Tubular negative plate of lead-carbon battery

A tubular negative electrode, lead-carbon battery technology, applied in lead-acid battery electrodes, battery electrodes, circuits, etc., can solve the problems of easy falling off and poor stability of lead paste, achieve good low-temperature starting ability, stabilize lead paste structure, improve The effect of cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

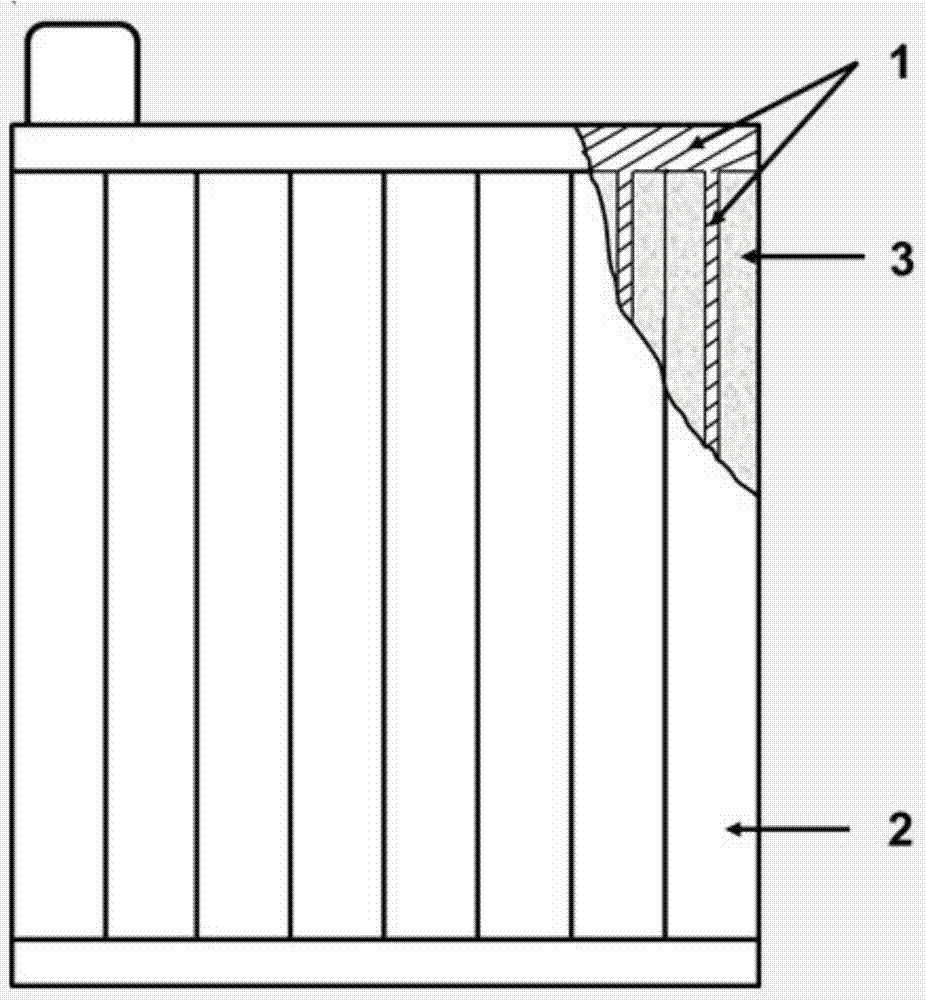

[0039] Such as figure 1 As shown in the present invention, a lead-carbon battery tube-type negative plate, the plate includes a lead-calcium multi-element alloy negative grid and filled active material powder, the negative grid is a beam and perpendicular to it. The fence structure composed of the core, the negative electrode grid is provided with a non-woven cover layer, and the gap between the cover layer and the conductive core is filled with active materials. The active material is composed of the following materials by weight percentage: lead powder 88.41wt%, capacitor 10wt% carbon material, 0.4wt% carbon black, 0.5wt% barium sulfate, 0.1wt% sodium lignosulfonate, 0.5wt% humic acid and 0.09wt% short fiber.

[0040] The cross section of the casing layer is circular.

[0041] The capacitive carbon material is 5wt% of activated carbon, 2wt% of expanded graphite, 2wt% of carbon fiber, and 1wt% of graphene.

[0042] The specific surface area of carbon black is less than 50...

Embodiment 2

[0049] Such as figure 1 Shown, a kind of lead-carbon battery tubular negative pole plate of the present invention, pole plate comprises the carbon foam negative pole grid that surface adopts lead-plated treatment and the active material powder that fills, and negative pole grid is constituted by beam and the conductive core perpendicular to it Fence structure, the outer surface of the negative electrode grid is provided with a polyester jacket, and the gap between the jacket and the conductive core is filled with active materials. The active materials are composed of the following materials in terms of weight percentage: lead powder 69.25wt%, capacitive carbon material 25wt% , carbon black 0.5wt%, barium sulfate 2.0wt%, sodium lignosulfonate 1.2wt%, humic acid 2.0wt% and short fiber 0.05wt%.

[0050] The cross-section of the casing is elliptical.

[0051] The capacitive carbon material is 10wt% of activated carbon, 3wt% of expanded graphite, 1wt% of carbon black, 3wt% of carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com