Lithium ion battery anode material LiCoPO4/Al2O3 and preparation method thereof

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as the inability to guarantee the stability of the electrolyte system, achieve the effects of suppressing adverse reactions, simple process, and improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

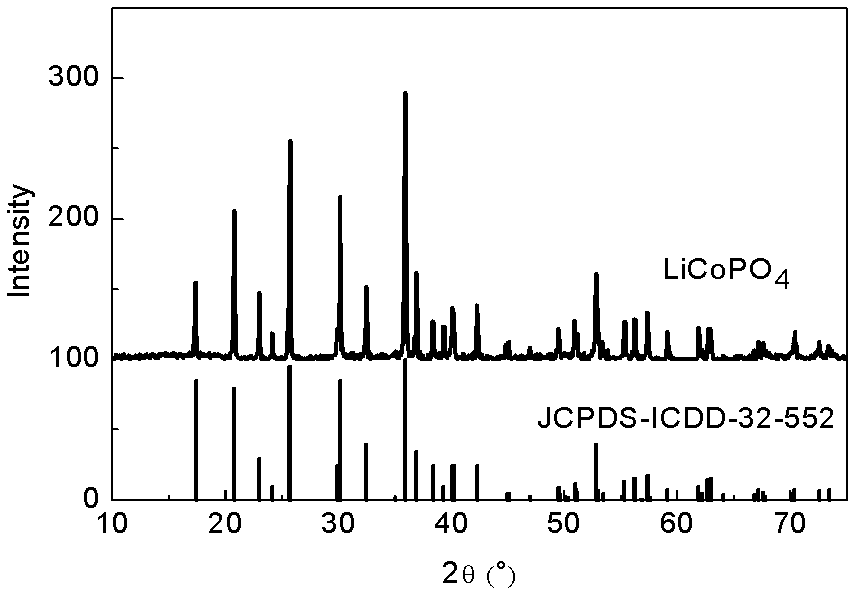

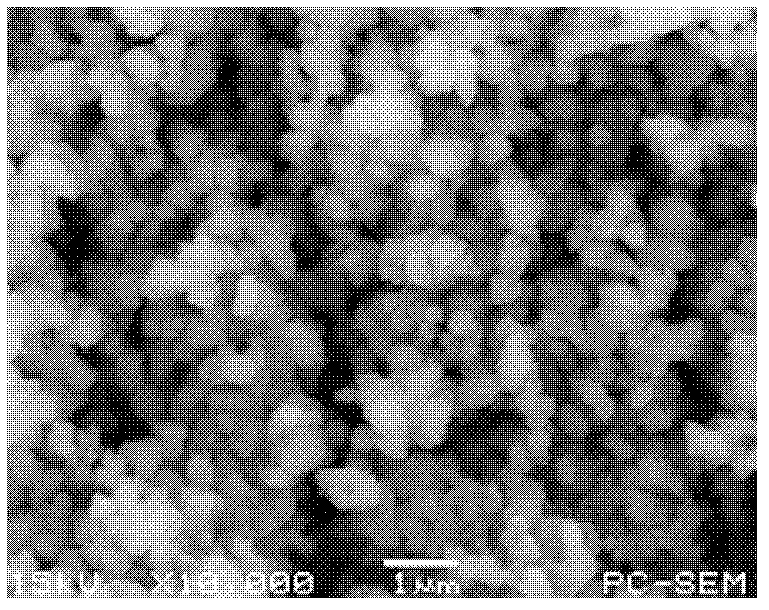

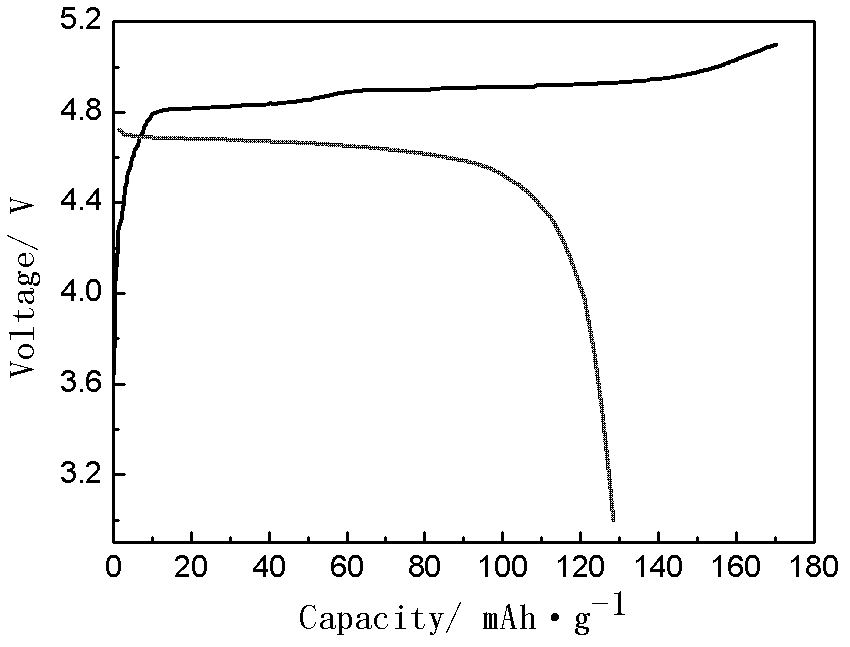

[0025] Dissolve 0.01mol of lithium acetate and ammonium dihydrogen phosphate in deionized water respectively to prepare a solution; dissolve 0.01mol of cobalt acetate and 0.02mol of citric acid in deionized water respectively; add cobalt acetate and citric acid dropwise to the above-mentioned Mix the solution, stir for 4 hours to mix evenly, then stir in a water bath at 75°C until it becomes a gel, then vacuum-dry it at 120°C to form a gel, calcinate at 350°C in air for 6 hours, cool and grind, and then calcinate at 650°C in air for 12 hours. The resulting product was analyzed by X-ray diffraction, and the product was olivine-type LiCoPO 4 .

Embodiment 2

[0027] Lithium nitrate and cobalt nitrate were used to replace lithium acetate and cobalt acetate respectively and dissolve them in deionized water. Other conditions were the same as in Example 1 to obtain olivine-type LiCoPO 4 .

Embodiment 3

[0029] Dissolved in deionized water with tartaric acid instead of citric acid, and other conditions were the same as in Example 1 to obtain olivine-type LiCoPO 4 .

[0030] 2. Coated Al 2 o 3 film

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com