Testing device for carbonization resistance of cement based materials and testing method

A technology of cement-based materials and testing devices, which is applied in the direction of analysis materials, preparation of test samples, instruments, etc., to achieve the effect of simple measurement and good carbonation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

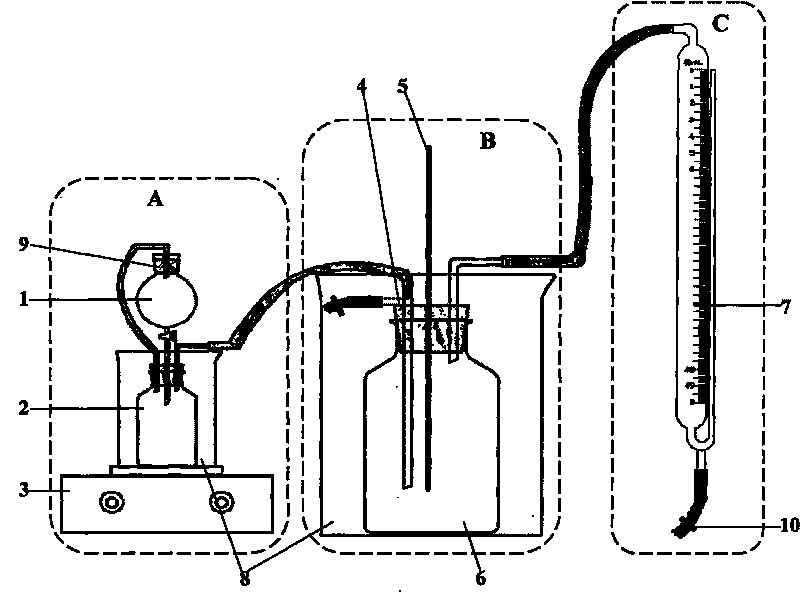

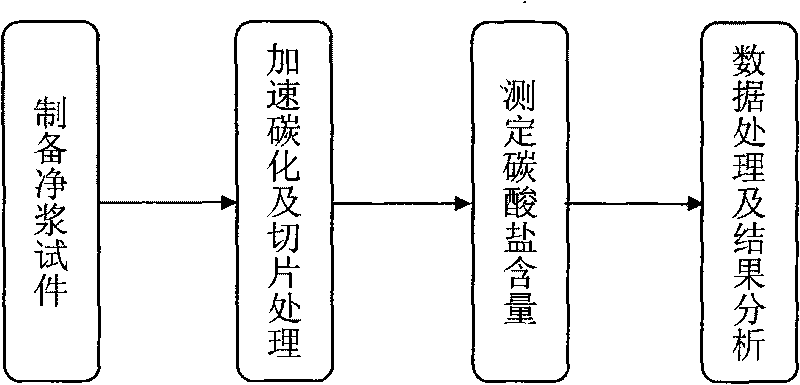

[0058] like figure 1 As shown in the figure, a test device for the anti-carbonation performance of cement-based materials is composed of a reaction part A, a buffer part B and a gas collection measurement part C, which are communicated with each other through a rubber tube.

[0059]The reaction part A mainly includes a separatory funnel 1, a reaction flask 2, a magnetic stirrer 3 and the like. The separatory funnel 1 is composed of a bucket body, a standard grinding mouth set at the upper end and a funnel neck (ie, a funnel) at the lower end. The bucket body is a spherical glass container with a volume of 30ml; dilute hydrochloric acid is placed in the bucket body, a rubber stopper 9 with a through hole is set at the grinding mouth to seal it, and a glass tube is inserted into the through hole, and the glass tube passes through. The rubber tube communicates with the glass tube inserted into the through hole of the rubber stopper 9 of the bottle mouth of the reaction bottle 2 ...

Embodiment 2

[0094] A test device for the anti-carbonation performance of cement-based materials, the same as in Example 1, wherein: the volume of the separatory funnel 1 is 40ml, and the bucket body is pear-shaped; the reaction flask 2 is a conical flask with a volume of 75ml; the volume of the buffer bottle 6 is 1000ml.

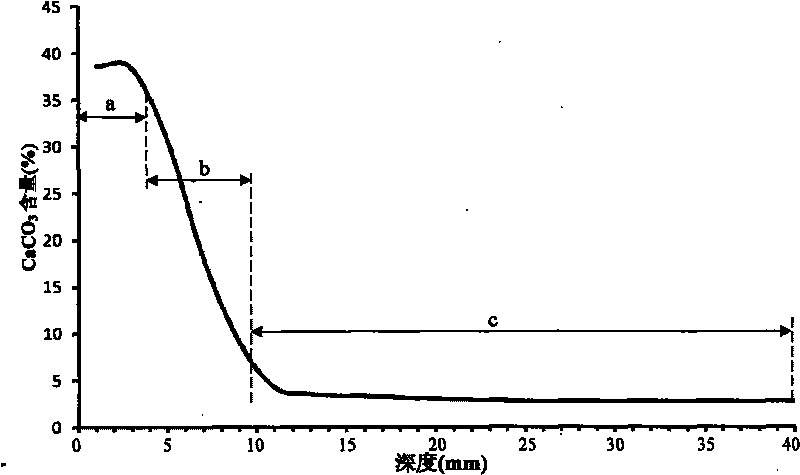

[0095] The concrete steps of a method for testing the anti-carbonation performance of cement-based materials are the same as those in Example 1, wherein: in the preparation of the clean slurry test piece in the (1) step, the water-to-binder ratio is 0.40; in the (2)-2) step During slicing and grinding, the thickness of the slice is 2mm; in the preparation of step (3)-1), the weight of the sliced powder is 0.50g, and the amount of dilute hydrochloric acid is 12ml; the "carbonate content-depth" curve is as follows Figure 4 shown.

Embodiment 3

[0097] A test device for the anti-carbonation performance of cement-based materials, the same as in Embodiment 1, wherein: the volume of the separatory funnel 1 is 50ml; the reaction bottle 2 is a wide-mouth bottle with a volume of 100ml; the volume of the buffer bottle 6 is 1500ml; The glass tube in the through hole of the rubber stopper 9 at the bottle mouth and connected with a glass tube of the glass tee 4 in the through hole of the rubber stopper 9 at the bottle mouth of the buffer bottle 6 through the rubber tube is a straight glass tube.

[0098] The concrete steps of a method for testing the anti-carbonation performance of cement-based materials are the same as those in Example 1, wherein: in the step (1) preparing the pure slurry test piece, the water-to-binder ratio is 0.45; in the step (2)-2) In slicing and grinding, the thickness of the slice is 3; in the preparation of step (3)-1), the weight of the sliced powder is 0.55g, and the amount of dilute hydrochloric ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com