Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70results about How to "Eliminate Pollution Potential" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

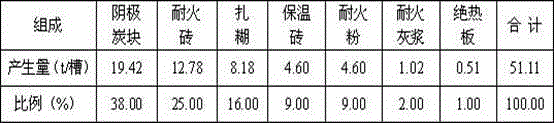

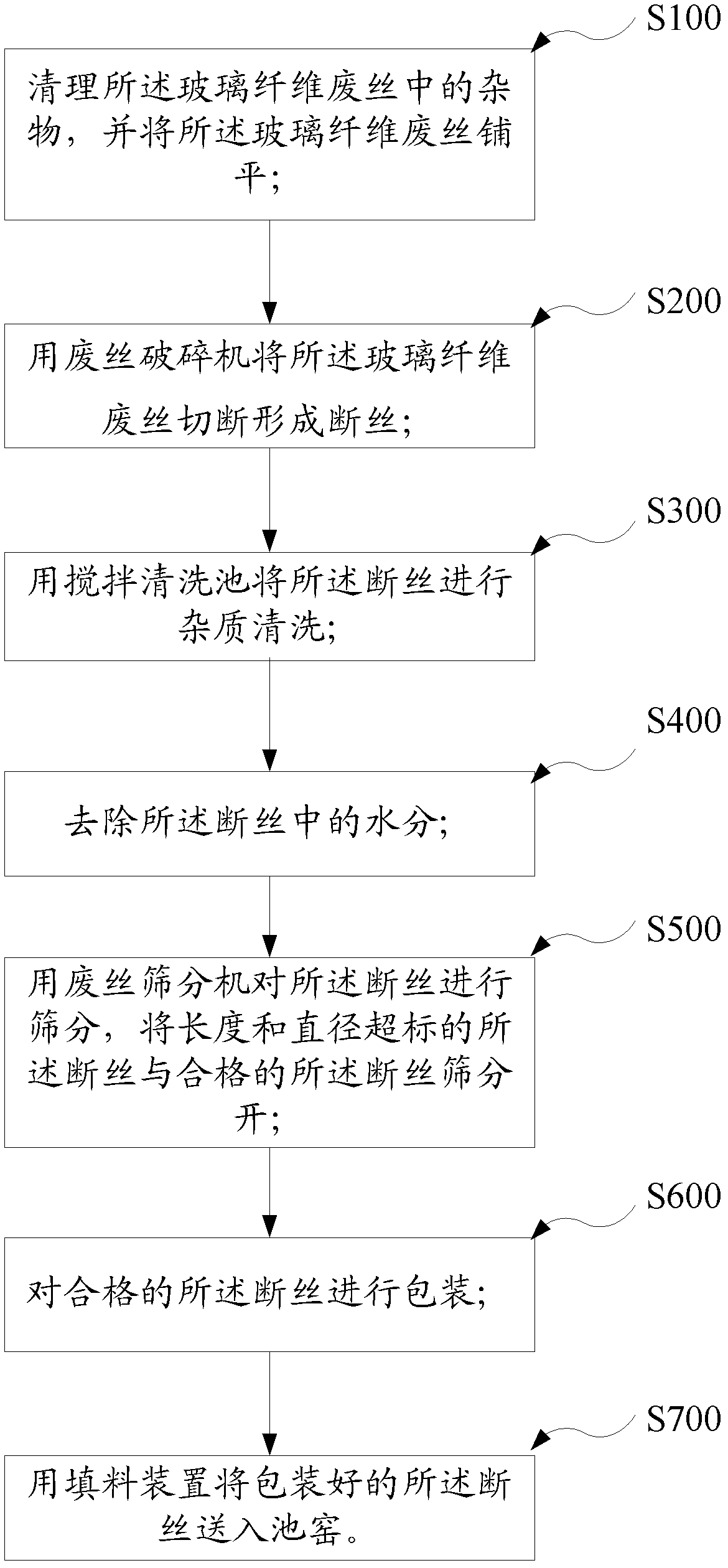

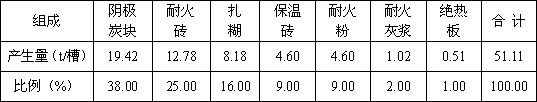

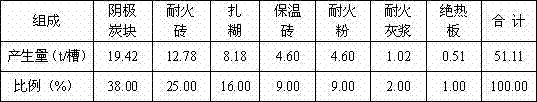

Deep comprehensive resource utilization method for electrolytic cell overhaul slag

ActiveCN102978659AHigh purityAchieve recyclingElectrolysis componentsSolid waste disposalMetallurgical slagBrick

The invention discloses a deep comprehensive resource utilization method for electrolytic cell overhaul slag. The method is characterized by comprising the following steps of: sorting electrolytic cell overhaul slag, respectively obtaining electrolyte blocks, cathode bars, waste cathode carbon blocks, waste refractory bricks, waste insulating bricks, waste heat-insulating plates, waste paste and residual mixed slag charge; respectively leaching the sorted blocks in water, crushing and leaching after the blocks are selected, recovering the selected blocks, grinding and floating the residual powder, selecting carbon powder and refractory material powder, and manufacturing a metallurgical slag former from the residual powder. According to the method, fluoride salts which are difficultly removed in the electrolytic cell overhaul slag are separated, the recycling value of the electrolytic cell overhaul slag is improved, waste materials are changed into valuable materials, economic and pollution-free recovery of the electrolytic cell overhaul slag is realized, and the pollution hidden danger is fundamentally eliminated.

Owner:周俊和 +1

Method for recycling overhauling slag waste cathode carbon blocks of electrolytic bath

ActiveCN102992298AHigh fluorine and sulfur contentAchieve recyclingCarbon preparation/purificationElectrolysisSlag

The invention discloses a method for recycling overhauling slag waste cathode carbon blocks of an electrolytic bath. The method is characterized by comprising the following steps: separating the overhauling slag of the electrolytic bath to obtain waste cathode carbon blocks; respectively conducting water leaching to the separated waste cathode carbon blocks, conducting secondary smashing and water leaching to the separated blocks, recycling the separated blocks, grinding and floating the rest powder, and separating carbon powder from the rest powder. According to the method, fluoride salt difficultly removed from the overhauling slag waste cathode carbon blocks of the electrolytic bath can be separated, the recycling value of the overhauling slag waste cathode carbon blocks of the electrolytic bath can be improved, the overhauling slag waste cathode carbon blocks of the electrolytic bath can be changed into valuables, the overhauling slag waste cathode carbon blocks of the electrolytic bath can be economically recycled without pollution, thereby fundamentally removing the hidden pollution hazard.

Owner:周俊和 +1

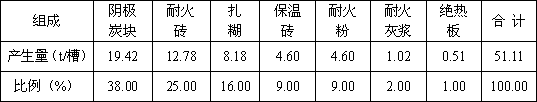

Method for promoting hydrolysis of sludge by using calcium peroxide and increasing effect of anaerobic digestion of sludge

ActiveCN103880259AEliminate Pollution PotentialImprove the efficiency of anaerobic digestionWaste based fuelBiological sludge treatmentBiogasAerobic digestion

The invention relates to a method for promoting hydrolysis of sludge by using calcium peroxide and increasing effect of anaerobic digestion of sludge, which comprises the following steps: 1)a calcium peroxide processing unit: placing the calcium peroxide in the sludge, wherein the mass ratio of calcium peroxide to sludge is 0.01: 1-0.6:1, reacting for 1-24 hours, and hydrolyzing the sludge; and 2)an anaerobic digestion unit: after processing the calcium peroxide, performing anaerobic digestion on sludge under the effect of anaerobe and amphimicrobe in an anaerobic digestion tank, rapidly using an organic compound in the sludge, conversing to methane, carbon dioxide and water, increasing the sludge biogas output and then realizing the quantitative reduction. Compared with the prior art, the method for promoting hydrolysis of sludge by using calcium peroxide and increasing effect of anaerobic digestion of sludge has the advantages of low cost, shortened digestion time and easy enforcement.

Owner:TONGJI UNIV

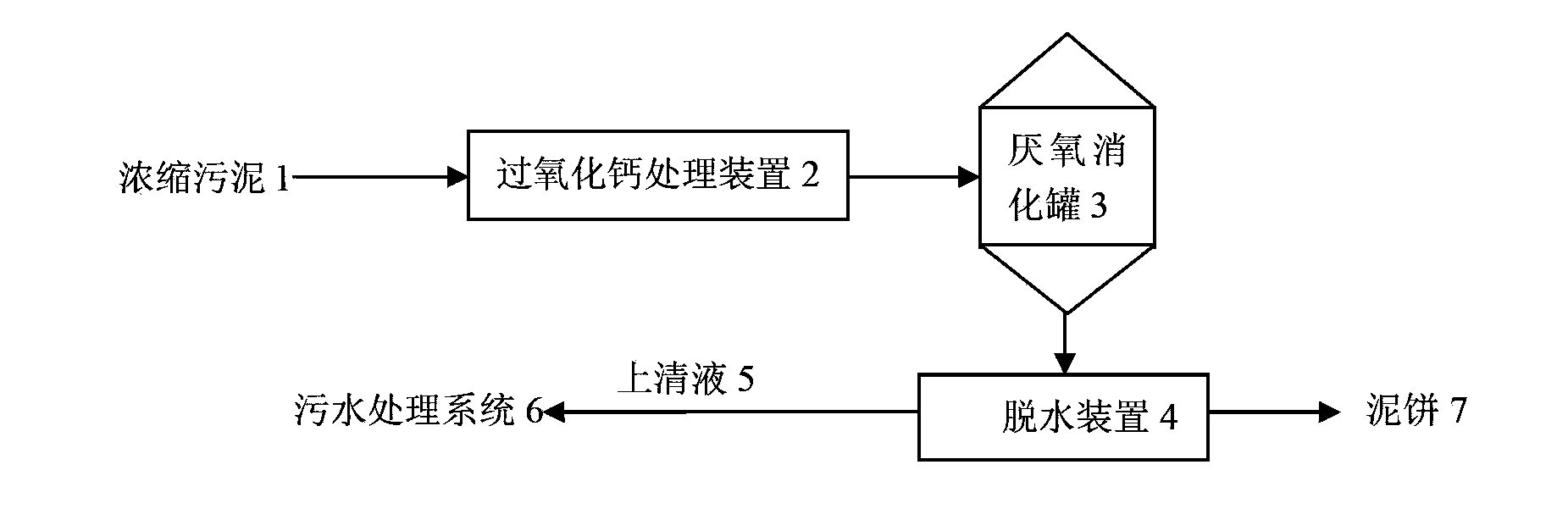

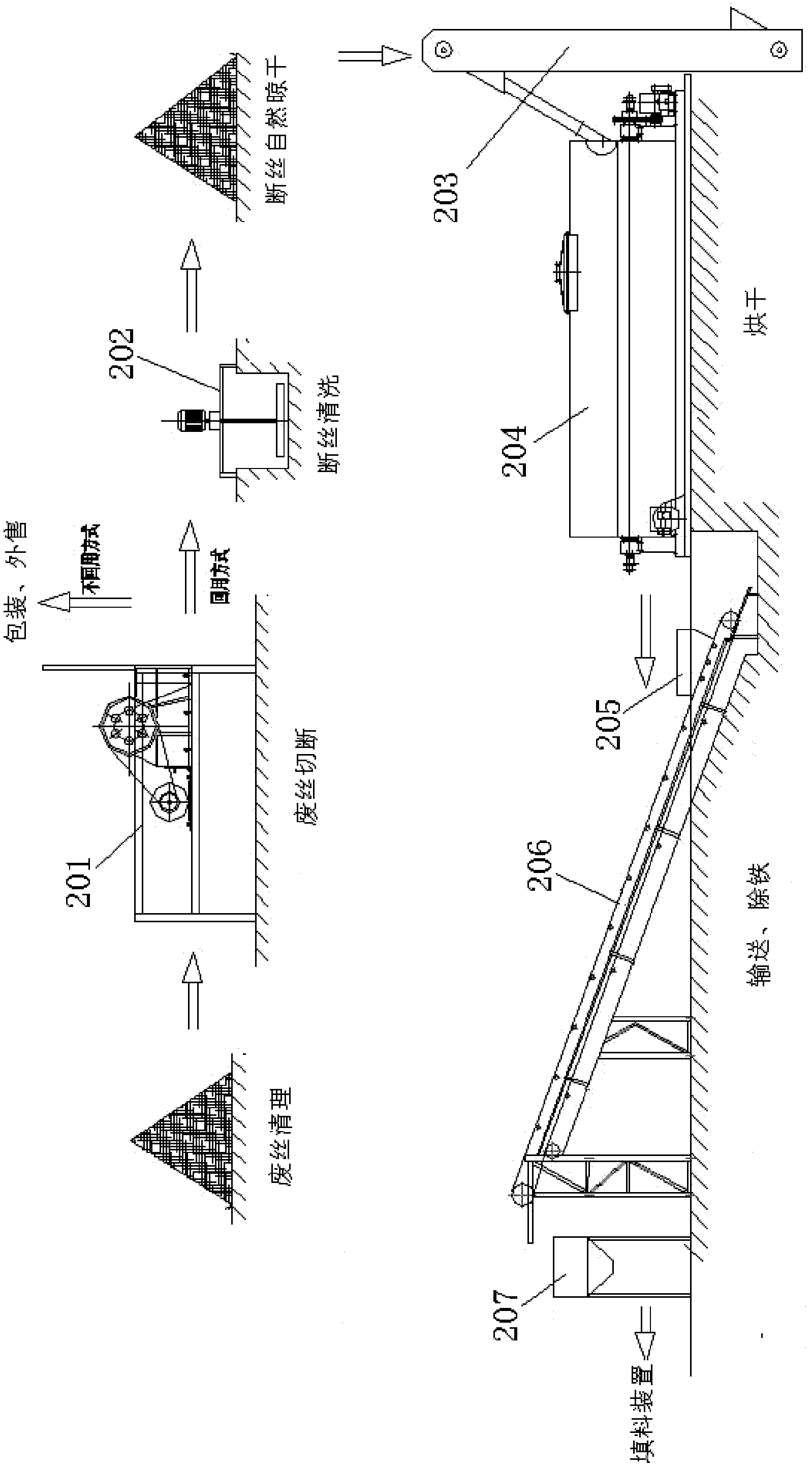

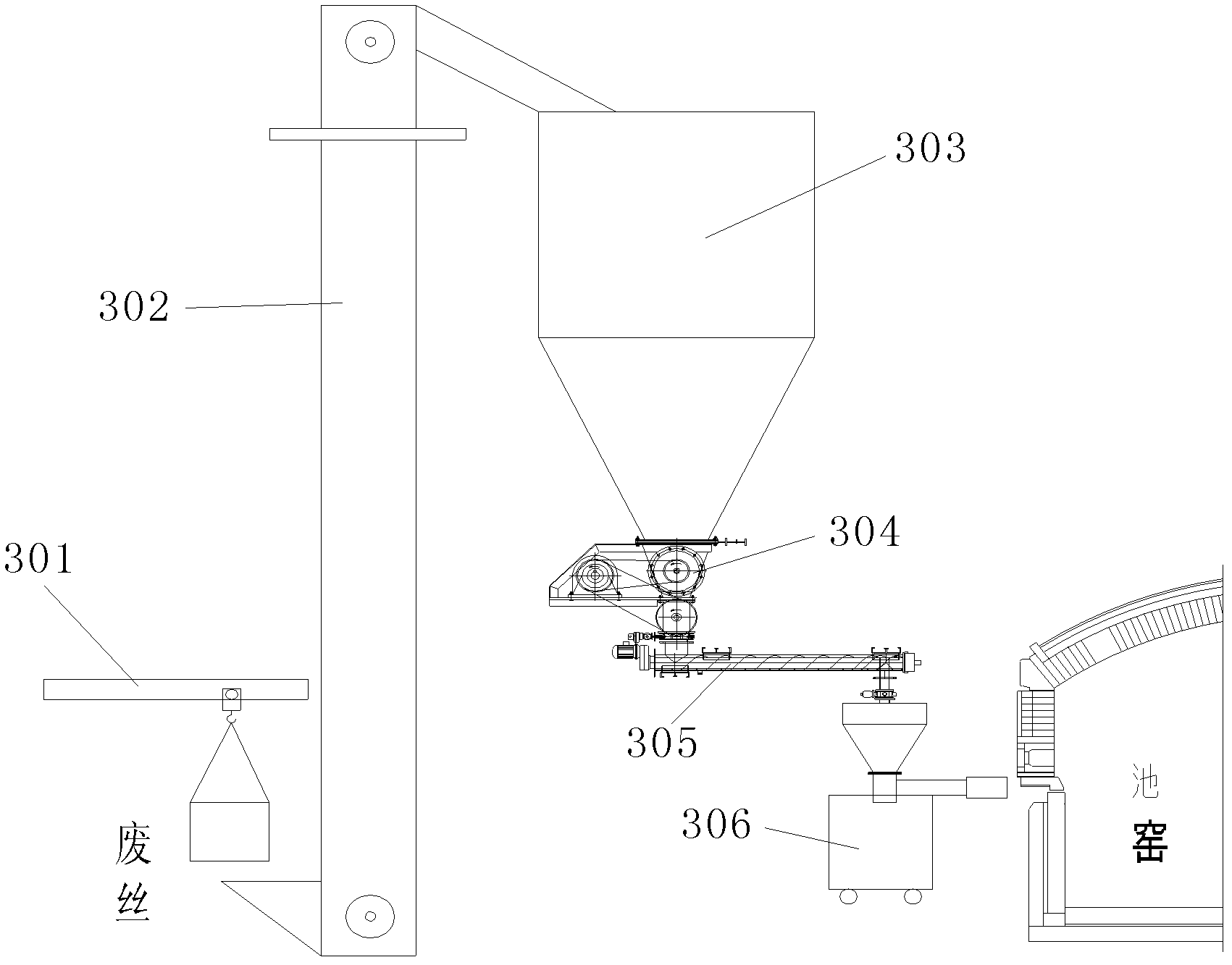

Recovery method for glass fiber waste silks

InactiveCN102489492AEfficient use ofSave raw materialsSolid waste disposalGlass fiberRecovery method

