Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

127results about How to "Improve activity index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Blending material for high-early-strength concrete

InactiveCN101508557AImprovement of early strength and high strengthReduce dosageSolid waste managementHigh strength concreteCalcium formate

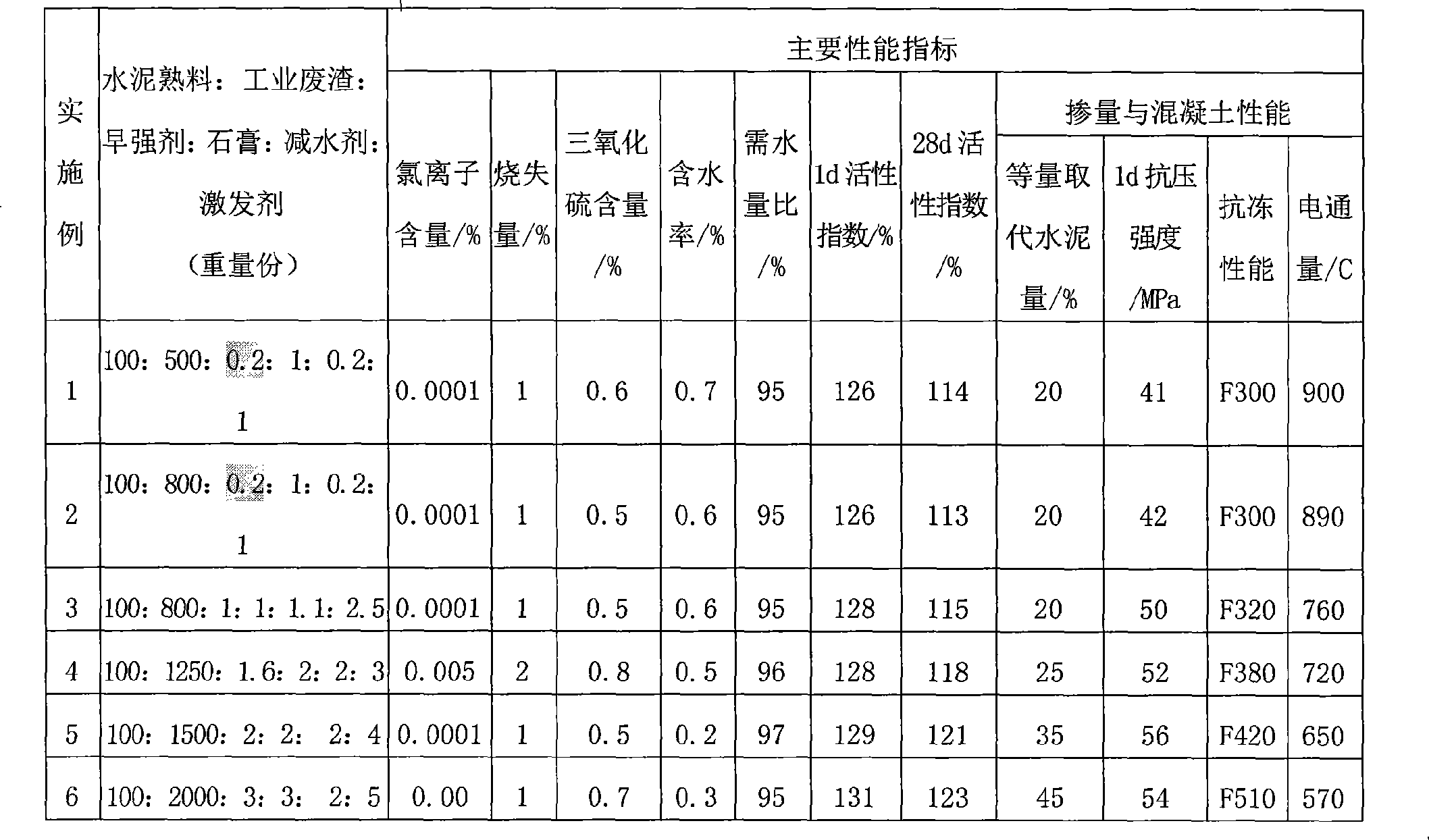

The invention relates to an admixture for high early strength of concrete, characterized in that the admixture is formed by mixing and stirring cement clinkers, industrial residues, early strength agents, plaster, water reducing agents and excitants. The parts by weight of the components are as follows: 100 parts of cement clinkers, 500-2000 parts of industrial residues, 0.2-3 parts of early strength agents, 1-3 parts of plaster, 0.2-2 parts of water reducing agents and 1-5 parts of excitants. The excitant is the mixture of aluminum hydroxide, calcium nitrite and calcium nitrate; wherein, the aluminum hydroxide accounts for 50% of the mixture while the calcium nitrite and the calcium nitrate are in any proportion; the early strength agent is the mixture of trolamine, lithium carbonate and calcium formate, wherein, the trolamine accounts for 50% of the mixture while the lithium carbonate and the calcium formate are in any proportion. The admixture for concrete provided by the invention has high activity index and low content of harmful ions. Adding the admixture can obviously improve the demoulding strength, long-term mechanical property and durability of the concrete.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

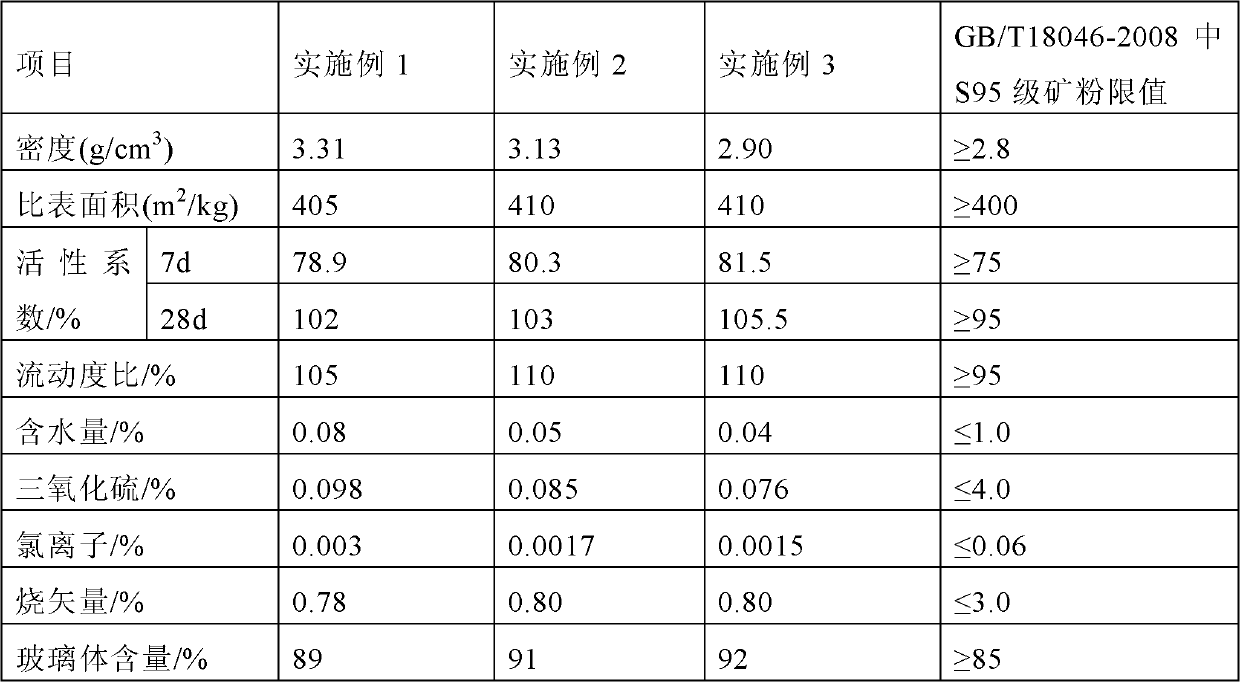

Modified steel slag composite admixture and preparation method thereof

InactiveCN102491664AOvercoming stability issuesImprove early activitySolid waste managementWork performanceSlag

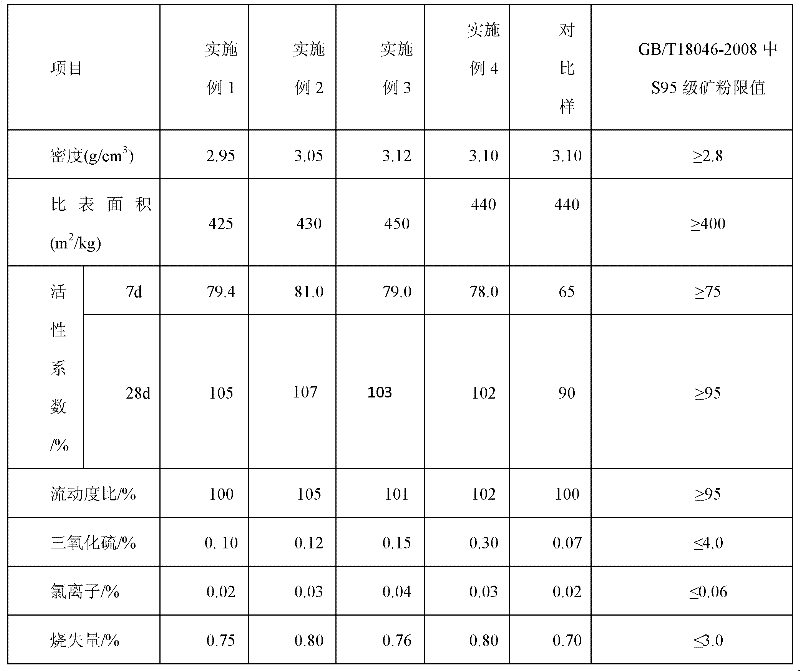

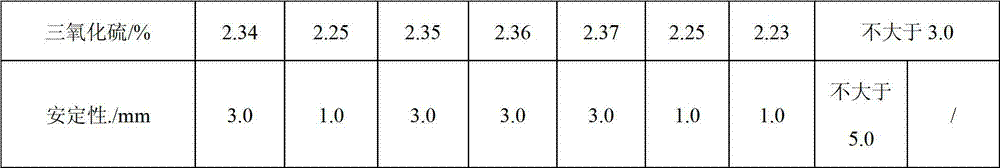

The invention discloses a modified steel slag composite admixture and a preparation method thereof. The modified steel slag composite admixture comprises 55-75wt% of micro mineral slag powder, 20-40wt% of micro steel slag powder, and 1-5wt% of sintering desulphurization slag. Concrete prepared by mixing the modified steel slag composite admixture of the invention with cement has the following characteristics: the seven day active index is greater than 75%, the twenty-eight day active index is greater than 100%, the specific surface area is equal to or greater than 400m<2> / kg, the sulfur trioxide content is equal to or less than 4.0%, the chloride ion content is equal to or less than 0.06%, the ignition loss amount is equal to or less than 3.0%, and the autoclaving stability is qualified. The modified steel slag composite admixture which allows a low early strength disadvantage of steel slag composite admixtures to be overcome, working performances of concrete to be effectively improved, the strength and the endurance of concrete to be improved, and energy consumption required by slag grinding to be effectively reduced and is in favor of the low carbon economy realization, is a resource use type concrete admixture.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS

