Molybdenum-containing nickel-saving austenitic stainless steel with excellent corrosion resistance and manufacturing method thereof

A technology for austenitic stainless steel and its manufacturing method, which is applied in the field of nitrogen-containing nickel-free austenitic stainless steel and its manufacturing, and can solve the problems of reducing corrosion resistance and negative corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

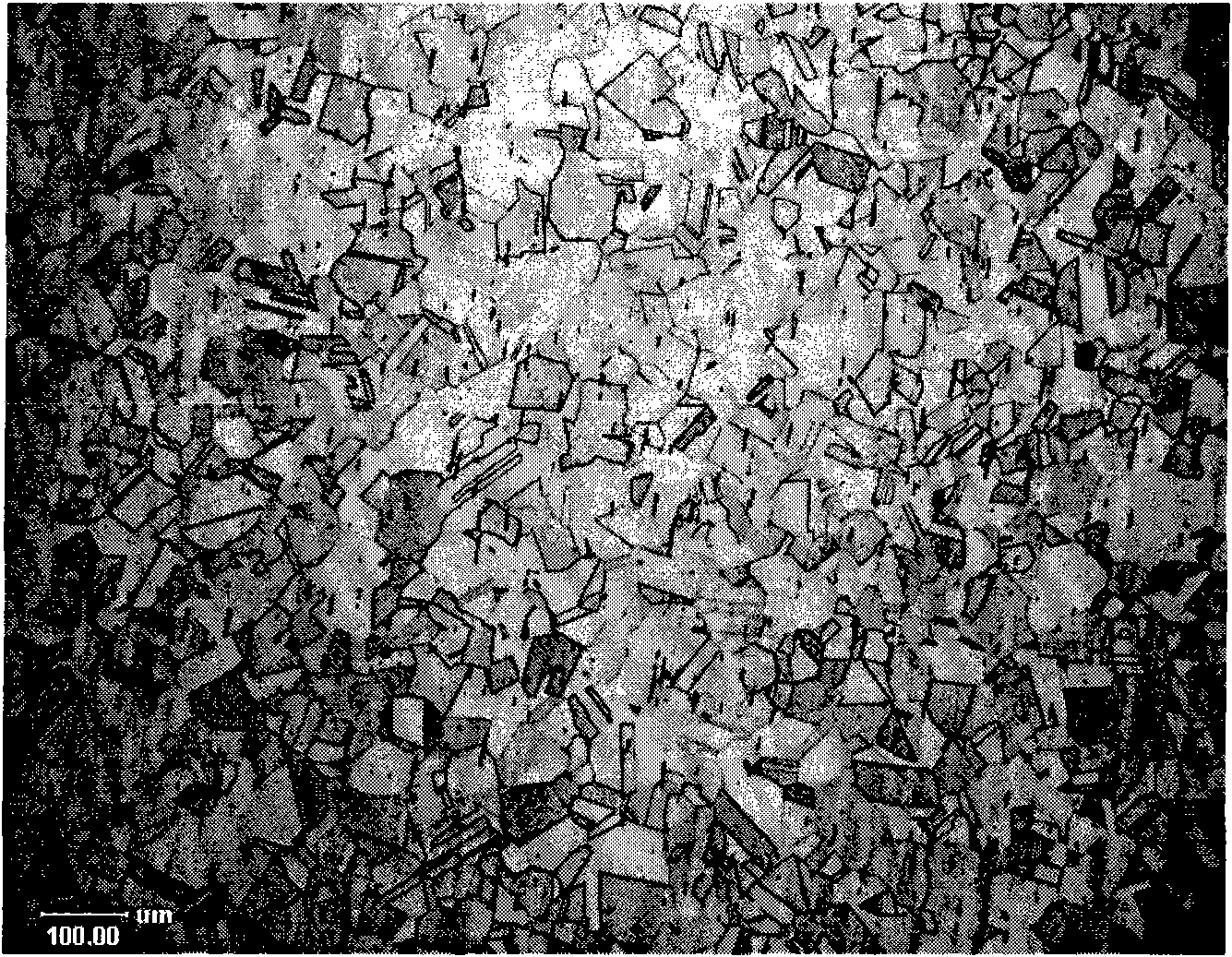

[0048] The alloy metallographic diagram of embodiment 1 is as figure 1 As shown (austenite structure at room temperature), the sample was electrolytically corroded, the etchant was saturated oxalic acid solution, and the corrosion current was 0.2-0.4A / cm 2 . Table 2 shows the mechanical properties and corrosion properties of the steels of the present invention and comparative steels. The mechanical properties are taken from the hot-rolled annealed sheet, which is processed and tested according to JIS 13B standard. The pitting corrosion resistance equivalent is calculated according to the general formula PREN=Cr%+3.3Mo%+30N%-Mn%.