The invention discloses a recovery method for glass fiber waste silks. The recovery method for the glass fiber waste silks comprises the following steps of: 1) cleaning sundries in the glass fiber waste silks and paving the glass fiber waste silks; 2) cutting off the glass fiber waste silks by using a waste silk crushing machine so as to form broken filaments; 3) cleaning impurities of the broken filaments by using a stirring cleaning pool; 4) removing moisture in the broken filaments; 5) sieving the broken filaments by using a waste silk sieving machine, and separating the broken filaments with exceeding lengths and diameters from the qualified broken filaments; 6) packaging the qualified broken filaments; and 7) transmitting the packaged broken filaments into a tank furnace by using a filling device, wherein the method further comprises a step 41) of removing metal impurities in the broken filaments by an electromagnetic iron remover (205) between the step 4) and the step 5), wherein the broken filaments in the step 2) can be broken filaments with the lengths of not more than 30 mm. According to the recovery method provided by the invention, the production cost of the glass fiber can be reduced.

Owner:CHONGQING POLYCOMP INT

Stainless steel waste residue composite adsorbent and preparation method thereof

InactiveCN102836697AEfficient use ofIncrease profitOther chemical processesDispersed particle separationSorbentSulfur

The invention discloses a stainless steel waste residue composite adsorbent and a preparation method thereof. The stainless steel waste residue composite adsorbent is prepared from the following raw materials in parts by weight: 10-35 parts of cement, 50-70 parts of stainless steel waste residues, 5-15 parts of sawdust and 10-35 parts of water. The adsorbent can be taken as a desulfurizer for application to desulfurization in liquid or gas; and the sulfur capacity is more than or equal to 25 percent, and the compressive strength is more than or equal to 50N / cm. In the adsorbent, the stainless steel waste residues are utilized effectively, so that the utilization ratio of waste resources is increased, and the hidden trouble of environmental pollution caused by the stainless steel waste residues is eliminated simultaneously.

Owner:中国科学院唐山高新技术研究与转化中心

Method for treating chromic slag by acid pickling process

InactiveCN1635170AEliminate Pollution PotentialReduce processing costsSolid waste disposalProcess efficiency improvementAfter treatmentSlag

The invention relates to a method for treating chromic slag by acid pickling process. Wherein: mixing waste acid and chromic slag, leading supersonic wave into the acid tank by supersonic wave generator, discharging the acid liquor after treatment, deacidizing the hexavalent chromium ion in chromic slag to trivalent chromium ion completely by treating the acid liquor. The invention adopts resource method for treating chromic slag, and realizes innocuousness, resource-saving and economic benefit increasing.

Owner:刘克柱

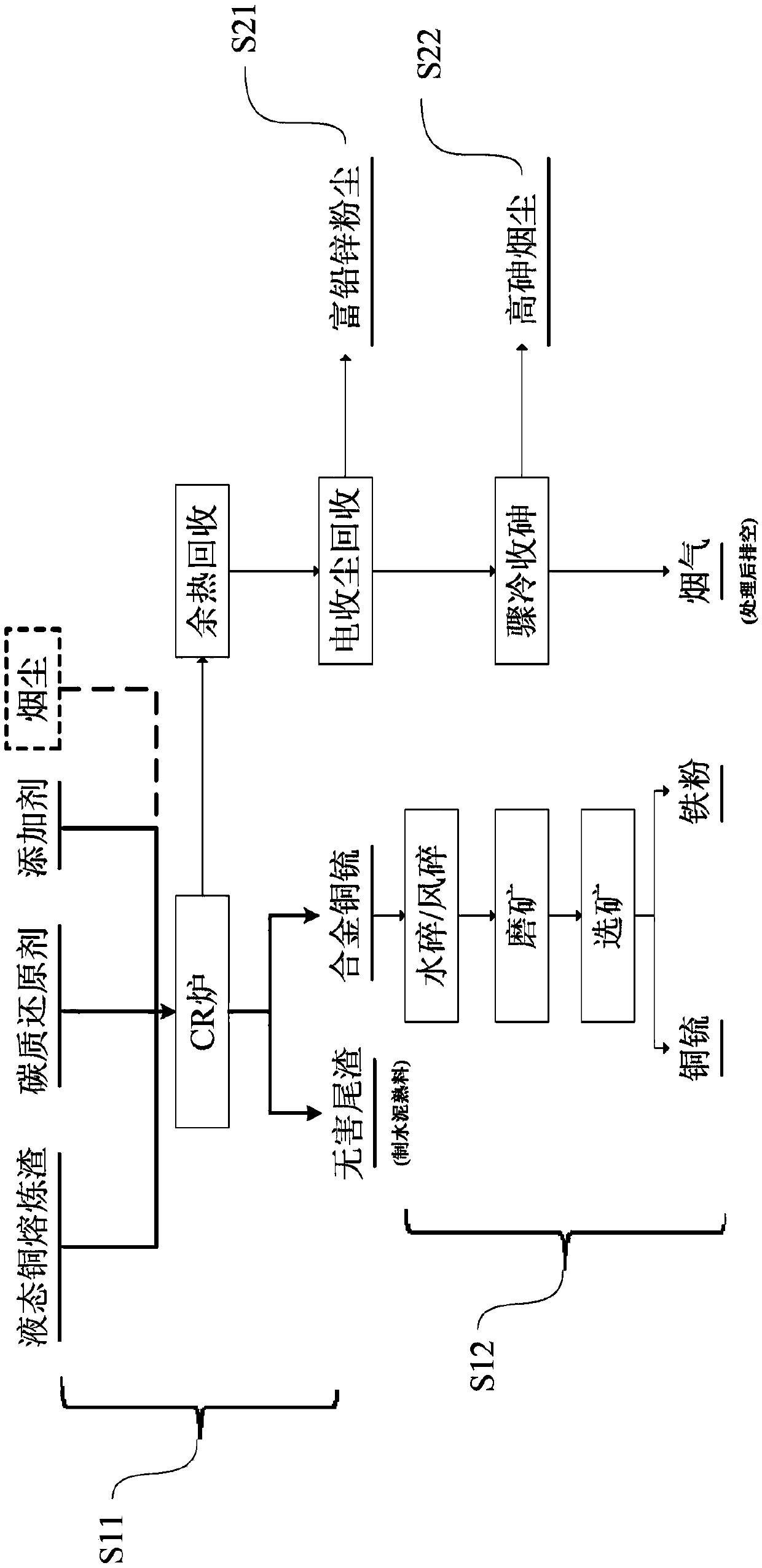

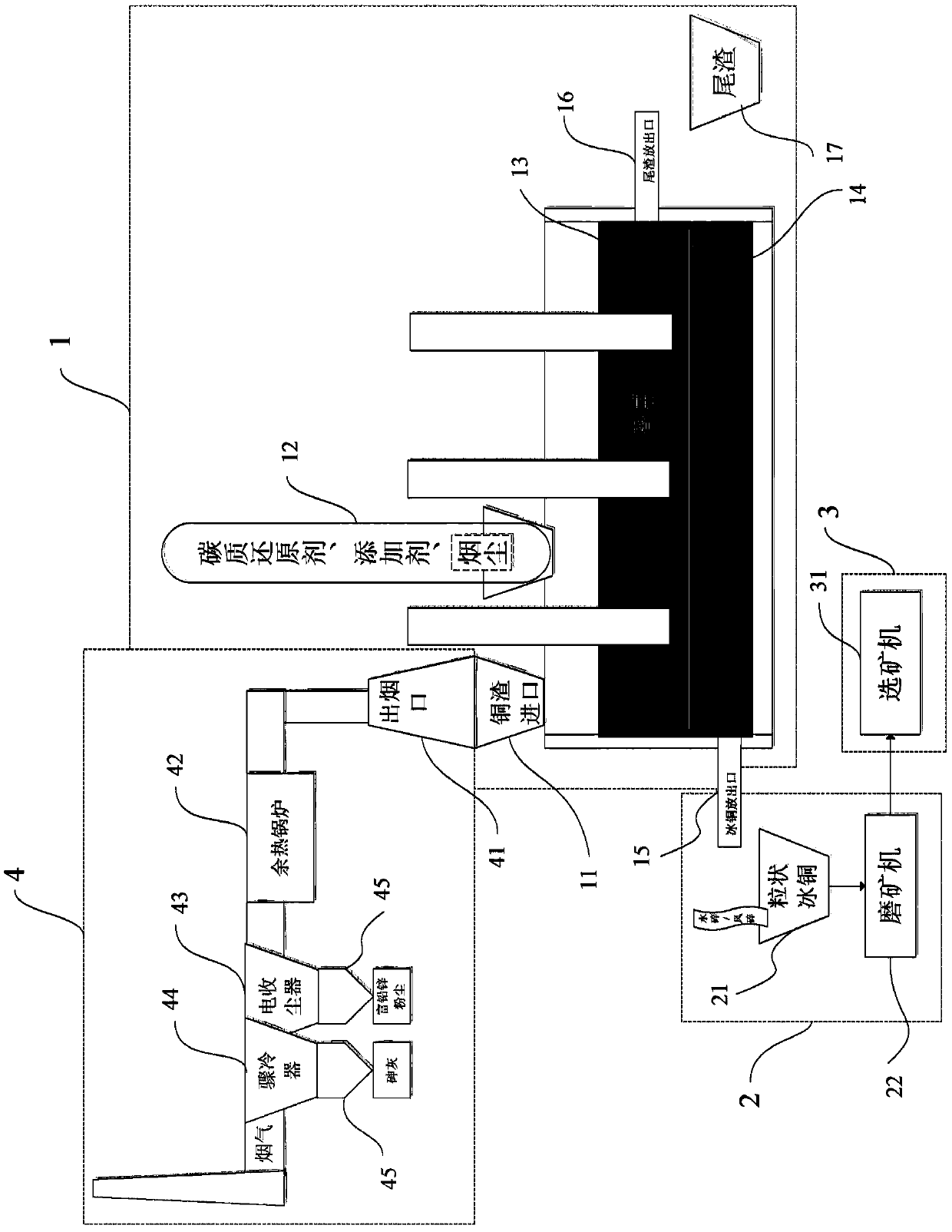

Copper slag processing system and method

InactiveCN109652660AAchieve full utilizationEliminate Pollution PotentialCement productionProcess efficiency improvementAlloyPower intensity

A copper slag processing method comprises the steps that S11, copper slag and carbonaceous reducing agents accounting for 3-20% of the mass of the copper slag are put into a comprehensive recycling furnace to be smelted, the operation temperature of the comprehensive recycling furnace is 1350-1550 DEG C, operation power intensity is 100-250 kW / m<2>; and S12, copper matte of the alloy phase discharged from the bottom of the comprehensive recycling furnace is subjected to ore grinding to the beneficiation standard after water crushing or wind crushing, and the copper matte with the copper content of 30-75 wt%, iron powder with the iron content of more than 80 wt% and tailings are produced after magnetic separation and / or flotation. The invention further provides a copper slag processing system. The smelting slag is processed through a copper slag resourceful treatment technology, smoke rich in lead and zinc is processed in a matched mode, and the effect that copper, lead, zinc, stibium and arsenic in the slag are decreased to be 0.3%, 0.1%, 0.15%, 0.01% and 0.005% or below separately.

Owner:CHINA ENFI ENGINEERING CORPORATION

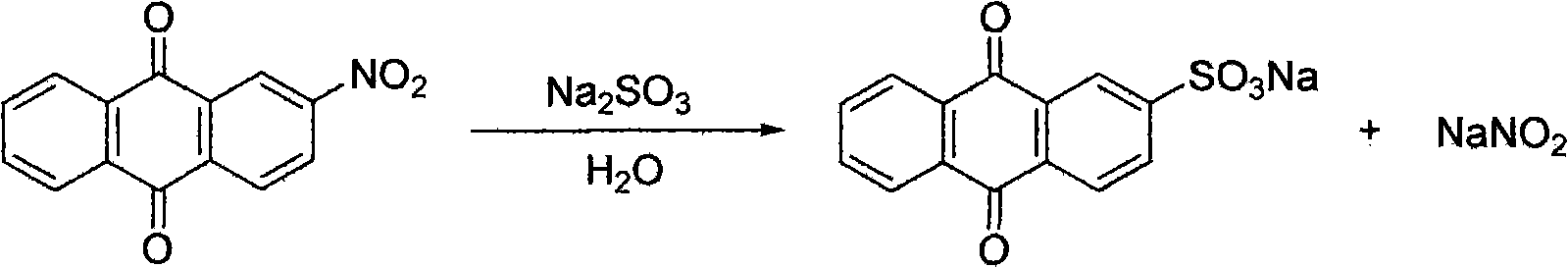

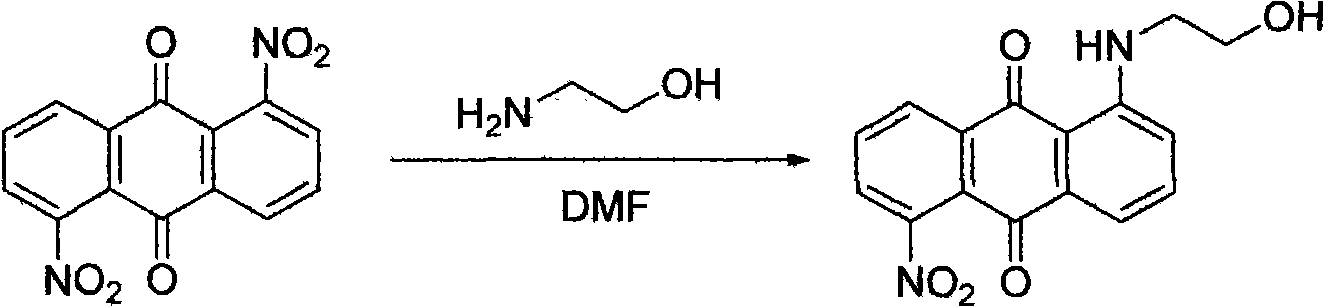

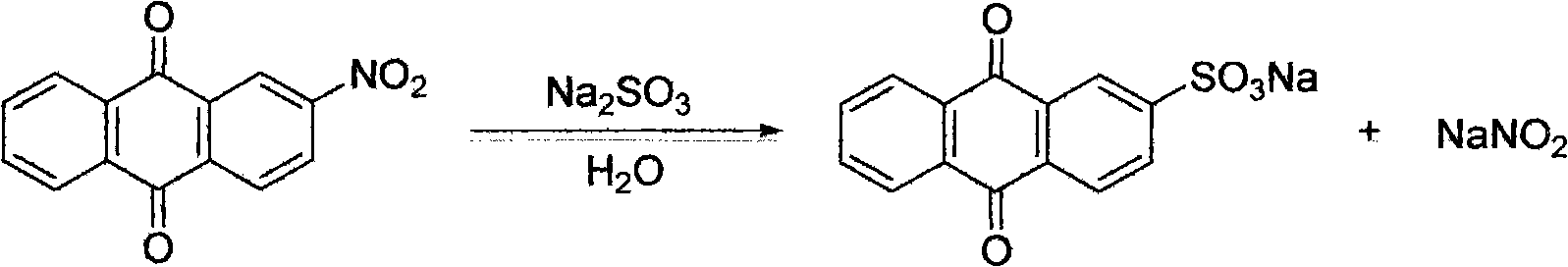

Novel process for controlling waste residue and recycling resources in 1-anthraquinone production