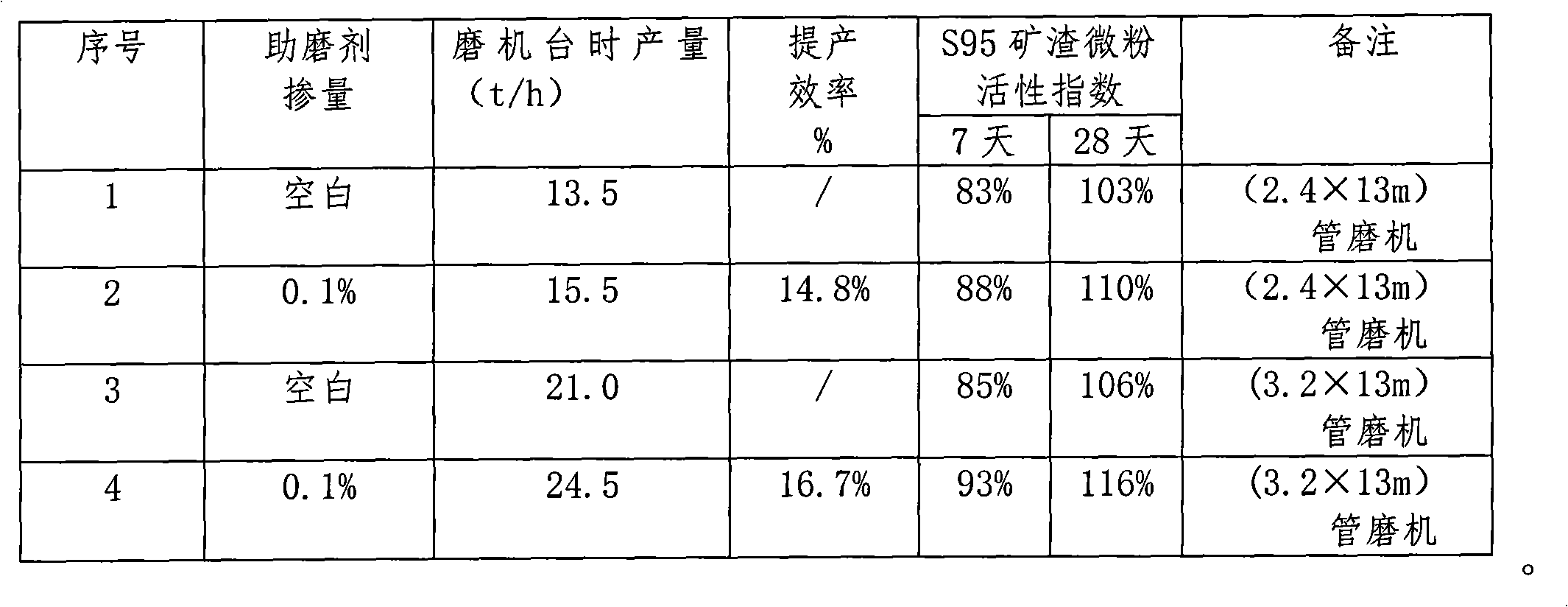

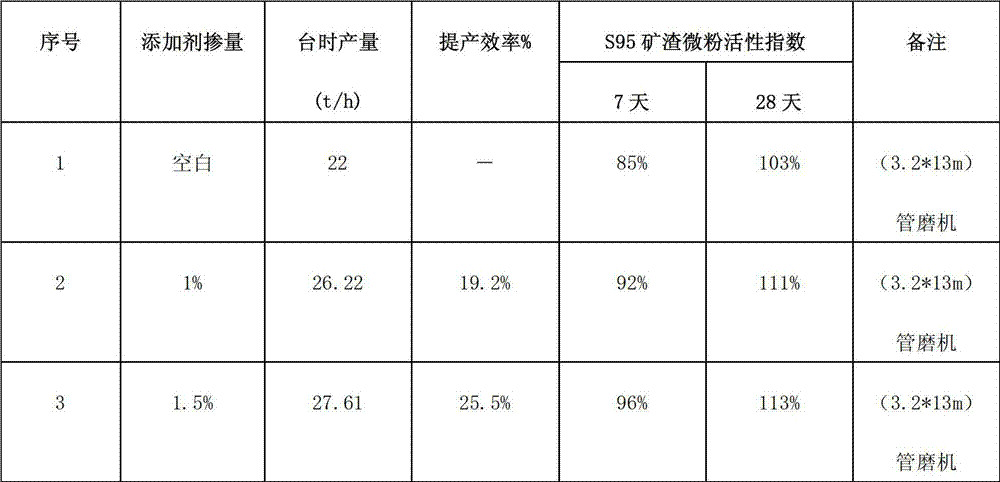

Vertical mill slag grinding aid and preparation method thereof

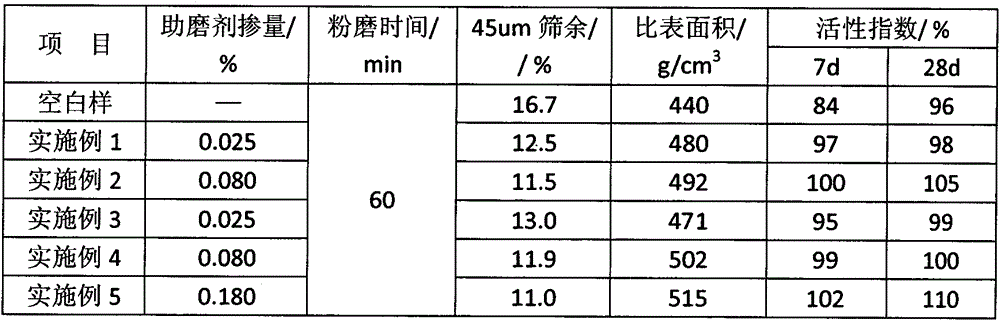

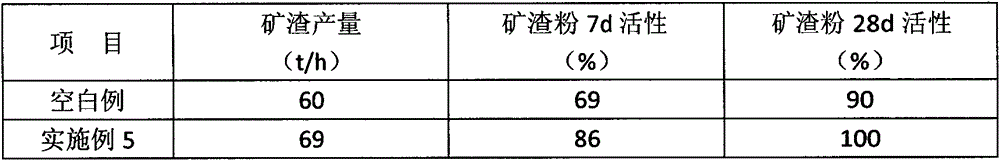

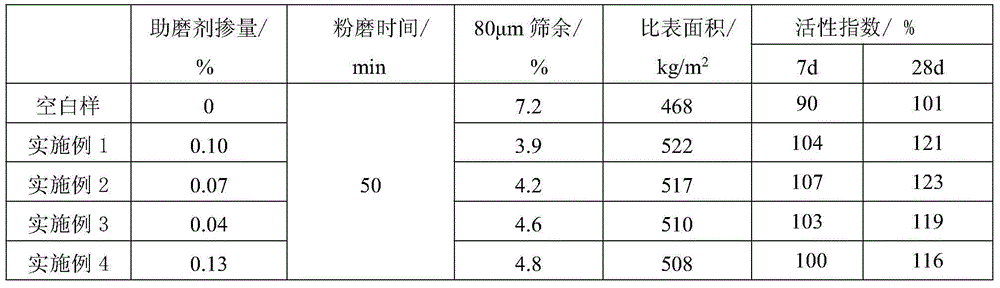

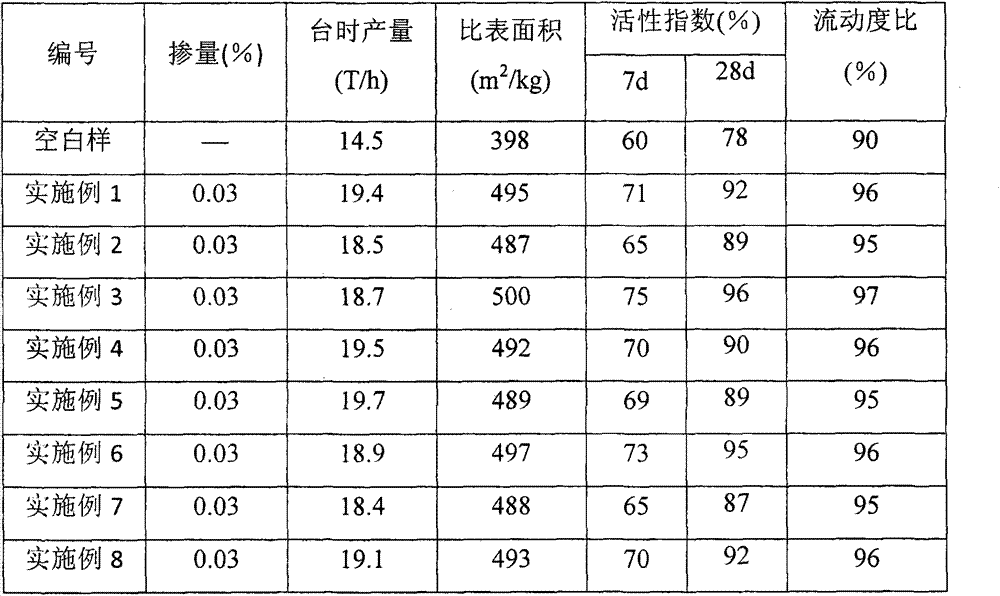

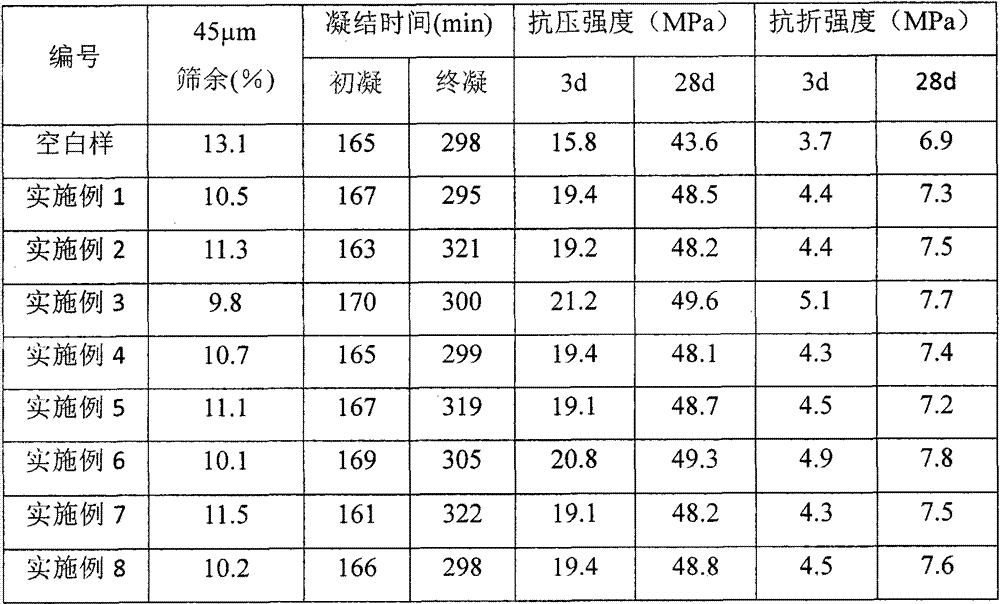

The invention discloses a vertical mill slag grinding aid and a preparation method thereof. The slag grinding aid comprises the following components in percentage by weight: 5 to 40% of polyol amine, 10 to 60% of polymeric polyol, 5 to 40% of polyol, 3 to 20% of inorganic salts, and the balance being water. The provided preparation method is suitable for the production of vertical mill slag grinding aid. The slag yield is increased by 5 to 20%. The activity indexes of slag are increased to different degrees. The fineness (residue on sieve) and specific surface area of mineral powder are prominently improved, and the performance of cement is not influenced. The preparation method can improve the fluidity of mineral powder, thus reduces the phenomenon of over grinding, improves the powder selecting efficiency, and prominently increases the content of fine particles with a size less than 32 [mu]m. The provided preparation method improves the grinding efficiency of grinding machine, reduces the wear degree of grinding machine, thus reduces the maintenance cost and production cost, and has a high performance / cost ratio. Moreover, the production technology and equipment are simple and practical.

