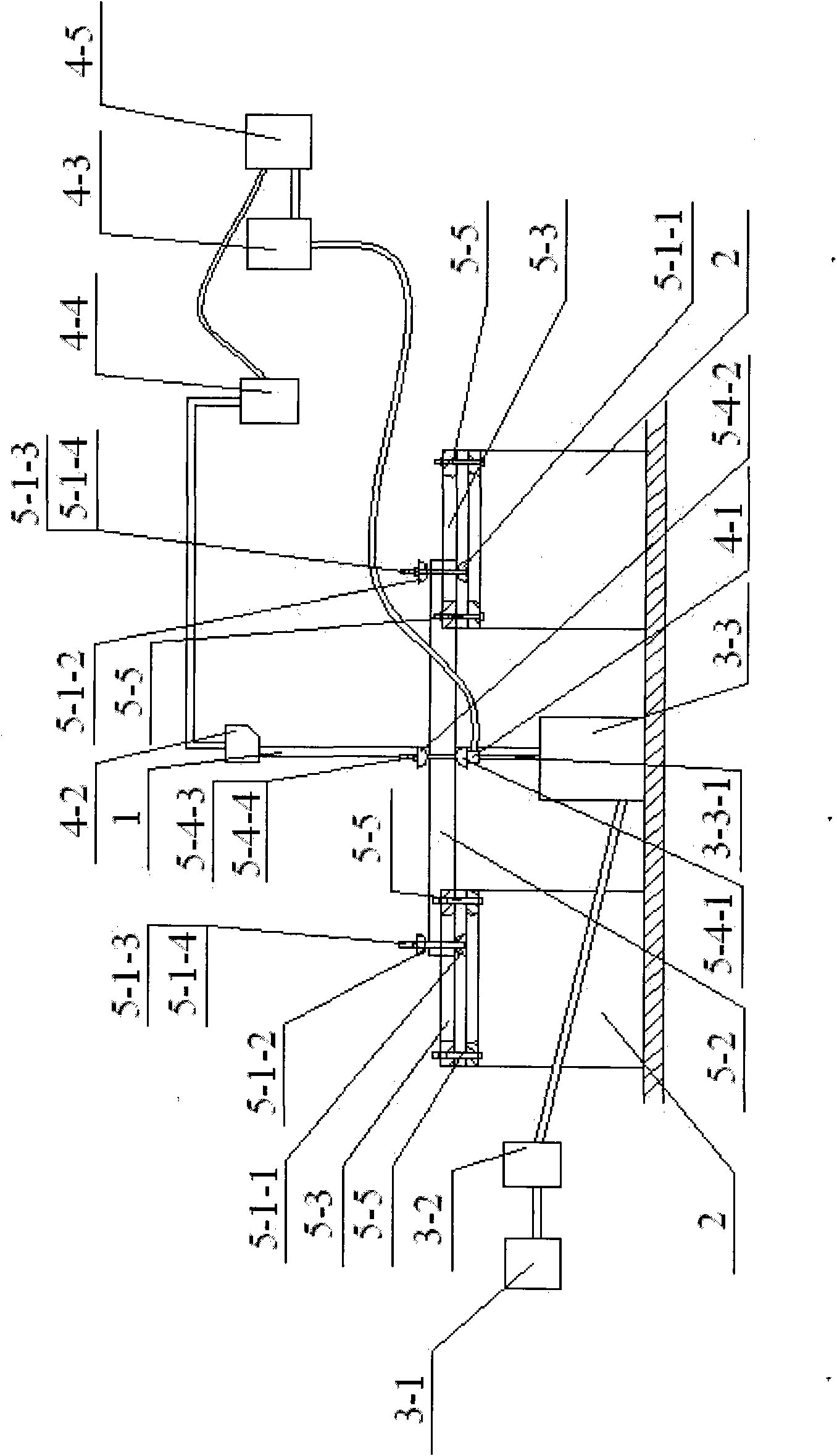

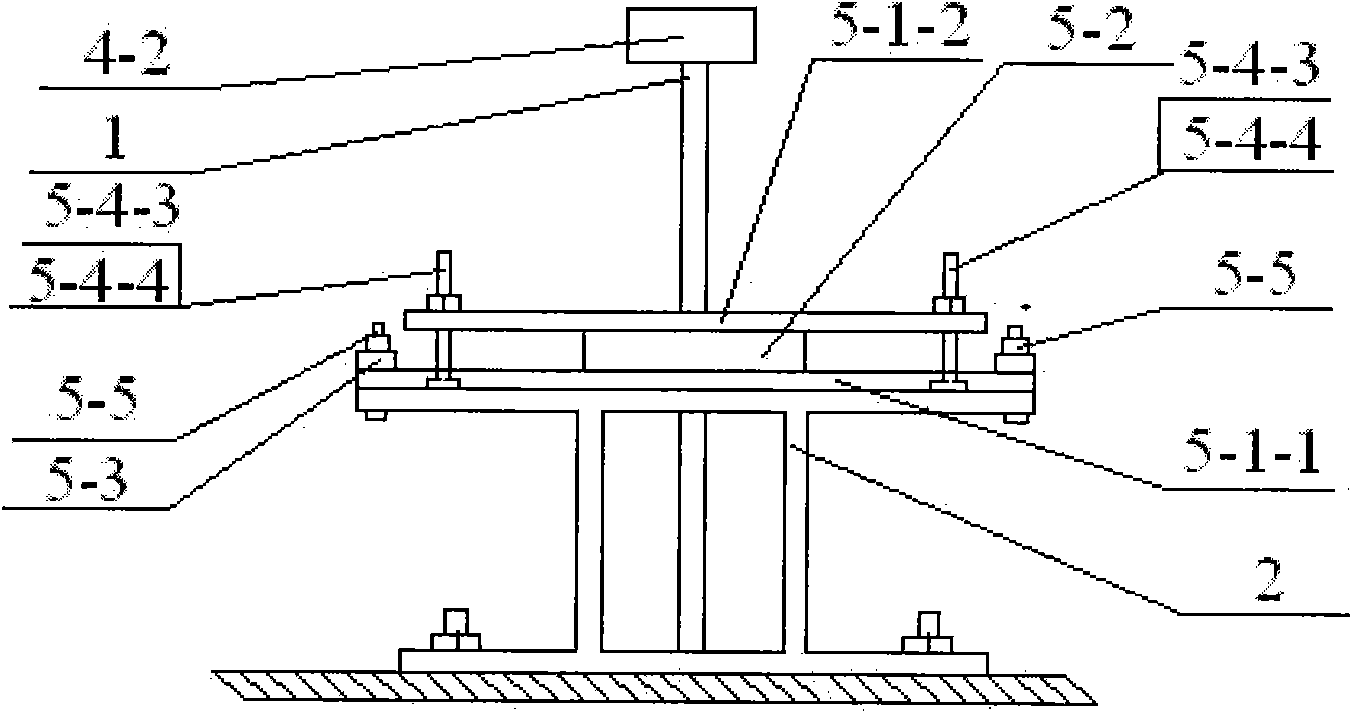

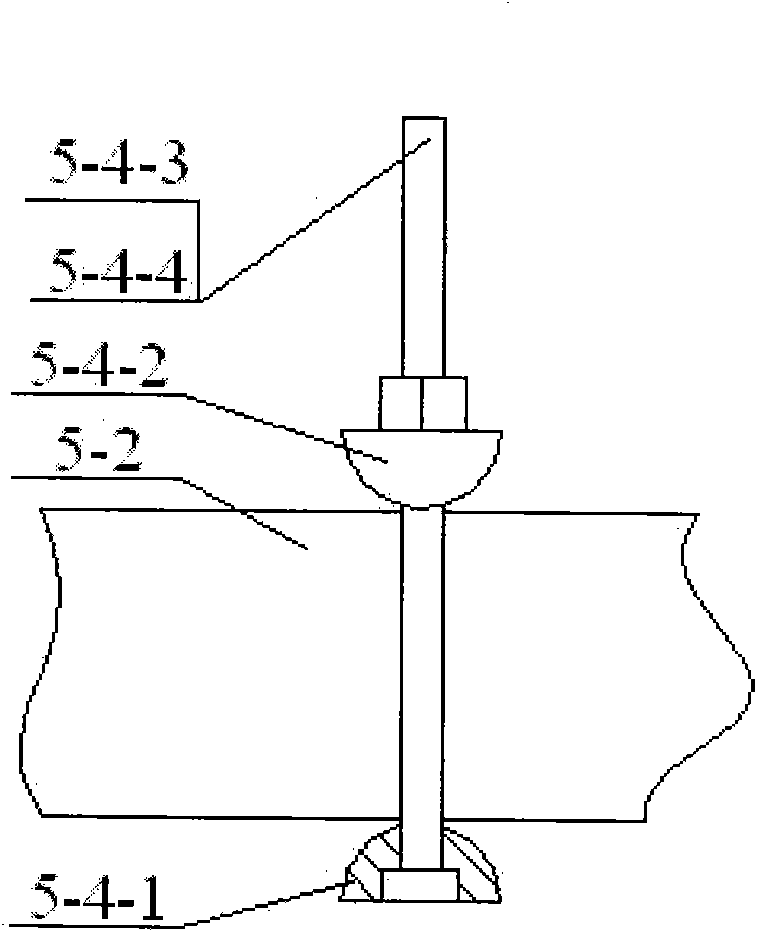

Testing device for carbonization resistance of cement based materials and testing method

ActiveCN101694449AEliminate the effects ofImproves carbonation resistancePreparing sample for investigationCarbonizationMagnetic stirrer

A testing device for carbonization resistance of cement based materials and a testing method belong to the technical field of test of carbonization resistance of concrete. The device mainly comprises a separating funnel, a reaction bottle, a magnetic stirrer and the like of a reaction part, a buffer bottle, a thermometer, a glass tee joint and the like of a buffer part, and a eudiometer and the like of a gas collection measuring part, wherein the eudiometer consists of a meter tube, a balance tube and a drain pipe which are communicated by rubber pipes. By using the device, the method completes the test of carbonization resistance of the cement based material by the following steps: preparing a clean paste test piece, speeding up carbonization and slice treatment, determining the content of carbonate and conducting data processing and result analysis. The invention is characterized by simple method, fast measuring speed, accurate test, scientific and reliable result analysis and the like. The device and the method can be widely applied to the test of carbonization resistance of the cement based materials, and also applicable to the test of the effect of various concrete admixtures, maintaining conditions, carbonization conditions and the like on the carbonization resistance of the cement based materials.