ActiveCN101838204AQuality improvementEasy to handleOrganic chemistryOrganic compound preparationN dimethylformamideSulfite salt

The invention discloses a process for controlling waste residue and recycling resources in 1-anthraquinone production, which comprises the following steps that: (1) waste residue, sodium sulfite and water are mixed and react so as to convert components of the waste residue which contain Beta-nitroanthraquinone into water-soluble substances to be removed by filtration, and a filter cake is dried for the next-step operation; and (2) the dried filter cake reacts with an organic amine, is cooled and crystallized in N, N-dimethylformamide, the 1,5-, 1,8-dinitro-anthraquinone components are converted into organic amines, cooled and crystallized, removed together with the unreacted anthraquinone, and the product which contains 1-mitro-anthraquinone 88 percent is obtained after the crystal is collected. The process for controlling waste residue and recycling resources in 1-anthraquinone production effectively treats a large amount of solid waste residue produced in a solvent method 1-amino-anthraquinone process, obtains high-quality 1-nitro-anthraquinone, and can further process and produce 1-anthraquinone or other products.

Owner:YANCHENG OUHUA CHEM IND

Method for recycling slag slurry of overhauling groove slag of electrolytic cell

The invention discloses a method for recycling slag slurry of overhauling groove slag of an electrolytic cell. The method is characterized by comprising the following steps of a. sorting the overhauling groove slag of the electrolytic cell and selecting waste slag slurry; b. carrying out powder grinding on the waste slag slurry and carrying out floating selection to select carbon powder; drying and then calcining at a high temperature being 1700-1900 DEG C; and gasifying sodium fluoride and sulfur to obtain a high-purity carbon material. According to the method disclosed by the invention, fluoride salts which are difficult to remove in the waste slag slurry of the overhauling groove slag of the electrolytic cell are separated, so that the recycling value of the overhauling groove slag of the electrolytic cell is improved, and wastes are changed into valuable things; and the economical and pollution-free recycling of the overhauling groove slag of the electrolytic cell is realized and the hidden danger of pollution is radically eliminated.

Owner:周俊和 +1

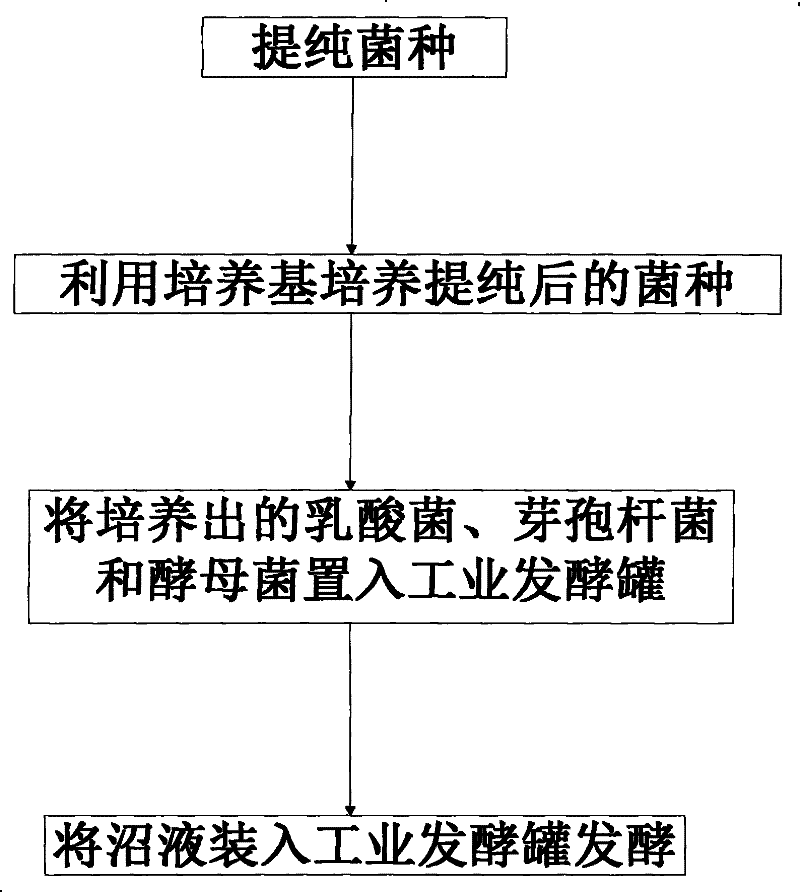

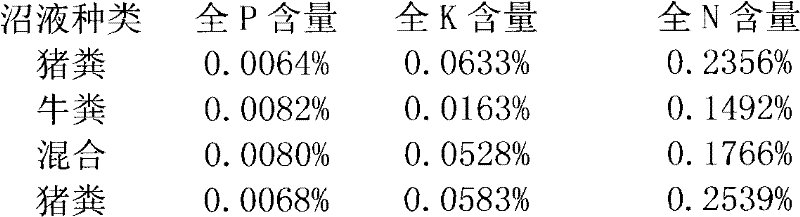

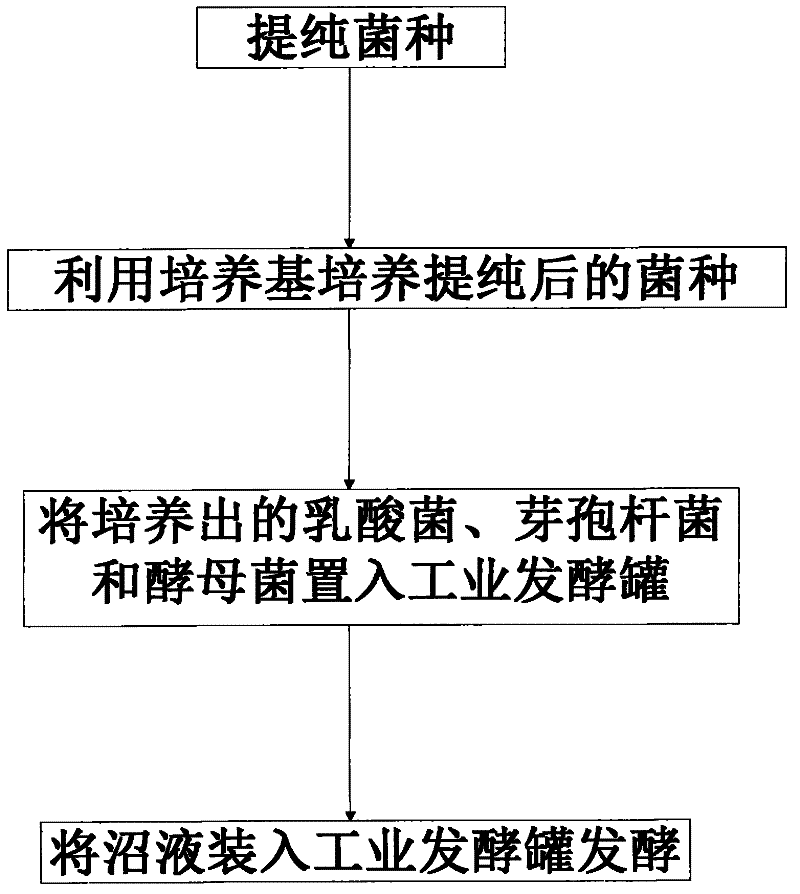

Biological liquid organic fertilizer and preparation method thereof

InactiveCN102531714AEliminate Pollution PotentialReduce alkalinityBio-organic fraction processingWaste based fuelSlurryINCREASED EFFECT

The invention discloses a biological liquid organic fertilizer and a preparation method thereof, belonging to the field of microbial fermentation. According to the preparation method, biogas slurry and biogas residue generated by a biogas digester are taken as a culture medium, lactic acid bacteria, bacillus and yeast are taken as beneficial microflora, the culture medium is used for culturing the beneficial microflora, and the biogas slurry, the biogas residue and the beneficial microflora are fermented for 72-96 hours in an industrial fermentation tank, wherein the fermentation temperature is at 60-70 DEG C. After the biogas slurry is prepared into the concentrated liquid high-efficient biological organic fertilizer, the concentrated liquid high-efficient biological organic fertilizer can be transported in a larger region, can be convenient to use and has the advantages of upgraded effect and reduced cost and the pollution hidden trouble caused by direct use of the biogas slurry is eliminated. The biological liquid organic fertilizer prepared by the method can reduce the alkalinity of soil, avoid the generation of white nitrate on the surface of land, loosen and soften soil so that the soil has good air permeability; moreover through application of the biological liquid organic fertilizer, crops can grow uniformly and vigorously the yield increasing effect is very obvious.

Owner:BEIJING HANHUA UNITED ENVIRONMENTAL PROTECTION TECH CENT

Manufacturing technique for geothermal floor base material and base material

InactiveCN106903773AFast heat conductionImprove insulation effectDomestic articlesFlat articlesFiberAdhesive

The invention belongs to the technical field of beaver board production and relates to manufacturing of floor base materials, in particular to a manufacturing technique for a geothermal floor base material and the base material. According to the manufacturing technique for the geothermal floor base material, the production technological process comprises the steps of wood chip forming, screening, water washing, stewing, hot grinding, applying of a non-formaldehyde adhesive and a waterproof agent, drying, applying of additives, paving, prepressing, hot pressing, cooling and grading packaging. According to the manufacturing technique for the geothermal floor base material, by adjusting the adhesive applying technique, aluminum oxide and carbon fiber powder are added in fibers, and thus the manufactured floor base material is free of formaldehyde and good in water resistance. The heat conductivity and size stability of the geothermal floor base material are improved, the hidden danger that formaldehyde pollution is released in the using process of composite geothermal floors is eliminated, the problems of deformation, arching, open joint contraction and the like during usage of the composite floors are reduced, the heat conductivity and the heat insulation of the geothermal floors are improved, and the energy consumption is reduced.

Owner:DARE WOOD BASED PANEL GRP

Recycle method of water recycled from overhaul slot slag of electrolytic cell

ActiveCN103028592AHigh purityAchieve recyclingSolid waste disposalWater/sewage treatment bu osmosis/dialysisSodium fluorideMetallurgical slag

The invention discloses a recycle method of water recycled from overhaul slot slag of an electrolytic cell. The recycle method is characterized by comprising the following steps of: carrying out water leaching on the overhaul slot slag of the electrolytic cell, so as to enable sodium fluoride in the overhaul slot slag of the electrolytic cell to be dissolved in water to remove fluorine in the overhaul slot slag of the electrolytic cell, recovering the water in the treatment by a reverse osmosis water treatment system, recycling separated clean water, and producing a metallurgical slag former by using obtained high-fluoride residue, so that the recycle of production water can be realized. According to the recycle method, fluoride salt which is hard to remove in the overhaul slot slag of the electrolytic cell can be separated, and the recycle value of the overhaul slot slag of the electrolytic cell can be improved, so that a waste material can be recycled, the overhaul slot slag of the electrolytic cell can be economically recycled without pollution, and the pollution hidden danger can be basically eliminated.

Owner:周俊和 +1

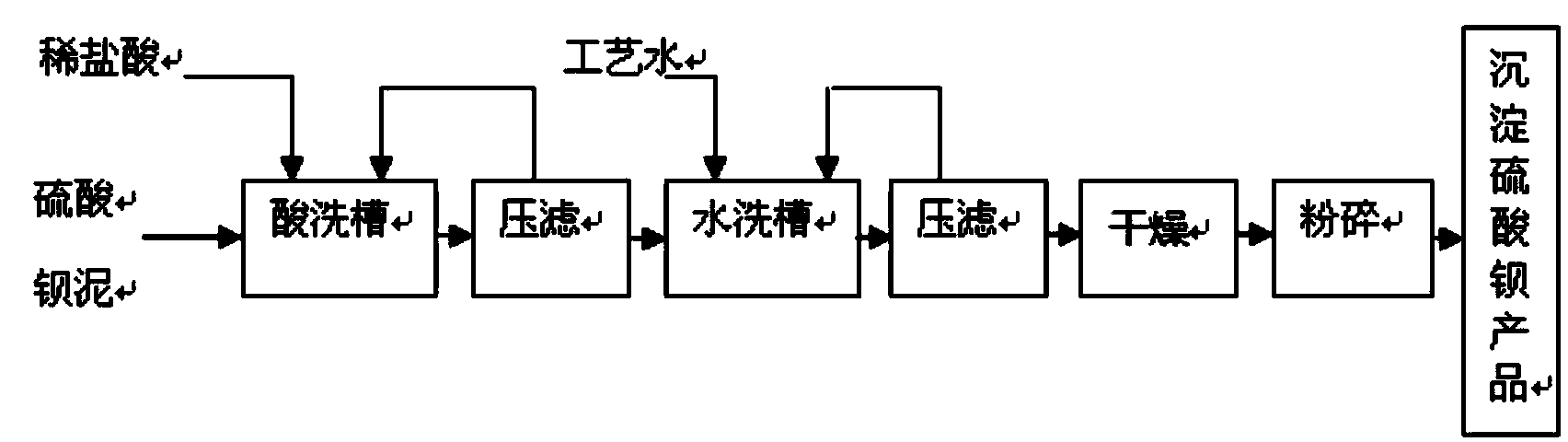

Method for producing barium sulfate from combination-process industrial ammonium chloride solid waste

InactiveCN103553110AImprove the economic efficiency of the enterpriseEliminate hidden dangers of environmental pollutionCalcium/strontium/barium sulfatesChemistryAmmonium chloride mixture

The invention relates to a method for producing barium sulfate from combination-process industrial ammonium chloride solid waste. The method comprises the following steps: (1) stirring and washing the combination-process industrial ammonium chloride solid waste, namely barium sulfate mud and a dilute hydrochloric acid solution in a pickling tank, then filter-pressing, and feeding filtrate to an industrial ammonium chloride production system to prepare a barium chloride solution when filtrate is recycled to be neutral, wherein the hydrochloric acid concentration is smaller than or equal to 25%; (2) stirring and washing a filter cake in the step (1) and process water in a rinsing bath, then filter-pressing, and feeding filtrate to the pickling tank to wash the barium sulfate mud when the filtrate is recycled to weak acidity; (3) drying and crushing the filter cake in the step (2), so as to obtain a precipitated barium sulfate product. By adopting the method, barium resources can be fully utilized; precipitated barium sulfate is produced in an attached manner; the economic benefits of an enterprise are improved; meanwhile, the solid waste barium sulfate mud in combination-process industrial ammonium chloride production can be thoroughly removed; a hidden danger of environmental pollution is also removed.