Owner:DONGYUAN HONGCHAO TECH

Blast furnace slag liquid grinding aid and preparation method thereof

InactiveCN101597655AEasy to measure and addImprove grinding efficiencyRecycling and recovery technologiesSlagCement grinding

The invention discloses a blast furnace slag liquid grinding aid, which comprises the following components by mass percentage: 10%-20% of diglycol, 10%-15% of cane sugar slag waste liquid, 10%-20% of sorbitol, 10%-20% of glycerin, 1-5% of sodium tripolyphosophate, 1-10% of sodium carbonate, and the remainder being water. The grinding aid prepared by the invention has the advantages of remarkably improving slag grinding output, enhancing slag micro powder strength, easily purchasing raw materials with low cost and the like. The further optimized scheme for the invention is as follows: 1-5% of glycol and 1-5% of sodium dodecyl benzene sulfonate by mass percentage are added into the grinding aid, which can further enhance the effect of slag grinding efficiency. At the same time, the invention also discloses a preparation method of the liquid cement grinding aid.

Owner:NANJING YONGNENG MATERIALS

Preparation of low aldehyde long-acting urea-formaldehyde slow release fertilizer

ActiveCN101353270AImprove activity indexReduced release rateUrea compound fertilisersRoom temperatureWater soluble

The invention discloses a preparation method of a low aldehyde long-acting slow-release urea formaldehyde fertilizer. The method comprises the following steps: urea aqueous solution and formaldehyde aqueous solution are prepared, then added with an active assistant, after the solution is stable, the PH value of the solution is regulated to 0.9-4.5, after polymerization is finished, the PH value of the solution is regulated to 6.5-7.5, then the solution is added with an aldehyde removing agent, and after the solution is cooled to the room temperature, the suspension is filtrated, the filtrate obtained is collected for recycling, and the low aldehyde long-acting slow-release urea formaldehyde fertilizer is obtained after a filter cake is dried, crushed and prilled. The method has simple process, effectively reduces the release rate of cold water soluble nutrients of the low urea formaldehyde slow-release fertilizer particles by the active assistant and the aldehyde removing agent, reduces the content of free formaldehyde, and increases the active index of the slow-release urea formaldehyde fertilizer, and provides the slow-release urea formaldehyde fertilizer with low formaldehyde content, high activity index and long fertilizer effect for crop growing.

Owner:CNOOC FUDAO

Liquid composite grinding aid for granulated blast-furnace slag and preparation method thereof

InactiveCN102923982ASieve reductionLarge specific surface areaSolid waste managementCement productionSodium acetateSlag

The invention relates to liquid composite grinding aid for granulated blast-furnace slag and a preparation method thereof. The grinding aid is prepared by triethanolamine 1-30 parts, mixed alcohol 15-20 parts, glycerin 5-10 parts, molasses 5-10 parts, sodium acetate 1-10 parts, sodium tripolyphosphate 1-10 parts, sodium sulfate 1-10 parts and water 40-50 parts. The liquid composite grinding aid is low in toxicity, non-volatile, stable in source, sufficient in supply, simple in processing and preparation and low in cost. Can improve distribution and morphology of powder particles after doped into the granulated blast-furnace slag, has no adverse effects on mineral powder quality, has the good advantages of improving the yield and the mineral powder quality, and simultaneously reduces energy consumption greatly. The liquid composite grinding aid is stable in performance, low in price and high in cost performance, wide in adaptability and low in admixture amount, improves the grinding effect, increases specific surface area of the mineral powder and improves activity index of the mineral powder under the condition of same grinding time.

Owner:SHENYANG JIANZHU UNIVERSITY

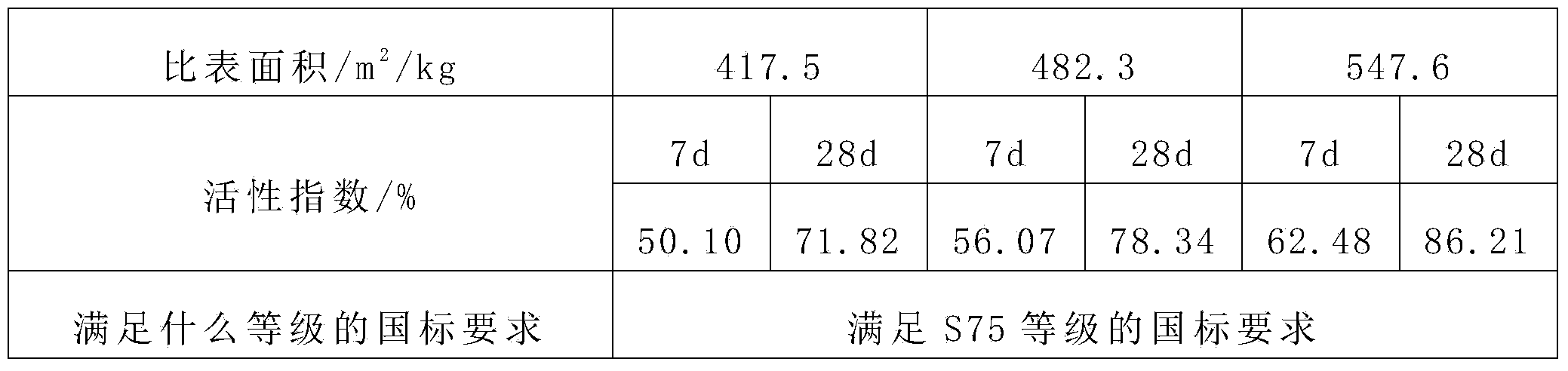

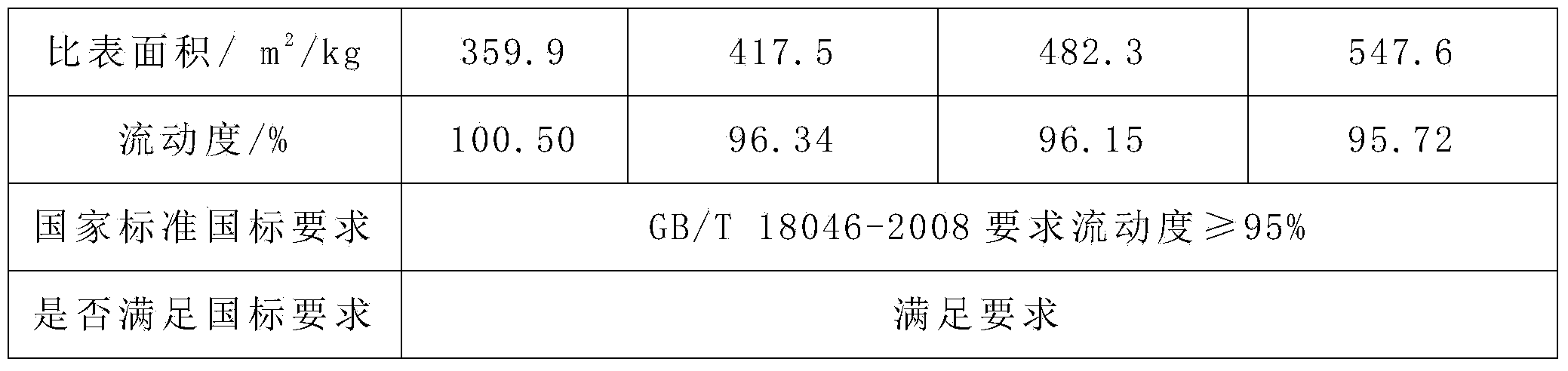

Nickel iron slag micropowder and preparation method thereof

InactiveCN103771739AUniform surface area distributionImprove activity indexSolid waste managementSocial benefitsEcological environment

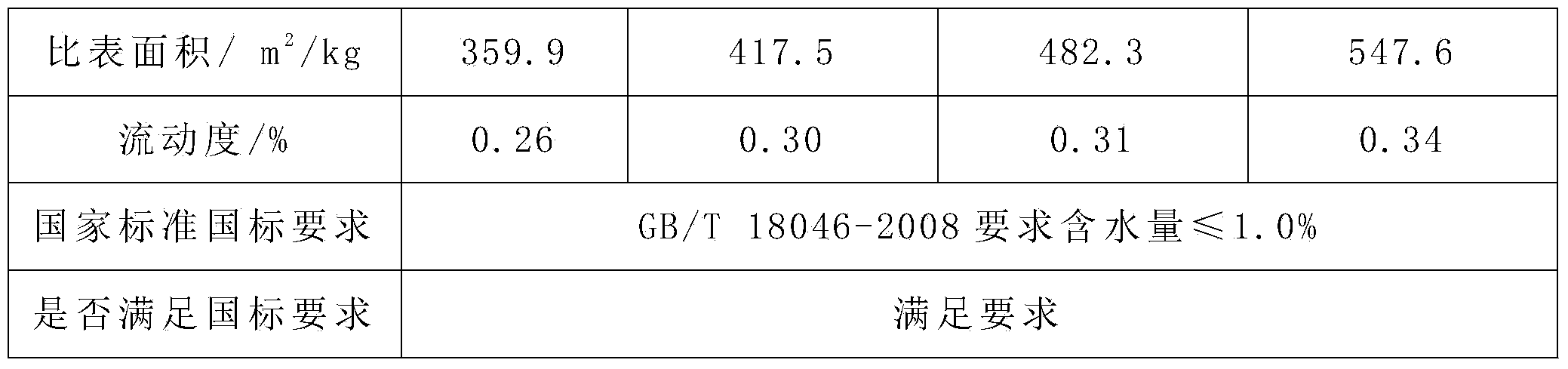

The invention relates to nickel iron slag micropowder and a preparation method thereof. The method comprises the following steps: performing magnetic separation on nickel iron slag taken as a raw material and grinding the nickel iron slag so as to obtain the nickel iron slag micropowder with the specific surface area being 359.9m<2> / kg to 550m<2> / kg. The specific surface area of the nickel iron slag micropowder is uniformly in distribution; the nickel iron slag micropowder with the certain specific surface area has a good activity index, thereby conforming to the international S75-level standard. In addition, the water content, the ignition loss and the like of the nickel iron slag micropowder all conform to rules in 'Granulated Blast Furnace Slag Powder Used in Cement and Concrete' of GB / T18046-2008. The prepared nickel iron slag micropowder can be taken as a blending stock of the cement and the concrete. Meanwhile, after the nickel iron slag micropowder is prepared from the nickel iron slag, the purposes of recycling wastes and turning wastes into wealth are realized. Thus, pollutions to atmosphere, soil and water, which are caused by the nickel iron slag, are lightened, namely, the ecological environment is optimized; the high added-value is obtained while the cost is low. As a result, the significant economic and social benefits are achieved.

Owner:SHANDONG WEIYE NEW BUILDING MATERIAL

Grinding additive for powder-grinding steel slag in vertical mill

The invention discloses a grinding additive for powder-grinding steel slag in a vertical mill. The grinding additive is prepared from the following raw materials in percentage by weight: 1-5 percent of polyacrylic acid, 5-10 percent of molasses, 1-5 percent of sodium hexametaphosphate, 2-6 percent of tetraethylammonium oxalic acid, 3-10 percent of triethanolamine, 5-20 percent of aluminum sulfate and 46-81 percent of carriers. All components of the grinding additive are cooperated with each other, so that the grinding efficiency of the steel slag in the vertical mill is improved, the active indexes are improved, and the adverse effect on cement and concrete performance is avoided. Compared with the prior art, the grinding additive for grinding steel slag in the vertical mill has the advantages that a material layer can be stabilized, the yield of the mill is increased, and the active indexes of the high steel slag powder 7d and 28d can also be increased.

