Nb microalloyed Ni-Co-Fe-Cr-Al high-entropy alloy

A high-entropy alloy and micro-alloying technology, which is applied in the field of Nb micro-alloyed Ni-Co-Fe-Cr-Al high-entropy alloys, can solve the problems of mismatching strength and toughness of multi-principal alloys, and achieve small deformation resistance, The effect of high yield strength and good deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

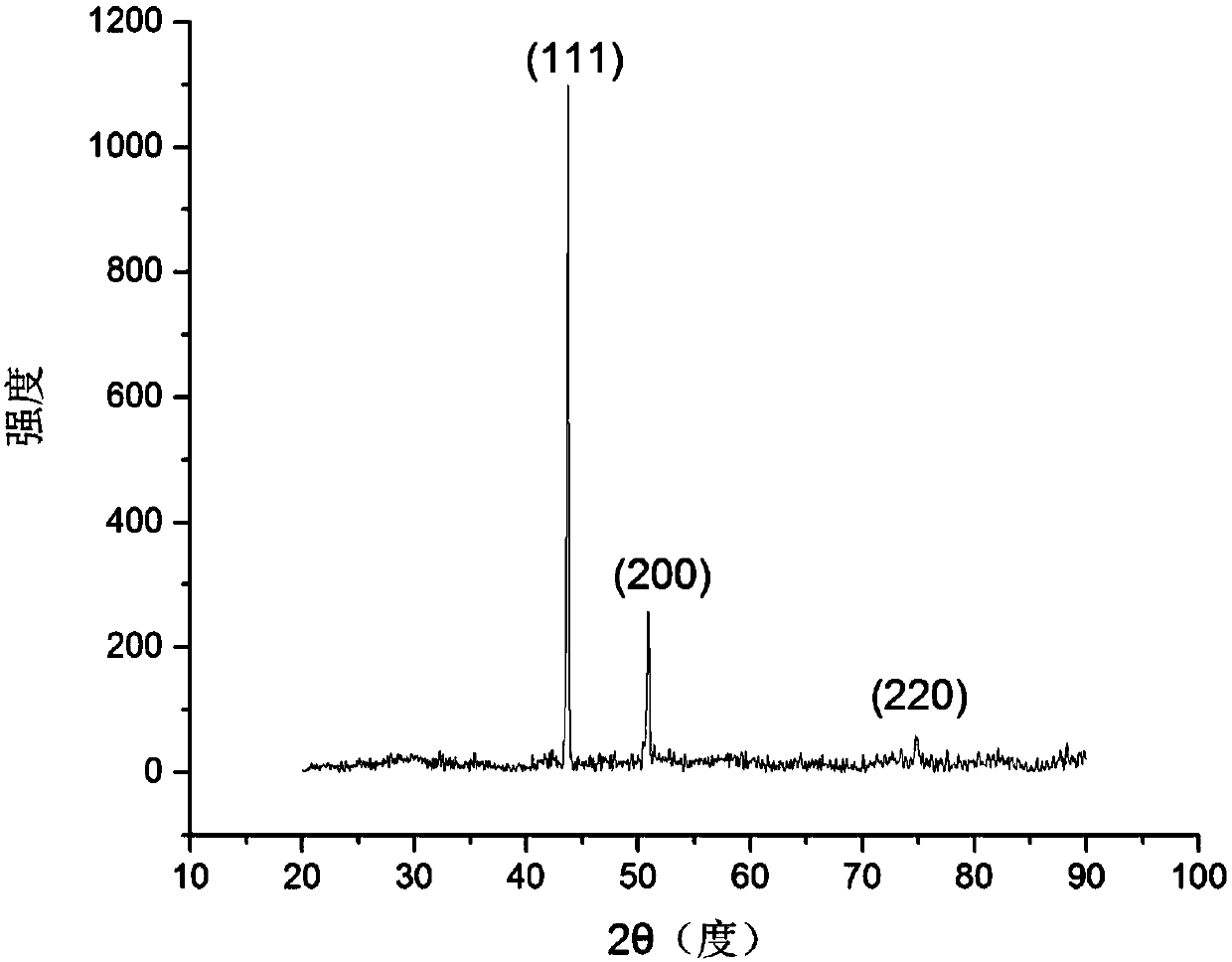

Embodiment 1

[0045] The preparation of a kind of Nb microalloying Ni-Co-Fe-Cr-Al high entropy alloy, concrete steps are as follows,