Owner:HUBEI SHUANGHUAN SCIENCE AND TECHNOLOGY STOCK CO LTD

Heavy metal contaminated soil humic acid green in-situ curing repair technology

InactiveCN109351769ARecovery functionAvoid Pollution HazardsContaminated soil reclamationMetalHumic acid

The invention discloses a heavy metal contaminated soil humic acid green in-situ curing repair technology. The technology comprises the steps that 1, when heavy metal contaminated soil is smashed, humic acid is added for in-situ reduction and curing, wherein the ratio of the humic acid to heavy metal is 5-30:1, and humic acid promotes soil granulated wrapping to prevent exudation and migration ofheavy metal in granules; and 2, after 24h of aging, 1%-3% of semi-cock bacterial manure is added into the reduced heavy metal contaminated soil to be mixed evenly, permanent reduction and fixing are achieved, and a soil planting function is achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

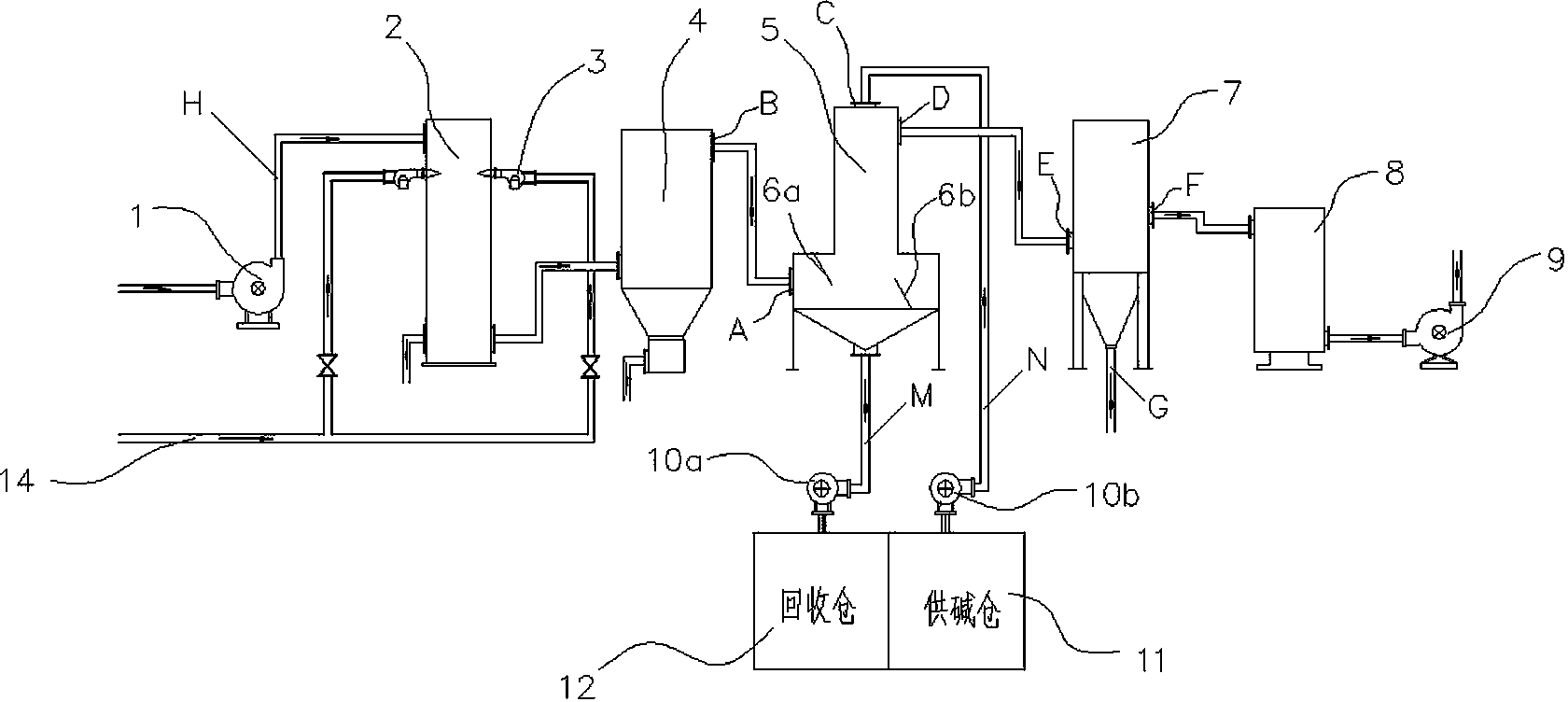

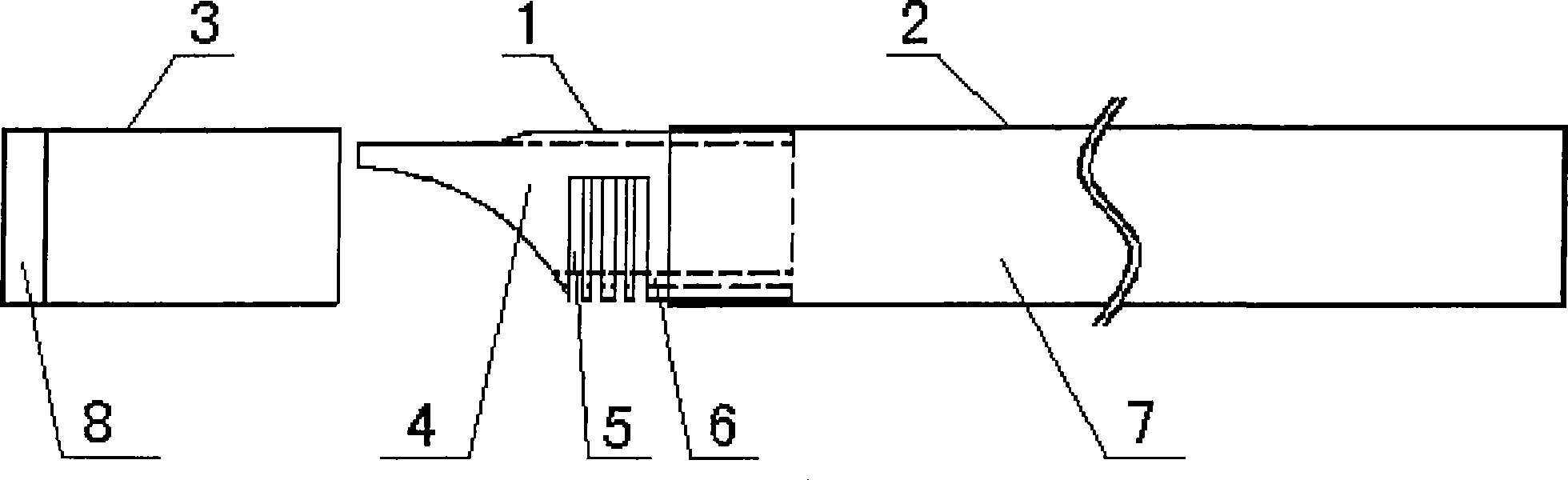

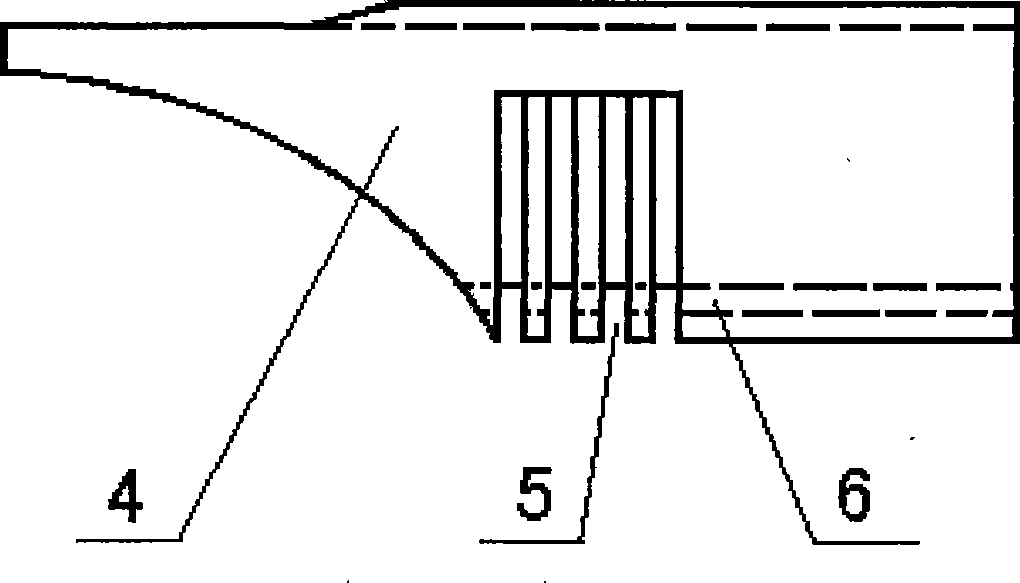

Waste gas dry purifying device for CVD (chemical vapor deposition) on-line function film plating

ActiveCN103017178AEliminate water pollutionLow running costCombination devicesIncinerator apparatusActivated carbonExhaust fumes

The invention relates to a waste gas dry purifying device for CVD (chemical vapor deposition) on-line function film plating. The device comprises an air source pipeline H, wherein the front end of the air source pipeline H is sequentially provided with a combustion chamber (2) and an ultrahigh temperature static dust remover (4), and the tail end of the pipeline is provided with an active carbon fiber purifier (8). The device is also characterized in that the pipeline is provided with a dry type deacidifying device (5) and a bag type dust remover (7). The device provided by the invention has the advantages that a dry purifying method is adopted, so the hidden hazard of water pollution caused by the existing wet purifying device is avoided, the running cost is reduced, and the service life of equipment is prolonged; the application prospect is wide, the combustible or non-combustible corrosive waste gas with complicated components and higher temperature can be purified and treated sufficiently and highly efficiently; and the film plating waste gas which has high temperature and acidity and contains dust, heavy metals and the like can also be treated, the purifying efficiency is high, and the purifying efficiency can reach more than 99.99%.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

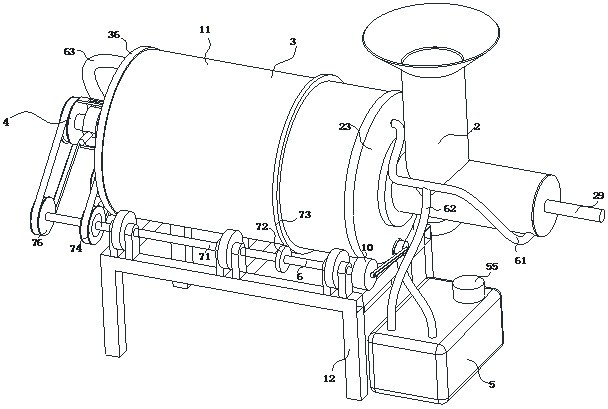

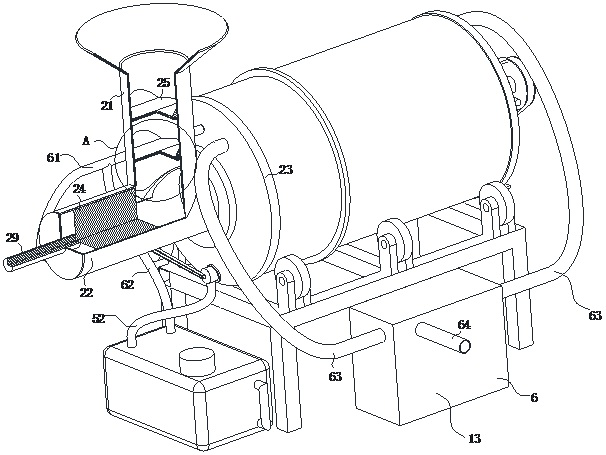

Microbial fermentation deodorization device applied to kitchen waste treatment

PendingCN112552085AEasy dischargeEliminate Pollution PotentialBioreactor/fermenter combinationsBiological substance pretreatmentsEnvironmental engineeringWaste treatment

The invention discloses a microbial fermentation deodorization device applied to kitchen waste treatment, which belongs to the technical field of kitchen waste treatment and comprises a low-speed motor, a fermentation kettle, supporting legs and a deodorization box, the motor is fixedly arranged on the supporting legs through a bracket, the deodorization box is fixedly arranged on the side edges of the supporting legs, and the fermentation kettle is fixedly arranged at the upper ends of the supporting legs, and comprises a feeding mechanism, a fermentation mechanism, a material returning mechanism, a water removal mechanism, a deodorization mechanism and a transmission mechanism, the feeding mechanism is fixedly arranged at the front end of the fermentation mechanism, the fermentation mechanism is rotatably connected to the upper ends of supporting legs through a plurality of rotating wheels, the supporting legs are fixedly arranged on the ground, and the water removal mechanism is fixedly arranged at the front ends of the supporting legs, the deodorization mechanism is fixedly arranged on the two ends of the fermentation kettle, the transmission mechanism is fixedly arranged on the edge of the upper end of the supporting leg, and the problems that an existing kitchen garbage disposal machine can emit foul irritant gas in the kitchen garbage disposal process, discharging is difficult, and feeding and cleaning cannot be continued are solved.

Owner:西安网浪互联网科技有限公司

Disposable pen

InactiveCN101422998ALow costSimple recipeWriting connectorsInk reservoir pensEngineeringInjection moulding

The invention relates to a disposable pen, which comprises a pen head, a pen ink cavity and a pen cap and is characterized in that the pen head is an integration structure of an injection molding pen nib and an ink storage part of a pen tongue and is communicated with the pen ink cavity internally injected with pen ink in a sealing way; the part from the pen nib to the ink storage part of the pen tongue is provided with a semi-closed type pen nib ink-supply capillary slit longitudinally along the axle center of the pen head, i.e., the front end of the pen nib is in a shape with middle slitting, the ink storage part of the pen tongue corresponds to the upper and lower parts of the pen nib ink-supply capillary slit and takes a closed shape; and the lower part of the pen nib ink-supply capillary slit is communicated with an air intake pipe arranged in parallel with the capillary slit, and the middle part of the pen head is provided with a ink storage semi-ring groove. The section of the air intake pipe is one shape of round, triangle or rectangle. The pen nib ink-supply capillary slit is internally provided with fiber fibroin. The pen nib ink-supply capillary slit which is arranged longitudinally is correspondingly and horizontally provided with an auxiliary capillary slit in a crossing way. The top inside the pen cap is provided with a pen nib pad which keeps the pen nib wet. The pen has simple structure, low cost, easy use and obvious effect.