Owner:SHANDONG HONGYI TECH

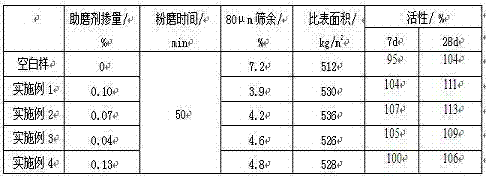

Active excitatory grinding aid for ferronickel slag and preparation method for active excitatory grinding aid

ActiveCN105084793ASolve the problem of poor wearabilityResolve low activitySolid waste managementPolyolMetallurgy

The invention discloses an active excitatory grinding aid for ferronickel slag and a preparation method for the active excitatory grinding aid. The grinding aid is composed of polymeric glycol, cocoanut fatty acid diethanolamide, sodium pyrophosphate, ethyl acetate, an excitant and water, wherein the excitant is composed of calcined alunite, water glass and sodium abietate. The additive amount of the grinding aid in the ferronickel slag is 0.02-0.10% by mass of the ferronickel slag. The active excitatory grinding aid disclosed by the invention is sufficient in raw materials, simple to process and prepare, low in doping amount, stable in performance and high in cost performance. As the ferronickel slag which is ground is added, the problem that the ferronickel slag is poor in grindability can be solved. Under the condition that the grinding time is equal, the specific surface area of the ferronickel slag micropowder can be improved by 4.5-9%, the mill output is increased by over 15%, the energy consumption is remarkably reduced, and moreover, the active index of the ferronickel slag can be further improved by 10-35%.

Owner:UNIV OF JINAN +1

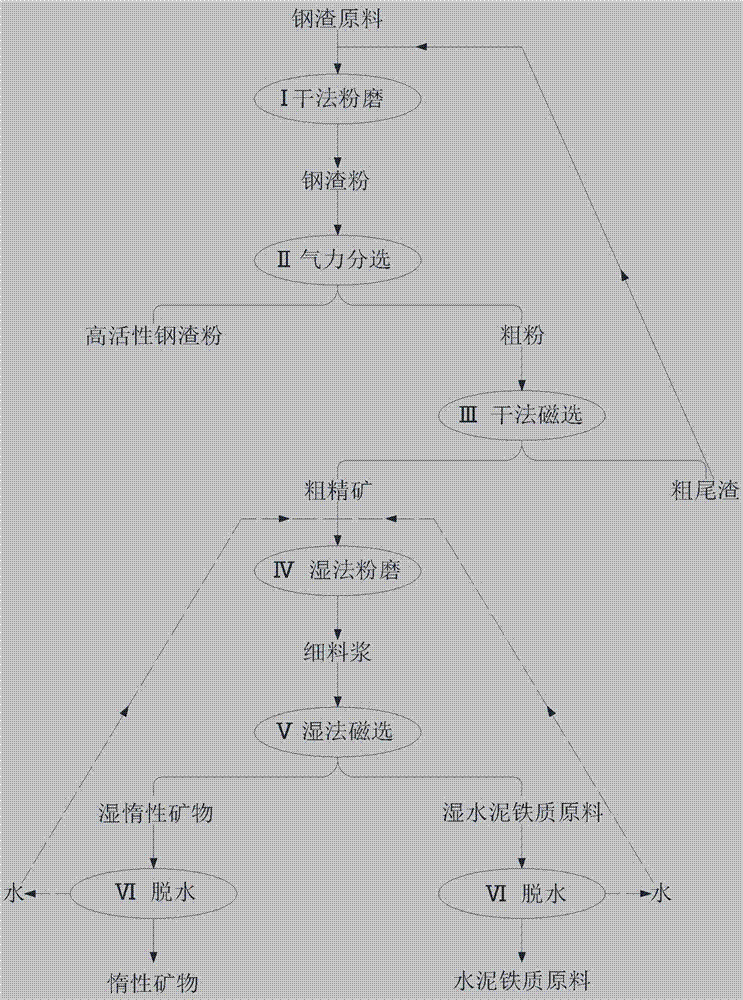

Technology of producing high-activity steel slag powder and inert mineral product by using steel slag

ActiveCN106755650AIncrease added valueGood adhesionCement productionRecycling and recovery technologiesResource utilizationSlag

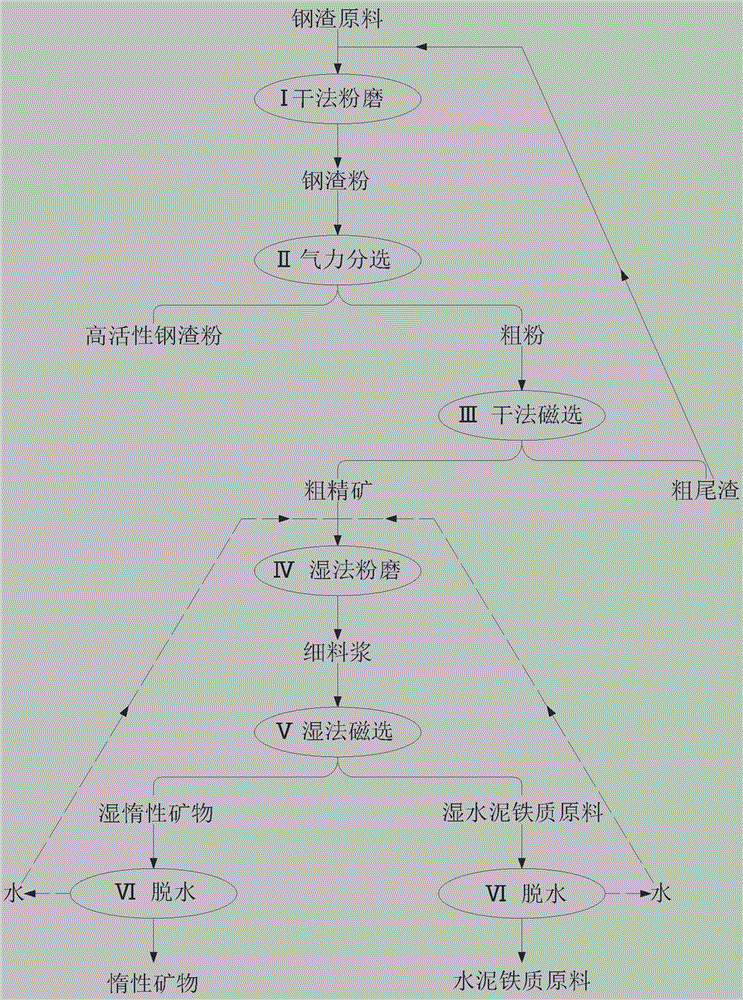

The invention discloses a technology of producing high-activity steel slag powder and an inert mineral product by using steel slag. The technology comprises the six steps of dry process grinding, pneumatic separation, dry process magnetic separation, wet process grinding, wet process magnetic separation and dehydration. In the step of the dry process grinding, tailings after slag iron are recovered are ground into steel slag powder, and inert mineral dissociation is realized; in the step of the pneumatic separation, the steel slag powder is subjected to size grading by using a superfine powder concentrator, so that the enrichment of inert minerals in coarse powder is realized, and fine powder is a high-activity steel slag powder product; in the step of the dry process magnetic separation, the coarse powder is purified to be coarse concentrate by employing the magnetism of the inert minerals, and coarse tailings return back to the dry process grinding step; the coarse concentrate is made into fine pulp through the wet process grinding; the fine pulp is separated into a humid inert mineral raw material and a humid cement iron raw material through the wet process magnetic separation; and after the humid inert mineral raw material and the humid cement iron raw material are dehydrated separately, the inert mineral product and a cement iron raw material are obtained, and water returns to the wet process grinding step. According to the technology, the steel slag is processed into the high-activity steel slag powder, the high-iron-grade inert mineral product and the cement iron raw material, so that the full resource utilization of the steel slag is realized.

