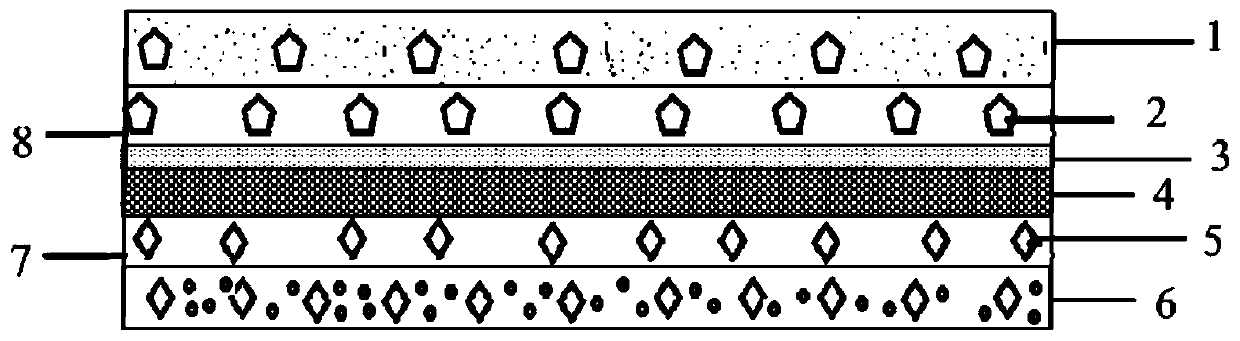

Water-based high-viscosity glued diaphragm, preparation method thereof, and application of diaphragm in battery

A high-viscosity, glue-coating technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of accelerated cycle life attenuation, neglect, and increase in internal resistance of cells, to improve cycle life and safety performance, The best shaping effect and the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] (1) Preparation of slurry:

[0059] Add 75g of alumina ceramic powder, 10g of polyethylene glycol, and 10g of polytetrafluoroethylene to deionized water in sequence, disperse at high speed for 2 hours, and finally add 5g of sodium dodecylbenzenesulfonate, disperse at high speed for 3 hours to obtain a solid content of 60wt% water-based ceramic slurry;

[0060] Add 80 g of polytetrafluoroethylene, 15 g of triethyl phosphate and 5 g of sodium dodecylbenzenesulfonate to deionized water in sequence, and disperse at high speed for 3 hours to obtain an aqueous polymer slurry C with a solid content of 30 wt %;

[0061] Add 80 g of pure benzene latex powder, 15 g of triethyl phosphate, and 5 g of sodium dodecylbenzenesulfonate to deionized water, disperse at high speed for 3 hours, and obtain an aqueous polymer slurry D with a solid content of 30 wt % after dispersing evenly;

[0062] (2) Coating: apply the above-mentioned ceramic slurry on the positive electrode side of the 1...

Embodiment 2

[0067] (1) Preparation of slurry:

[0068] Add 90g of boehmite ceramic powder, 4g of polyvinylpyrrolidone and 5g of polyvinylidene fluoride-trifluoroethylene in sequence to deionized water, disperse at high speed for 5 hours, and finally add 1g of octylphenol polyoxyethylene ether, disperse at high speed for 1 hour to obtain 30wt The aqueous ceramic slurry of % solid content;

[0069] 90 g of polyvinylidene fluoride-trifluoroethylene, 9 g of polyvinylpyrrolidone and 1 g of octylphenol polyoxyethylene ether were sequentially added to deionized water, and dispersed at high speed for 1 hour to obtain an aqueous polymer slurry C with a solid content of 10 wt %;

[0070] Add 75g of polyacrylonitrile, 15g of triethyl phosphate, and 10g of sodium dodecylbenzenesulfonate to deionized water, disperse at high speed for 3 hours, and finally add, disperse at high speed for 1 hour, and obtain a water-based polymer slurry with a solid content of 10wt% after dispersing evenly Material D;

...

Embodiment 3

[0074] (1) Preparation of slurry:

[0075] Add 85g of titanium dioxide powder, 8g of laurate, and 4g of vinylidene fluoride-hexafluoropropylene polymer to deionized water in sequence, and disperse at high speed for 5 hours. content of water-based ceramic slurry;

[0076] Add 75 g of vinylidene fluoride-hexafluoropropylene polymer, 15 g of laurate and 10 g of polyether siloxane copolymer to deionized water in sequence, and disperse at high speed for 1 hour to obtain an aqueous polymer slurry C with a solid content of 20 wt %;

[0077] Add 90 g of polybutyl methacrylate powder, 9 g of laurate and 1 g of polyether siloxane copolymer to deionized water, disperse at high speed for 3 hours, and obtain an aqueous polymer slurry D with a solid content of 20 wt % after dispersing evenly;

[0078] (2) Coating: apply the above-mentioned ceramic slurry on the positive electrode side of the 8 μm base film by extrusion, the coating speed is 60 m / min, pass through the transfer roller, and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com