Low-air-permeability one-time forming safety air bag and production technology thereof

An airbag and production process technology, applied in vehicle safety arrangement, pedestrian/occupant safety arrangement, removal of liquid/gas/vapor, etc., can solve the problems of organic silica gel raw material pollution, etc. The effect of environmental protection in the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

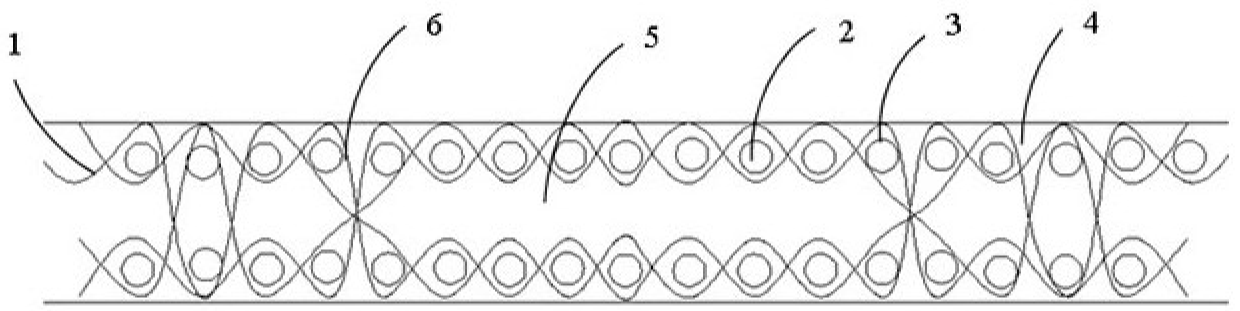

[0025] The warp and weft yarns of the fabric layer of low air permeability one-time forming airbag are woven from high-strength polyester fibers, the density of warp and weft yarns is 500D, the density of warp yarn 1 is 440 / 10cm, the density of weft yarn 2 is 380 / 10cm, and the strength is 7.5g / D . Wetting layer 3 is added to the surface of the fabric. After the fabric passes through JFC-2: 0.5 parts, JFC-E: 0.6 parts, ERKANTOL ® NR: 1.2 parts, water: 97.7 parts, the liquid carrying rate of the fabric after passing through the press bar is 40%, and it is dried at 130°C Dry the fabric to form a wet layer3. The fabric is treated with a cylinder heat dryer at a temperature of 130° C. and a treatment time of 1.5 minutes. The fabric is calendered, the temperature is 100°C, the speed is 15m / min, the line pressure is 620 N / mm, the silicone coating is treated, the weight of the front and back coating is 45±3 grams per square meter, and the drying temperature of the coating is 175°C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com