Owner:西安鼎岩钢渣应用科技有限公司

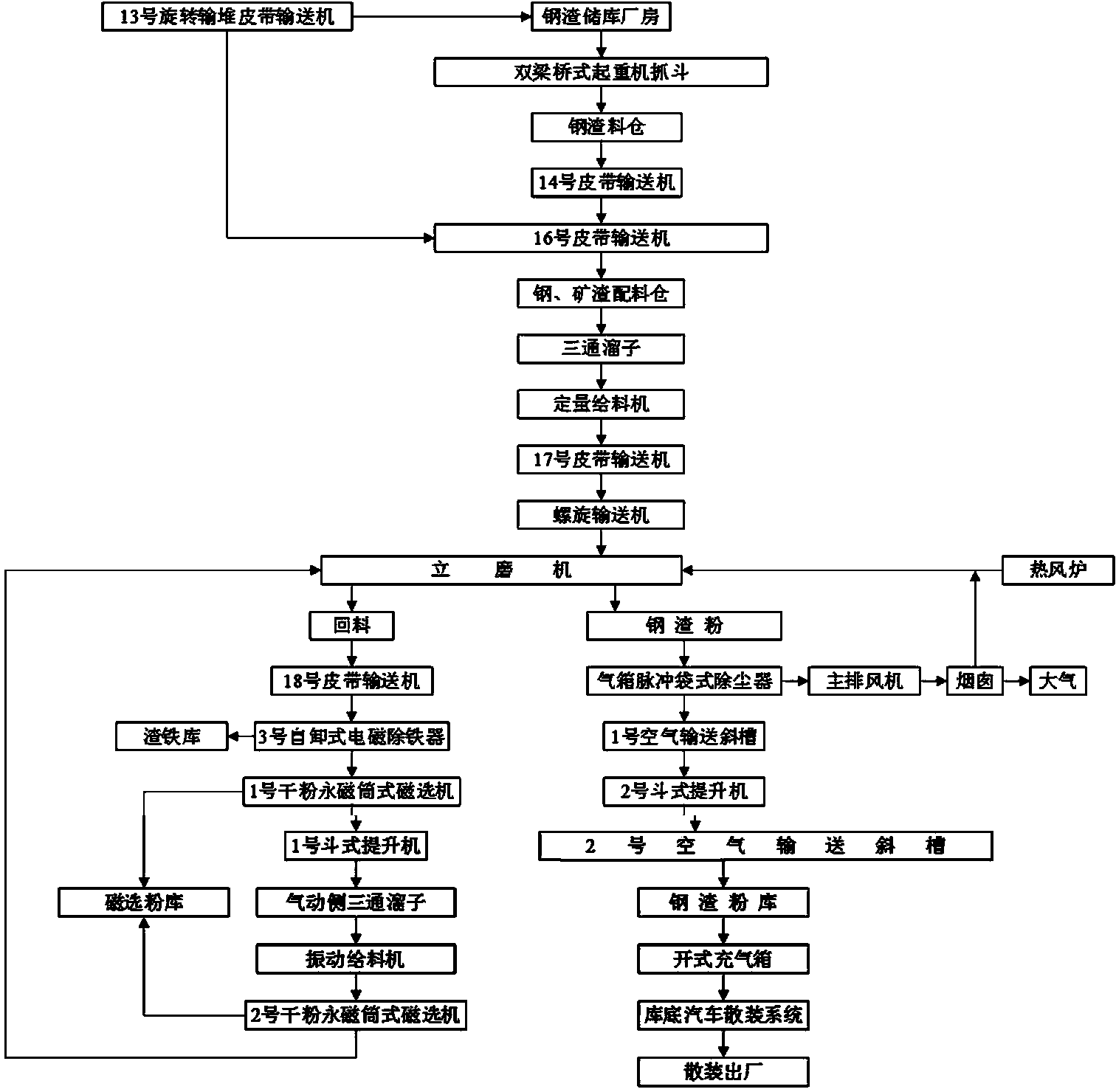

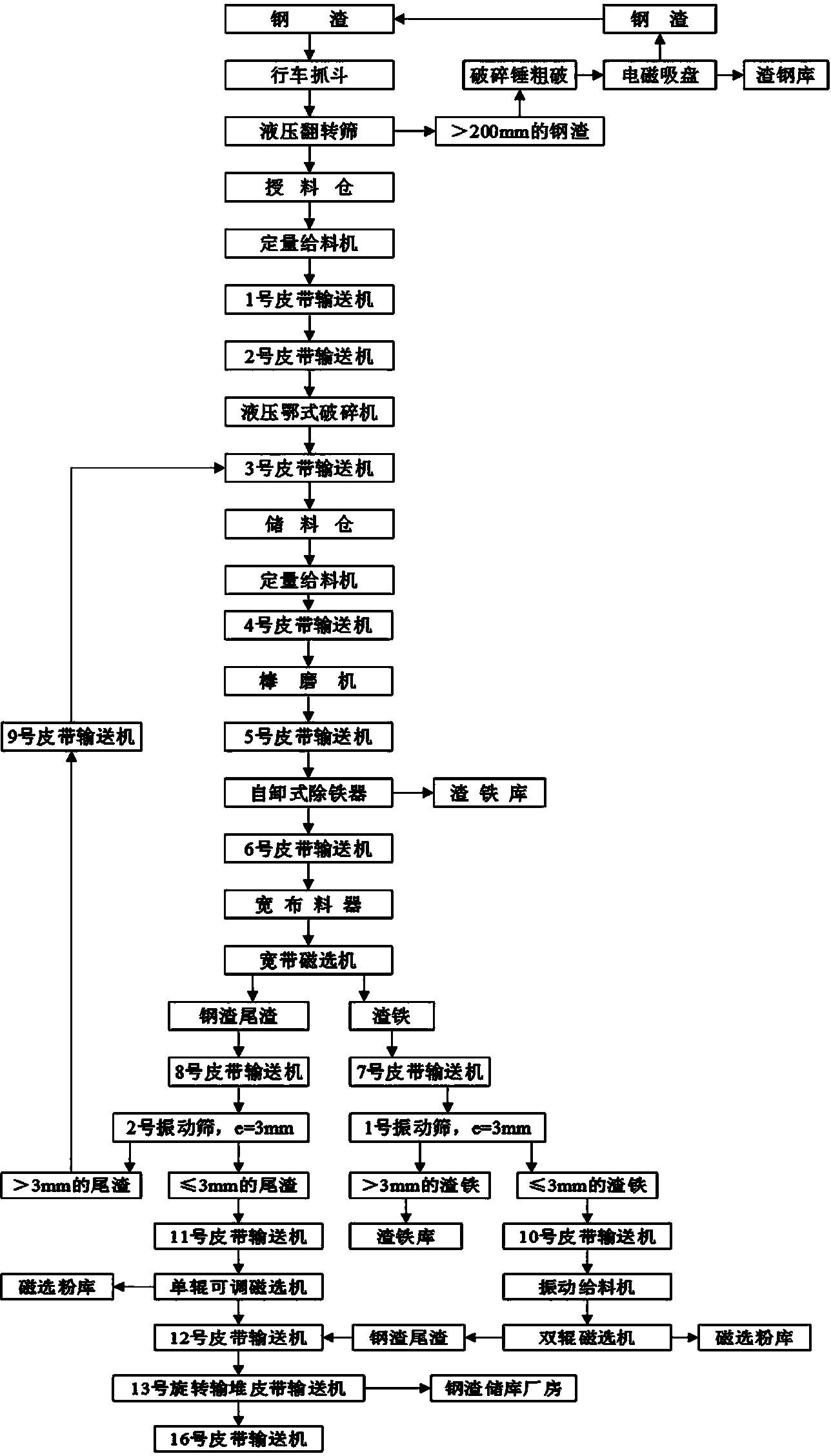

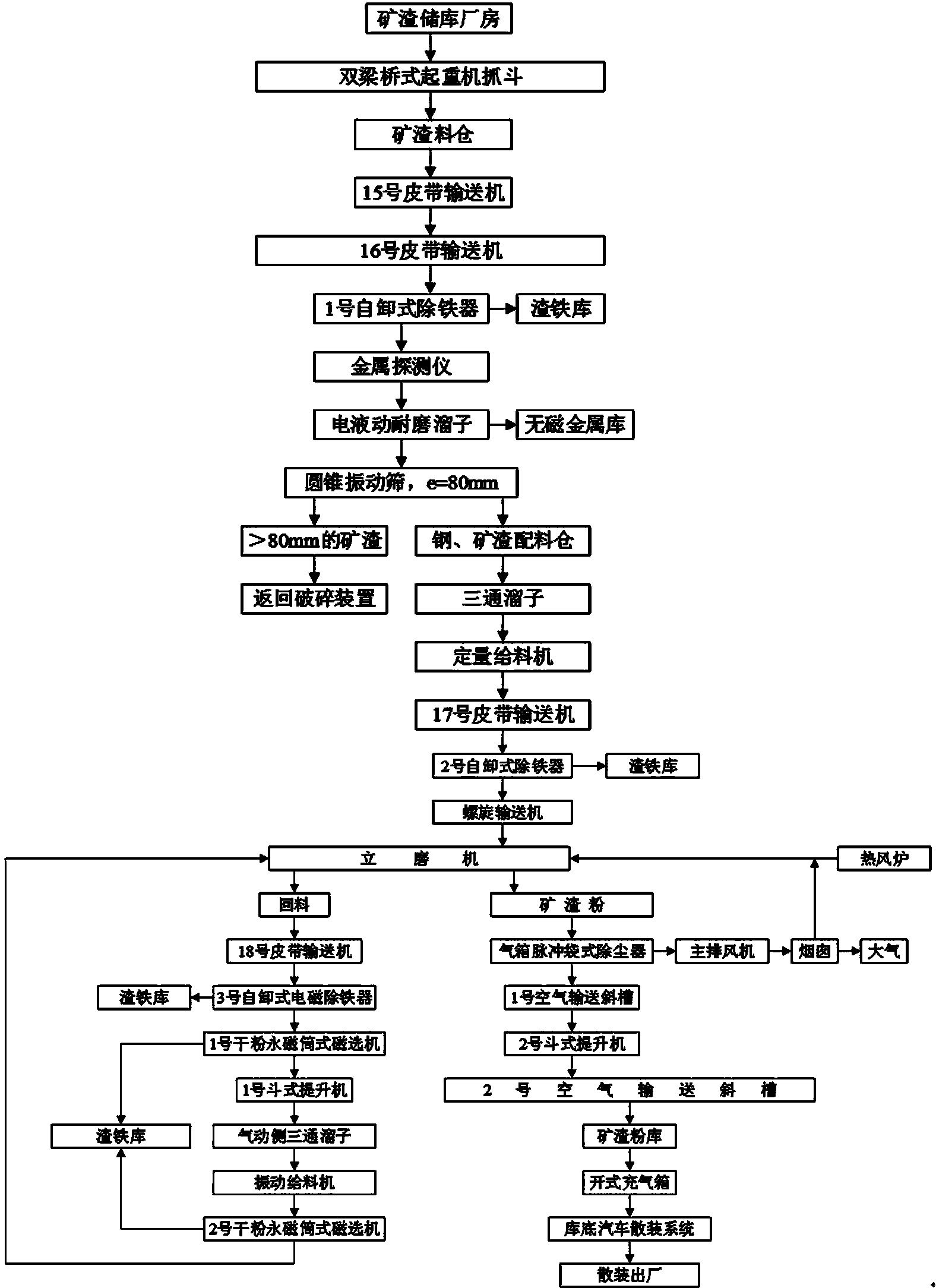

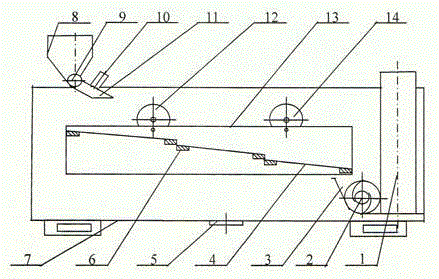

A method of grinding steel slag powder and mine slag powder and producing steel and iron slag powder by a vertical grinding mill

ActiveCN104307614AProduction successfully realizedIncrease profitRecycling and recovery technologiesGrain treatmentsIron powderSlag

A method of grinding steel slag powder and mine slag powder and producing steel and iron slag powder by a vertical grinding mill is disclosed. The method is characterized in that: the same vertical grinding mill is adopted to separately grind the steel slag powder and the mine slag powder; the grinding of the steel slag powder by the vertical grinding mill includes steps of grinding the steel slag powder by the vertical grinding mill and performing material-returning closed-loop circulation of the steel slag powder by the vertical grinding mill; the grinding of the mine slag powder by the vertical grinding mill includes steps of pretreating mine slag to remove metals, grinding the mine slag powder by the vertical grinding mill and performing material-returning closed-loop circulation of the mine slag powder by the vertical grinding mill; and the steel slag powder and the mine slag powder which are prepared by the vertical grinding mill and are qualified are respectively weighted by a corresponding seal constant weight feeder, fed into a rolling type material mixer and fully mixed, thus achieving a process of producing the steel and iron slag powder. The yield of the steel slag powder reaches 45 t / h. The yield of the mine slag powder reaches 60 t / h. The specific surface area of the steel slag powder is larger than 460 m<2> / kg, and the specific surface area of the mine slag powder is larger than 430 m<2> / kg, thus meeting the national standards. The single-machine product power consumption of the steel slag powder is 30 kwh per ton, and the single-machine product power consumption of the mine slag powder is 28 kwh per ton.

Owner:JIANGSU RONGDA NEW MATERIAL

Modified slag compound admixture and preparation method thereof

InactiveCN103288333AOvercome the disadvantage of low early strengthImprove activity indexSteelmakingActivity index

The invention belongs to the technical fields of resource utilization of solid wastes, environmental protection and energy conservation, and discloses a modified slag compound admixture and a preparation method thereof. The slag compound admixture disclosed by the invention is prepared from the following components in percentage by mass: 60-80% of slag powder, 15-30% of steelmaking slag powder, and 5-10% of white slag. The preparation method disclosed by the invention comprises the step of 60-80% of stirring slag powder, 15-30% of steelmaking slag powder and 5-10% of white slag for 3-5 min. The modified slag compound admixture disclosed by the invention has the most outstanding advantages that the disadvantage of being low in early strength of the compound admixture caused by doping a lot of steelmaking slag is overcome; furthermore, both the activity indexes for 7 days and 28 days are higher than the requirements of GB / T 18046-2008 on S95-level mineral powder; particularly, the activity index for 28 days is greatly increased; the long-period strength still can be increased continuously.

