Lithium ion battery high-voltage anode material preparation and surface coating method

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as battery failure and scrapping, electrode charge and discharge capacity, and cycle reversible performance attenuation, so as to avoid specific capacity decline and suppress adverse reactions , Improve the effect of interface conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

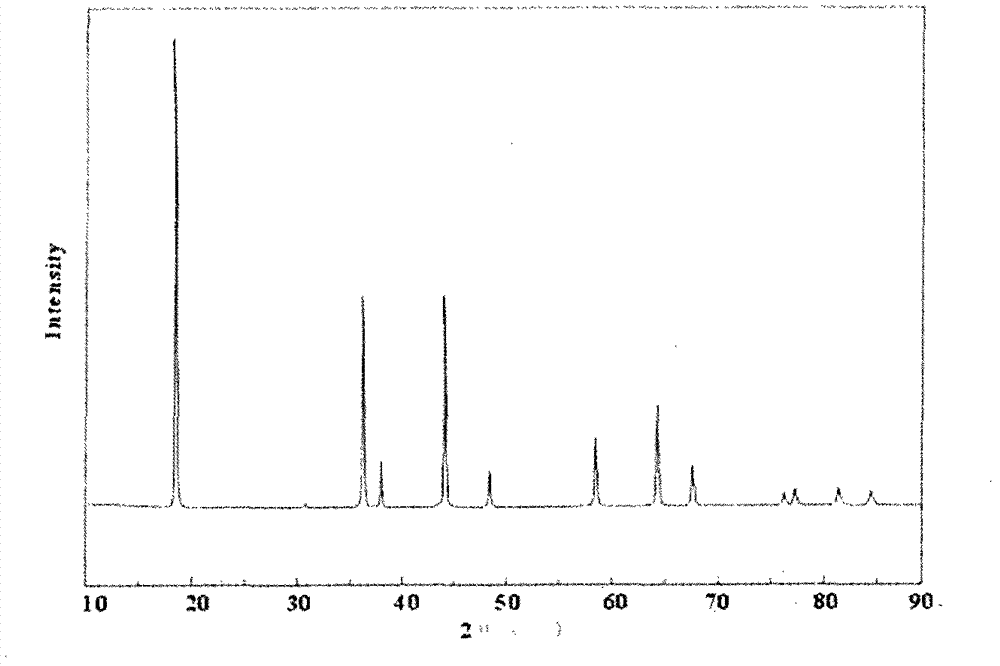

[0027] Dissolve nickel acetate (12.69g) and manganese acetate (37.135g) in dehydrated ethanol respectively to prepare a solution; dissolve citric acid (42.028g) in dehydrated ethanol; mix the above three solutions, stir for 4h to mix evenly, Then it was dried at 70°C to form a sol, and then dried at 100°C to form a gel, and then calcined at 350°C for 4 hours in the air to obtain nickel-manganese oxide powder. Nickel manganese oxide and lithium carbonate were weighed in a molar ratio of 1:1.1, added to absolute ethanol for ball milling and mixing for 5 hours, dried at 100°C, and heat-treated at 400°C in air for 12 hours. The resulting product is analyzed by X-ray diffraction, and the product is spinel LiNi 0.5 mn 1.5 o 4 .

Embodiment 2

[0029]Dissolve nickel sulfate (13.143g) and manganese sulfate (25.3515g) in deionized water respectively to prepare a solution; dissolve citric acid (42.028g) in deionized water; mix the above three solutions, stir for 4h to mix evenly, and then 80 ℃ to dry into a sol, then dried to a gel at 100°C, and then calcined at 350°C in air for 4 hours to obtain nickel-manganese oxide powder. Nickel manganese oxide and lithium carbonate were weighed in a molar ratio of 1:1.1, added to absolute ethanol for ball milling and mixing for 5 hours, dried at 100°C, and heat-treated at 400°C in air for 12 hours. The resulting product is analyzed by X-ray diffraction, and the product is spinel LiNi 0.5 mn 1.5 o 4 .

Embodiment 3

[0031] Dissolve nickel nitrate (14.5405g) and manganese nitrate (37.6515g) in dehydrated ethanol respectively to prepare a solution; dissolve citric acid (42.028g) in dehydrated ethanol; mix the above-mentioned 3 kinds of solutions, stir for 4h to mix well, Then it was dried at 70°C to form a sol, and then dried at 100°C to form a gel, and then calcined at 350°C for 4 hours in the air to obtain nickel-manganese oxide powder. Nickel manganese oxide and lithium carbonate were weighed in a molar ratio of 1:1.1, added to absolute ethanol for ball milling and mixing for 5 hours, dried at 100°C, and heat-treated at 400°C in air for 12 hours. The resulting product is analyzed by X-ray diffraction, and the product is spinel LiNi 0.5 mn 1.5 o 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com