Intelligent high-speed hybrid equipment for multi-functional new material processing

A high-speed mixing, new material technology, applied in mixers, mixers, chemical instruments and methods with rotary stirring devices, etc., can solve the problems of inconvenient feeding, low intelligence, and single function, and improve efficiency. , the effect of increasing the mixing speed and increasing the function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

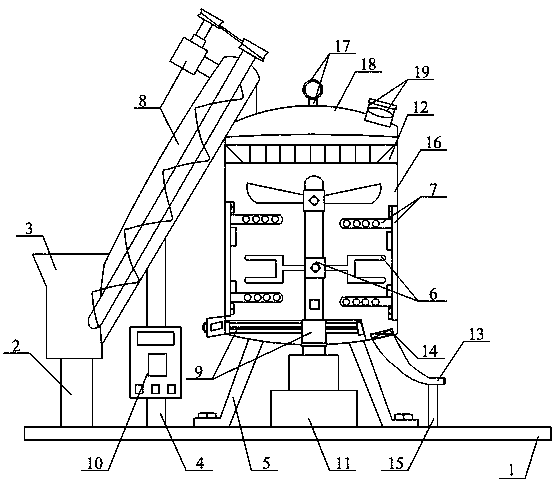

[0050] as attached figure 1 to attach Figure 7 shown

[0051] The present invention provides an intelligent multifunctional high-speed mixing equipment for processing new materials, which includes a fixed base 1, a support column 2, a hopper 3, a support rod 4, a support frame 5, a speed-measuring mixing rod structure 6, a temperature-measuring guide Flow plate structure 7, convenient feeding device 8, heating chamber structure 9, intelligent control cabinet structure 10, motor base 11, filter screen plate 12, discharge pipe 13, solenoid valve 14, telescopic rod 15, mixing kettle 16, lifting ring 17 , protective kettle cover 18 and sight glass tube 19, described support column 2 bolts are connected on the left side of the upper surface of fixed base 1; Described hopper 3 is screwed on the upper end of support column 2; Described support rod 4 Bolts are connected to the upper surface of the fixed base 1 on the right side of the support column 2; The upper surface; the speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com