Owner:TONGJI UNIV

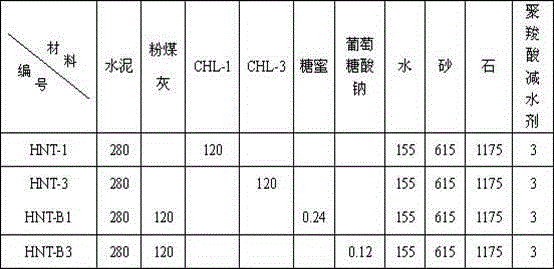

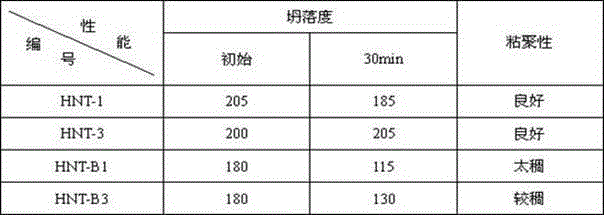

Fly ash composite admixture for concrete and preparation method of admixture

ActiveCN103435287ASolve storage problemsSolve problems such as land occupationSolid waste managementSlagBall mill

The invention relates to a fly ash composite admixture for concrete, and a preparation method of the admixture, and belongs to a building material for building, and a preparation method of the building material. The fly ash composite admixture and the preparation method mainly solve the technical problems that the existing mineral admixture is too large in slump, larger in chemical shrinkage and self-shrinkage, and high in use cost. The fly ash composite admixture for the concrete adopts the technical scheme that the fly ash composite admixture is prepared by taking 20-30wt% of slag, 4-15wt% of stone chips, 58-73wt% of fly ash and 1-4wt% of desulphurization gypsum as raw materials. The preparation method comprises the following steps that the fly ash is smashed into ultrafine fly ash by ultrafine smashing equipment; the slag, the stone chips and the desulphurization gypsum are mixed uniformly and ball-milled into powder; the ultrafine fly ash and the ball-milled powder are mixed and homogenized; and the fly ash composite admixture for the concrete is prepared.

Owner:SHUOZHOU JUGUANG BUILDING MATERIAL DEV CO LTD +1

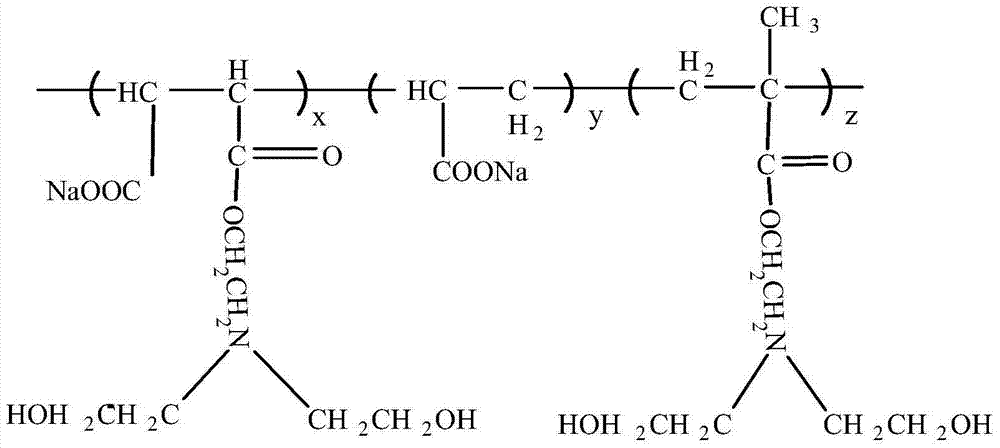

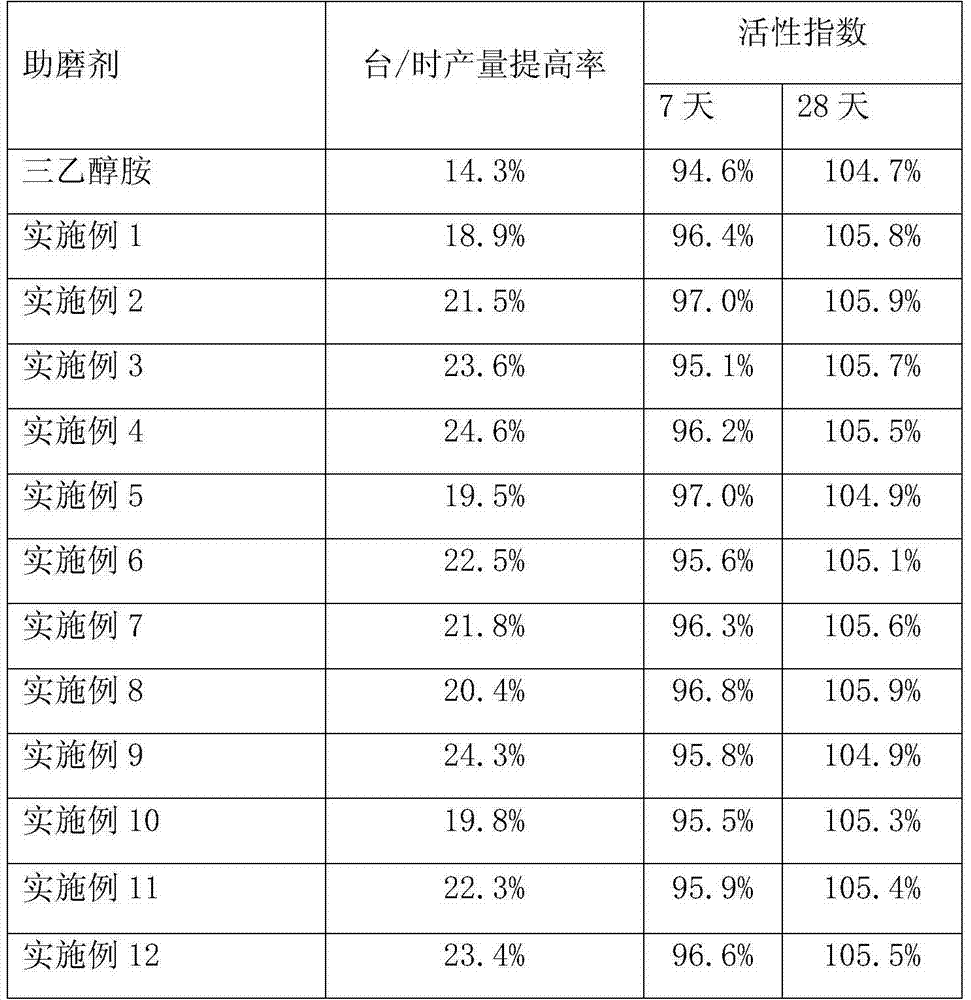

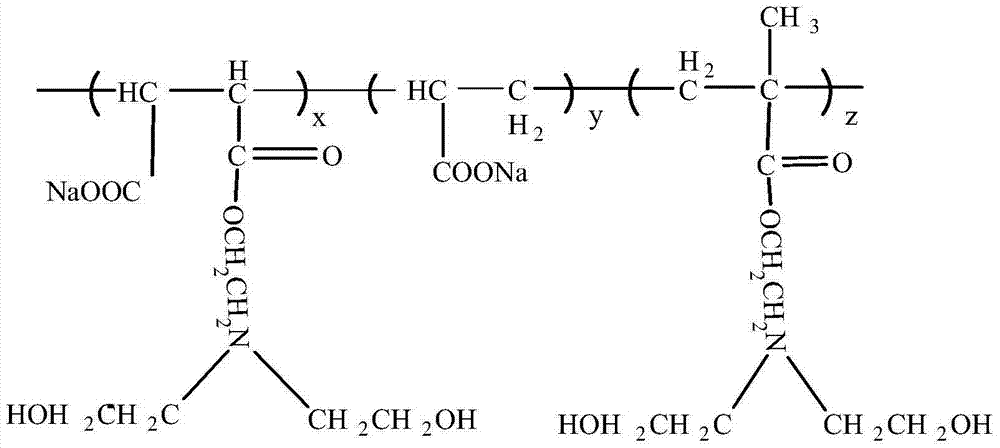

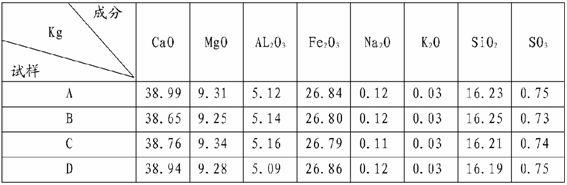

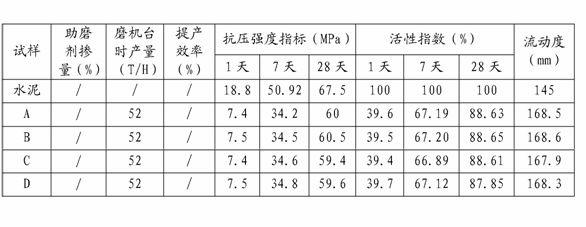

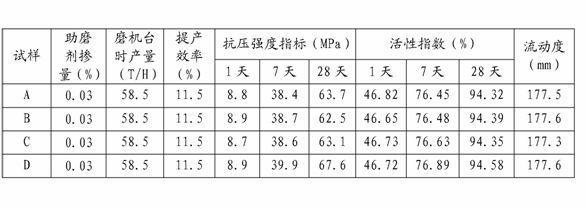

High-molecular slag grinding aid, and preparation method and application thereof

The invention discloses a high-molecular slag grinding aid with the general formula shown in the specification. In the general formula, x is a value of 5-8000, and x:y:z is equal to 1:0.1-1:0.1-0.6. The invention aims at providing the high-molecular slag grinding aid capable of effectively shortening slag grinding time and improving slag hydration activity.

Owner:GUANGZHOU AUSPICIOUS CHEM

Slag grinding aid

InactiveCN102618011AEliminate static electricityImprove grinding efficiencyOther chemical processesPolyolSlag

The invention discloses a slag grinding aid, which comprises the following components in percentage by weight: 40-60 percent of polymeric polylol, 5-15 percent of molasses, 2-8 percent of calcium lignosulphonate, 4-6 percent of glycerol and the balance of water. Due to the adoption of the slag grinding aid, the grinding efficiency of slag and the machine-hour yield of a grinder are increased, and the effect of improving mineral powder activity index can be enhanced. The slag containing a large quantity of vitreous bodies is ground separately, and the slag grinding aid is doped, so that the grinding efficiency can be increased by 10-15 percent, the energy consumption is lowered by 10-15percent, the 7-day activity index of slag fine powder obtained by grinding is increased by 4-6 percent, and the 28-day activity index is increased by 2-4 percent; and after slag mineral powder is added into cement, the cement mortar flowing degree is increased by 5-10 percent.

Owner:柳州宝能建材科技有限公司

Granulated blast furnace slag liquid composite grinding aid

The invention relates to a granulated blast furnace slag liquid composite grinding aid and belongs to the technical field of granulated blast furnace slag grinding process admixtures. The granulated blast furnace slag liquid composite grinding aid is prepared from triethanolamine, mixed alcohol, propanetriol, molasses, potassium carbonate, sodium pyrophosphate, sodium sulfate and water; and the granulated blast furnace slag liquid composite grinding aid is formed by composition of the most common chemical raw materials and industrial wastes, and has the advantages of low toxicity, no volatilization, stable sources, sufficient sources and low cost. After the granulated blast furnace slag liquid composite grinding aid provided by the invention is added into a grinding machine, the distribution and appearance of slag powder particles can be improved, the adverse effects on quality of slag powder are avoided, the effects of saving power consumption and improving grinding efficiency can be realized, and the granulated blast furnace slag liquid composite grinding aid has the advantages of better increasing the yield and improving the quality of the slag powder. Under the situation of same grinding time, the specific surface area of the slag powder is effectively improved, the screening residues are reduced, and the activity indexes of the slag powder in the early stage (7d) and the late stage (28d) are significantly improved.

