Slag grinding aid

A grinding aid and slag technology, applied in the field of admixtures, can solve the problems of high energy consumption and low slag grinding efficiency, and achieve the effects of improving the grinding efficiency, avoiding the phenomenon of powder encapsulation, and improving the grinding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

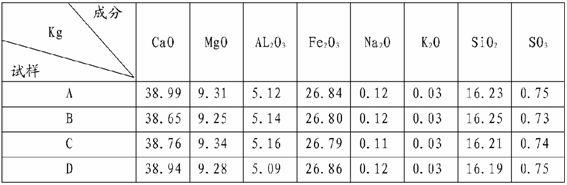

Examples

Embodiment 1

[0018] The slag grinding aid (1 ton) in the present embodiment includes the raw materials of following weight content: 500 kilograms of polyester polyols, 100 kilograms of molasses, 50 kilograms of calcium lignosulfonate, 50 kilograms of glycerol, and its configuration method is Weigh the calcium lignosulfonate according to the above weight and add it to the reaction kettle, add water and stir for 15 minutes to make the calcium lignosulfonate fully dissolve in the water, then add molasses into the reaction kettle according to the amount, control the temperature at 50°C, and keep the temperature constant Stir for 15 minutes, then add glycerol into the reaction kettle according to the amount, stir for 10 minutes, finally add polyester polyol into the reaction kettle according to the amount, stir for 15 minutes, and finally form a uniform mixed liquid, which is the method of the present invention. Liquid cement grinding aid.

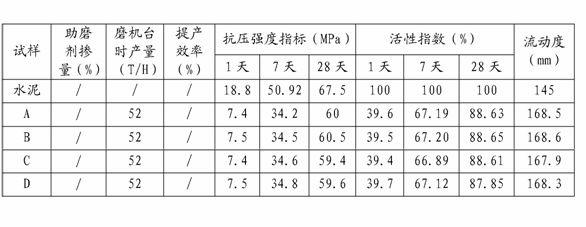

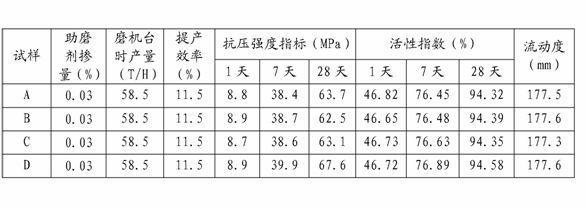

[0019] Under the same test conditions as in Table 2, ...

Embodiment 2

[0023] The slag grinding aid (1 ton) in the present embodiment includes the following raw materials by weight: 400 kilograms of dipropylene glycol, 120 kilograms of molasses, 60 kilograms of calcium lignosulfonate, and 40 kilograms of glycerol. The configuration method is Weigh the calcium lignosulfonate according to the above weight and add it to the reaction kettle, add water and stir for 15 minutes to make the calcium lignosulfonate fully dissolve in the water, then add molasses into the reaction kettle according to the amount, control the temperature at 50°C, and keep the temperature constant Stir for 15 minutes, then add glycerol into the reaction kettle according to the amount, stir for 10 minutes, finally add dipropylene glycol into the reaction kettle according to the amount, stir for 15 minutes, and finally form a uniform mixed liquid, which is the method of the present invention. Liquid cement grinding aid.

[0024] Under the same test conditions as in Table 2, each ...

Embodiment 3

[0028] The slag grinding aid (1 ton) in the present embodiment includes the following raw materials by weight: 400 kilograms of polyether polyols, 200 kilograms of tripropylene glycol, 50 kilograms of molasses, 40 kilograms of calcium lignosulfonate, glycerol 50 kilograms, its disposition method is to take calcium lignosulfonate by the above-mentioned weight and add in the reactor, add water and stir for 15 minutes, calcium lignosulfonate is fully dissolved in water, then adds molasses according to the amount in the reactor, will Control the temperature at 50°C, stir at constant temperature for 15 minutes, then add glycerol into the reaction kettle according to the amount, stir for 10 minutes, finally add polyether polyol and triglyceride into the reaction kettle according to the amount, stir for 15 minutes, and finally Forming a uniform mixed liquid is the liquid cement grinding aid described in the present invention.

[0029] Under the same test conditions as in Table 2, eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com