Owner:CHONGQING UNIV

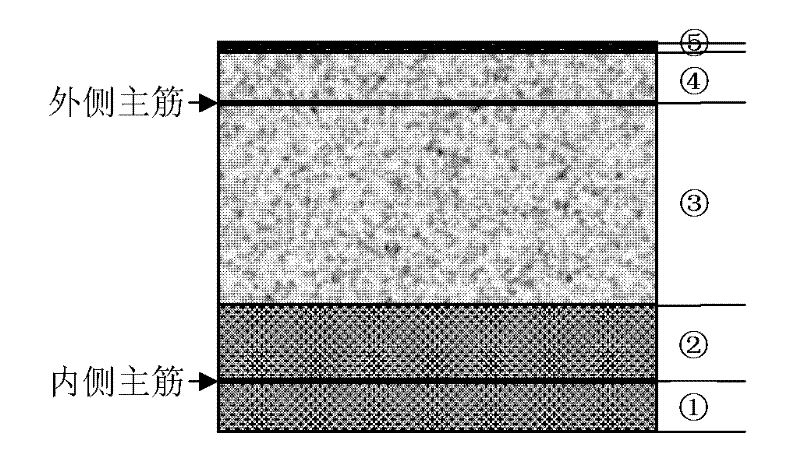

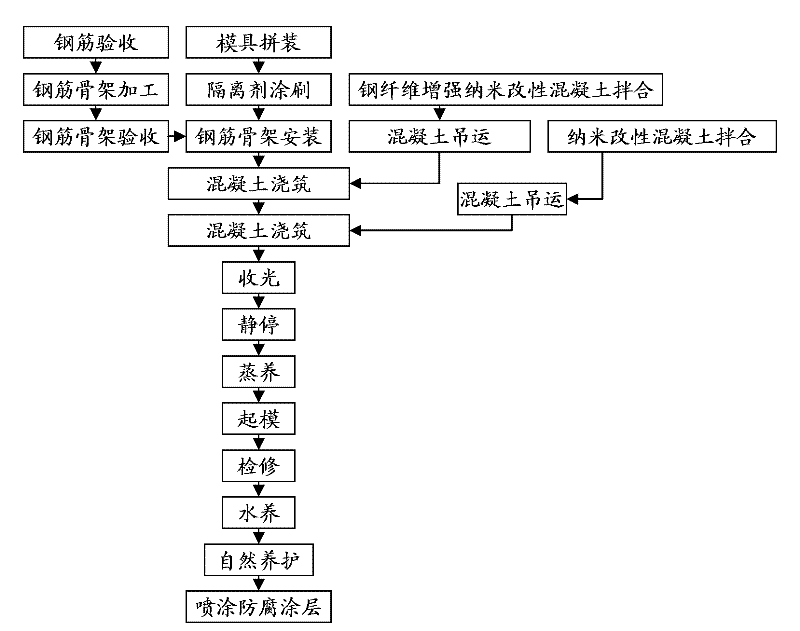

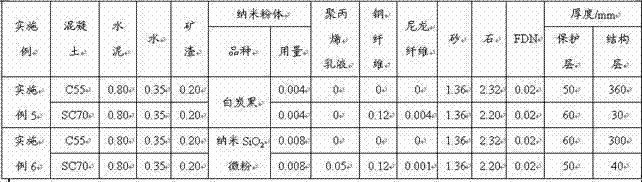

High-performance functionally-gradient shield lining segment and preparation method thereof

InactiveCN102207000AReduce breakage rateImproves carbonation resistanceUnderground chambersWater-setting substance layered productFiberReinforced concrete

The invention discloses a high-performance functionally-gradient shield lining segment and a preparation method thereof. The high-performance functionally-gradient shield lining segment, from top to bottom, sequentially comprises an external nano-modified concrete protection layer, an external nano-modified concrete structure layer, an internal steel fiber reinforced nano-modified concrete toughening structure layer and an internal steel fiber reinforced nano-modified concrete toughening protection layer, wherein the external nano-modified concrete protection layer and the external nano-modified concrete structure layer are connected into a whole; and the internal steel fiber reinforced nano-modified concrete toughening structure layer and the internal steel fiber reinforced nano-modifiedconcrete toughening protection layer are connected into a whole. The invention effectively solves the problems that the existing reinforced concrete segment is easy to damage, poor in durability and low in cost and the like because the existing reinforced concrete segment is completely prepared from high-toughness concrete.