Owner:SHENYANG JIANZHU UNIVERSITY

Mineral waste residue liquid composite grinding aid and preparation method thereof

The invention relates to a mineral waste residue liquid composite grinding aid and a preparation method thereof. The mineral waste residue liquid composite grinding aid is prepared from the following raw materials: 15-20 parts by weight of mixed alcohol, 5-10 parts by weight of ethyl acetate, 5-10 parts by weight of molasses, 1-10 parts by weight of lauryl sodium sulfate, 1-10 parts by weight of sodium hexametaphosphate and 800-100 parts by weight of water. The mineral waste residue liquid composite grinding aid has low toxicity, does not volatile and is stable in sources, sufficient in supplies, simple to process and prepare and low in cost; after granulated blast-furnace slag is doped in the mineral waste residue liquid composite grinding aid, the distribution and the morphology of separate particles can be improved, and the quality of mineral waste residue micro powder is not affected; the mineral waste residue liquid composite grinding aid has the advantages of increasing the yield and improving the quality of the mineral waste residue micro powder and meanwhile greatly reduces the energy consumption. The mineral waste residue liquid composite grinding aid has stable property, high cost performance and wide adaptability, is low in cost and mixing amount and can be used for improving the grinding effect and increasing the yield of a grinder by above 15%, the specific surface area of the mineral waste residue micro powder by 4.7%-6.2% under the condition of the same grinding time and the activity index of the mineral waste residue micro powder.

Owner:辽宁天宝华瑞建材有限公司

Modified coal ash used in cement and concrete and preparation method of modified coal ash

InactiveCN102951862AImprove activity indexReduce grinding energy consumptionSolid waste managementPolymer scienceCoal

The invention discloses modified coal ash used in cement and concrete and a preparation method of the modified coal ash. The modified coal ash comprises the following raw materials: 95-99wt% of F-class coal ash or C-class coal ash and 1-5wt% of sintering dry-process desulfurized fly ash. The modified coal ash has the characteristics of fineness being not more than 25.0 percent, water demand ratio being not more than 105 percent, ignition loss being not more than 8.0 percent, water content being not more than 1.0 percent, sulfur trioxide content being not more than 3.0 percent, free calcium oxide content being not more than 4.0 percent, qualified stability and strength activity index being not less than 78 percent. Compared with the common coal ash, the modified coal ash disclosed by the invention has the advantages that the 28-day activity index is greatly increased, the fineness requirement can be properly reduced, and the grinding energy consumption can be effectively reduced.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS

Slag compound activating grinding aid and preparation method thereof

The invention relates to the technical field of production and processing of cement, and provides a slag compound activating grinding aid and a preparation method thereof. The slag compound activating grinding aid comprises the following components in percentage by weight: 5-10 percent of water glass, 5-10 percent of sodium carbonate, 3-8 percent of sodium abietate, 12-20 percent of betaine mother liquor, 7-12 percent of non-ionic surface active agent, 2-10 percent of molasses, 5-10 percent of water-soluble polymer and the balance of water. The preparation method comprises the steps of: sequentially adding water glass, sodium carbonate, the betaine mother liquor and the non-ionic surface active agent in water with a temperature of 40-65 DEG C according to the weight ratio, uniformly stirring; then adding sodium abietate, molasses and the water-soluble polymer, and uniformly stirring to obtain the liquid slag compound activating grinding aid product. According to the slag compound activating grinding aid, the production cost is lowered, and the damage to the environment is reduced; the slag compound activating grinding aid is stable in application property, and remarkable in effects of enhancing and improving activation grinding assistance of slag and physical properties of the cement.

Owner:阳江市大地环保建材有限公司

Construction waste activating method

The invention provides a construction waste activating method which comprises the following steps: performing primary calcination on construction wastes at a temperature of 600-800 DEG C for 3-5 hoursso as to obtain a first calcined material; mixing the first calcined material and gypsum powder, lime powder and slag powder, and performing secondary calcination on the obtained mixed material at atemperature of 850-950 DEG C for 2-5 hours so as to obtain a second calcined material; and performing chemical excitation on the second calcined material in an alkaline environment, thereby obtainingthe activated construction powder. According to the activating method provided by the invention, the obtained activated construction powder has characteristics of binding materials, so that the construction powder can serve as a binding material to be applied to non-sintered building materials, and reutilization of the construction wastes is realized. Experimental results in the embodiment show that the activated construction powder has high activity index, the activity index within 3 days is 83.9, and the activity index within 28 days is 92.9.

Owner:SHENZHEN HUAWEI ENVIRONMENTAL PROTECTION BUILDINGMATERIAL

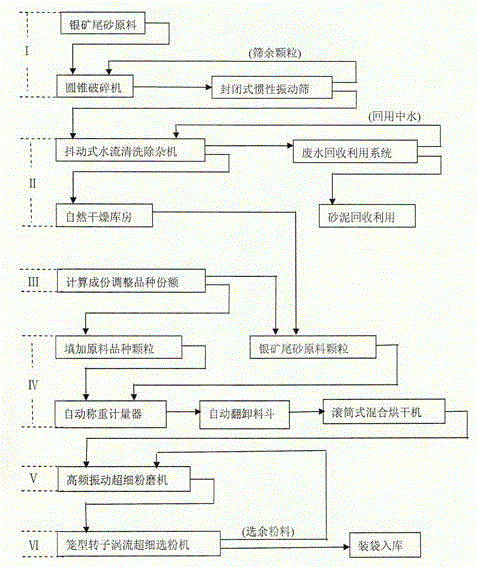

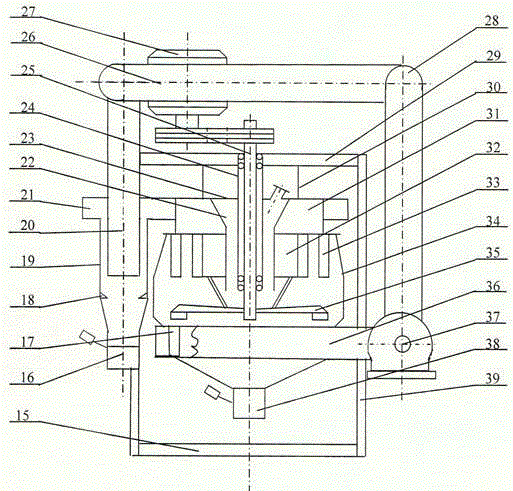

Silver mine tailings ultra-fine activated fine powder and preparation technology thereof

InactiveCN106031895ASmall particle sizeLarge specific surface areaGrain treatmentsHigh strength concreteResource utilization

The invention discloses silver mine tailings ultra-fine activated fine powder and a preparation technology thereof. According to the present invention, the technical route comprising crushing screening, washing and impurity removing, component adjusting, mixing drying, ultra-fine grinding, vortex powder separation and other operation units is set, the special and originally-designed technical equipment such as a vibrating type water flow washing impurity removing machine and a cage type rotor vortex ultra-fine powder separator is used, and silver mine tailings are adopted as a raw material to produce the silver mine tailings ultra-fine activated fine powder, wherein the outstanding characteristics of complete system, advanced and mature technology, high production efficiency, good operation quality and the like are provided; the produced silver mine tailings ultra-fine activated fine powder can be used for the large-scale replacement of the cement clinker to produce the high-performance cement products, can further be used as the fine material so as to be directly used for mixing the high-strength concrete, and can further be used as the high-quality building decoration product main raw material; and the multiple benefits such as solid waste resource utilization, environmental pollution control, energy source consumption reducing, material variety increasing, and the like can be achieved.

Owner:四平市昊平建材科技有限公司

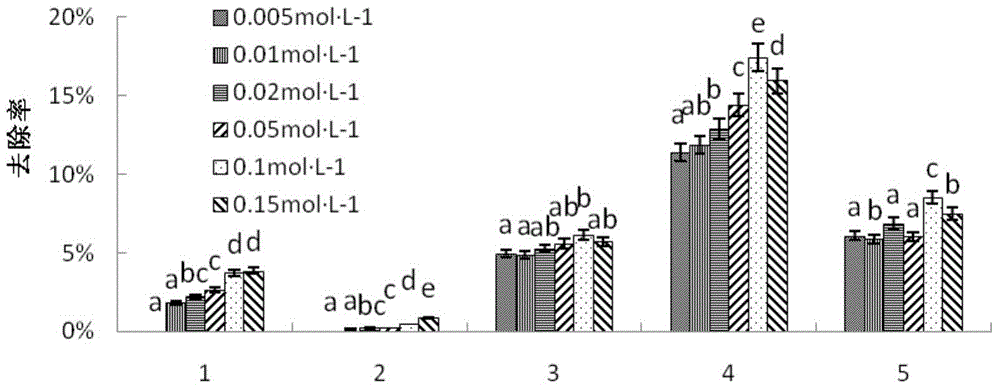

Oxidation-chelation leaching combined remediation method for Cr-contaminated soil

ActiveCN105149334APromote conversionHigh removal rateContaminated soil reclamationMicrowaveAqueous solution

The invention relates to an oxidation-chelation leaching combined remediation method for Cr-contaminated soil. The remediation method comprises the following steps: performing microwave treatment on a H2O2 oxidizing process: uniformly mixing a H2O2 aqueous solution with Cr-contaminated soil for microwave treatment; adding H2O for leaching, and removing leaching liquid; performing chelation leaching, that is, adding a chelating agent for chelation leaching, and removing Cr (VI) and part of Cr (III). Through adoption of the remediation method, Cr in soil can be effectively removed; the remediation method is suitable for Cr-contaminated soil remediation, is relatively high in oxidation efficiency, is a microwave oxidation method without affecting subsequent chelation leaching, and can realize relatively high remediation efficiency through leaching with water or the chelating agent.

Owner:SHANDONG NORMAL UNIV

Blast-furnace slag powder and blast-furnace slag and coal cinder compound powder excitant

A trigger for stimulating the early-phase activity of the blast furnace slag powder or the mixture of blast furnace slag powder and cinder powder is proportionally prepared from triethanolamine and early strengthening agent (calcined gypsum or bihydrated gypsum or potassium chromium sulfate).

Owner:SOUTH CHINA UNIV OF TECH

Steel slag grinding aid and preparation method thereof

The invention discloses a steel slag grinding aid. The grinding aid comprises the following raw material component in parts by weight: 8-12 parts of acrylamide, 8-12 parts of benzamide, 15-20 parts of alkanolamine, 5-10 parts of ethylene diamine phosphate, 10-15 parts of calcium lignin sulfonate, 8-12 parts of sodium lignin sulfonate, 0.1-0.5 part of tributyl phosphate and 20-80 parts of water. The preparation method comprises the steps of adding acrylamide, benzamide, alkanolamines in water in a certain ratio, dissolving, then sequentially adding ethylenediamine phosphate, calcium lignin sulfonate and sodium lignin sulfonate, mixing and finally adding tributyl phosphate, stirring to obtain steel slag grinding aid. The process is simple and the activity index of steel slag can be regulated.

