Negative plate of lead-carbon battery and preparation method

A technology of lead-carbon battery and negative plate, which is applied in the direction of lead-acid battery electrodes, battery electrodes, circuits, etc., which can solve the problems of large specific surface area of activated carbon materials and water loss of batteries, and achieve good crystallinity, prolong service life, and easy The effect of electron transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

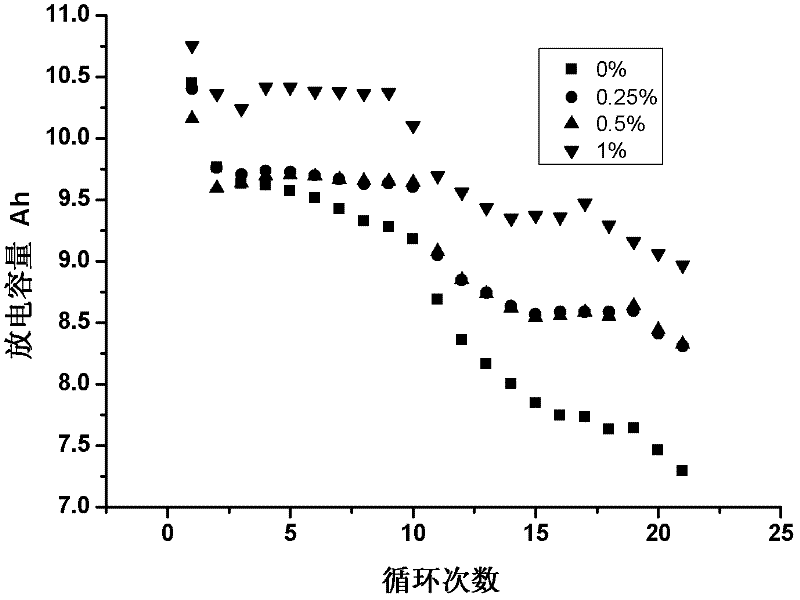

[0028] Example 1: Preparation of negative plate with 0% addition of carbon nanotubes

[0029] Take 3kg of lead powder, 2.1g of polyester fiber, 6g of sodium lignosulfonate, 24g of barium sulfate, and 15g of conductive carbon black. Stir and mix the above five materials for 10 minutes, then slowly add 15℃ =1.350±0.004g / cm 3 dilute sulfuric acid, control the flow rate for 10-15 minutes, then continue to stir for 5 minutes, add an appropriate amount of water to adjust the apparent density of the lead paste to 4.25g / cm 3 , hand-painted panels.

Embodiment 2

[0030] Example 2: Preparation of negative plate with multi-walled carbon nanotubes added in an amount of 0.25%

[0031] Take 7.5g of multi-walled carbon nanotubes and disperse them into 400g of water. The ultrasonic power is controlled at 500-700W, with 4s and 4s intervals, and the total ultrasonic time is 1h. The carbon nanotubes used have a diameter of 30-50nm, a length of 5-20μm, and a specific surface area of 300m 2 / g of hydroxylated multi-walled carbon nanotubes TNMH7.

[0032]Get 3kg of lead powder, 2.1g of polyester fiber, 6g of sodium lignosulfonate, 24g of barium sulfate, and 15g of conductive carbon black. Stir and mix the above materials for 10 minutes, add the mixture of dispersed carbon nanotubes and water, continue stirring for 10 minutes, and then slowly Add slowly and the specific gravity is d 15℃ =1.350±0.004g / cm 3 Add dilute sulfuric acid, control the flow rate for 10-15 minutes, continue stirring for 5 minutes, add an appropriate amount of water, and a...

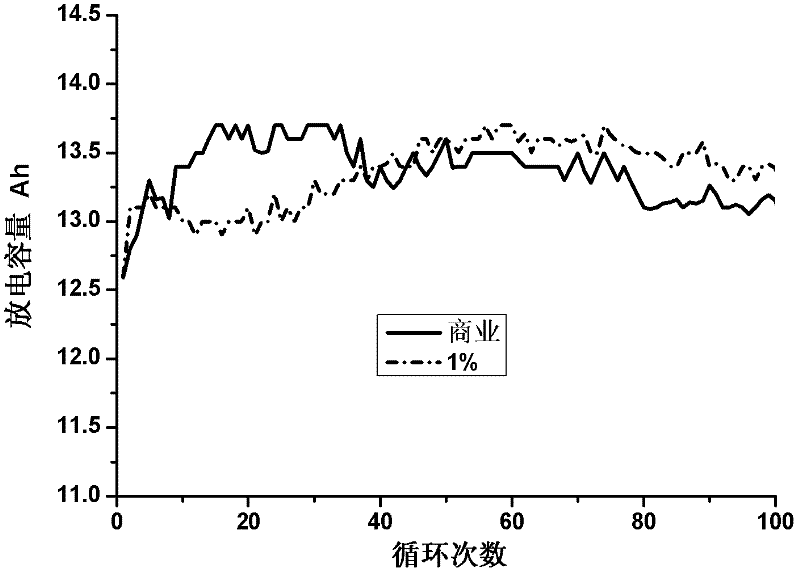

Embodiment 5

[0053] Example 5: Preparation of negative plate with 1% addition of multi-walled carbon nanotubes

[0054] Take 100g of carbon nanotubes and disperse them into 1400g of water. The ultrasonic power is controlled at 500-700W, the ultrasonic wave is 4s and the interval is 4s, and the total ultrasonic time is 1.5h. The carbon nanotubes used are multi-walled tubes MWCNTs.

[0055] Get 10kg of lead powder, 7g of acrylic fibers, 28g of a mixture of sodium lignosulfonate and humic acid with a mass ratio of 9:1, 80g of barium sulfate, and 50g of colloidal graphite, stir and mix for 10min, add the mixture of dispersed carbon nanotubes and water, Continue to stir for 10min, then slowly add the specific gravity d 15℃ =1.350±0.004g / cm 3 Add dilute sulfuric acid, control the flow rate for 10-15 minutes, then continue to stir for 5 minutes, add an appropriate amount of water to adjust the apparent density of the lead paste to 4.05g / cm 3 , hand-painted panels.

[0056] Performance Testing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com