Method for treating red mud by using soil stabilizer

A technology of soil stabilizer and red mud, which is applied in the field of environmental protection, can solve the problems of unreasonable treatment process and unsatisfactory treatment effect, and achieve the effects of maintaining sustainability, promoting local economic development, and improving water immersion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Taking Shandong Chiping red mud as an example, it is used as pavement base course and subbase course material, and the mixing ratio of each raw material (in mass percentage) (water is externally added):

[0048] The amount of soil curing agent is 0.02% of the mass sum of cement, hydrated lime, and red mud; the mass ratio of cement, hydrated lime, and red mud is 5:5:90; the amount of added water is the total mass (that is, the total dry mass except water) 27%, determined according to the site soil, not too wet or too dry. Mixing, paving, rolling, curing, etc. form a hardened body. The interval between mixing and rolling shall not exceed 6 hours.

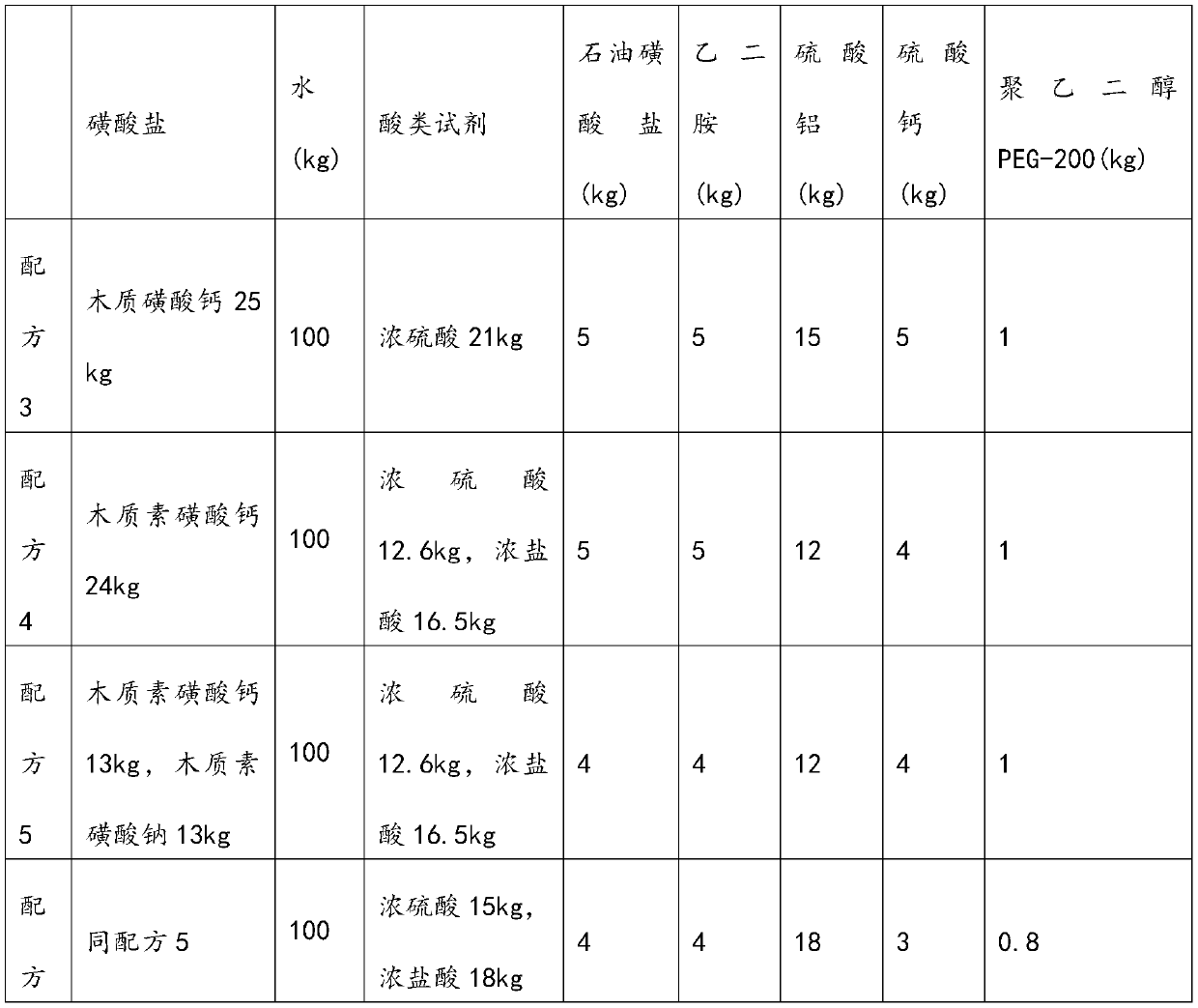

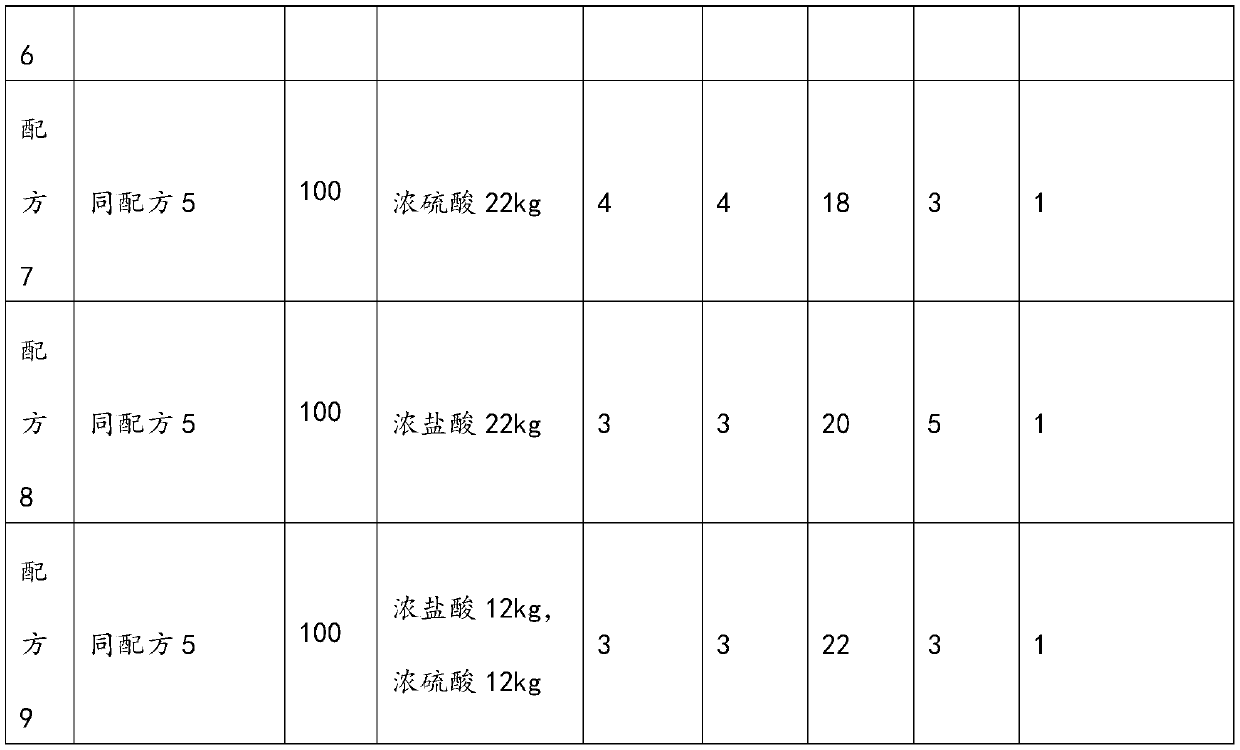

[0049] The formula of the soil stabilizer is: calcium lignosulfonate 30kg, water 100kg, concentrated hydrochloric acid 35kg, anionic active agent petroleum sulfonate 5kg, catalyst ethylenediamine 5kg, aluminum sulfate 18kg, early strength agent calcium sulfate 5kg, nonionic Surfactant polyethylene glycol PEG-200 1kg.