[0046] (1) Ingredients: Use sandpaper and a grinder to remove the oxide skins on the surface of the metal elements Al, Ni, Co, Cr, Fe and Nb, and then use absolute ethanol to perform ultrasonic cleaning to obtain clean metal elements; according to Ni:Co: The atomic percentage of Fe:Cr:Al:Nb=36.81:20.45:20.45:14.31:7.98:0, accurately weighed out the mixed raw material whose total mass is 80g;

[0047] (2) Alloying and smelting: Put the mixed raw materials into the water-cooled copper crucible in the high vacuum non-consumable arc melting furnace, and then vacuumize until the vacuum degree in the melting furnace reaches 2.5×10 -3 After Pa, fill high-purity argon as a protective gas; before melting the alloy, first melt the pure titanium metal ingot to further reduce the oxygen content in the cavity, and then carry out alloy melting. During the melting process,...

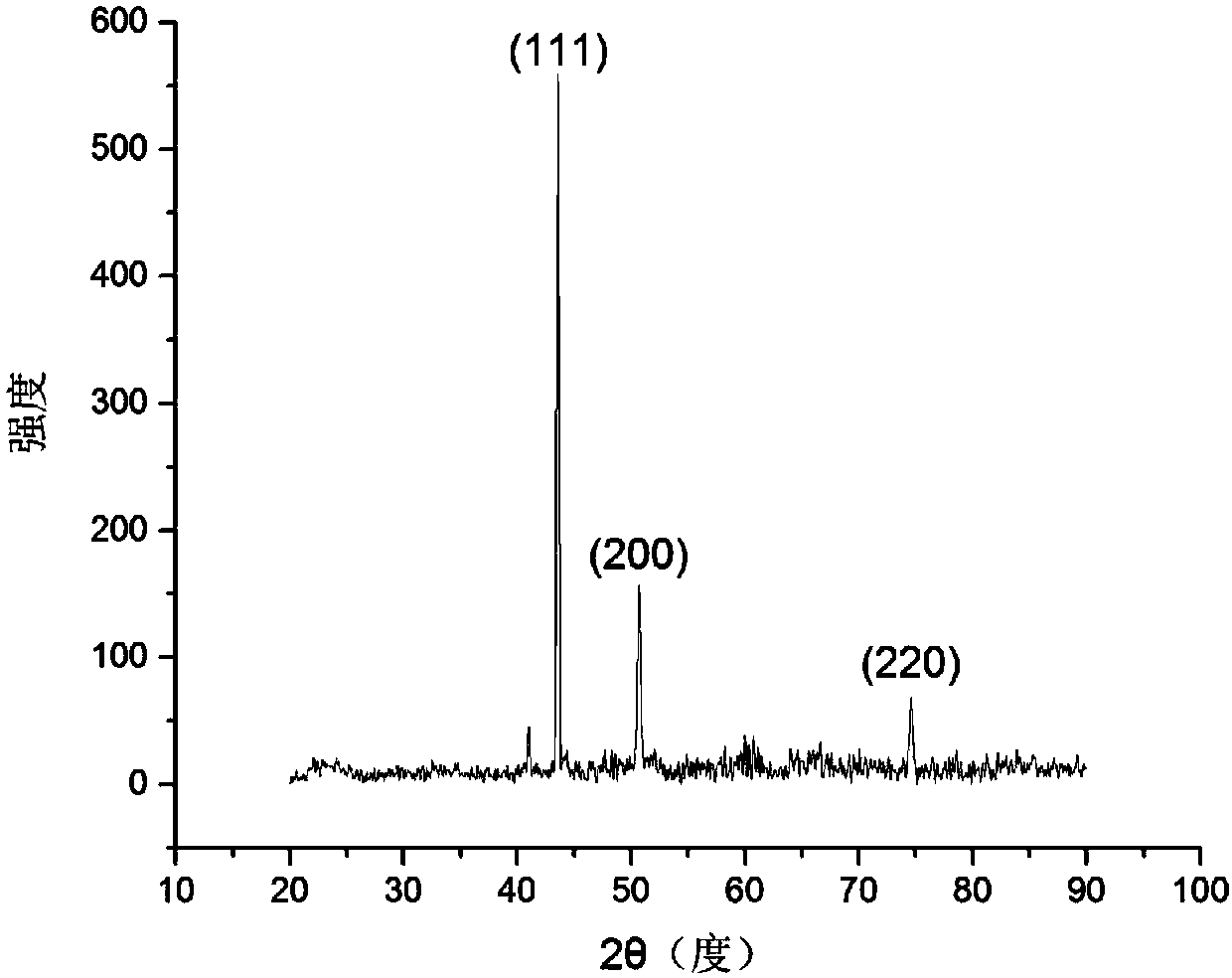

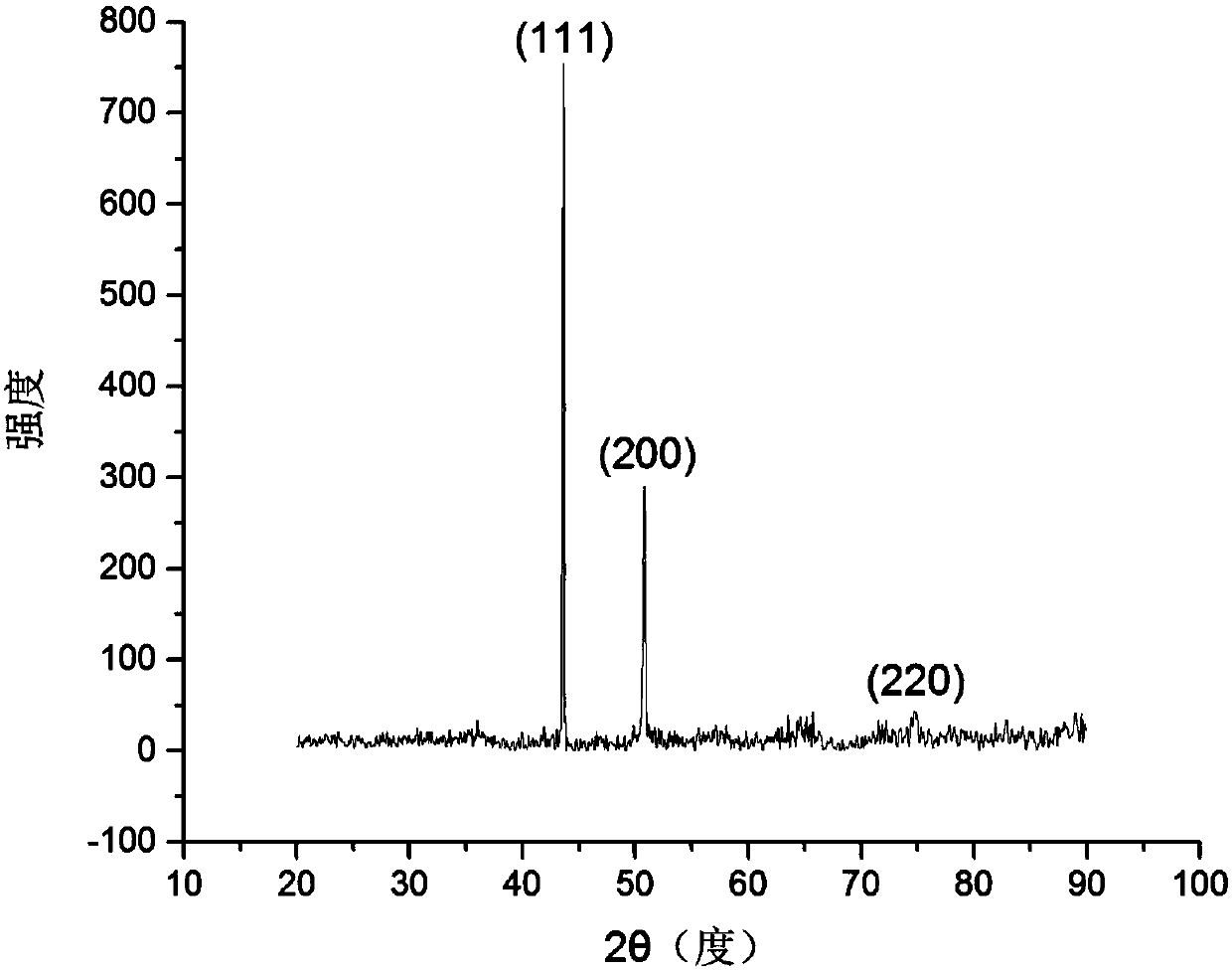

Embodiment 2~22

[0049] Examples 2-22: On the basis of Example 1, only the atomic percentages among Ni, Co, Fe, Cr, Al and Nb were changed, other steps and conditions were the same as in Example 1, and high-entropy alloys 2 were prepared respectively ~22; Among them, the atomic percentage among Ni, Co, Fe, Cr, Al and Nb is shown in Table 3.

[0050] table 3

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com