Owner:ZHEJIANG UNIV OF TECH +1

Mechanism sand dry-mixed mortar and preparation method thereof

The invention discloses a mechanism sand dry-mixed mortar and a preparation method thereof, belonging to the technical field of building materials. According main points in a technical scheme of the invention, the mechanism sand dry-mixed mortar comprises the following components: cement, tailing sand, natural river sand, fly ash, a water-retaining thickener, redispersible latex powder, metakaolin, shell powder and a polycarboxylic acid water reducer. According to the invention, the tailing sand widely available is used as a main fine aggregate, and the compounding of the natural river sand and mechanism sand can make up for the problems of poor grading characteristics and grain shape defects of the mechanism sand; by strictly controlling the content of stone powder in the tailing sand, the processing properties of drying and grading of the tailing sand are improved; gaps in the dry-mixed mortar are filled in by the metakaolin and shell powder, so the compactness and impermeability ofthe hardened mortar are enhanced; the water-retaining and thickening properties of the dry-mixed mortar is improved through the water-retaining thickener; and the raw materials of the dry-mixed mortarare improved in dispersion uniformity and workability is improved, and the adhesion between the raw materials of the dry-mixed mortar is enhanced.

Owner:北京建工新型建材有限责任公司

Multifunctional anti-leakage shrinkage type concrete surface layer reinforcer

The invention relates to a multifunctional anti-leakage shrinkage type concrete surface layer reinforcer which is prepared from the following components in percentage by weight: 10-20 percent of high polymer, 1-7 percent of film forming aided compound, 5-10 percent of surface layer active agent compound, 1-4 percent of leakage aided compound, 1.5-4.5 percent of active compound and the balance of water. The invention has good concrete surface layer enhancement effect, can obviously reduce the shrinkage of surface layer concrete, obviously improves the carbonization resistance and the medium leakage resistance of surface layer concrete, has convenient construction and obvious economic benefit and can be widely applied to the strengthening treatment operations on the surface layers of cement and concrete pouring components, concrete components under corrosion environment conditions such as piers, dams, and the like and deformed concrete components difficult to be strengthened by adopting a conventional method.

Owner:湖州苏博特新材料有限公司

Roll-formed alkali slag and building rubbish plate

InactiveCN106316246AHeat of hydrationImprove impact resistanceConstruction materialSlagCarbonization

The invention discloses a roll-formed alkali slag and building rubbish plate, and belongs to the technical field of building material preparation. The roll-formed alkali slag and building rubbish plate comprises a surface layer and a middle material layer, and a fiberglass mesh is laid between the surface layer and the middle material layer. Industrial waste residues and building rubbish are adopted as raw materials, the advantages of being high in solid waste utilization rate and low in price and cost are achieved, the potential hydration activity of the alkali slag and the the building rubbish is fully utilized, and waste is turned into wealth. The roll-formed alkali slag and building rubbish plate has the advantages of being high in wear resistance, low in heat of hydration, high in impact resistance, low in contractibility rate, good in fatigue resistance, high in carbonization resistance, good in durability and the like, and can be widely applied to the building fields of inner wallboards, outer wallboards and the like. The process has the advantages of being simple, low in price and environmentally friendly, saving energy and the like, and is suitable for volume production.

