A crmo series gear round steel

A round steel and gear technology, applied in the manufacturing field of CrMo series gear round steel, can solve the problem of high production cost of gear steel, and achieve the effect of reducing internal oxidation tendency, reducing production cost and improving competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with embodiment the present invention is further described.

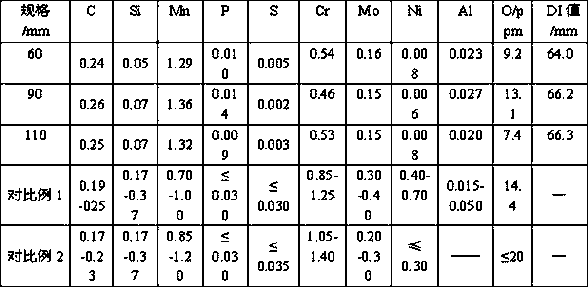

[0012] A Cr-Mo series gear round steel, its composition and weight percentage (Wt%) are: C: 0.22-0.27%, Si: 0.03-0.12%, Mn: 1.20-1.45%, S≤0.020%, P≤ 0.020%, Cr: 0.30-0.60%, Mo: 0.10-0.18%, Al: 0.015-0.040%, Ni≤0.10%; residual element O≤15×10 -6 , the rest is Fe and some other trace residual elements. At the same time, in order to ensure the hardenability, the DI value in the steel is controlled within the range of 50-70mm through narrow-band control of the chemical composition.

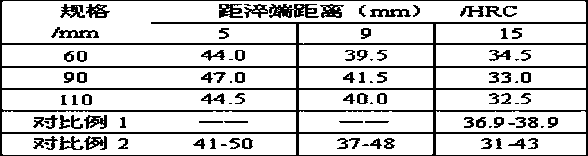

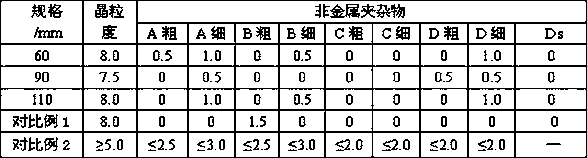

[0013] According to the composition design of the plan, converter smelting, LF refining, RH refining and continuous casting of blooms are adopted. The smelted steel billets are heated and rolled into 60mm, 90mm and 110mm round steel, of which 90mm and 110mm round steel After rolling, it is hung into the slow cooling pit and slowly cooled to below ≤200°C before exiting the pit. The chemical composition, perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com