[0050...

Embodiment 2

[0057] Taking Shandong Chiping red mud as an example, it is used as pavement base and sub-base materials, and the mixing ratio of each raw material (water is added outside):

[0058] The consumption of soil solidifying agent is 0.02% of the quality sum of cement, slaked lime, red mud (i.e. the total dry mass except water); the mass ratio of cement, slaked lime, red mud is 4:4:92; 27% of the mass, determined according to the soil quality of the site, not too wet or too dry. Mixing, paving, rolling, curing, etc. form a hardened body. The interval between mixing and rolling shall not exceed 6 hours.

[0059] The formula of the soil stabilizer is: calcium lignosulfonate 25kg, water 100kg, concentrated sulfuric acid 18kg, concentrated hydrochloric acid 10kg, anionic surfactant petroleum sulfonate 5kg, catalyst ethylenediamine 5kg, aluminum sulfate 15kg, early strength agent calcium sulfate 5kg, nonionic surfactant polyethylene glycol PEG-200 1kg.

[0060] Above-mentioned soil so...

Embodiment 3

[0067] Taking Shandong Chiping red mud as an example, it is used as pavement base course and subbase course material, and the mixing ratio of each raw material (in mass percentage) (water is externally added):

[0068] The dosage of the soil curing agent is 0.015% of the mass sum of cement, hydrated lime and red mud (that is, the total dry mass except water); the mass ratio of cement, hydrated lime and red mud is 3:4:93. The amount of additional water is 27% of the total mass, determined according to the soil quality on site, and should not be too wet or too dry. The rest are the same as in Example 1.

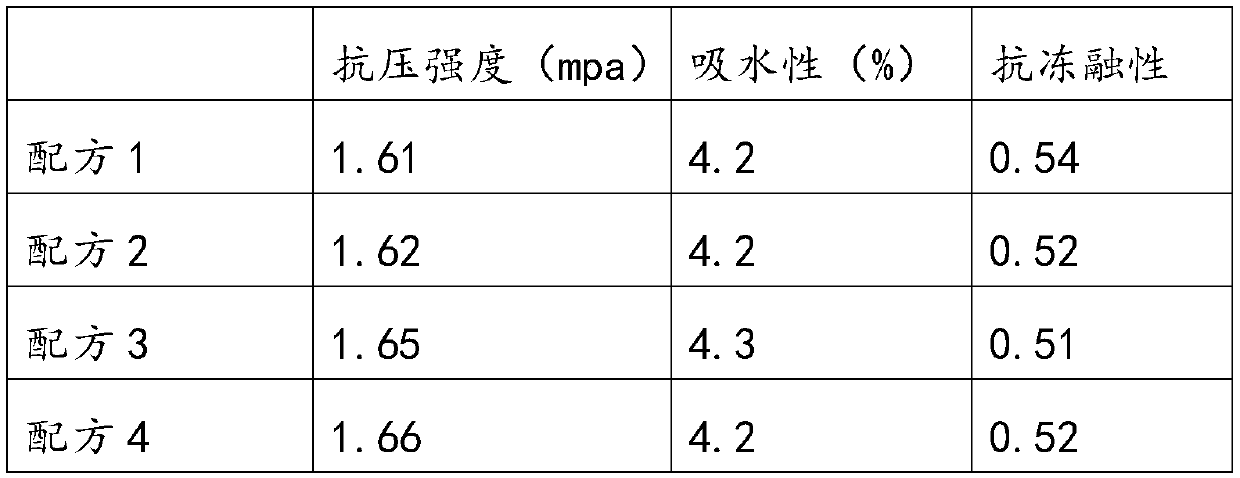

[0069] The experimental results are as follows: The heavy-duty compaction test and the unconfined compressive strength test of the pavement base material are carried out according to the "Test Regulations for Highway Engineering Inorganic Binder Stable Materials" JTG E51-2009 and "Highway Soil Engineering Test Regulations" JTG E40-2007. The maximum dry density of this mix rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry density | aaaaa | aaaaa |

| Dry density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com