Owner:李畅

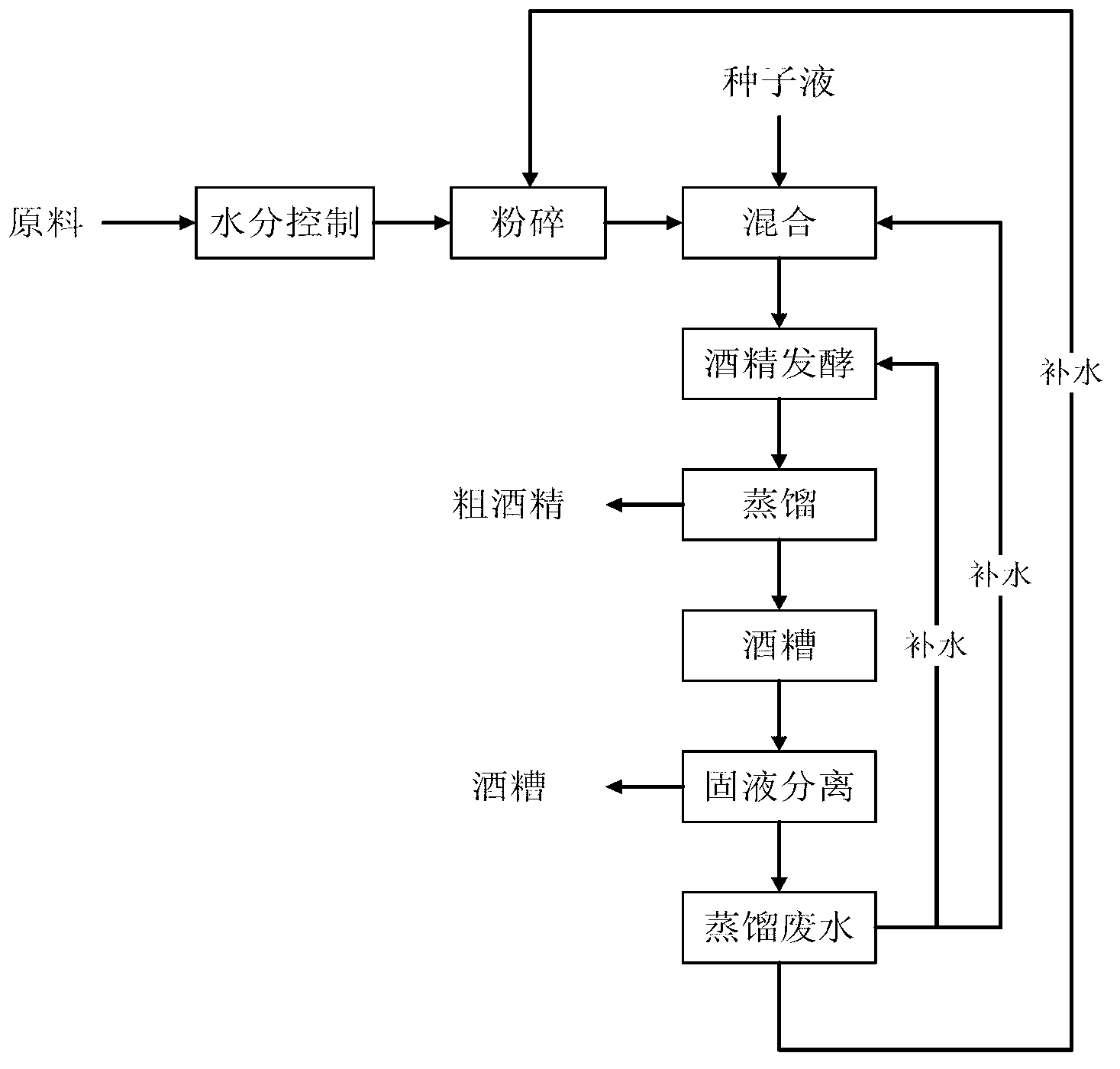

Alcohol production method by taking sugariness raw material as fermentation substrate

InactiveCN103266138AReduce construction landReduce construction costsBiofuelsMicroorganism based processesAlcohol productionEconomic benefits

The present invention relates to an alcohol production method by taking sugariness raw material as fermentation substrate, which includes: smashing the stored raw materials; adjusting the moisture of the smashed material by taking anaerobic wastewater as a moisture modulator; accessing well-cultivated yeast seed liquid and blending the liquid with the material for alcohol fermentation; distilling to get crude alcohol and a vinasse after fermentation; squeezing the vinasse; putting the obtained distilled wastewater into the smashed material for moisture modulation; accessing well-cultivated yeast seed liquid for alcoholic fermentation, and perform the next steps in cycle. In the present invention, the distilled wastewater is used as moisture modulator of the materials, which can significantly reduce water consumption in solid alcohol fermentation, and can realize zero discharge of wastewater to achieve significant environmental and economic benefits.

Owner:TSINGHUA UNIV

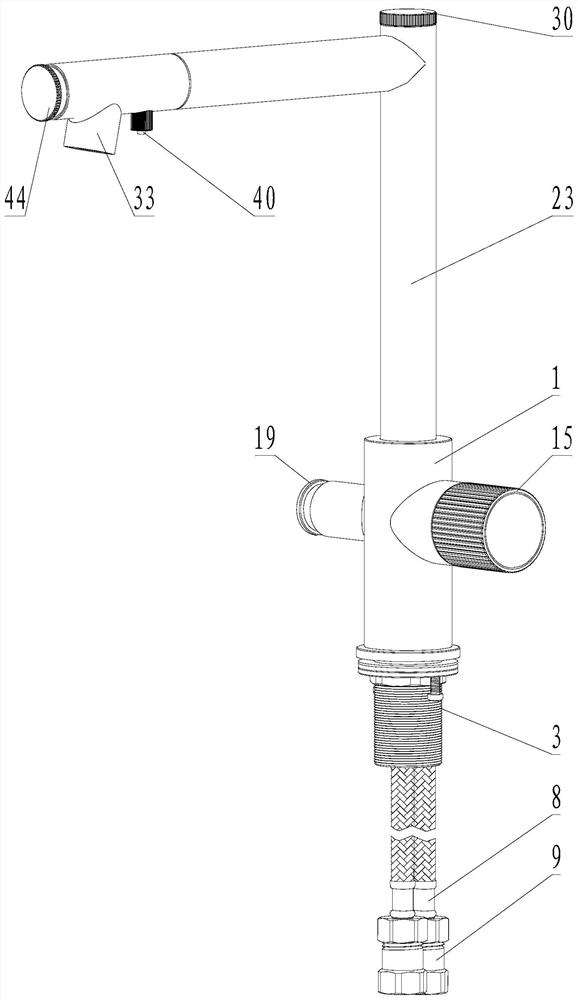

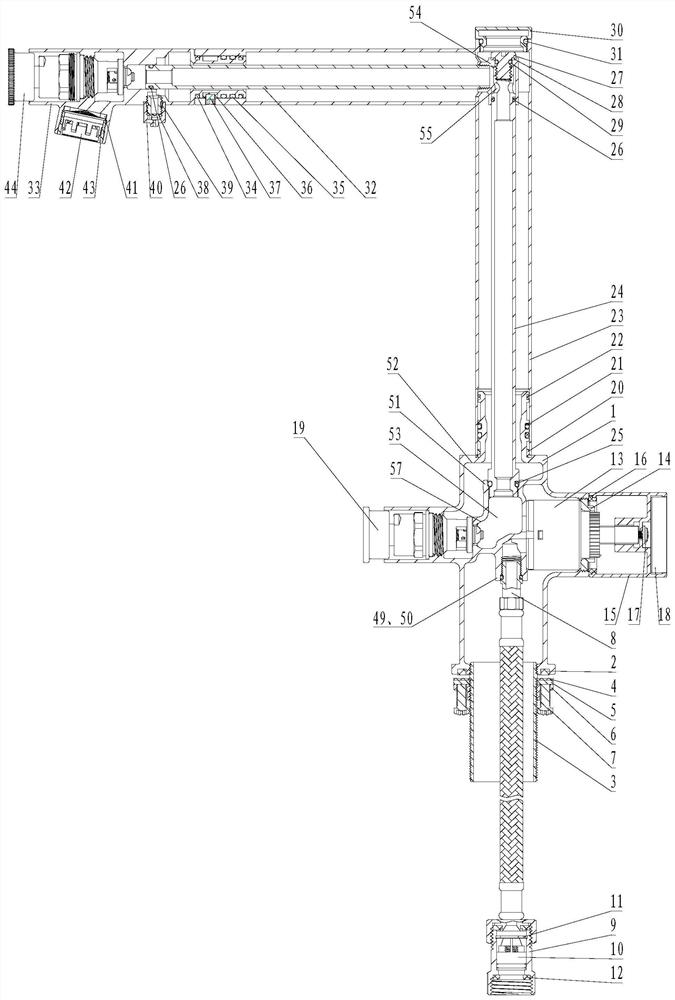

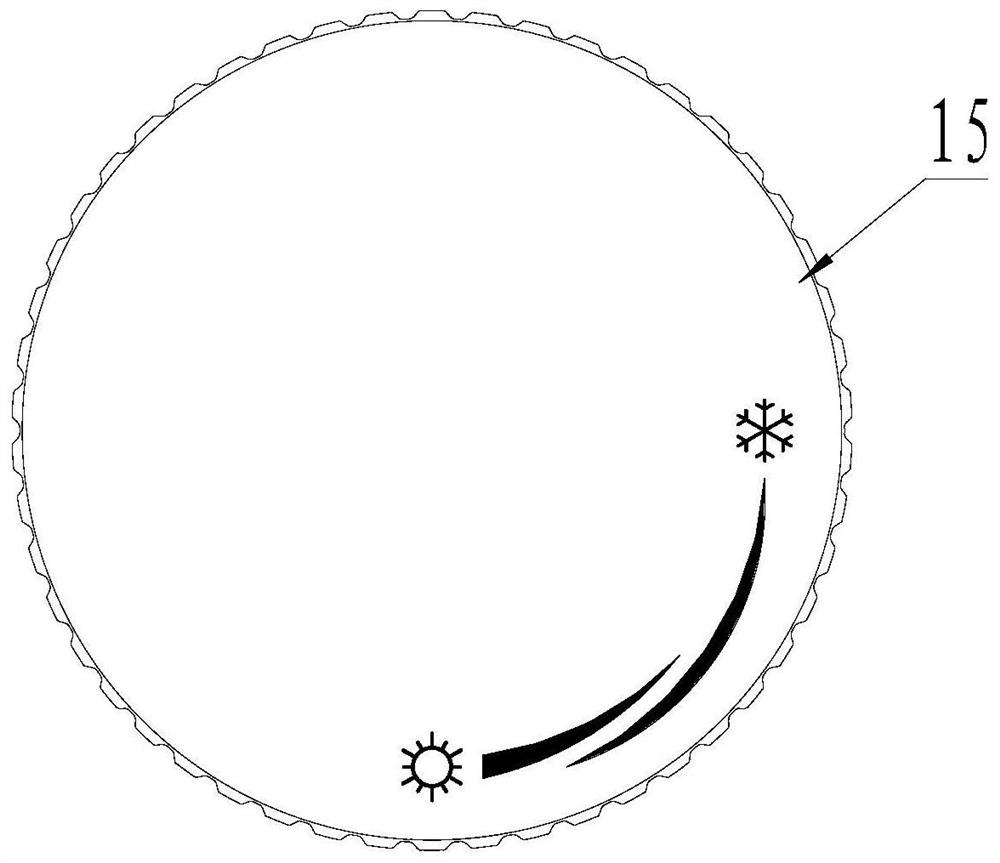

Dish washing faucet

PendingCN112814087AEasy to addIncrease in sizeGeneral water supply conservationDomestic plumbingTap waterPotable water

The invention discloses a dish washing faucet, and relates to the field of kitchen and bathroom accessories. The dish washing faucet comprises a faucet body, a water inlet assembly, a temperature control assembly, a water outlet pipe assembly, a water outlet nozzle assembly and a switch valve assembly. The dish washing faucet has the double-water-outlet function (one path is used for outputting original tap water, and the other path is used for outputting mixed tap water added with a detergent and other cleaning agents), and great convenience is brought to dish washing, pot washing, melon, fruit and vegetable washing and other kitchen cleaning work. The dish washing faucet has the beneficial effects that the cleaning agents are convenient to add; the size of a cleaning water runner is large, the flow needed by spraying water output is extremely small, the cleaning agents can be used for a long time after being added once, and a liquid storage tank is omitted; a gap between the plane of an inner hole of a spraying head and the outer end face of an inclined runner can be changed by rotating the spraying head, and therefore the umbrella-shaped water output angle and flow are adjusted; and cleaning water can be effectively prevented from flowing back into tap water, and the hidden danger that drinking water is possibly polluted is eliminated.

Owner:何仁熙

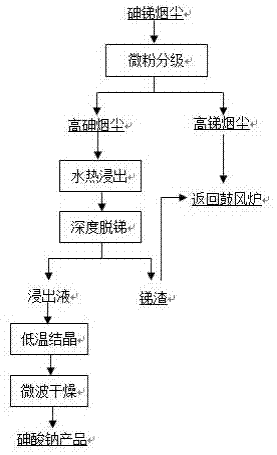

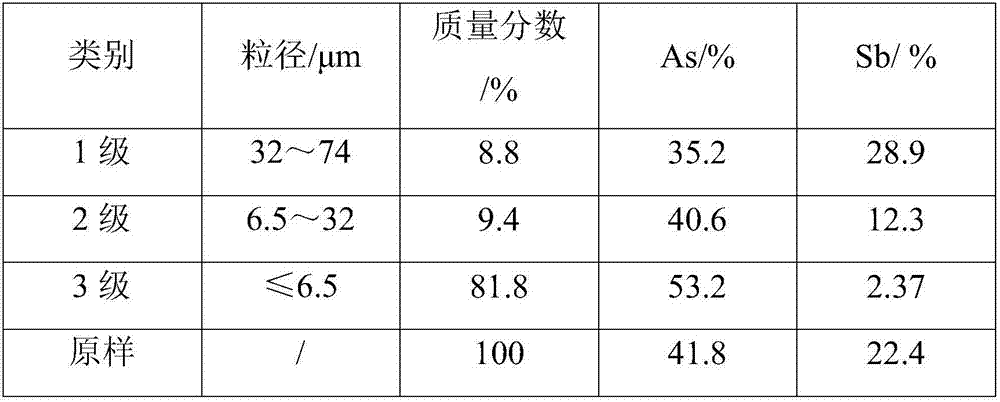

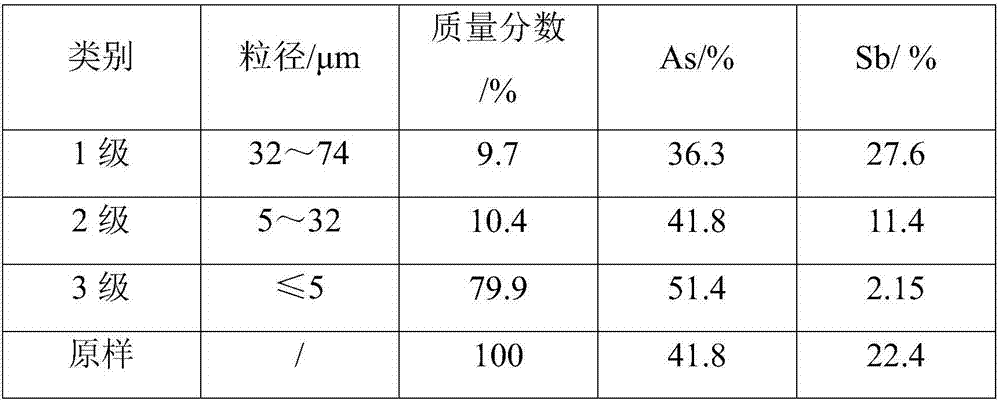

Efficient comprehensive utilization method of arsenic and antimony in arsenic and antimony smoke

ActiveCN107365913AReduce Pollution PotentialEliminate Pollution PotentialProcess efficiency improvementSodium saltArsenic product

The invention relates to an efficient comprehensive utilization method of arsenic and antimony in arsenic and antimony smoke and belongs to the technical field of non-ferrous metallurgy. The method comprises the specific steps that the arsenic and antimony smoke is subjected to stge treatment, fine powder smoke obtained through separation is put into hot water according to the formula that the liquid-solid ratio is 5:1, agitation leaching is conducted for 60 min at the temperature is 85 DEG C, and solid-liquid separation is conducted after leaching; an oxidizing agent is slowly added into leaching liquid, the volume percentage of the oxidizing agent is 3%, stirring is continuously conducted for 60 min, and arsenic-containing leaching post-liquid and antimony-containing leaching residues are obtained after filtering; a sodium salt solution is added into the leaching post-liquid, the mixture is subjected to low-temperature concentration and crystallization under the microwave condition after sufficient stirring, sodium arsenate crystals are obtained after centrifugal filtering, and crystallization mother liquor is used circularly; and the sodium arsenate crystals are sent to microwave drying equipment to be dried, and products are obtained after drying. According to the method, the arsenic and antimony smoke is subjected to stage treatment according to the grain size, enrichment and separation of arsenic and antimony can be achieved, operation is easy, and the cost is effectively reduced; and separated arsenic-enriched smoke is leached, refined and crystallized, arsenic products are formed for export sales, antimony-containing materials return to the procedure, and resource recycling is achieved.

