Ferritic stainless steel for fuel cell bipolar plate, method for regulating and controlling surface roughness, method for forming passive film and application

A surface roughness, fuel cell technology, applied in fuel cell parts, fuel cells, anodizing and other directions, can solve the problems of poor corrosion resistance, uncontrollable growth and composition of passivation film, and difficulty in stamping. Effects of good elongation and deformability, dense and continuous, good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-21

[0099] Ingots were prepared according to the ferritic stainless steels of different steel grades shown in the above table 1, wherein, the corresponding relationship between the ingots of each embodiment and the ferritic stainless steels of different steel grades is shown in Table 2, and the ingots are obtained by opening the ingot to 100mm The stainless steel plate is then hot rolled, the heating and holding temperature is 1200 °C, the holding time is 2h, the opening rolling temperature is controlled at 1100 °C, and the rolling is carried out to 3mm after 8 passes, and the final rolling temperature is controlled at 800 °C. After hot rolling, annealing treatment is carried out, the annealing temperature is 1050°C, and the holding time depends on the size of the hot rolled coil, and pickling treatment is carried out after hot rolling. After that, take out the air cooling, and then perform cold rolling to make a foil of the required thickness, and then perform an annealing treatme...

Embodiment 22-30

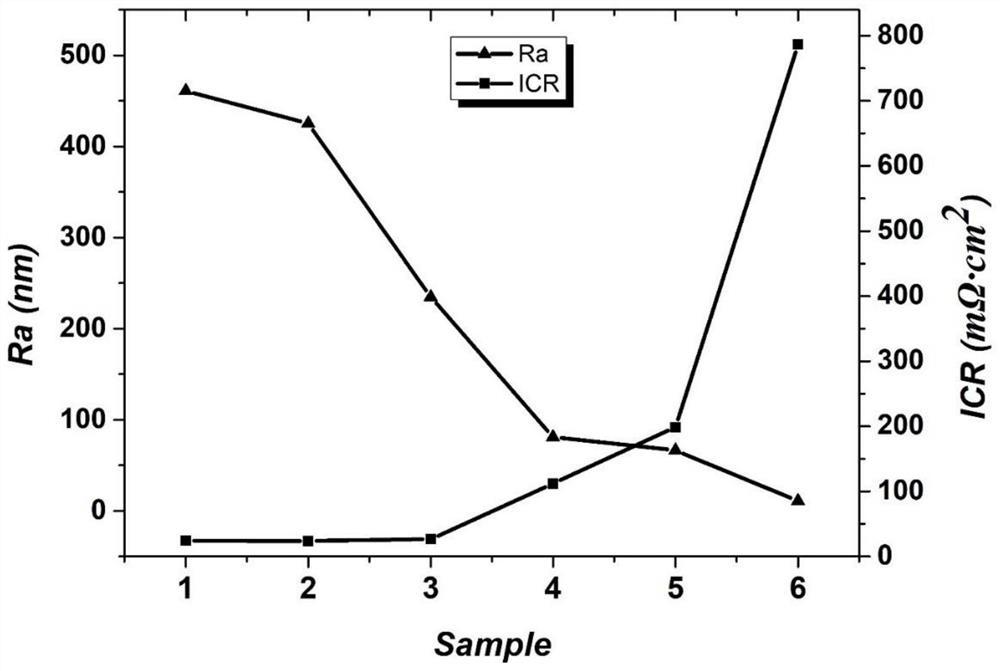

[0127] The difference from Example 1 is that electrochemical passivation treatment is performed with different parameters, and the analysis and evaluation are carried out according to the same method as Example 1. The electrochemical passivation conditions and test results of Example 1 and Examples 22-30 shown in Table 5.

[0128] table 5

[0129]

[0130]

[0131] Note: Example 30 in Table 5 is a bare sample, and on the basis of Example 1, no electrochemical passivation is performed.