Owner:ZHUODA NEW MATERIALS TECH GRP WEIHAI CO LTD

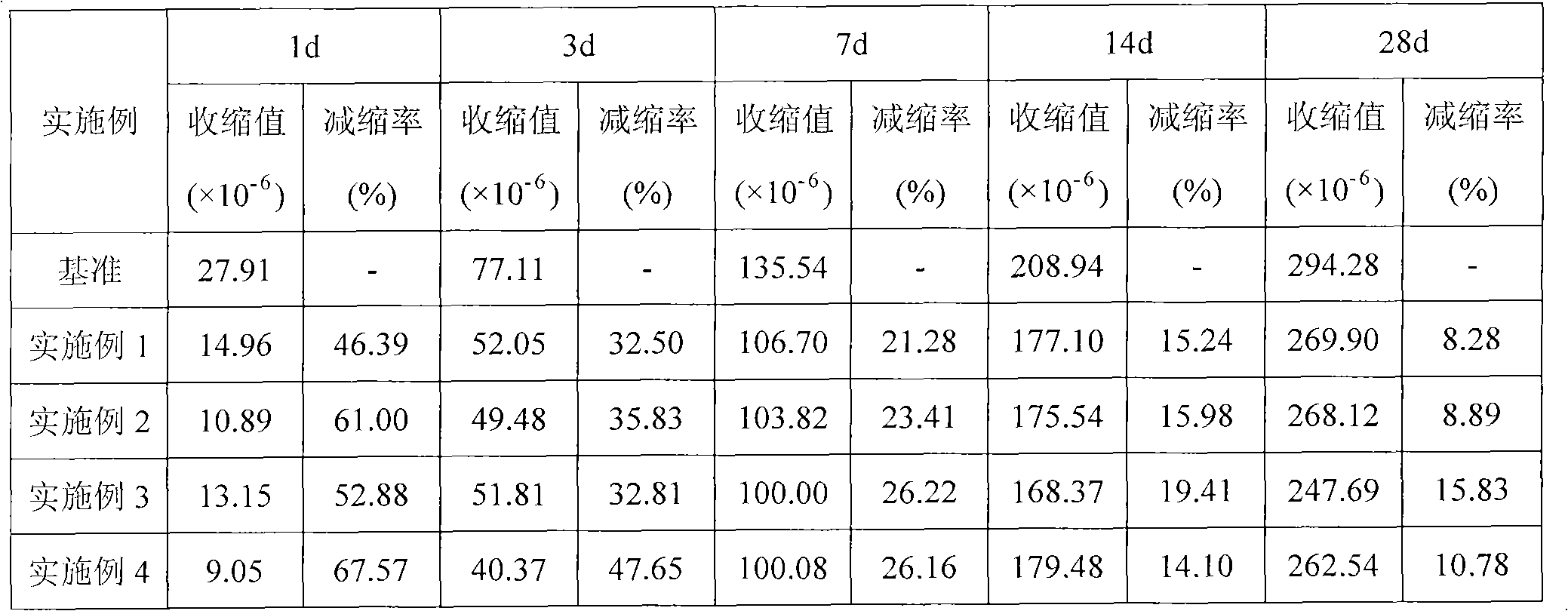

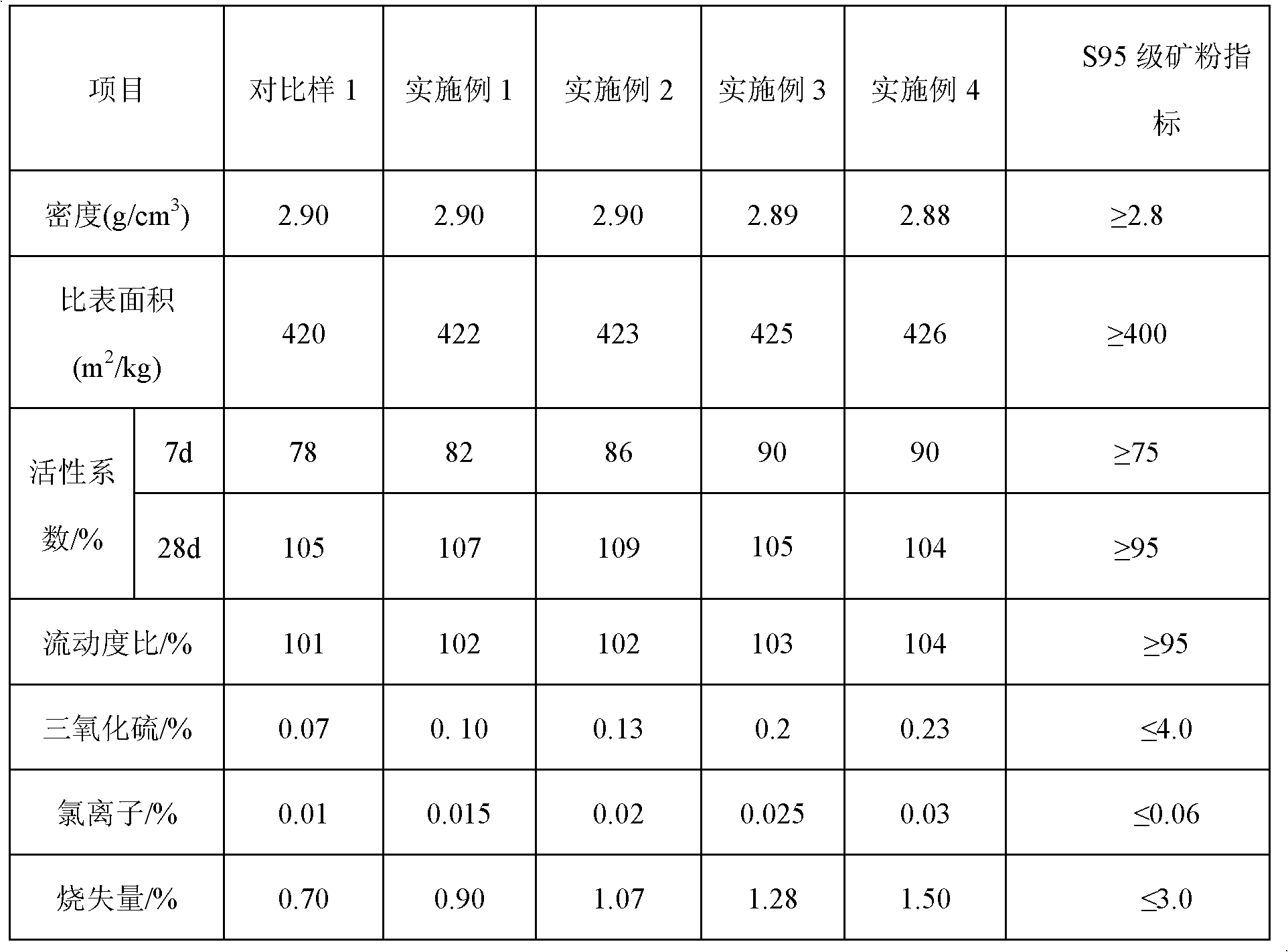

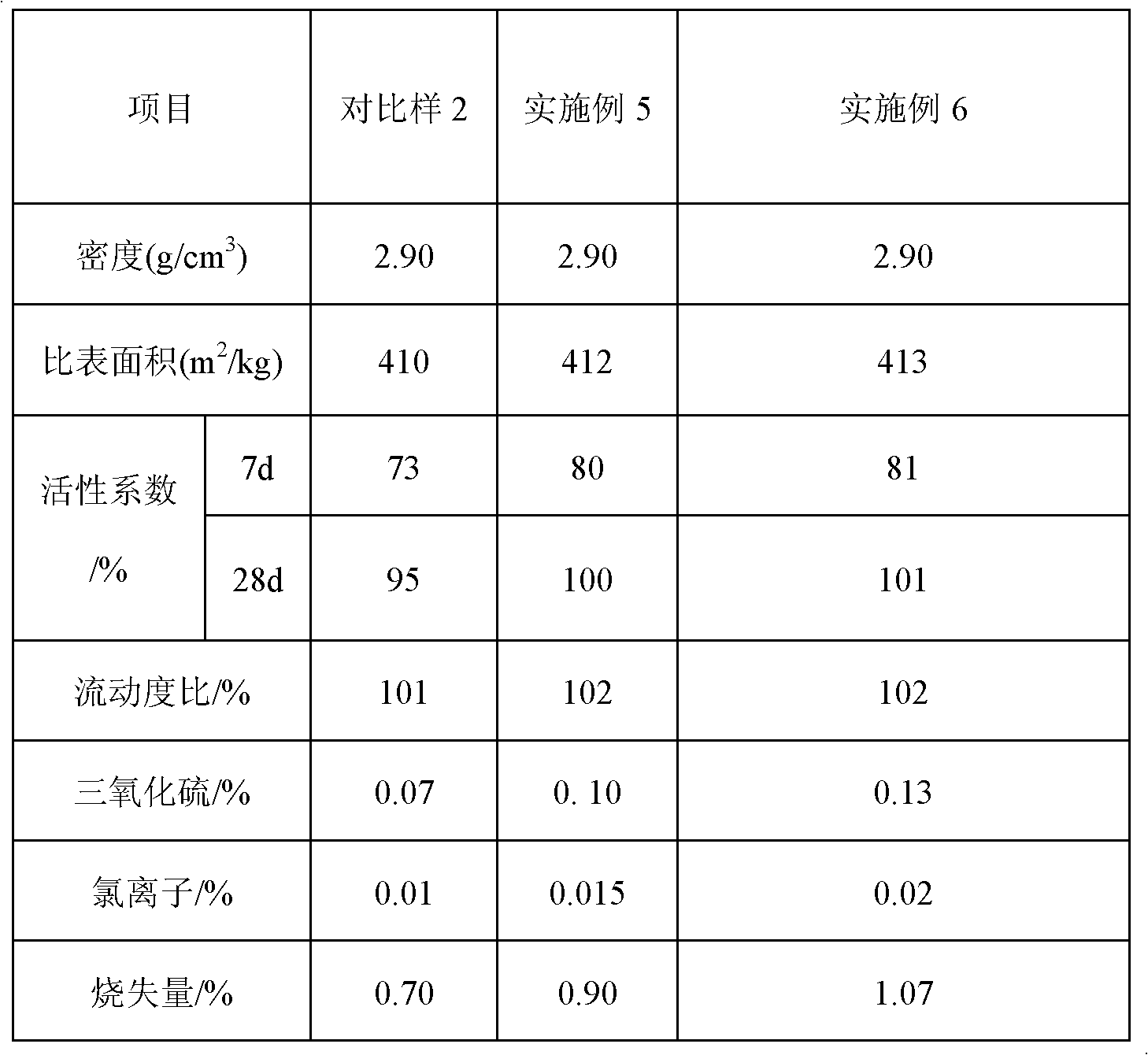

Mineral powder modified by sintering dry desulphurization ash and preparation method thereof

InactiveCN102584062ASmall specific surface areaImprove early shrinkage crack resistanceSolid waste managementCrack resistanceWork performance

