High anti-permeability basalt fibre concrete and preparation method thereof

A basalt fiber and concrete technology, which is applied in the field of high impermeability basalt fiber concrete and its preparation, can solve the problems of endangering the safety and normal use of concrete structures, economic losses, and the impact of concrete durability, so as to improve the permeability resistance of chloride ions , promote development, and reduce economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

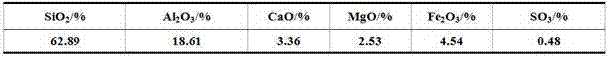

[0020] A kind of high impermeability basalt fiber concrete, its main raw materials include: 22 parts of cement, 35 parts of fine aggregate, 16 parts of coarse aggregate, 8 parts of water, 0.05 part of water reducing agent and synergist in parts by weight 0.1 part; The raw material of described concrete also comprises dopant, and described dopant is chopped basalt fiber and fly ash, and wherein, the doping amount of chopped basalt fiber is 1.2kg / m 3 , the doping amount of fly ash is 30 wt % of the total gelled concrete.

[0021] The preparation method of described high impermeability basalt fiber concrete specifically comprises the following steps:

[0022] (1) Add cement, fine aggregate, fly ash and chopped basalt fiber into the mixer and stir for 45-60 seconds;

[0023] (2) Mix the coarse aggregate into the mixture obtained in step (1) and stir for 30-60 seconds;

[0024] (3) Add water reducer, synergist and water into the mixer, and continue stirring for 3~5 minutes;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com