Hot-isostatic-press intermediate-phase graphite anode material used in lithium battery and preparation method thereof

A technology of mesophase graphite and hot isostatic pressing, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of damaging lithium ion mobility, accelerating electrolyte reaction, and reducing charge and discharge efficiency, so as to improve discharge capacity and Effects of cycle efficiency, improvement of processing performance, and stable product properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

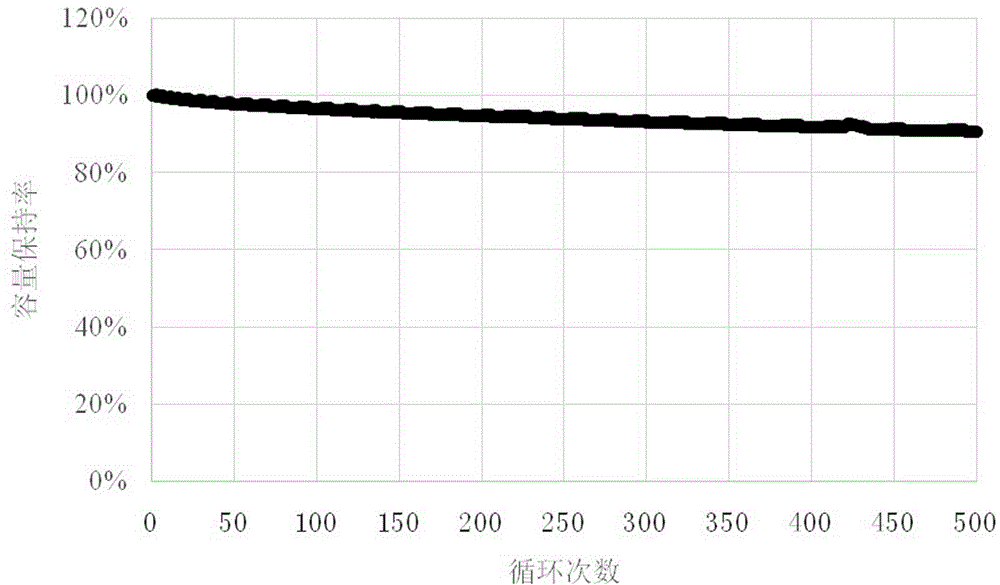

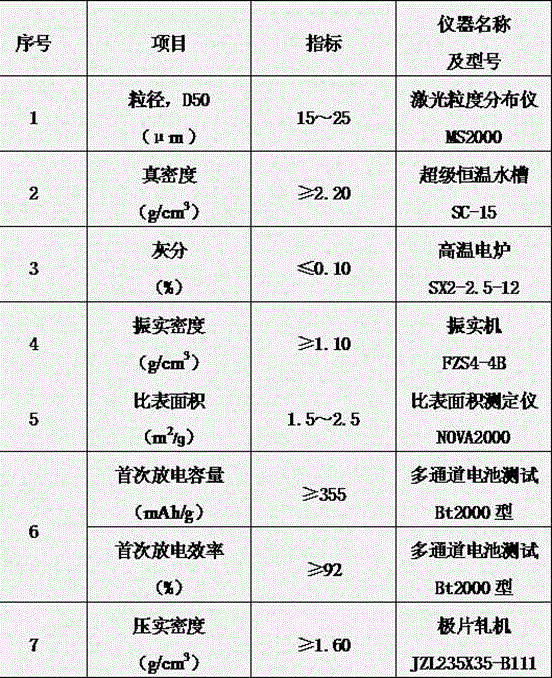

[0023] Using self-baking mesophase carbon microsphere powder (particle size 12.5 μm) as raw material, it was preformed in a molding machine with a molding pressure of 25 MPa, put into a hot isostatic press, and argon gas was used as a medium to heat up and pressurize. 500°C calcination temperature and 50MPa pressure for 1 hour, then naturally lower the temperature, and then carry out graphitization high-temperature treatment (2800°C). And carry out pulverization and classification to prepare lithium ion battery negative electrode hot isostatic pressing mesophase graphite material. The half-cell capacity is 356.5mAh / g, the initial efficiency is 92.8%, and the compacted density is 1.67g / cm 3 .

Embodiment 2

[0025] Self-baking mesophase carbon microsphere powder (particle size 12.5 μm) was used as raw material, preformed in a molding machine with a molding pressure of 50 MPa, put into a hot isostatic press, and argon gas was used as a medium to heat up and pressurize. 500°C calcination temperature and 50MPa pressure for 1 hour, then naturally lower the temperature, and then carry out graphitization high-temperature treatment (3000°C). And carry out pulverization and classification to prepare lithium ion battery negative electrode hot isostatic pressing mesophase graphite material. The half-cell capacity is 358.1mAh / g, the initial efficiency is 93.2%, and the compacted density is 1.61g / cm 3 .

Embodiment 3

[0027] Using self-baking mesophase carbon microsphere powder (particle size 12.5 μm) as raw material, it was preformed in a molding machine with a molding pressure of 25 MPa, put into a hot isostatic press, and argon gas was used as a medium to heat up and pressurize. 500°C calcination temperature and 60MPa pressure for 1 hour, then naturally lower the temperature, and then carry out graphitization high-temperature treatment (3000°C). And carry out pulverization and classification to prepare lithium ion battery negative electrode hot isostatic pressing mesophase graphite material. The half-cell capacity is 355.6mAh / g, the first efficiency is 92.6%, and the compacted density is 1.65g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com