Method and apparatus for recovering PGM and ferro-chrome from PGM bearing chromite ore

A chromite and alloy technology, applied in lighting and heating equipment, furnace types, furnaces, etc., can solve problems such as discarding chromium, and achieve the effect of energy saving and easy beneficiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

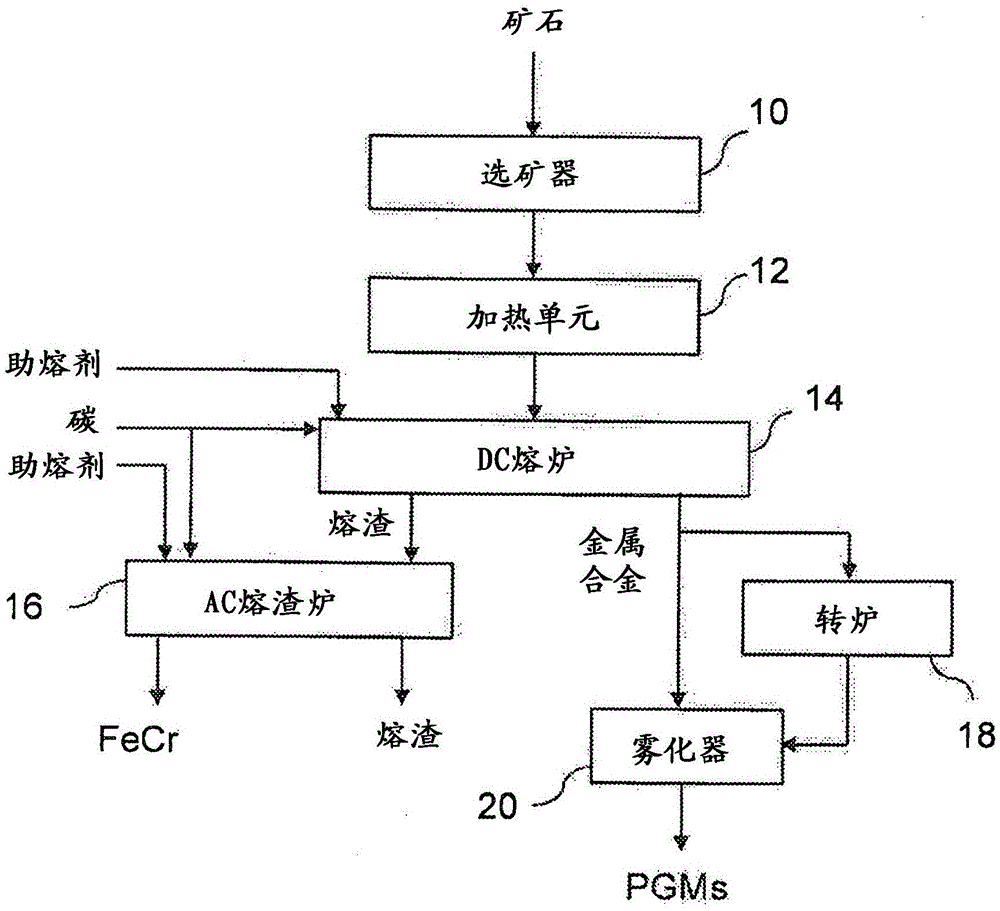

[0030] The chromite containing PGM is finely ground to release the PGM particles. The already finely ground ore is beneficiated in a concentrator 10 where the goal is to remove the gangue while leaving iron, chromium, base metals and PGM in the concentrate. This method is simpler than beneficiation methods currently used in PGM recovery because there is no need to separate chromium and iron from the base metal and PGM.

[0031] The concentrate is thermally treated in the heating unit 12 , wherein it is dried (when required) and possibly preheated before being fed to the furnace 14 . The heating unit 12 can be, for example, a fluidized bed reactor, a rotary kiln or a drying tower. When the raw material contains large amounts of sulfides and / or volatiles, roasting can be performed in the heating unit 12 in order to oxidize the metal sulfides. The CO gas produced in the subsequent melting and slag furnaces 14 , 16 can be used as a heat source in the heating unit 12 .

[0032] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com