The invention discloses a mineral powder modified by sintering dry desulphurization ash and a preparation method thereof. The 7-day activity index of the mineral powder modified by sintering dry desulphurization ash is more than 80%, the 28-day activity index is more than 100%, the specific surface area is more than or equal to 400 m2 / kg, the sulfur trioxide content is less than or equal to 4.0%, the chloride ion content is less than or equal to 0.06%, the loss on ignition is less than or equal to 3.0% and the motility ratio is more than or equal to 100%. The mineral powder is made from the following raw materials in percentage by weight: 95 to 99% of blast-furnace slag powders and 1 to 5% of sintering dry desulphurization ash. The 7-day activity index and 28-day activity index of the modified mineral powder are greatly increased as compared with the common mineral powders, the requirement for specific surface area is reduced, and the energy consumption for milling slag powders can be reduced effectively. When applied to premixed concrete, the modified mineral powder is excellent in durability indices such as carbonization resistance, freeze resistance and chloride ion infiltration resistance, can effectively improve the working performance of concrete and improve the early-stage shrinkage crack resistance of hardened concrete.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Light-weight high-strength cement-based composite material

InactiveCN105272004AMeet the requirements of construction mobilityThe material surface is denseSolid waste managementChemical admixtureCarbonization

The invention relates to a light-weight high-strength cement-based composite material. By optimizing grain composition of a multi-component cementitious material and grain composition of aggregates and utilizing chemical additives such as a water reducing agent, a thickening agent and the like, the volume weight of the material can be obviously lower than that of ordinary concrete, and the compression resistive strength of 20MPa or more can be obtained. The light-weight high-strength cement-based composite material has technical advantages that under the volume weight less than or equal to 1650kg / m<3>, the compression resistive strength is greater than or equal to 20MPa after the material is standard cured for 28 days; by optimizing the grain composition of the cementing material and the grain composition of the aggregates, the construction mobility requirement can be met under a low water-binder ratio; the surface of the hardened material is compact, and the hardened material has durable performance such as permeation resistance, carbonization resistance, chlorine ion erosion resistance and the like.

Owner:浙江宏日泰耐克新材料科技有限公司

Recycled micropowder concrete and preparation method thereof

InactiveCN103771776AHigh strengthImproves carbonation resistanceCement productionSoil scienceEnvironmental engineering

The invention relates to a recycled micropowder concrete and a preparation method thereof. The recycled micropowder concrete comprises cement, sand, gravel, water, recycled micropowder and activator Ca(OH)2. The preparation method comprises the following steps: 1) crushing waste concrete into fine aggregate, and screening out the recycled micropowder with the diameter of less than 0.16mm; 2) according to the amounts of materials of the concrete with the water-to-cement ratio of 0.54 and the calculated strength grade of C30, replacing 10% of cement with equal mass of recycled micropowder, and adding the activator Ca(OH)2 which accounts for 3.5 wt% of the recycled micropowder; and 3) weighing the cement, recycled micropowder and activator Ca(OH)2, adding into a stirrer, stirring uniformly, adding water, stirring, sequentially adding the sand and gravel, and stirring. The recycled micropowder concrete prepared by the method has higher strength and carbonization resistance than normal concrete with the same mixing proportion, is safely applied to practical engineering, and enhances the utilization ratio of the waste concrete.

Owner:CHINA UNIV OF MINING & TECH

High-performance concrete admixture in use of waste ceramic powder and implementing method thereof

InactiveCN104817287AThe stability result is qualifiedImprove liquiditySolid waste managementEnvironmental resistanceFiber

The invention discloses a high-performance concrete admixture in use of waste ceramic powder and an implementing method thereof. The high-performance concrete admixture is prepared by the following steps: utilizing waste ceramics as a main material and utilizing active seed crystals and a modified enhancer as auxiliary materials; performing modified treatment and high-temperature smelting on various materials, then putting into a cement mill to mill the materials to be pre-finished products with specific area of 300-450 m2 / kg, and finally, doping mixed fibers. The high-performance concrete admixture comprises the raw materials in parts by weight: 80-100 parts of waste ceramic powder, 6-9 parts of active seed crystal, 2-6 parts of modified enhancer and 5-10 parts of mixed fibers. By adopting mixed ceramic powder, density of cement mortar is effectively increased; strength of concrete is improved and durability of concrete is remarkably improved. Energy problems are solved, and meanwhile, an environmental protection purpose is considered; the high-performance concrete admixture has remarkable technical, economic and social benefits.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Heat-preserving heat-insulating composite material for exterior wall of buildings and construction method thereof

InactiveCN101219872AIncrease late stage (28d) intensityLow costSolid waste managementInsulation systemUltimate tensile strength

The invention discloses a temperature preservation and heat insulation composite on an exterior wall of a building and a construction method thereof; the composite comprises 1 weight portion of composite powders and 0.06 to 0.120 portions of polyphenylene particles. Before construction, the mixing ratio of dry-mixed mortar composite, the polyphenylene particles and water satisfies that composite powders: polyphenylene particles: water is equal to 1(kg): (60 to 120)(g): (1.2 to 1.4)(kg). The ratio of each component in the temperature preservation and heat insulation composite material of the exterior wall provided by the invention is reasonable, leading to excellent temperature preservation and heat insulation effects, and high bonding strength and good chemical performance of the heat insulation material. At the same time, the composite has waterproof function. The large amount of added fly ash of the invention provides a new path for the application of fly ash in the exterior wall temperature preservation system. The application of regenerated polyphenylene foams is a new attempt to make the waste to the worth in the temperature preservation and heat insulation system and also eliminates the harmful environmental pollution caused by the regenerated polyphenylene foams.

Owner:SHANGHAI SHUNGANG ENERGY SAVING BUILDING MATERIALSCI

Magnesian sulphoaluminate cement, and method of preparing sheet material with the cement and fiber-reinforced composite material

InactiveCN105130228AReduce alkalinityEfficient use ofSolid waste managementAluminateAluminum sulphate

The invention relates to magnesian sulphoaluminate cement, and a method of preparing a sheet material with the cement and a fiber-reinforced composite material, and belongs to the technical field of magnesian cement formulas and products. The magnesian sulphoaluminate cement mainly includes the following raw materials: light-burned magnesium oxide, magnesium sulfate, aluminum sulfate, calcined bauxite and water. The invention, compared with the prior art, has following beneficial effects: 1) the cement is high in strength; 2) the cement is low in alkali degree; 3) low-grade bauxite can be utilized so that a novel approach is developed for effective utilization and reasonable allocation of resources; 4) the cement is long in service life; and 5) the magnesian sulphoaluminate cement can be composited with plant fiber directly.

