Electrode and method for manufacturing same

An electrode manufacturing and electrode technology, which is applied in the field of electrodes and its manufacturing, can solve problems such as limited process control capability, safety hazards, difficult lithium batteries, etc., to increase absorption rate and liquid absorption, reduce safety hazards, and increase specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

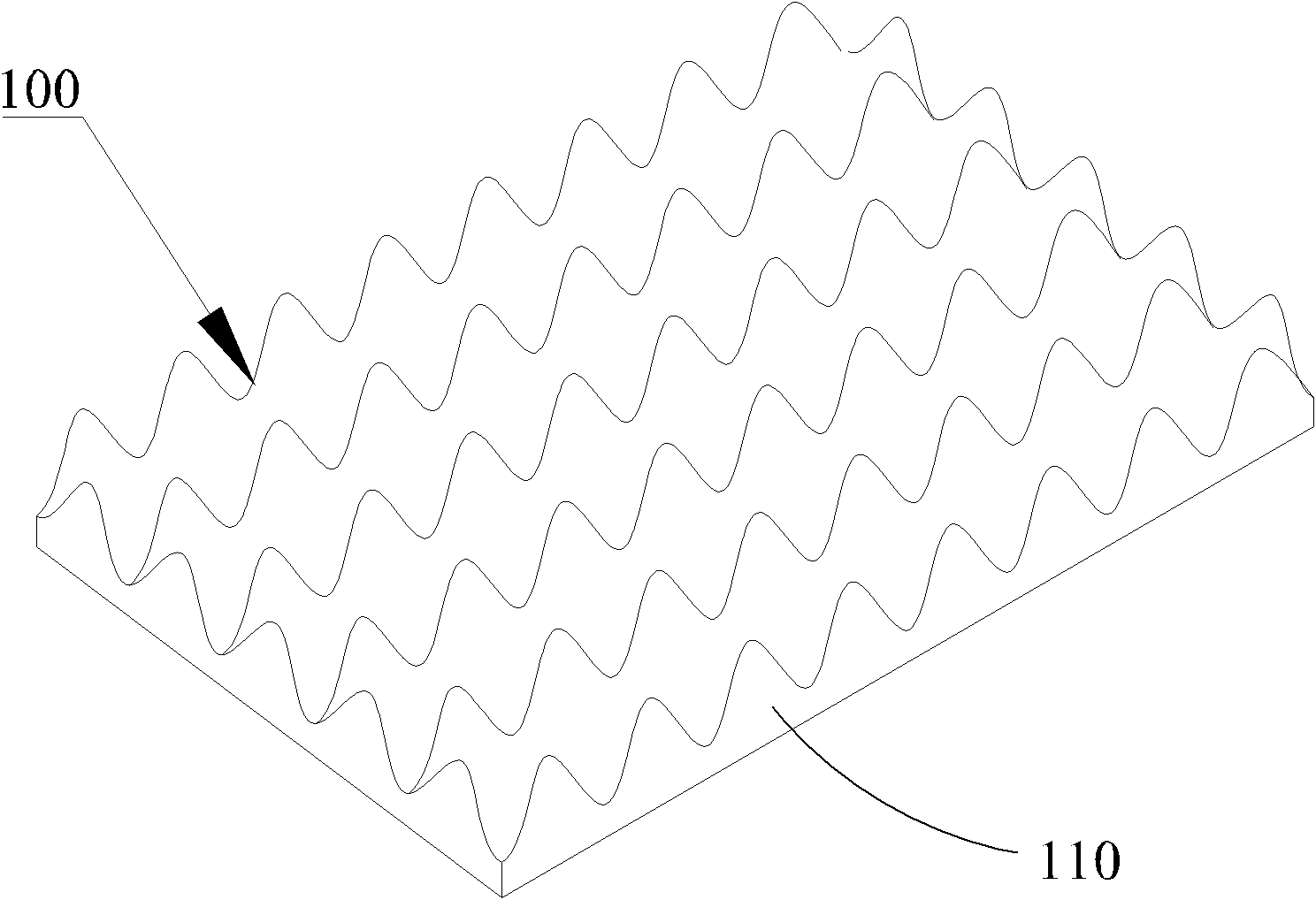

[0033] In this embodiment, the electrode 100 uses laser etching to roughen the surface of the electrode material layer 110, and the degree of roughening is controlled at 50% of the coating amount on one side of the electrode material layer 110, that is, the peak-to-valley drop distance is 50% of the layer 110 is coated on one side, and the roughening treatment is performed after the electrode 100 is dried, then rolled and cut into shape. The electrode active material particle size of the electrode 100 is not greater than 12 microns. At the same time, the electrode 100 is used to prepare a lithium battery by adopting a traditional cylindrical crimping process.

[0034] Test and evaluate the liquid absorption rate and liquid absorption volume of the electrode 100, and test the rate performance and rate cycle life of the lithium battery prepared by using the electrode 100. The test data are shown in Table 1:

[0035]

[0036] Table 1

Embodiment 2

[0038] In this embodiment, the electrode 100 uses laser etching to roughen the surface of the electrode material layer 110, and the degree of roughening is controlled at 50% of the coating amount on one side of the electrode material layer 110, that is, the peak-to-valley drop distance is 50% of the layer 110 is coated on one side, and the roughening treatment is performed after the electrode 100 is dried, then rolled and cut into shape. The electrode active material particle size of the electrode 100 is not greater than 30 microns. At the same time, the electrode 100 is used to prepare a lithium battery by adopting a traditional cylindrical crimping process.

[0039] Test and evaluate the liquid absorption rate and liquid absorption amount of the electrode 100, and test the rate performance and rate cycle life of the lithium battery prepared by using the electrode 100. The test data are shown in Table 2:

[0040]

[0041]

[0042] Table 2

Embodiment 3

[0044] In this embodiment, the electrode 100 uses laser etching to roughen the surface of the electrode material layer 110, and the degree of roughening is controlled at 30% of the coating amount on one side of the electrode material layer 110, that is, the peak-to-valley drop distance is 30% of the layer 110 is coated on one side, and the roughening treatment is performed after the electrode 100 is dried, then rolled and cut into shape. The electrode active material particle size of the electrode 100 is not greater than 12 microns. At the same time, the electrode 100 is used to prepare a lithium battery by adopting a traditional cylindrical crimping process.

[0045] Test and evaluate the liquid absorption rate and liquid absorption volume of the electrode 100, and test the rate performance and rate cycle life of the lithium battery prepared by using the electrode 100. The test data are shown in Table 3:

[0046]

[0047] table 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com