Owner:JIANGSU RONGDA NEW MATERIAL

Powdered ore additive

InactiveCN102965077ALow costIncrease productionOther chemical processesFood additiveGallic acid ester

The invention discloses a powdered ore additive. The powdered ore additive comprises the following components by weight: 5 to 20% of aqueous polymer, 10 to 40% of furfural residue, 0.5 to 1.5% of gallic acid, and 50 to 80% of coal ash. The aqueous polymer adopts vinyl acetate and maleic anhydride as the polymerizing monomers, water serves as the reaction medium, and the free radical polymerization is carried out, thus obtaining the powdered ore additive. The powdered ore additive is remarkable in grinding aid effect, about 20% of output of a grinding machine can be increased, the activity of the powdered ore can be effectively excited, and about 10% of 28-day activity index of the powdered ore can be increased.

Owner:SOUTHEAST UNIV

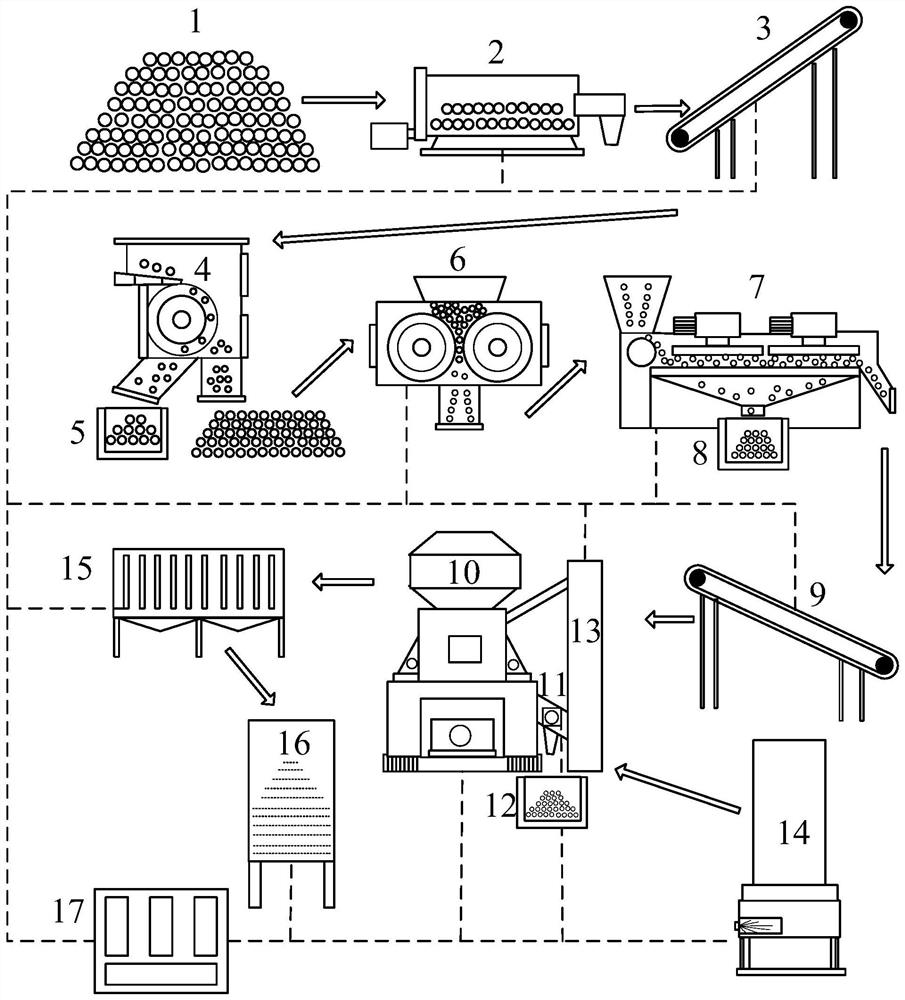

Steel slag multistage crushing and grinding ultrafine powder preparation device and method

PendingCN111747669APromote zero emissionsLow metallic iron contentSolid waste managementCement productionSlagIron removal

The invention relates to a steel slag multistage crushing and grinding ultrafine powder preparation device and method. The device comprises: a steel slag tailing bin (1), a rod grinding slag breaker (2), a first belt line (3), an electromagnetic roller iron remover (4), a first magnetic separation powder bin (5), a double-roller slag breaker (6), a disc magnetic separator (7), a second magnetic separation powder bin (8), a second belt line (9), a vertical slag grinder (10), a powerful magnetic separator (11), a third magnetic separation powder bin (12), a bucket elevator (13), a hot blast stove (14), a dust collector (15) and a finished product warehouse (16). With the multistage crushing and magnetic separation treatment process, the granularity of the steel slag tailings and the contentof iron elements such as metallic iron in the steel slag tailings are gradually reduced, the grinding power consumption of the steel slag is greatly reduced, and the activity index of the steel slag ultrafine powder is remarkably improved; meanwhile, the recycling of iron resources is efficiently realized, and the resource utilization value of the steel slag is systematically improved.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION +1

High-fluidity concrete additive and preparation method thereof

InactiveCN104591571AImprove liquidityReduce mixing water consumptionSolid waste managementActivity indexSURFACTANT BLEND

The invention relates to a high-fluidity concrete additive and a preparation method thereof. The high-fluidity concrete additive comprises a surfactant material and coal ash. The preparation method comprises the step of adequately mixing boiling coal ash with an atomized surfactant solution. According to the high-fluidity concrete additive, the fluidity and the gradual fluidity of concrete can be improved, the activity index of coal ash can be improved, and the adaptability of a water reducer can be improved; the high-fluidity concrete additive is low in cost and easy to prepare and is particularly applicable to pump concrete or self-compacting concrete with relatively high requirement for fluidity.

Owner:TONGJI UNIV

Production technology for physical foaming cement insulation boards

The invention discloses a production technology for physical foaming cement insulation boards, and belongs to the field of building insulation materials. The technology comprises the steps that 1, general purpose portland cement, a composite aluminosilicate mineral admixture and a composite additive are metered and prestirred to obtain solid materials, and water is added for wet grinding to obtain non-bleeding unstratified slurry; 2, fiber is added into the slurry, and then high-speed stirring and dispersion are performed; then, foams with the diameter smaller than 0.3 mm are added to form foam bodies; 3, the foams obtained in the second step are molded by means of a mold, maintained and demolded and then cut into boards, high-molecular polymer waterproof lotion uniformly permeates microholes of the boards, and artificial drying or natural air-drying is performed to obtain the physical foaming cement insulation boards. According to the technology, high-pressure permeation equipment is adopted for enabling the high-molecular polymer waterproof lotion to rapidly and uniformly permeate the microholes of the boards, polymer inside the lotion will form films on the walls of the microholes after artificial drying or natural air-drying, passages of pores are blocked, the water absorption rate of the insulation boards can be effectively lowered, the toughness and strength of the boards can be improved, and board cracks are avoided.

Owner:郑州工大高新材料科技有限公司

Process for producing highly active steel slag powder and inert mineral products from steel slag

ActiveCN106755650BReduce contentImprove activity indexCement productionRecycling and recovery technologiesSlagResource utilization

The invention discloses a technology of producing high-activity steel slag powder and an inert mineral product by using steel slag. The technology comprises the six steps of dry process grinding, pneumatic separation, dry process magnetic separation, wet process grinding, wet process magnetic separation and dehydration. In the step of the dry process grinding, tailings after slag iron are recovered are ground into steel slag powder, and inert mineral dissociation is realized; in the step of the pneumatic separation, the steel slag powder is subjected to size grading by using a superfine powder concentrator, so that the enrichment of inert minerals in coarse powder is realized, and fine powder is a high-activity steel slag powder product; in the step of the dry process magnetic separation, the coarse powder is purified to be coarse concentrate by employing the magnetism of the inert minerals, and coarse tailings return back to the dry process grinding step; the coarse concentrate is made into fine pulp through the wet process grinding; the fine pulp is separated into a humid inert mineral raw material and a humid cement iron raw material through the wet process magnetic separation; and after the humid inert mineral raw material and the humid cement iron raw material are dehydrated separately, the inert mineral product and a cement iron raw material are obtained, and water returns to the wet process grinding step. According to the technology, the steel slag is processed into the high-activity steel slag powder, the high-iron-grade inert mineral product and the cement iron raw material, so that the full resource utilization of the steel slag is realized.

Owner:西安鼎岩钢渣应用科技有限公司

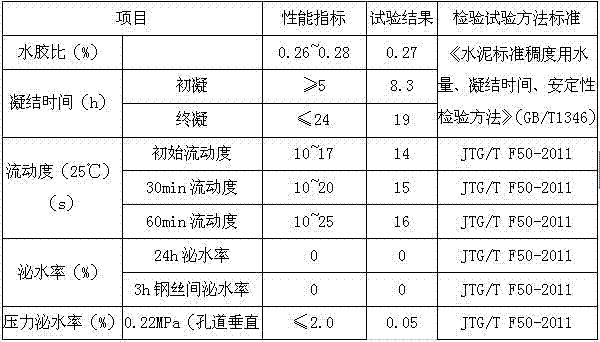

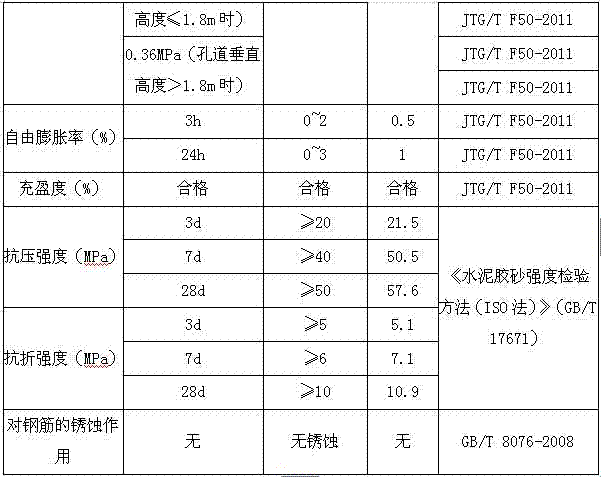

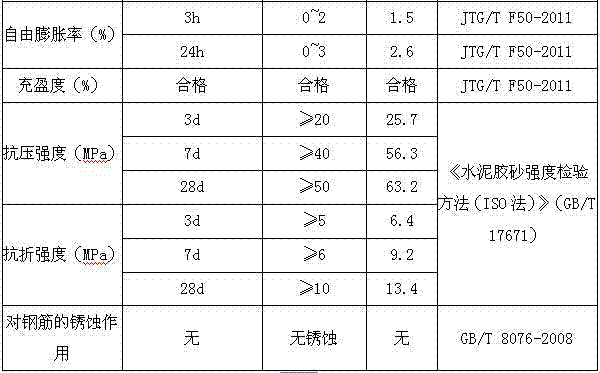

Novel prestressed duct mudjack material and preparation method of same

The invention relates to the field of building materials and discloses a novel prestressed duct mudjack material and a preparation method of same. The duct mudjack material includes 85-95 parts of ordinary Portland cement, 2-3.5 parts of industrial waste residues, 2.5-3.7 parts of a mineral admixture, 0.01-0.03 parts of a plastic expansion agent, 0.5-0.9 parts of Wacker powder, 0.5-1.5 parts of an expanding agent, 0.1-0.3 parts of a water reducing agent, 0.001-0.007 parts of an air entraining agent, and 0.001-0.003 parts of a defoamer. The duct mudjack material is free of layering and water bleeding, has good filling degree, is low in dry shrinkage, has stable volume and high strength, and achieves economic and environment-friendly utilization of the industrial waste residues.

Owner:GUIZHOU DR SHI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com