Owner:红河绿地环保科技发展有限公司

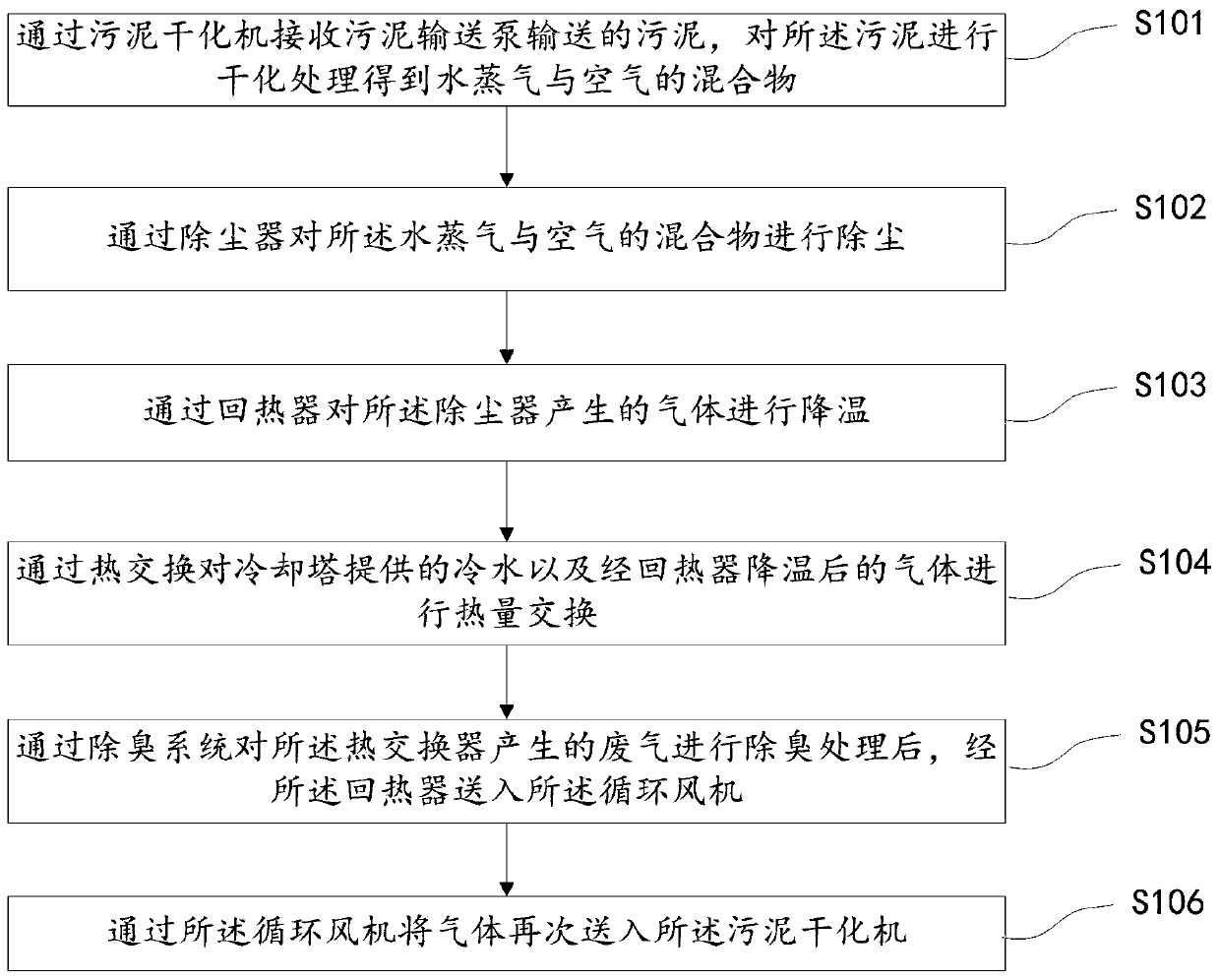

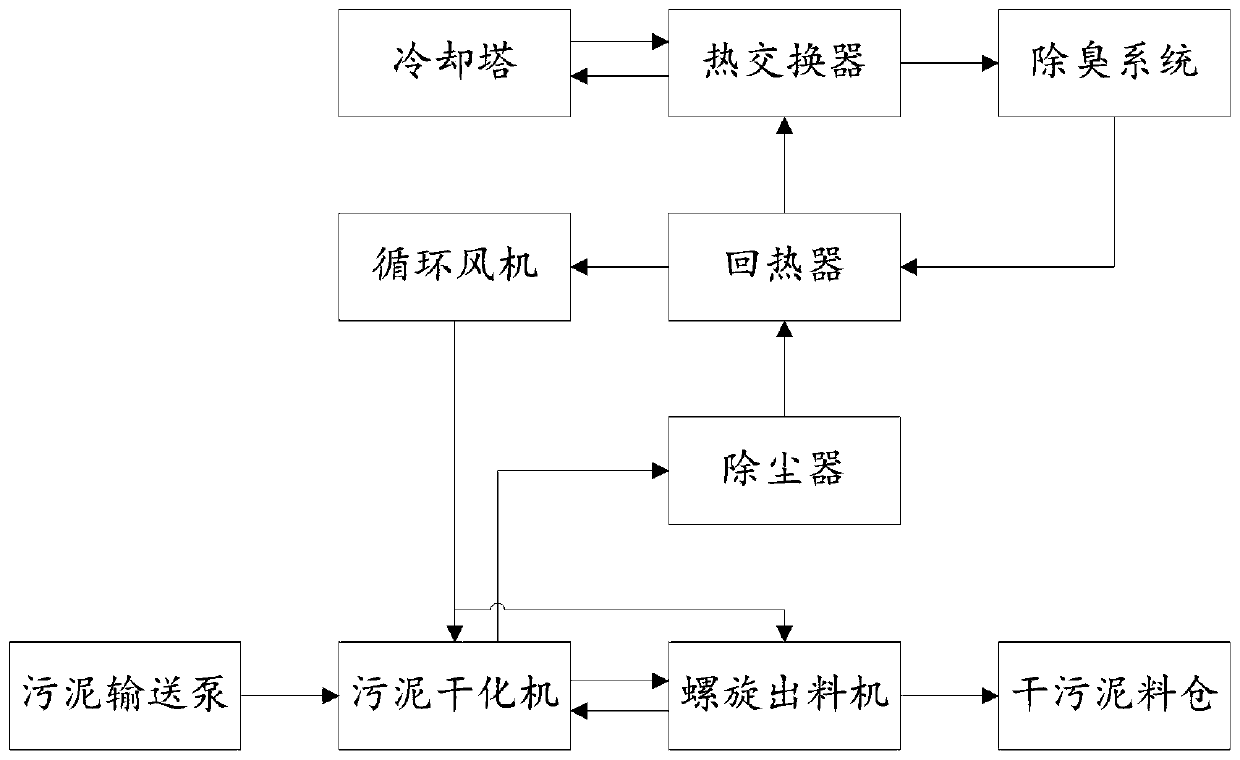

Sludge drying machine energy-saving consumption-reducing and waste gas zero-emission system and method based on zero-emission framework

PendingCN111170778AEliminate Pollution PotentialLong-term stabilityBio-organic fraction processingChemical industryCooling towerSludge

The embodiment of the invention discloses a sludge drying machine energy-saving consumption-reducing and waste gas zero-emission system and method based on a zero-emission framework. The system includes: a sludge drying machine, a spiral discharging machine, a dust remover, a heat regenerator, a circulating fan, a heat exchanger, a cooling tower and a deodorization system, the sludge drying machine is used for drying the sludge to obtain a mixture of water vapor and air; the dust remover is used for removing dust from the mixture of the water vapor and the air; the heat regenerator is used forcooling the gas generated by the dust remover; the heat exchanger is used for carrying out heat exchange on cold water provided by the cooling tower and gas cooled by the heat regenerator; the deodorization system is used for deodorizing waste gas generated by the heat exchanger and then feeding the deodorized waste gas into the circulating fan through the heat regenerator, and the circulating fan is used for feeding the treated gas into the sludge drying machine. According to the scheme, zero emission of waste gas treatment is achieved, the operation cost is saved to the maximum extent by recycling heat energy, and compared with a traditional sludge drying deodorization process, the treatment scale is greatly reduced, the cost performance is high, and good economic benefits are achieved.