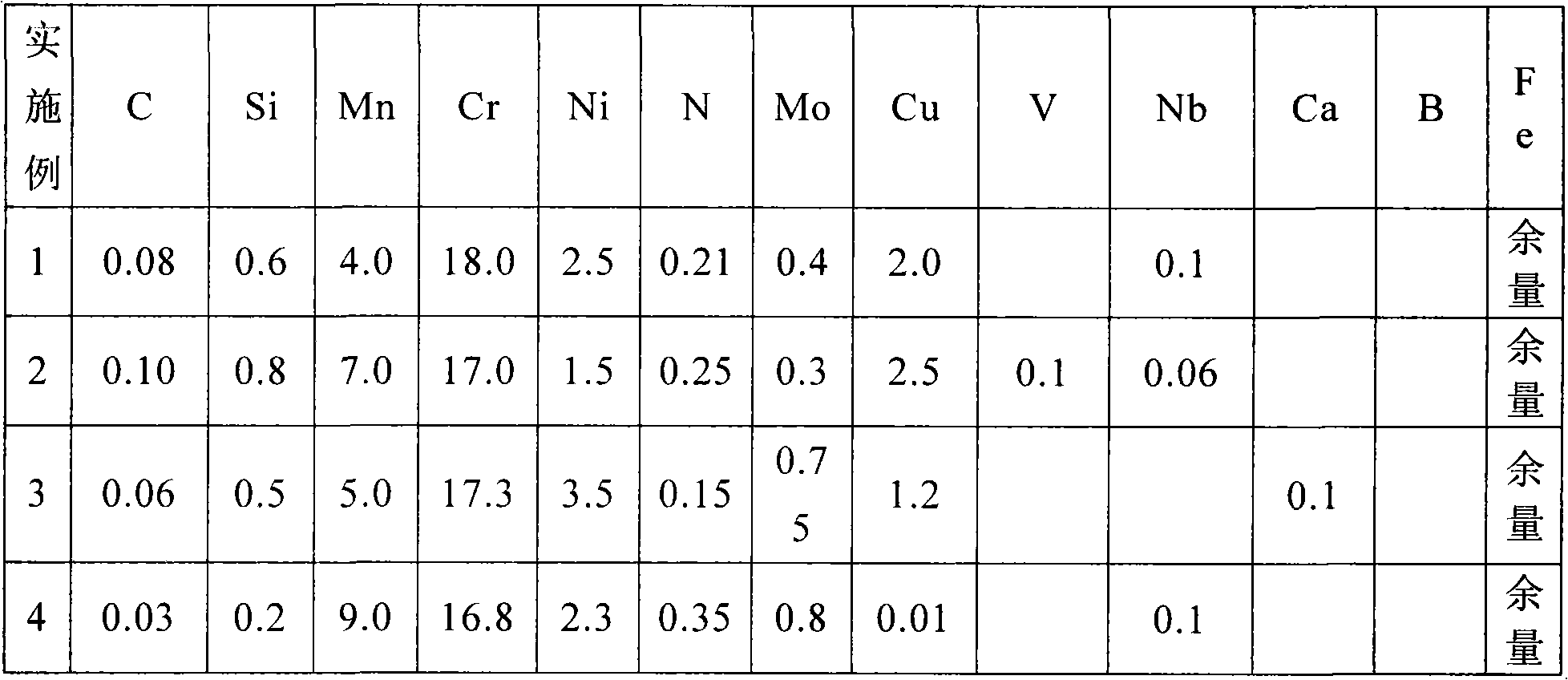

[0049] The composition unit of table 1 embodiment and comparative example: weight percent