Owner:谌萌 +1

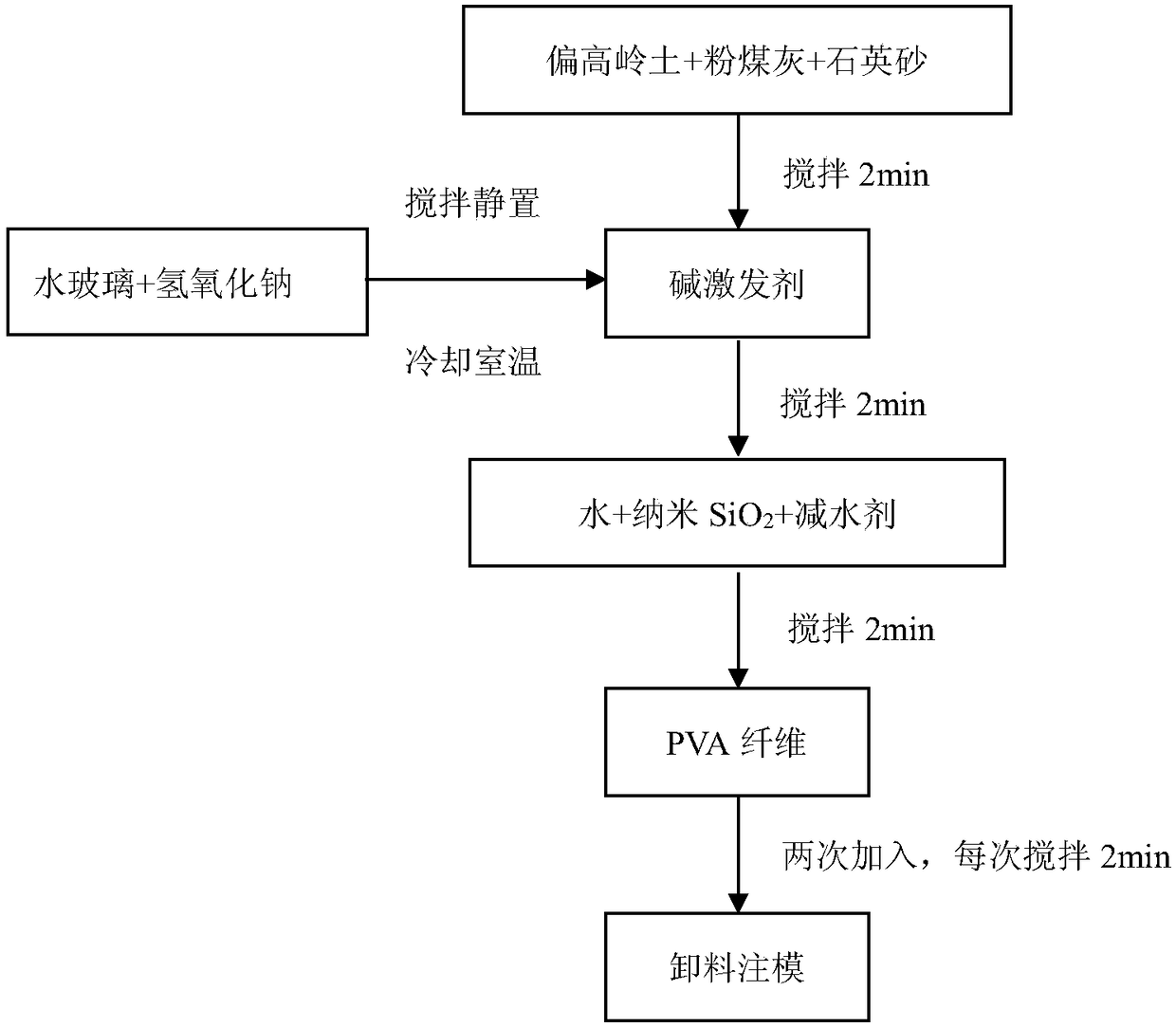

Method for preparing nano-SiO2 and PVA fiber reinforced polymer mortar

The invention discloses a method for preparing nano-SiO2 and PVA fiber reinforced polymer mortar, belonging to the field of inorganic polymer materials. The method comprises the following steps: stirring pre-treated metakaolin, pulverized fuel ash and quartz sands in a stirrer for 2 minutes; adding alkali-activator under a constant stirring state; continuously stirring for 2 minutes; adding a nano-SiO2 mixed solution, continuously stirring for 2 minutes; and adding PVA fibers twice under a constant stirring situation, stirring for 2 minutes each time to obtain the nano-SiO2 and PVA fiber reinforced polymer mortar. The nano-SiO2 and PVA fiber reinforced polymer mortar has excellent mechanical performance and excellent adhesion characteristic, and has a broad application prospect in the fields of construction, road and bridges, hydraulic engineering, military science and the like.

Owner:ZHENGZHOU UNIV

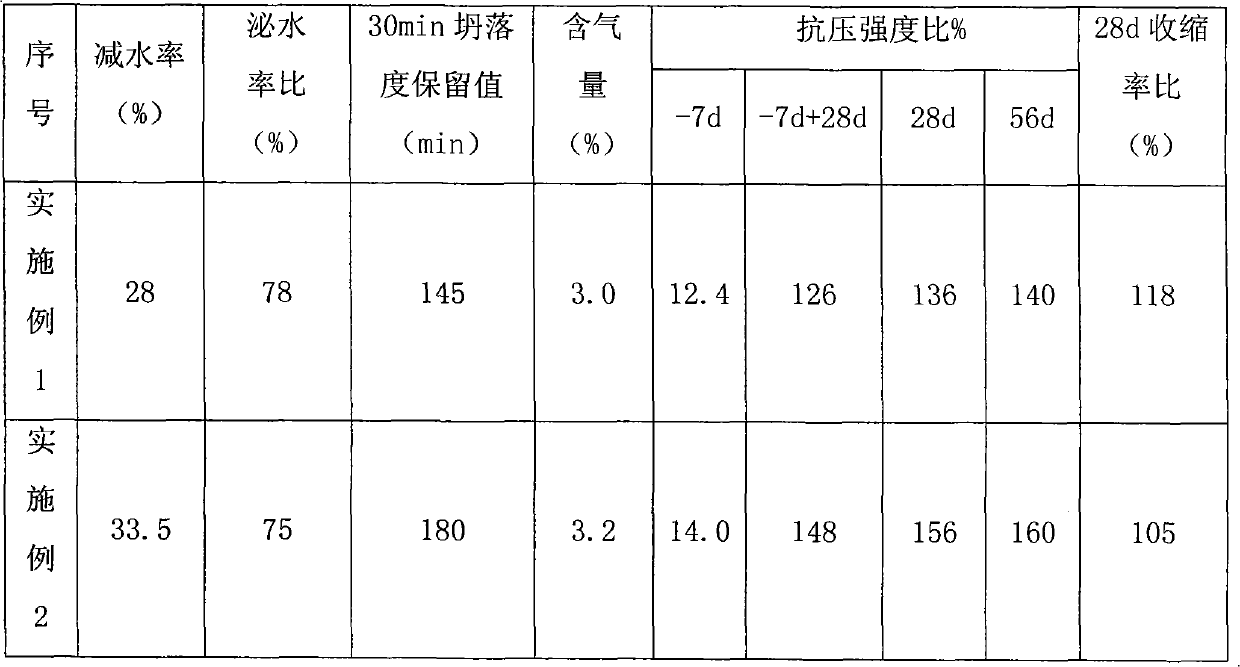

High-slump-loss-resistant synergist and preparation method and application thereof