Owner:GUANGZHOU GELOR SYST ENVIRONMENTAL PROTECTION ENG

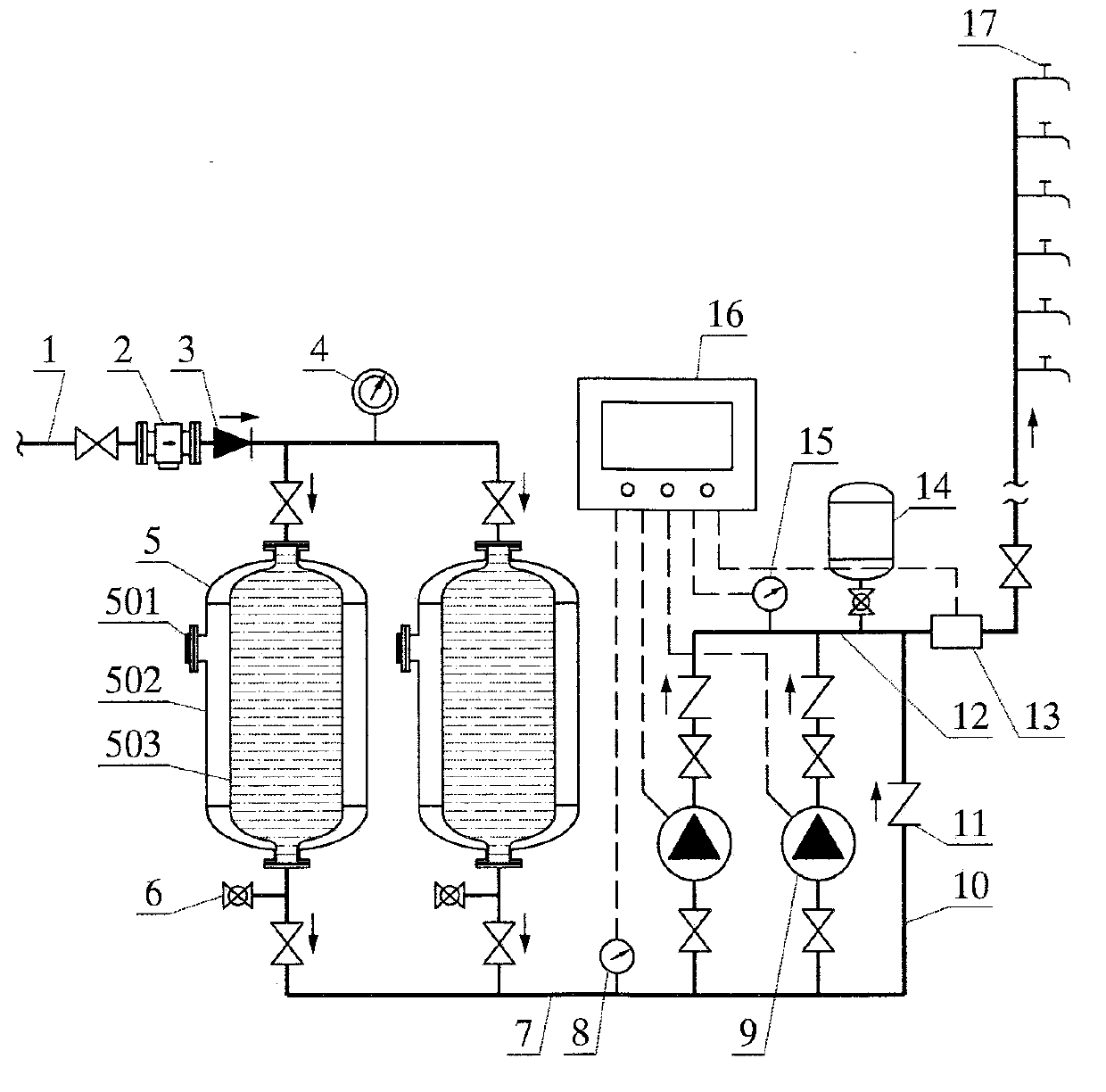

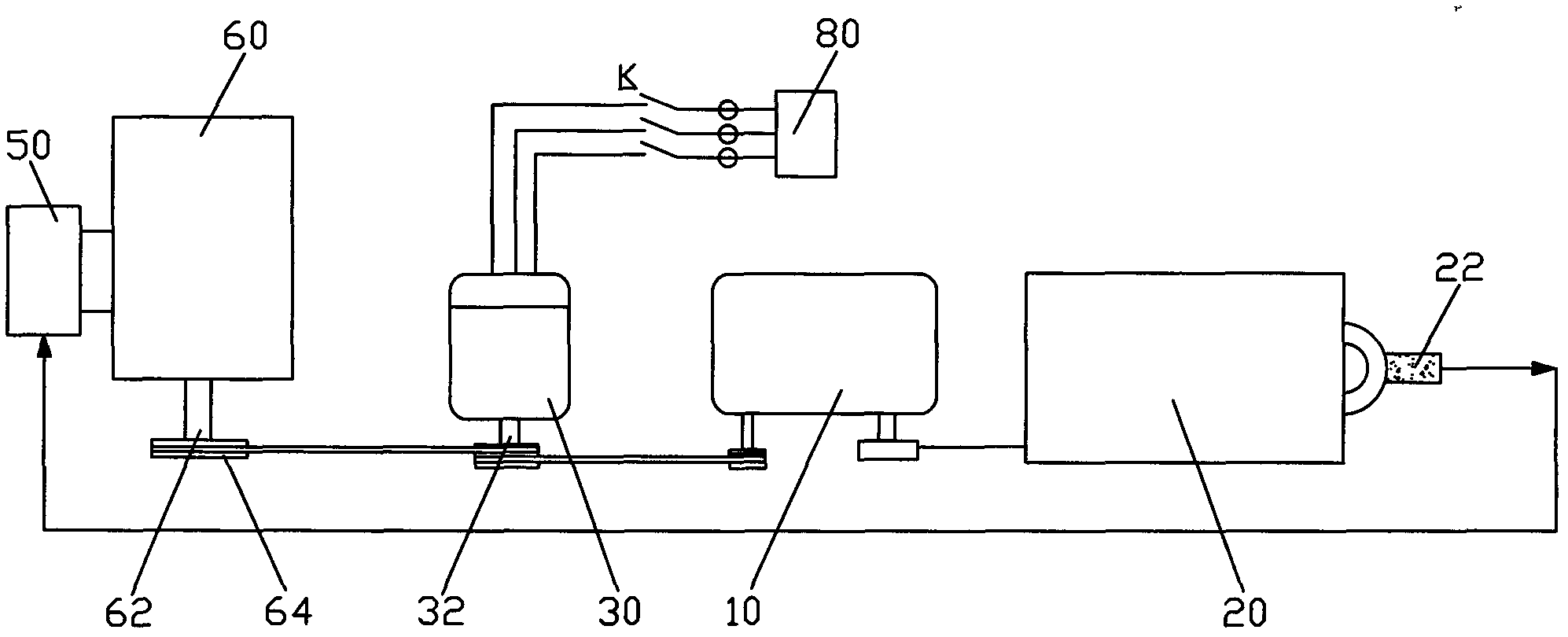

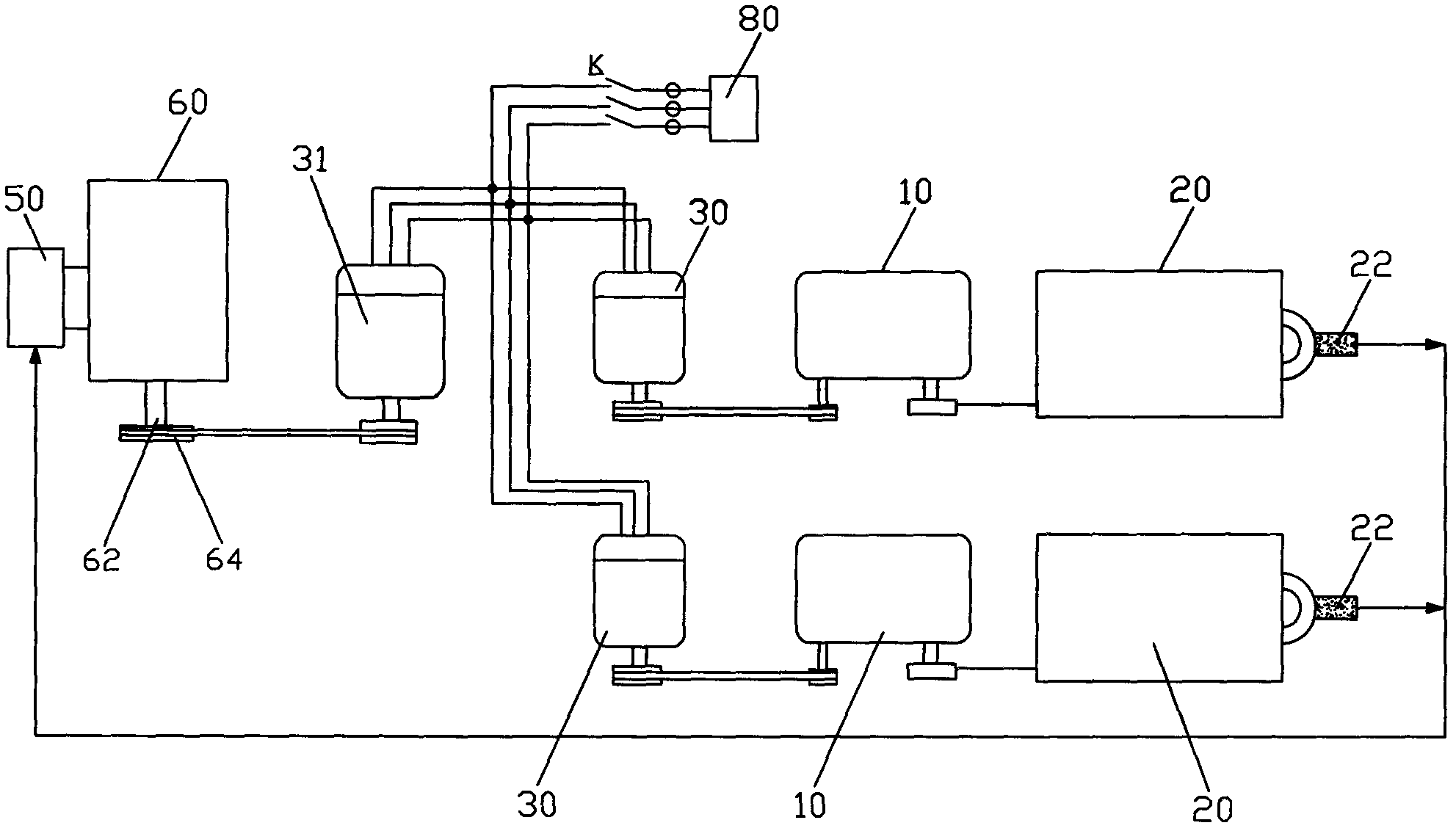

Double-tank adjustable pipe network pressure-superposed water supply device

InactiveCN104746555AEliminate Pollution PotentialAdjust water intakeService pipe systemsWater mainsTap waterAir pollution

The invention discloses a double-tank adjustable pipe network pressure-superposed water supply device which mainly consists of a filter, a backflow preventer, two bag type flow stabilization tanks, a water pump, a flow meter and a control cabinet. The two bag type flow stabilization tanks are connected in parallel, a tap water inlet pipe is connected with inlets of the flow stabilization tanks, each flow stabilization tank comprises a tank body and a rubber bag, the rubber bags are arranged inside tank bodies, breathers are arranged in the tank bodies and used for being in communication with outside air, the outer walls of the rubber bags are in contact with the air, the inner walls of the rubber bags are in contact with taper water, the tap water is completely isolated from the outside through the rubber bags, and the water amount is adjusted by utilizing the expandable-contractible performance of the rubber bags. The double-tank adjustable pipe network pressure-superposed water supply device has the advantages that the double-tank adjustable pipe network pressure-superposed water supply device can be directly and serially connected to a tap water pipe network to achieve supercharged water supply and energy-saving purpose, the arranged rubber bags enable the tap water to be completely isolated from the outside air, and the double-tank adjustable pipe network pressure-superposed water supply device has an intake water amount adjusting function, can eliminate the hidden danger of air pollution and has good using effect.

Owner:QINGDAO WANLI TECH

Method for preparing water purifying bacterium by utilizing obsolete fungus stick of edible fungus

InactiveCN101712928AThe ratio is simple and diverseReduce pollutionMicroorganismsBiological water/sewage treatmentBiotechnologyEcological environment

In recent years, with the rapid growth of the traditional edible fungus industry all over China, the pollution and the hazard generated to the entironment and the edible fungus industry per se by a large number of obsolete fungus sticks (slags) after the primary planting of edible fungi also become bigger and bigger, and the innocent treatment and the research development in the aspect of reutilization of the obsolete fungus sticks in the industry also become more and more, wherein the research of preparing the water purifying microbial inoculum by taking the obsolete fungus sticks as the main materials is an important research direction. The invention provides a method taking the obsolete fungus sticks after the edible fungi are planted as the main materials to ferment water purifying bacteria to prepare the water purification agent. In the invention, the obsolete fungus sticks and the fungus slags of the edible fungi are used as the main materials, wherein the weight proportion is higher than 50 percent, and then the main materials cooperate with other auxiliary materials, wherein the auxiliary material mixture ratio is simple and varied; then independently developed compound water purifying freeze-drying strains are adopted to be fermented, and thereby, the water purifying bacterium is prepared. The invention reduces the preparation cost, realizes the deep development and utilization of wastes, also reduces the pollution to the entironment and eliminates the pollution of the edible fungus planting industry. The invention can realize use and preparation and has simple operation, low cost, high product activity and good water purification effect.

Owner:北京普仁生态技术有限公司

Uninterrupted motive power system for oil pumping machine in oil field

InactiveCN102629779AEliminate Pollution PotentialSimple facility configurationFluid removalEmergency power supply arrangementsFuel oilGas pressure transducer

The invention discloses an uninterrupted motive power system for an oil pumping machine in an oil field. The uninterrupted motive power system comprises an oil pumping machine and an electric motor, wherein the oil pumping machine is connected with a speed reducing machine, the input end of the speed reducing machine is connected with an output shaft of the electric motor, the uninterrupted motive power system also comprises an automatic switching controller, an air pressure sensor, a gas mixing device, an engine and a power generator, wherein the gas mixing device is connected with an associated gas outlet end, the power generator is connected between the engine and the motor, when the associated gas is sufficient, the engine uses the associated gas for providing the motive power for the oil pumping machine, when the associated gas is interrupted or insufficient, the commercial power is automatically switched to supply electricity to the motor, and the oil pumping machine can realize the uninterrupted movement; and when the commercial power is unavailable, the automatic switching controller is automatically switched into a mode of using the associated gas and / or fuel oil for driving the power generator to generate electricity so that an output shaft of the motor maintains the uninterrupted rotation, and the oil pumping machine is ensured to continuously work. The uninterrupted motive power system has the advantages that the associated gas, the electric energy and the fuel oil are used as complementary energy sources for providing the motive power for the oil pumping machine, the hidden danger of environment pollution can be eliminated, the continuous work of the oil pumping machine is realized, in addition, the utilization rate is higher, and the economic performance is better.

Owner:重庆金之川动力机械有限公司

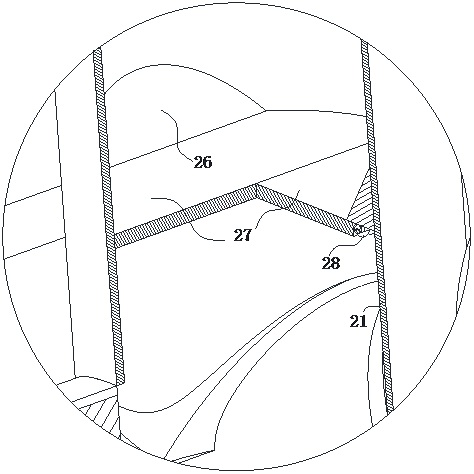

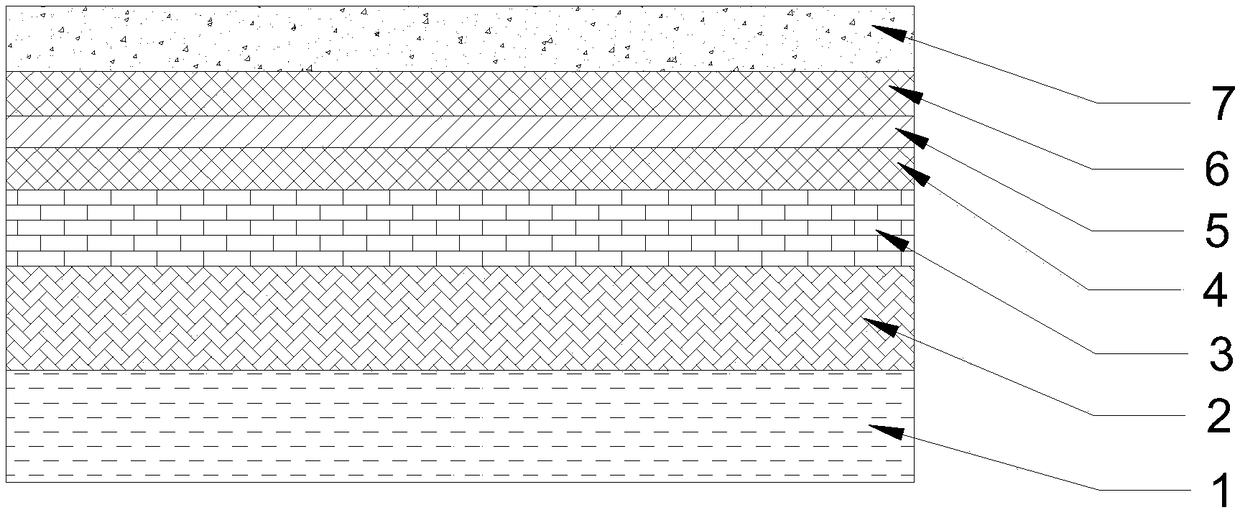

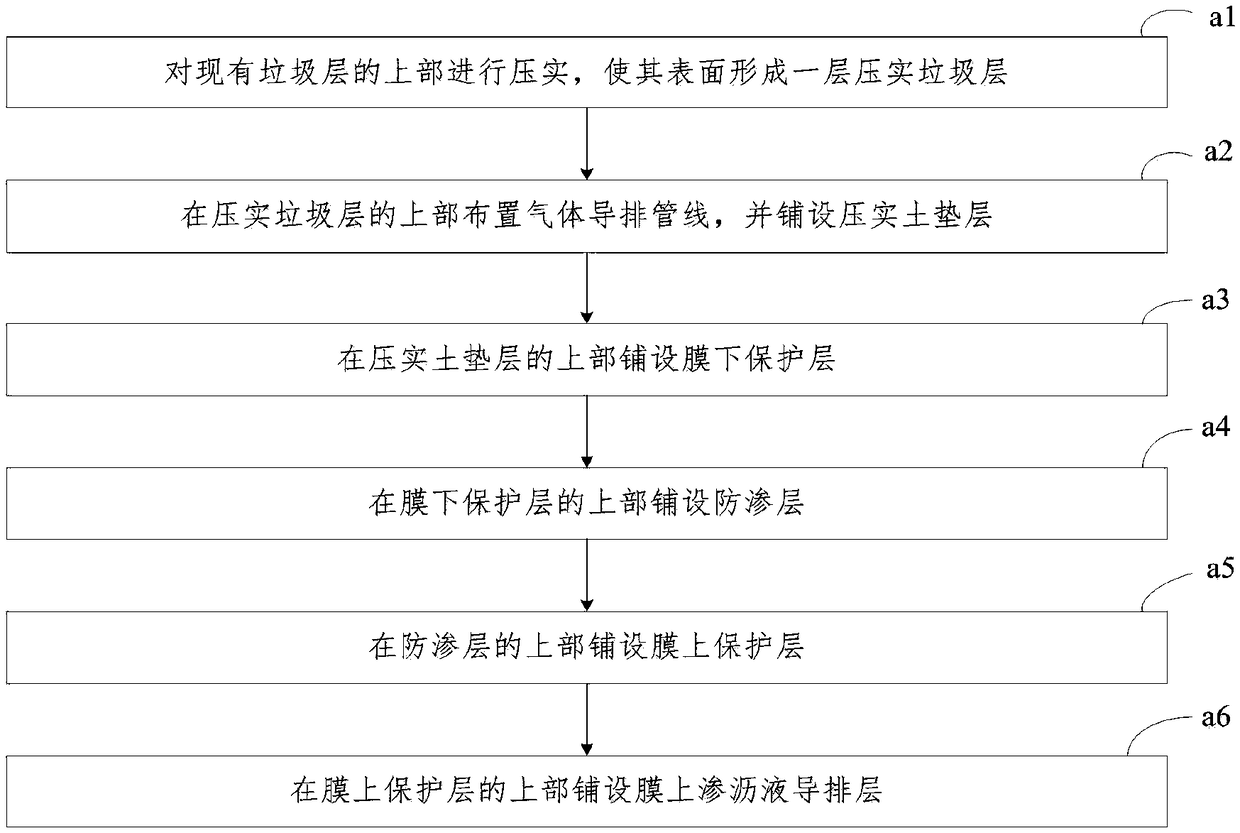

Pollution obstructing structure and method constructed based on seepage-proofing system

PendingCN108396785AAchieve vertical expansionEliminate Pollution PotentialProtective foundationEnvironmental engineeringProtection layer

The invention relates to a pollution obstructing structure and method constructed based on a seepage-proofing system. The pollution obstructing structure constructed based on the seepage-proofing system comprises a membrane upper infiltration liquid guiding and discharging layer, a membrane upper protective layer, a seepage-proofing layer, a membrane lower protective layer, a compacted soil cushion layer and a compacted garbage layer, and an original garbage layer is covered with the membrane upper infiltration liquid guiding and discharging layer, the membrane upper protective layer, the seepage-proofing layer, the membrane lower protective layer, the compacted soil cushion layer and the compacted garbage layer in sequence from top to bottom. A gas guiding and discharging pipeline is arranged in the compacted soil cushion layer. The outer surface of the gas guiding and discharging pipeline is wrapped with a water seepage sheet. According to the pollution obstructing structure and method constructed based on the seepage-proofing system, construction of a new seepage-proofing system can be completed in a short time, pollution obstructing is achieved, and the difficult problems of time, cost and leakage detecting brought by excavation are avoided; vertical expansion of a landfill is effectively achieved, and pollution hidden dangers in the later running process of the landfill are eliminated; existing pollution is solved mainly through collection and treatment modes; and due to no supplement of new pollution, original pollution can be completely solved after a period of timeso as to achieve the pollution control purpose.

