Steel slag concrete and preparation method thereof

A technology of steel slag concrete and steel slag, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of lack of steel slag concrete preparation methods, etc., achieve shortened final setting time, simple preparation method, and reduce cracking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

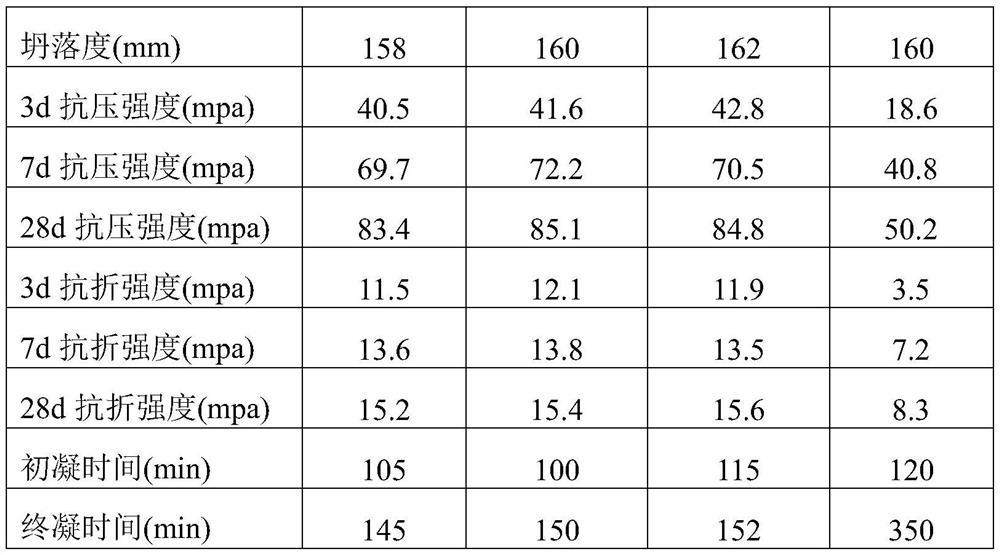

Embodiment 1

[0035] Concrete raw material is weighed by table 1, and step preparation step is as follows:

[0036] (1) Grind steel slag to 200 mesh to obtain steel slag powder, then add potassium hexatitanate, boric acid, anhydrous calcium hexaaluminate, plaster of paris and stir for 20 minutes, let stand at 130°C for 10 minutes, and collect the specific surface area >500m 2 / kg of mixed powder;

[0037] (2) Stir and mix the mixed powder obtained in step (1) with Portland cement, fly ash, light-burned magnesia, gravel, machine-made sand, and half of the water for 30 minutes to obtain a slurry;

[0038] (3) After mixing the remaining water and the water reducing agent, add it to the slurry in step (2), and continue to stir and mix for 5 minutes;

[0039] (4) Collect the slurry and pour it into the mold, put it on a vibrating table for vibration molding, after molding, cure it in an environment with a temperature of 20±2°C and a relative humidity of not less than 95% for 24 hours, then dem...

Embodiment 2

[0041] (1) Grind steel slag to 300 mesh to obtain steel slag powder, then add potassium hexatitanate, boric acid, anhydrous calcium hexaaluminate, and plaster of paris and stir and mix for 30 minutes, let stand at 140°C for 15 minutes, and collect the specific surface area >500m 2 / kg of mixed powder;

[0042] (2) Stir and mix the mixed powder obtained in step (1) with Portland cement, fly ash, light-burned magnesia, gravel, machine-made sand, and half of the water for 40 minutes to obtain a slurry;

[0043] (3) After mixing the remaining water and the water reducing agent, add it to the slurry in step (2), and continue to stir and mix for 10 minutes;

[0044] (4) Collect the slurry and pour it into the mold, put it on a vibrating table for vibration molding, after molding, cure it in an environment with a temperature of 20±2°C and a relative humidity of not less than 95% for 24 hours, then demold it, and then place it in a curing box Breed in reclaimed water for 4 days, and...

Embodiment 3

[0046] (1) Grind steel slag to 300 mesh to obtain steel slag powder, then add potassium hexatitanate, boric acid, anhydrous calcium hexaaluminate, and plaster of paris and stir and mix for 30 minutes, let stand at 130°C for 15 minutes, and collect the specific surface area >500m 2 / kg of mixed powder;

[0047] (2) Stir and mix the mixed powder obtained in step (1) with Portland cement, fly ash, light-burned magnesia, gravel, machine-made sand, and half of the water for 40 minutes to obtain a slurry;

[0048] (3) After mixing the remaining water and the water reducing agent, add it to the slurry in step (2), and continue to stir and mix for 5 minutes;

[0049](4) Collect the slurry and pour it into the mold, put it on a vibrating table for vibration molding, after molding, cure it in an environment with a temperature of 20±2°C and a relative humidity of not less than 95% for 24 hours, then demold it, and then place it in a curing box Breed in reclaimed water for 4 days, and y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com