Mineral powder modified by sintering dry desulphurization ash and preparation method thereof

A technology of dry desulfurization ash and sintered desulfurization ash, which is applied in the directions of climate sustainability, sustainable waste treatment, solid waste management, etc. Anti-shrinkage crack performance, reduced energy consumption, excellent resistance to chloride ion penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

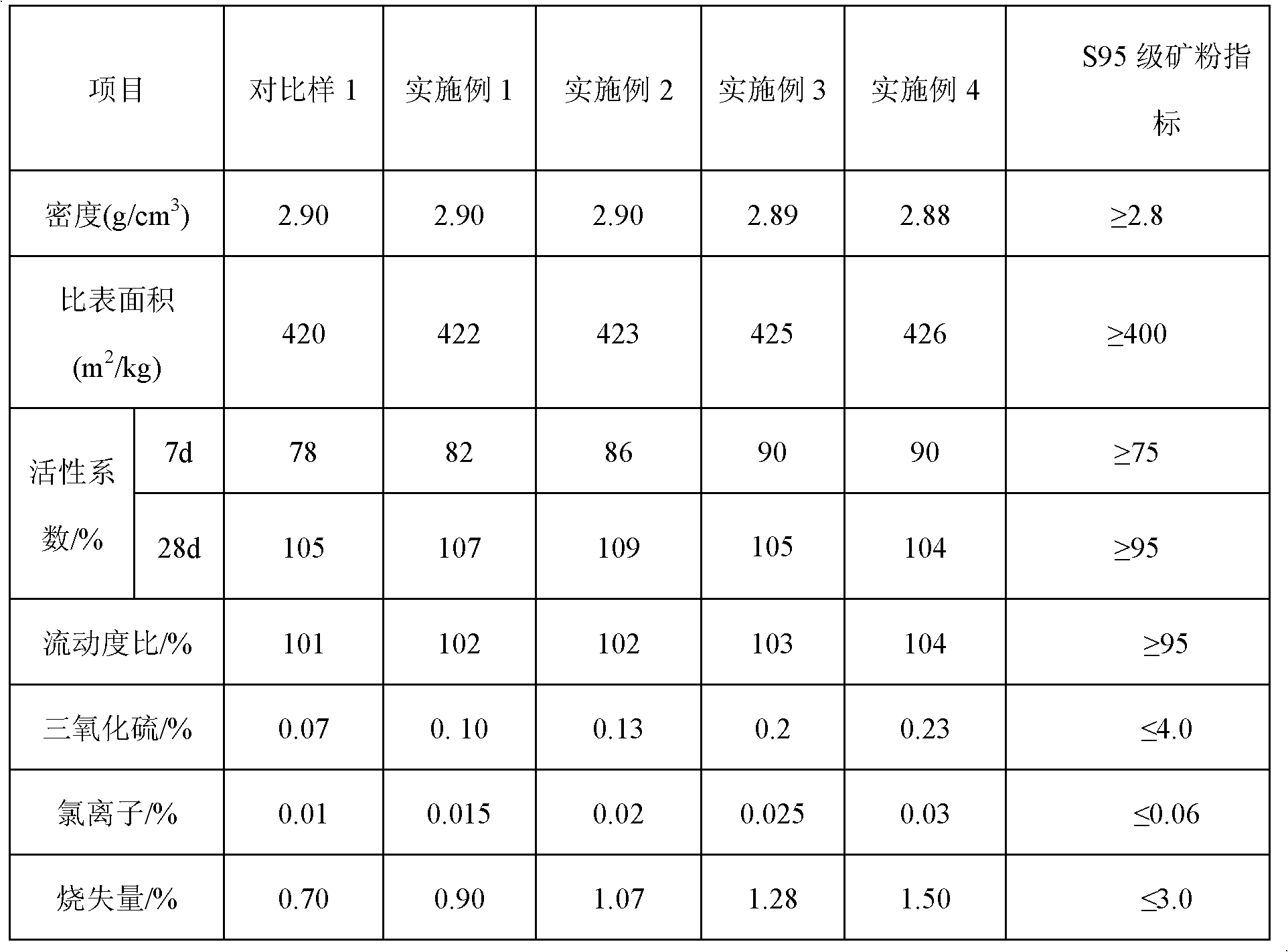

[0025] Slag powder 99wt%, 7d activity index 78%, 28d activity index 105%, density 2.90g / cm 3 , specific surface area 420m 2 / kg;

[0026] Sinter dry desulfurization ash 1wt%.

[0027] The above two materials are mechanically stirred and mixed uniformly to make a sintered dry desulfurization ash modified mineral powder sample. Refer to GB / T18046-2008 "Granulated Blast Furnace Slag Powder Used in Cement and Concrete" to test the performance of the sintered dry desulfurization ash modified slag powder sample. The benchmark cement is Conch brand 42.5 Portland cement, and the test results are shown in Table 1.

Embodiment 2

[0029] Blast furnace slag 98wt%;

[0030] Sinter dry desulfurization ash 2wt%.

[0031] The sintering dry desulfurization ash is put into the batching bin, and is put into the mill together with the blast furnace slag through the weighing belt according to the proportion, and processed into modified slag through grinding, powder selection and other processes. Sampling of the modified slag out-of-store samples, referring to GB / T18046-2008 "Granulated Blast Furnace Slag Powder Used in Cement and Concrete", to test the performance of the samples in all aspects. The benchmark cement is Conch brand 42.5 Portland cement, and the test results are shown in Table 1.

Embodiment 3

[0033] Slag fine powder 97wt%, 7d activity index 78%, 28d activity index 105%, density 2.90g / cm 3 , specific surface area 420m 2 / kg;

[0034] Sintered desulfurization ash 3wt%.

[0035] The sintering dry desulfurization ash enters the batching bin, and is fed into the mill with the blast furnace slag according to the proportion through the weighing belt, and is processed into modified slag through grinding, powder selection and other processes. Sampling the outbound sample of sintered dry desulfurization ash modified slag powder, referring to GB / T18046-2008 "Granulated Blast Furnace Slag Powder Used in Cement and Concrete" to test the performance of the sample in all aspects. The benchmark cement is Conch brand 42.5 Portland cement, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com