[0050]

[0051]

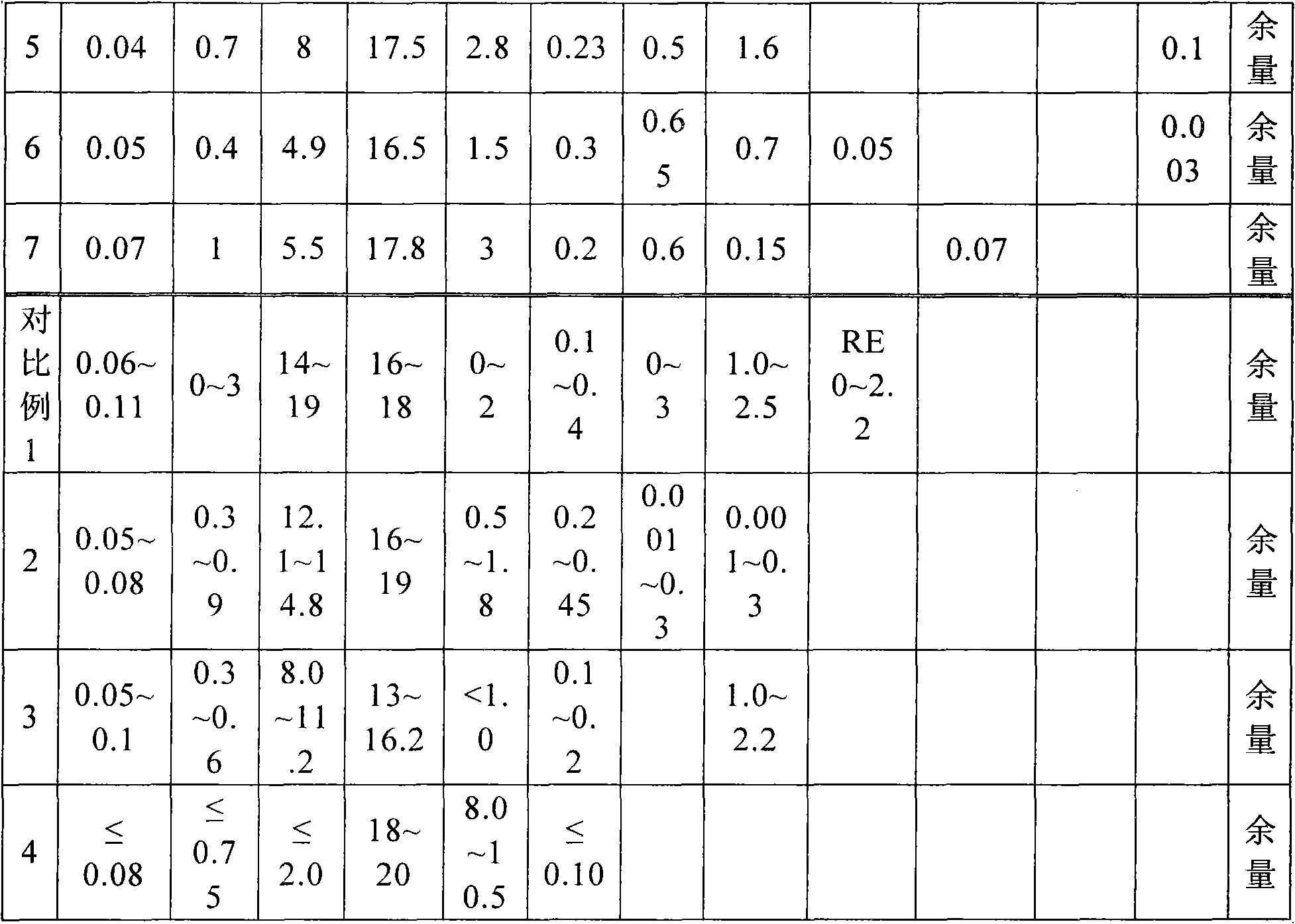

[0052] The performance of table 2 embodiment and comparative example

[0053]

[0054] Note: Comparative examples 1, 2, 3, and 4 are respectively CN101148740, CN101381852, CN101509104, and 304 austenitic s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pitting potential | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com