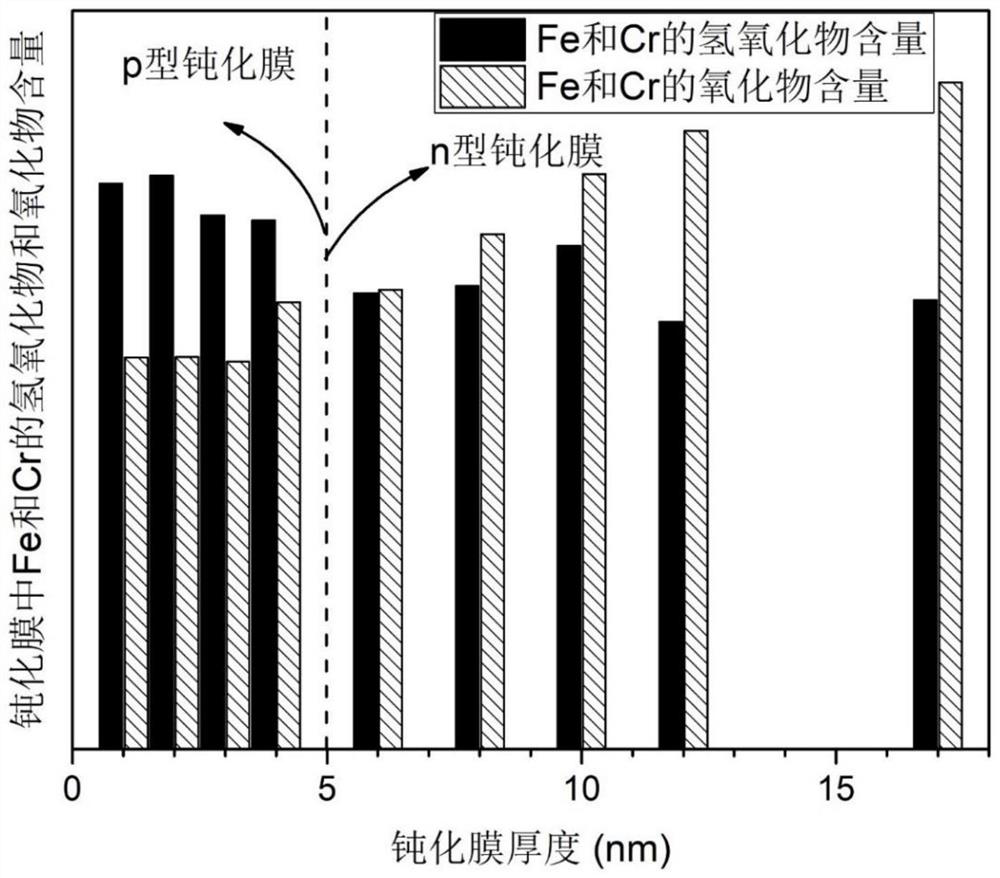

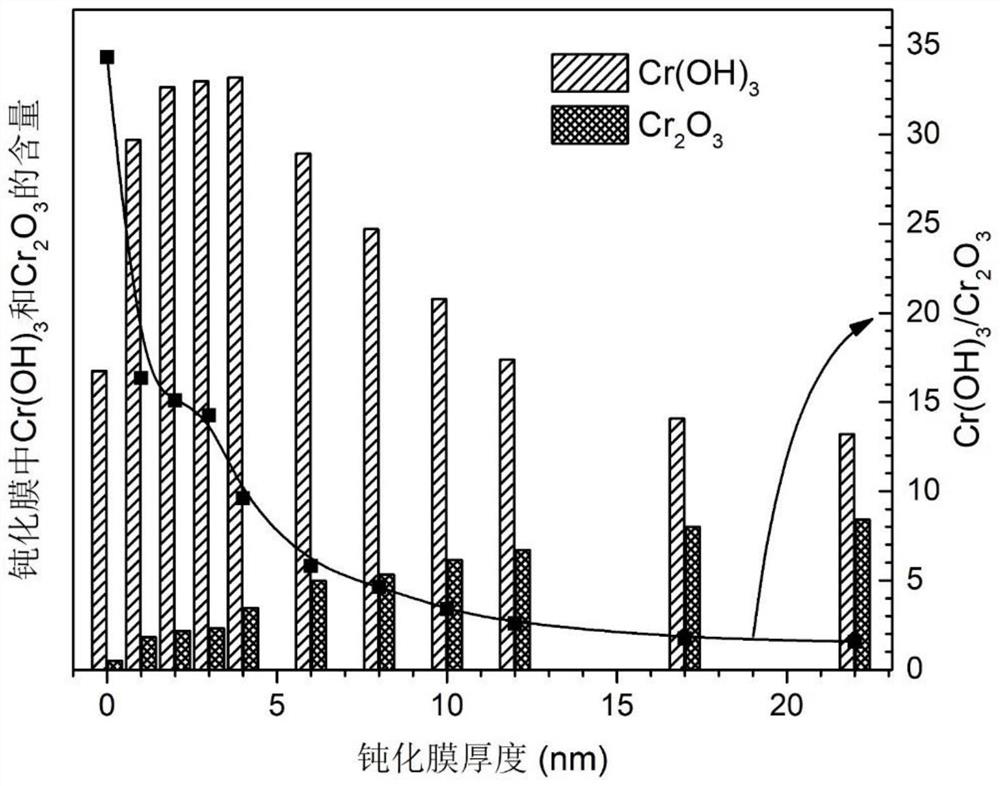

[0132] It can be seen from Table 4 that by adjusting the parameter conditions of electrochemical passivation, such as nitric acid concentration, temperature, potential and passivation time within the specified range, the performance of the passivation film can be further improved. Among them, the test results of the stainless steel sample of Example 1 after serving in the fuel cell environment for a period of time show that the passivation film can not only reduce the contact resistance ...

Embodiment 31-37

[0141] The difference from Example 1 lies in the steel grade, whether the surface roughness treatment is carried out, and whether the electrochemical passivation treatment is carried out. The results are shown in Table 5. Specifically, the surface roughness treatment may be directly performed after step (1) without electrochemical passivation treatment; the electrochemical passivation treatment may also be directly performed after step (1) without surface roughness treatment; Surface roughness treatment and electrochemical passivation treatment can also be performed in sequence after step (1);

[0142] Among them, the conditions of roughness treatment are: room temperature (25 ° C), H at 3 mol / L 2 SO 4 The samples were polarized at 10 V for 50 s in solution.

[0143] The conditions of chemical passivation treatment are: 1.6mol / LHNO at 40°C for the steel sheet obtained after the above roughness treatment 3 In solution, electrochemical passivation was performed at an anode vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com