Wall steel strand mesh polymer mortar reinforcing method

A polymer and wall steel technology, applied in building construction, construction, covering/lining, etc., can solve the problems affecting building wall reinforcement, long final setting time, etc., so as to prolong the initial setting time and improve the adhesion. Strong, well-mixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

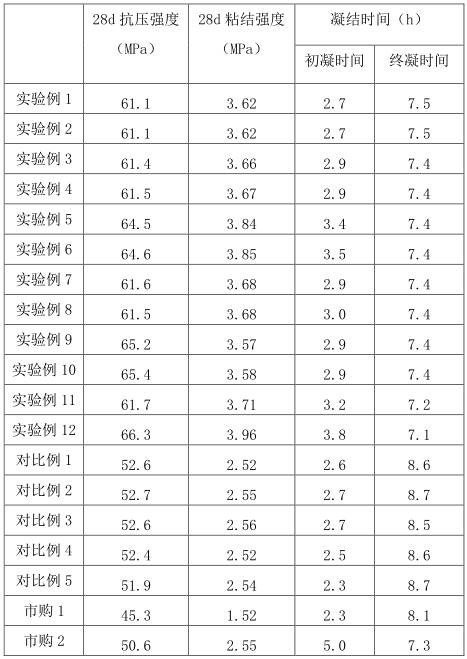

Examples

Embodiment 1-4

[0042] This embodiment discloses a polymer mortar reinforcement method for wall steel strand mesh, including the following steps:

[0043] (1) Preparation of mesh: use steel strands to prepare steel strand mesh according to the size of the site;

[0044] (2) Base treatment: eradicate the degraded concrete parts such as spalling, loosening and corrosion on the surface of the wall that need to be reinforced, expose the concrete structure layer, and repair the surface of the wall with cement mortar;

[0045] (3) Install and fix the mesh: drive anchor bolts on the end side of the base layer, and fix the edge of the mesh through the pull ring. After the pull ring is installed at the end of the steel strand, check carefully. If it is loose or falls off, it must be replaced. After the steel strand mesh is stretched to the pre-tightened (steel strand tensioned) state, the reinforcing member is installed, and the anchor bolt on the other side is fixed;

[0046] (4) Apply interface age...

Embodiment 5

[0054] The difference from Example 4 is that 120kg of calcium aluminate cement and 29kg of polyacrylamide were mixed evenly in advance, and then added to step (5) and mixed evenly with other components.

Embodiment 6

[0056] The difference from Example 4 is that 220kg of calcium aluminate cement and 16kg of polyacrylamide were mixed uniformly in advance, and then added to step (5) and mixed uniformly with other components.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com