Owner:BEIJING ENVIRONMENT ENG TECH CO LTD

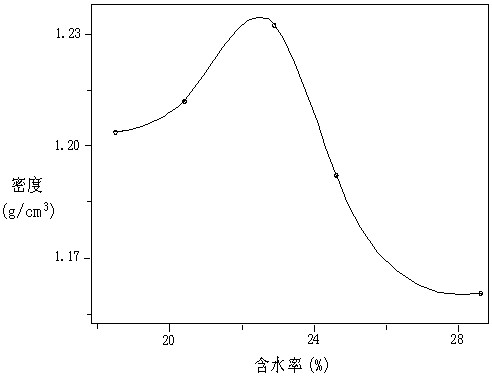

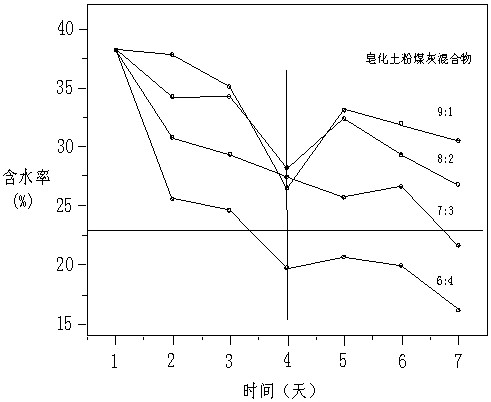

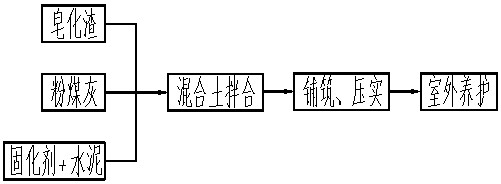

Application of epoxypropane saponification waste residues in curing of base layer paving material

ActiveCN111875275AHigh porosityReduce moisture contentRoadwaysSolid waste managementFirming agentEnvironmental engineering

The invention provides application of epoxypropane saponification waste residues in curing of a base layer paving material. The method comprises the following steps: drying saponified slag at 105-110DEG C, adding fly ash into the saponified slag according to a weight ratio of 8:2, controlling the moisture content of the mixture of the saponified slag and the fly ash at 23-28% of the weight, adding a curing agent and cement for blending the mixed earth, wherein the cement accounts for 6-8% of the weight of dry saponified slag, and the ratio of curing agent to cement is 4:5; then, the epoxypropane saponification waste residues are used as base layer paving materials to be paved and compacted in engineering, and finally outdoor maintenance is conducted on the epoxypropane saponification waste residues to replace traditional construction materials. According to the invention, fly ash, a curing agent and cement are added into saponified muck to be used as a base layer paving material. Therefore, saponified slag recycling is achieved, and saponified slag storage and potential safety hazards and environmental secondary pollution hazards possibly caused by saponified slag storage can be eliminated. The method is suitable for recycling epoxypropane saponification waste residues.

Owner:HANGJIN JINXI CHLOR-ALKALI CHEM CO LTD

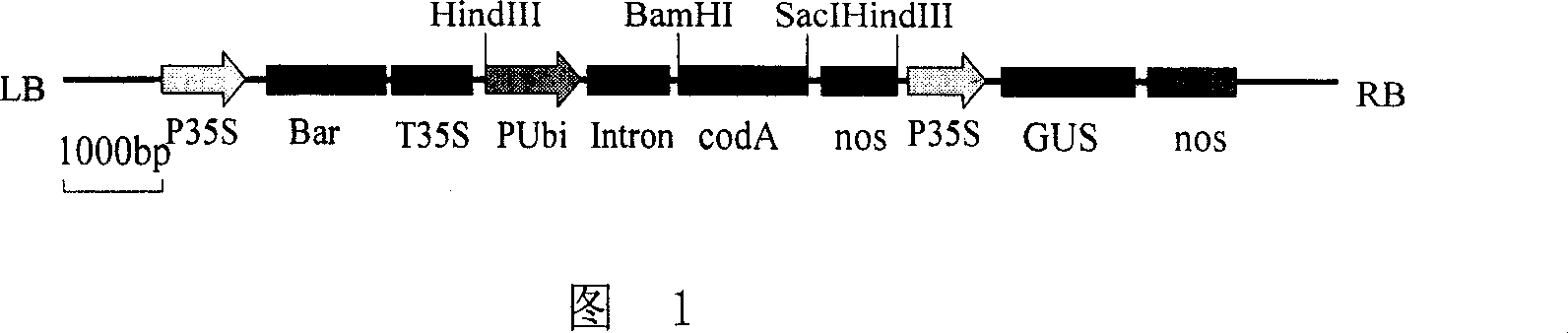

Method and its expression carrier for eliminating environmental pollution from Tr-gene plant gene drift

InactiveCN100350041CEliminate Pollution PotentialIncrease productionFermentationVector-based foreign material introductionGMO PlantsWild species

The invention provided a method to eliminate the gene shifting of the transforming gene plant and the expression carrier which includes the bomb gene expressing box and the target gene expressing box for avoiding the shift of the gene. The method includes converse the plant by the expressing carrier and get the conversion gene plant with the bomb gene expressing box which can express the target gene. Once the transforming plant is found to pollute the wild species, sub marginal species or the distant species, the gene bomb will be fired to kill the polluting plant. So the invention can solve the environment pollute by the transforming plant.

Owner:CHINA AGRI UNIV

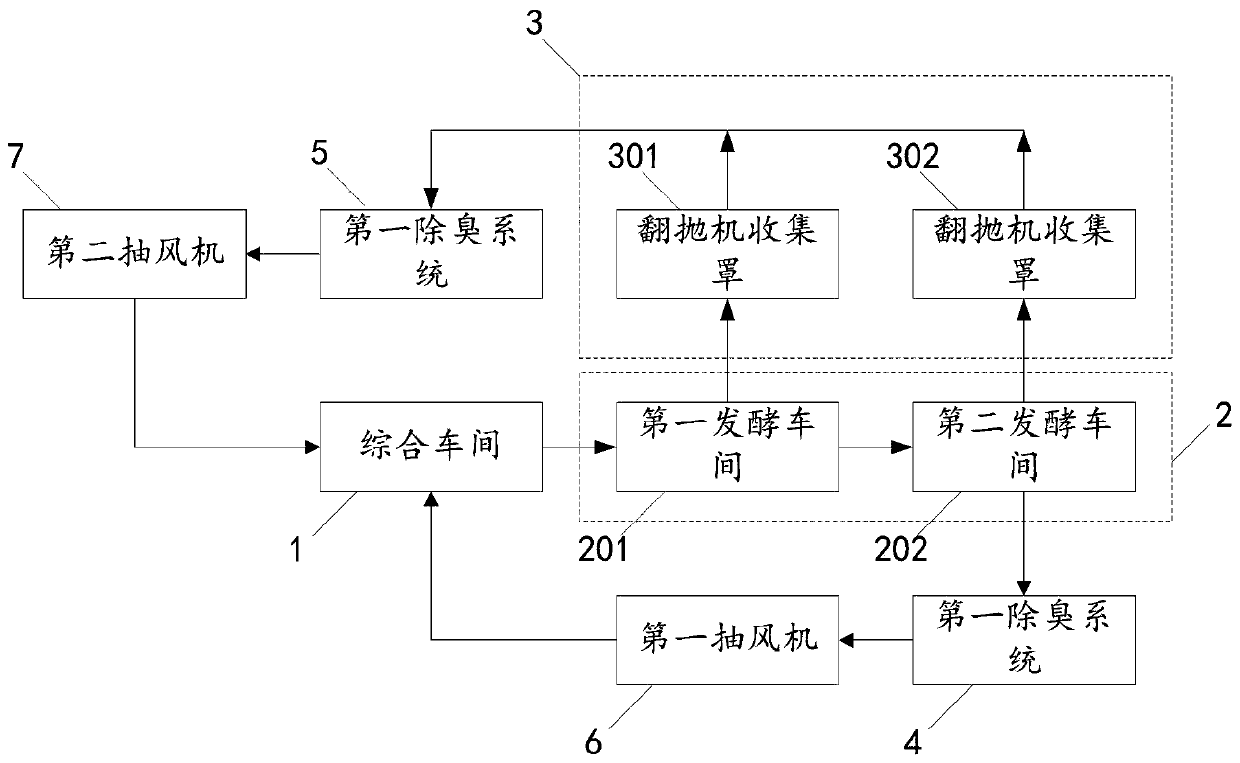

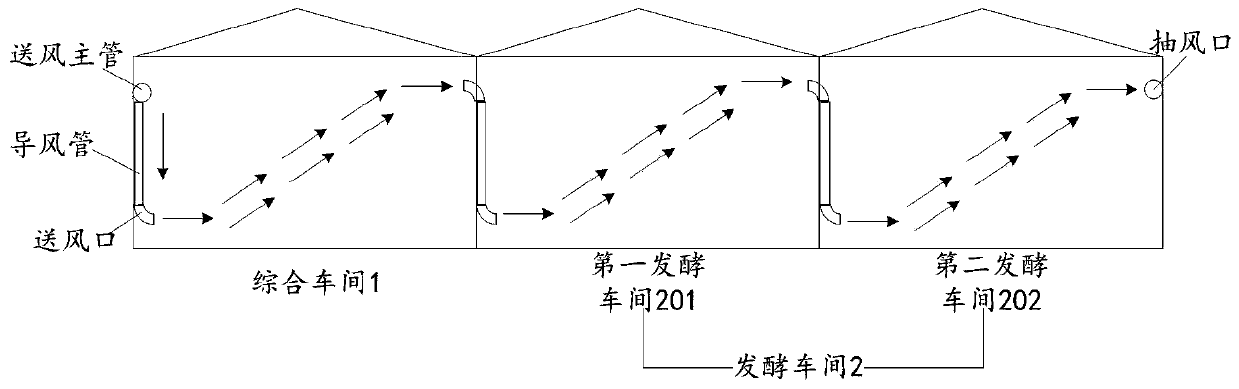

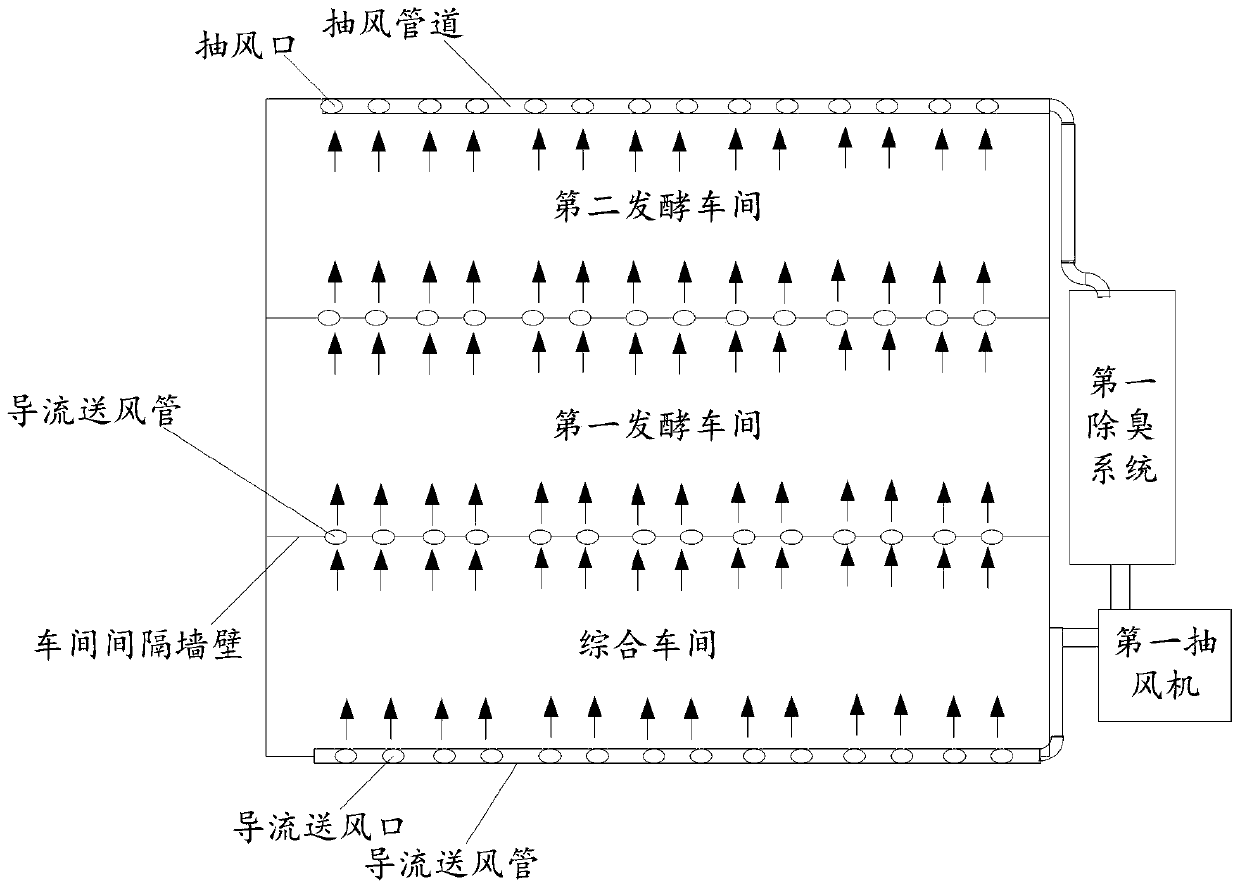

Garbage composting energy-saving consumption-reducing and waste gas zero-emission system and method based on zero-emission architecture

InactiveCN111153721AEliminate Pollution PotentialLong-term stabilityBio-organic fraction processingChemical industryProcess engineeringEnvironmental engineering

The embodiment of the invention discloses a garbage composting energy-saving consumption-reducing and waste gas zero-emission system and method based on a zero-emission architecture. The system comprises a comprehensive workshop, fermentation workshops, a turner collection cover, a first deodorization system, a second deodorization system, a first exhaust fan, a second exhaust fan and a flow guide, replacement, air supply and collection device. The flow guide, replacement, air supply and collection device is used for realizing gas circulation of the comprehensive workshop and the fermentationworkshop and guiding gas to the first deodorization system. The deodorization system is used for purifying the introduced gas. The first exhaust fan is used for conveying the purified gas into the comprehensive workshop. The turner collection cover is used for collecting water vapor, dust and odor brought out by turners in the fermentation workshops, and the water vapor, the dust and the odor areconveyed to a longitudinally-arranged exhaust pipeline through a high-pressure axial flow exhaust fan arranged at the upper end of the turner collection cover and are converged into the connected second deodorization system. The second exhaust fan is used for conveying the gas purified by the second deodorization system into the comprehensive workshop. According to the scheme, the gas flow state is reasonable, and zero emission of waste gas treatment is achieved.

Owner:GUANGZHOU GELOR SYST ENVIRONMENTAL PROTECTION ENG

Chromium-contaminated soil humic acid green in-situ remediation technique

PendingCN106862261ARestoring Planting FunctionAvoid Pollution HazardsContaminated soil reclamationHumic acidContaminated soils

A chromium-contaminated soil humic acid green in-situ remediation technique comprises the steps that firstly, when chromium-contaminated soil is crushed, humic acid matter with the agent-chromium ratio being 5-20:1 is added for in-situ reduction; secondly, after the chromium-contaminated soil with the particle size smaller than 3 mm is aged for 1 hour or longer, a strong reductant solution with the agent-chromium ratio being 10-30:1 is sprayed into the soil according to the detected hexavalent chromium content, and uniform mixing and forced reduction are conducted; and thirdly, after reduction, liquid humic acid with the agent-soil ratio being 1-5:100 is sprayed into the chromium-contaminated soil for granulation pelleting, particles are wrapped, seepage and migration of the hexavalent chromium in the particles are prevented, permanent reduction and fixation are achieved, and the planting function of the soil is restored.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Environment-friendly treatment method for recycling pollution-deactivated filter materials

InactiveCN110624315AReduce purchasing costsEliminate Pollution PotentialSpecific water treatment objectivesTreatment involving filtrationFiltrationSewage

The invention relates to the field of sewage filtration treatment, in particular to an environment-friendly treatment method for recycling pollution-deactivated filter materials. According to the environment-friendly treatment method for recycling pollution-deactivated filter materials, waste filter materials, deactivated because of pollution, generated in sewage filtering process are regeneratedand reutilized, solid wastes (a part of the filter materials are hazardous waste) are eliminated, a large amount of filter material purchasing cost is saved, and meanwhile solid waste treatment cost is also saved. The nvironment-friendly treatment method comprises the following steps: (1) filter material chemical agent treatment; (2) filter material vibration washing treatment unit; and (3) treatment in a filter material particle size screening treatment, wherein feeding a filter material obtained in the step (2) into a particle size screening treatment unit, screening the filter material according to a set particle size standard, drying and packaging. The environment-friendly treatment method is invented aiming at the characteristics of different pollutants, and first-stage treatment by utilizing a medicament is adopted; a mechanical device is adopted for separating solid attachments, and second-stage treatment is carried out; the filter material subjected to two-stage treatment is screened through a matched device, and the requirement of the process for the particle size of the filter material is met.

Owner:田大志

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com