High-multiplying-power type lithium iron phosphate/carbon composite material and preparation method thereof

A carbon composite material, lithium iron phosphate technology, applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of low electronic conductivity, slow diffusion rate, capacity performance, and fast charge and discharge rate performance. , to achieve the effects of high product crystallinity, stable cycle performance, and good high-current charge-discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Using medium-temperature coal tar pitch as raw material, the amphiphilic carbon material was prepared by acid oxidation method. The specific preparation process is as follows: the pitch is crushed and sieved by a ball mill, and the pitch particles with a particle size of less than 150 μm are taken as the raw material. Heat 50 ml of mixed acid (prepared with 65% concentrated nitric acid and 98% concentrated sulfuric acid in a volume ratio of 3:7) to 80 °C, stir at a stirring rate of 300 r / min, add 10 g of medium temperature Coal tar pitch, reacted for 3 h, poured the reactant into 500 mL of deionized water to terminate the reaction, filtered with a vacuum filtration device, and the obtained filter cake was washed with deionized water until neutral; the obtained solid matter was added to 500 mL of concentration 1 In mol / L NaOH solution, stir at 300 r / min for 1 h at 80 °C, filter under reduced pressure, and keep the pH value of the solution always greater than 12 during...

Embodiment 2-5

[0029] The preparation method is basically the same as that in Example 1, except that 0.1896 g of pitch-based amphiphilic carbon material was added in step (1) instead of 0.1835 g of graphene oxide, 0.1449 g of sulfonated pitch, and 0.1288 g of needle coke. Amphiphilic carbon material, 0.1521 g humic acid, the needle-shaped coke-based amphiphilic carbon material is made from petroleum needle coke as raw material, according to the preparation method in step 1, and the amount of mixed acid is 100 ml have to.

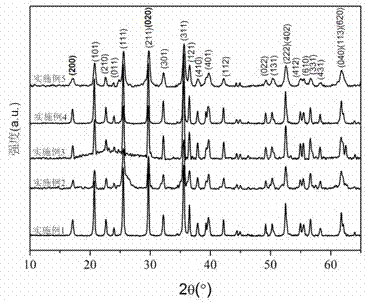

[0030] XRD tested (see figure 1 ), the peak ratio 1 of the (020) peak and the (200) peak of the lithium iron phosphate / carbon composite material prepared in Example 2-5 (020) / I (200) They are 3.5, 3.6, 4.0, 4.2 respectively. It shows that the acicular coke amphiphilic carbon materials and humic acid can also be used as structure inducers and promoters.

Embodiment 6

[0032] (1) Add 0.756 g of lithium hydroxide powder to 60 ml of ethylene glycol, and ultrasonically disperse for 30 min. Under the condition of magnetic stirring, 0.6917 g of phosphoric acid with a mass concentration of 85% was added dropwise to the suspension, and the stirring was continued for 30 min to obtain a lithium phosphate suspension. 1.668 g of ferrous sulfate and 0.0948 g of pitch-based amphiphilic carbon material were added to the above suspension, and stirring was continued for 30 min.

[0033] (2) is the same as step (2) of Example 1.

[0034] (3) is the same as step (3) of Example 1.

[0035] (4) is the same as step (4) of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com