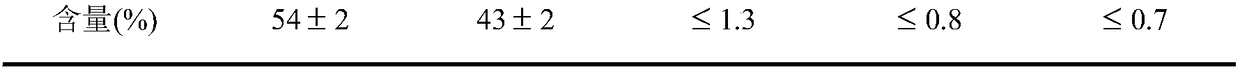

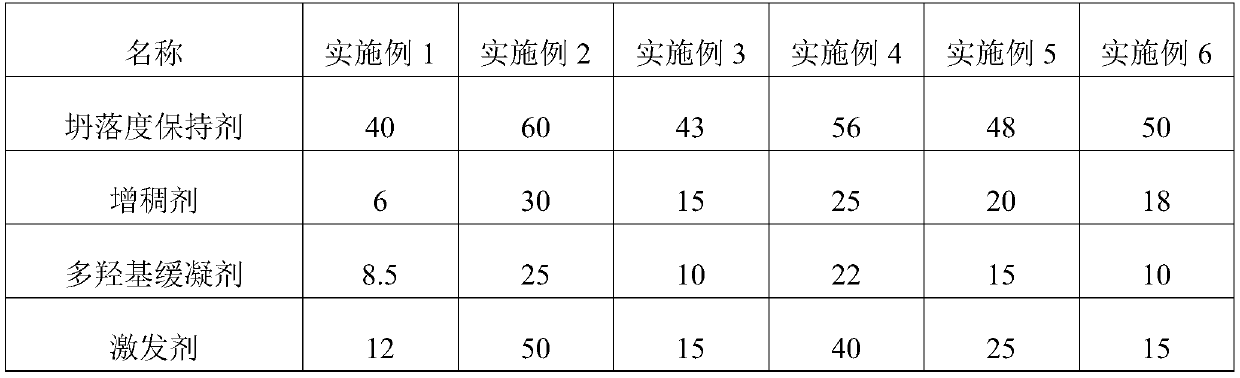

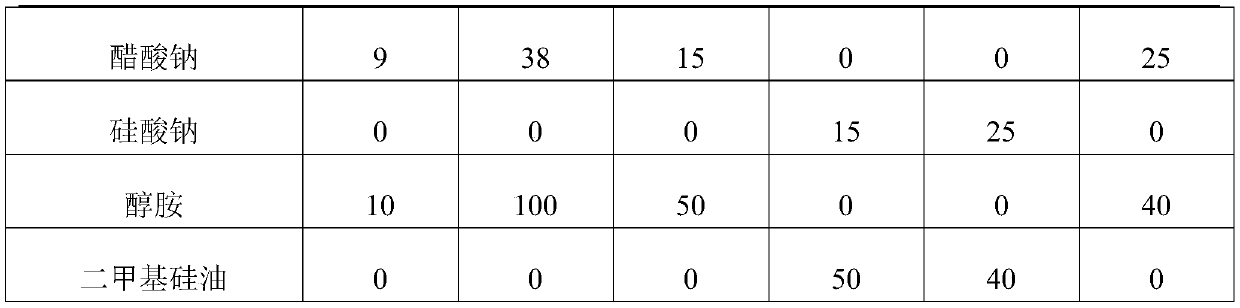

The invention belongs to the technical field of concrete, and provides a high-slump-loss-resistant synergist, which is prepared from 40 to 60 parts of slump maintainers, 6 to 30 parts of thickening agents, 8.5 to 25 parts of polyhydroxyl retarders, 12 to 50 parts of excitants, 9 to 38 parts of sodium acetate or sodium silicate and 10 to 100 parts of hydramine or simethicone, wherein the slump maintainers are prepared from 300 to 450 parts of polyether, 20 to 45 parts of unsaturated acid, 30 to 80 parts of acrylic ester, 1.1 to 3.8 parts of chain transferring agents and 0.5 to 1.5 parts of reducing agents. A preparation method comprises the following steps of adding polyether into water; performing heating dissolution; then, dripping a material A and a material B; performing reaction for one hour to obtain the slump maintainers; adding water into thickening agents for dissolution; sequentially adding the polyhydroxyl retarders, the excitants, sodium acetate or sodium silicate; after thedissolution, adding hydramine or simethicone; adding the slump maintainers; performing uniform mixing to obtain the high-slump-loss-resistant synergist applied to concrete preparation. By using the technical scheme, the high-slump-loss-resistant synergist solves the problem of fast concrete slump loss in the prior art; meanwhile, the intensity is improved.

Owner:兰州同邦建材有限公司

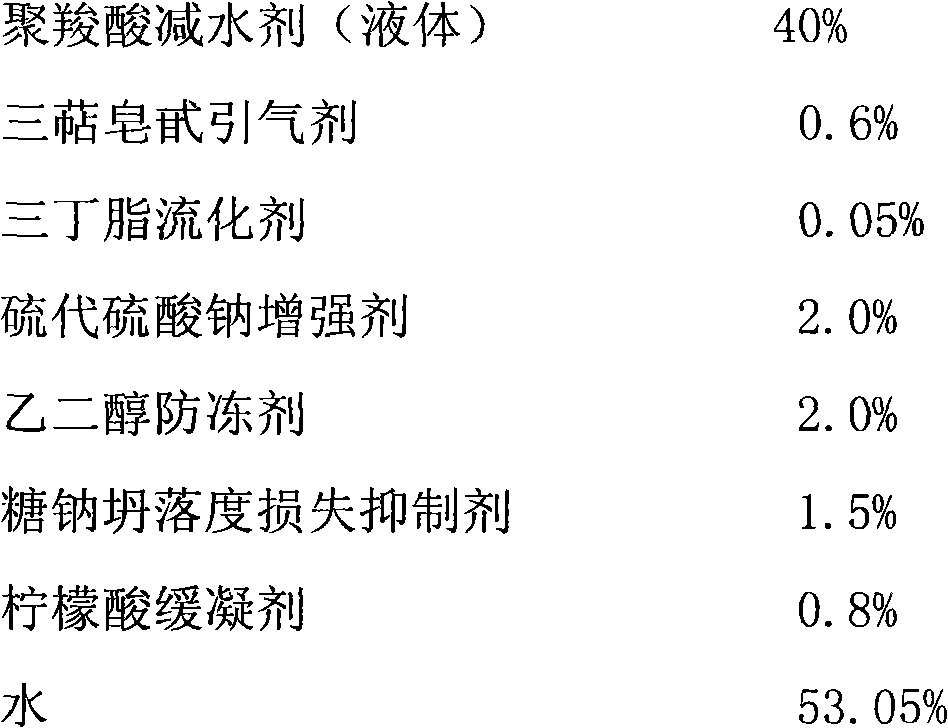

Concrete pumping antifreezing agent with adjustable performances

The invention relates to a concrete pumping antifreezing agent with adjustable performances, belonging to the field of building materials. The concrete pumping antifreezing agent comprises the following materials by weight percent: 28% -42% of water reducing agent, 0.3%-0.7% of air entraining agent, 0.05%-0.07% of fluidizing reagent, 1.5%-2.5% of reinforcing agent and 2.0%-3.0% of antifreezing agent, 1.5%-5.0% of slump loss inhibitor and 45%-65% of water, and the concrete pumping antifreezing agent is a novel pumping antifreezing agent and does not contain any chloride. The concrete pumping antifreezing agent is simple in production process, does not contain alkali and chlorine, and cannot corrode a steel bar. The concrete pumping antifreezing agent has the advantages that the peaceability of concrete is improved substantially, the volume is stable, the water-reducing rate is high, the anti-freezing performance is high, the early-strength performance is obvious, the increasing value of the later-stage concrete strength is high, the adaptability is good, and the like, and has good pumpability in the construction. The concrete pumping antifreezing agent is low in cost, good in performance and has good economical benefits and social benefits.

Owner:BAOTOU ANSHUN NEW BUILDING MATERIALS

Method for preparing construction waste micro-powder composite admixture

InactiveCN103086619AHas hydration activityPromote participation in hydration reactionsSolid waste managementCement productionAlkalinityPowder mixture

The invention discloses a method for preparing a construction waste micro-powder composite admixture. The method comprises the steps of: evenly mixing construction waste with lime and desulfurized gypsum, and grinding at room temperature to obtain a micro-powder mixture with specific surface area larger than 400m<2> / kg, wherein the mixing weight of the construction waste accounts for 90%-98% total weight of the micro-powder mixture, the mixing weight of the lime accounts for 1%-5% and the mixing weight of the desulfurized gypsum accounts for 1%-5%; mixing the ground micro-powder mixture with an additive of which the weight accounts for 1%-5% total weight of the micro-powder mixture to obtain a mixed material; and mixing the mixed material with slag in a weight ratio of 1:1 and then carrying out ball milling until the specific surface area of the material is larger than 450m<2> / kg, thereby obtaining the construction waste micro-powder composite admixture. The method has the advantages that the alkalinity of concrete can be supplemented, the mixing quantity of a construction waste micro-powder auxiliary gelation material in the concrete is increased and the carbonization resisting capacity of the concrete can be improved.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Preparation method of zeolite geopolymer cementing material

The invention discloses a preparation method of a zeolite geopolymer cementing material. The method comprises the following steps: (1), preparing a silicon-aluminum mixture; (2), preparing an alkalineactivator; and (3), preparing a zeolite geopolymer cementing material. According to the geopolymer cementing material, metakaolin, zeolite, red mud, coal ash, magnesium oxide and other raw materialsare reasonably utilized, so that activation reaction of all the material components is improved; alkali metal ions are firmly combined in a reaction product, and the surface frosting problem can be slightly relieved. The prepared zeolite geopolymer cementing material is high in strength and high in hardening speed, and the 28-day strength can reach over 48 MPa. Magnesium oxide in the raw materialsplays a role of a filling and expanding agent and can effectively absorb carbon dioxide. By optimizing the proportion, the geopolymer is more excellent in corrosion resistance by being compared withordinary Portland cement, small in capillary pore number, good in impermeability, small in shrinkage, high in setting speed and high in applicability, and the sustainable development requirements of ecological environmental protection can be met.

Owner:XIANGTAN UNIV

Inorganic high-performance fiber composite material decorating plate and preparation method thereof

ActiveCN105601207AConsistent thermal expansion and contraction performanceIncreased durabilityCopper platingFineness modulus

The invention discloses an inorganic high-performance fiber composite material decorating plate and a preparation method thereof. The inorganic high-performance fiber composite material decorating plate is prepared from the following components in parts by weight: 600-1000 parts of cement, 250-350 parts of active admixtures, 80-150 parts of inert admixtures, 700-1100 parts of sand, 50-70 parts of a water reducer, 80-130 parts of water, 60-150 parts of special-shaped copper plated steel fiber and 7-12 parts of a corrosion inhibitor, wherein the strength grade of the cement is not smaller than 42.5, the particle size range of the active admixtures is 0.01-10 microns, the average particle size of the inert admixtures is 20-60 microns, the fineness modulus of the sand is 1.4-2.0, the maximum particle size of the sand is not greater than 2.36mm, the water reducing rate of the water reducer is higher than 20%, the diameter of the special-shaped copper plated steel fiber is 0.10mm-0.15mm, and the length of the special-shaped copper plated steel fiber is 6mm-18mm. The decorating plate is high in tensile strength, can be used as a bearing capacity structure, can be randomly shaped, and is wide in material source, low in integral comprehensive cost, good in wear resistance and good in carbonization resistance.

Owner:GUANGDONG TOPNICE NEW MATERIALS TECH CO LTD

Fly ash-based cemented filling material and preparation method thereof

The invention discloses a fly ash-based cemented filling material and a preparation method thereof, belongs to the field of filling mining, and particularly relates to a filling material for mining and a preparation method thereof. The fly ash-based cemented filling material is used for solving the problems of high cost and slow solidification and consequent low roof contact rate of the existing cement filling material for mining. The filling material is prepared from waste fly ash, underground wastewater, an activator, lime, desulfurized gypsum, an early strength agent, sulphoaluminate cement and complex portland cement. The preparation method comprises the following steps of: (I) preparing raw materials; (II) pouring the underground wastewater into a stirring device, adding the waste fly ash, and adding the activator for activation treatment; (III) adding the lime, gypsum, complex portland cement, early strength agent and sulphoaluminate cement into the activated mortar, and stirring to obtain the filling slurry. According to the fly ash-based cemented filling material and the preparation method thereof disclosed by the invention, the cost of each ton of filling material is 80-115 yuan, the 8-hour uniaxial compressive strength is 1-2MPa, the 28-day uniaxial compressive strength is stabilized at 4-10MPa, and the roof contact rate can exceed 95%.

Owner:李凤义 +1

High-durability damping concrete and preparation method thereof

The invention discloses a high-durability damping concrete and a preparation method thereof, and relates to several concretes and a preparation method thereof. The invention solves the problems of low damping capability and poor durability of the conventional concrete structure material per se. The high-durability damping concrete is prepared by stirring and mixing cements, rubber powder, water, medium sand, stones, and adding fibers and silicon powder. In the invention, c the loss factors of the high-durability damping concrete are improved by about 80-200 percent compared with that of pain concrete under the condition of different frequencies. After maintenance for 28 days, the concrete prepared by using the method has chloridion-resistant permeability and carbonizing-resistant capability both superior to that of blank concretes.

Owner:刘铁军

Novel compound electric pole

InactiveCN105503065AHigh compressive strengthImproves carbonation resistanceSolid waste managementTowersCentrifugationEngineering

The invention belongs to the field of electric power materials and discloses a novel compound electric pole. The novel compound electric pole is prepared from concrete and a reinforcing mesh through compounding. The novel compound electric pole is prepared through uniformly distributing concrete in an electric pole mold with the reinforcing mesh through a material distribution machine, carrying out tensioning, carrying out centrifugation molding, carrying out standing for 4-5h and carrying out demolding. The novel compound electric pole has good performances and a wide application scope.

Owner:徐筱瑜

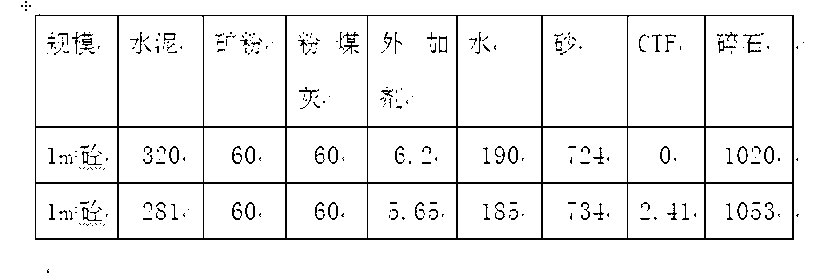

Concrete making formula

The invention relates to a concrete making formula. The formula mainly comprises the following components, by weight, 270-290 parts of cement, 55-65 parts of mineral powder, 55-65 parts of coal ash, 5-6 parts of an additive, 180-190 parts of water, 725-745 parts of sand, 1040-1060 parts of broken stone, and 2-3 parts of a CTF concrete synergist. The formula has the advantages of concrete material workability improvement, water segregation reduction, small pumping friction resistance, reduction of 10-15% of the application amount of cement, and realization of maintaining or exceeding a reference strength, and a product obtained in the invention has the advantages of non-toxicity, no pollution and no production discharge, and is a green environmentally-friendly building material.

Owner:NANTONG ZHONGJI PILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com