Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

88results about How to "Improve connection integrity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

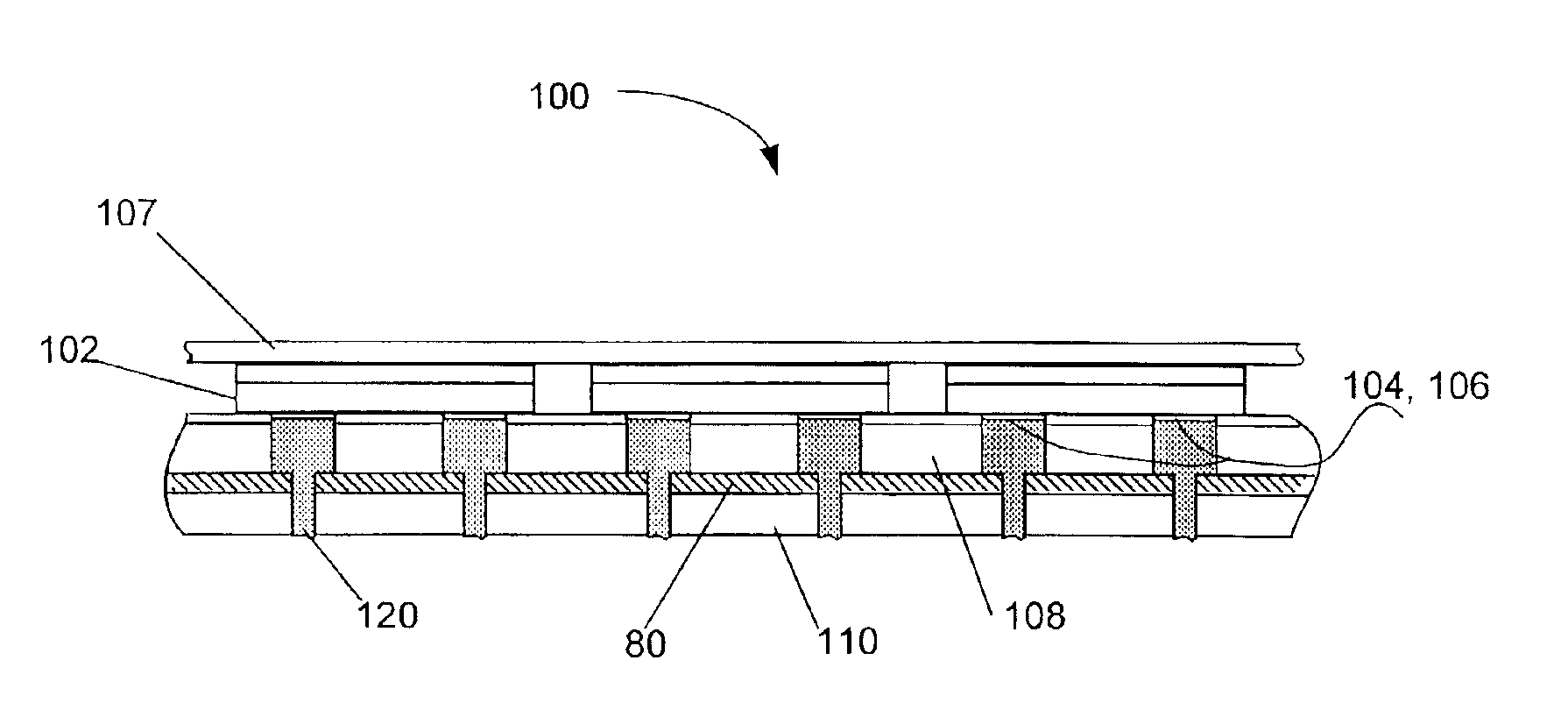

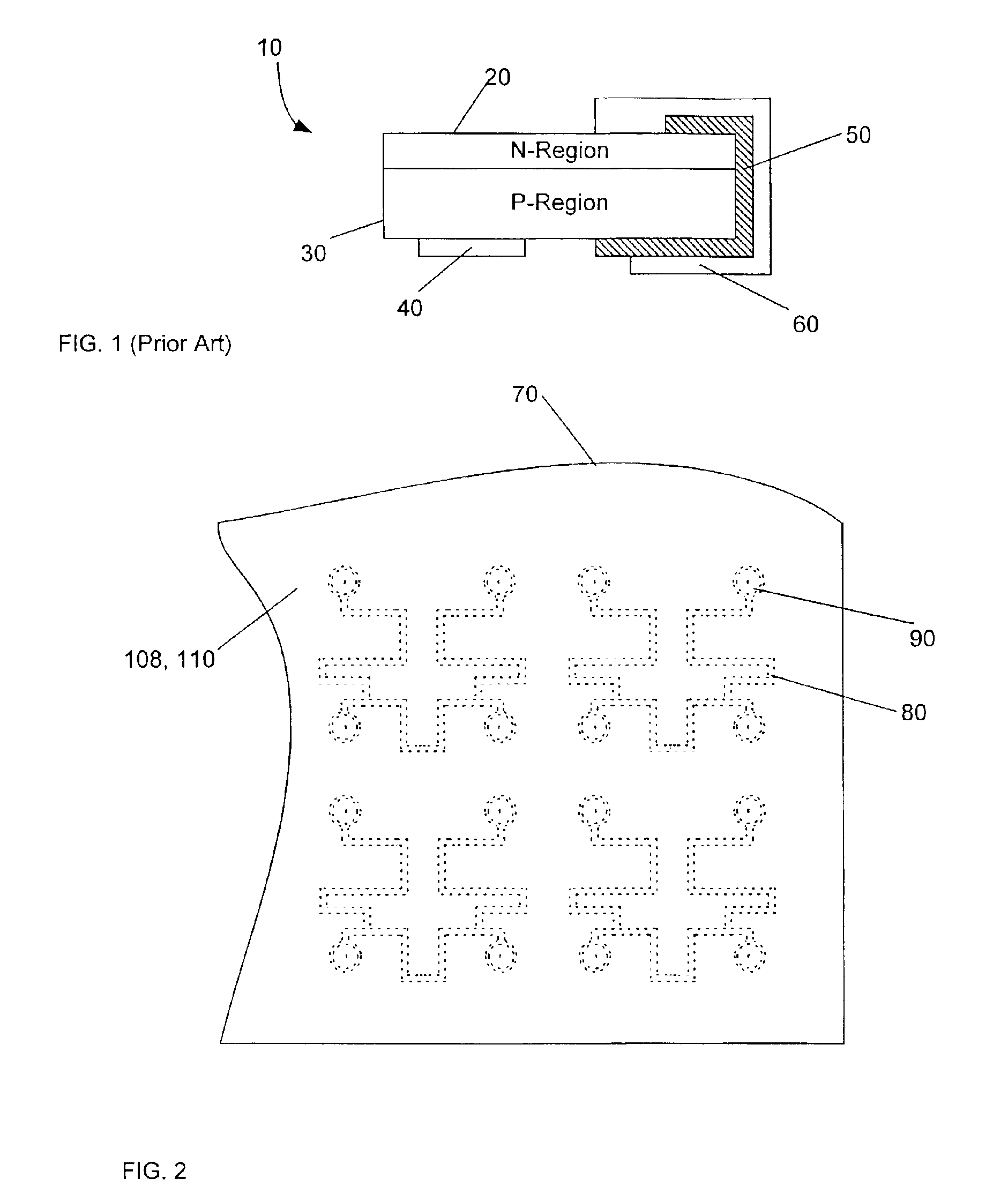

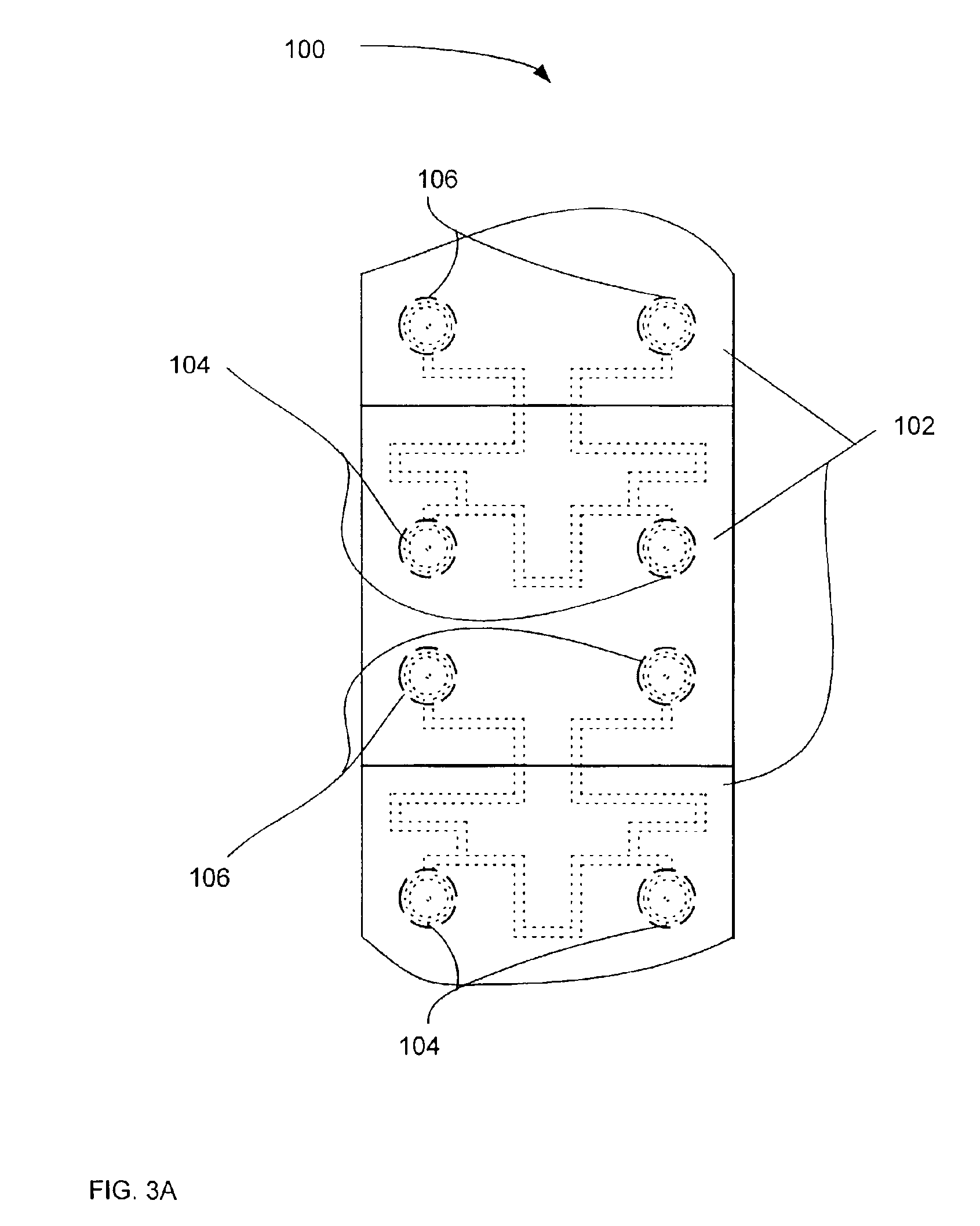

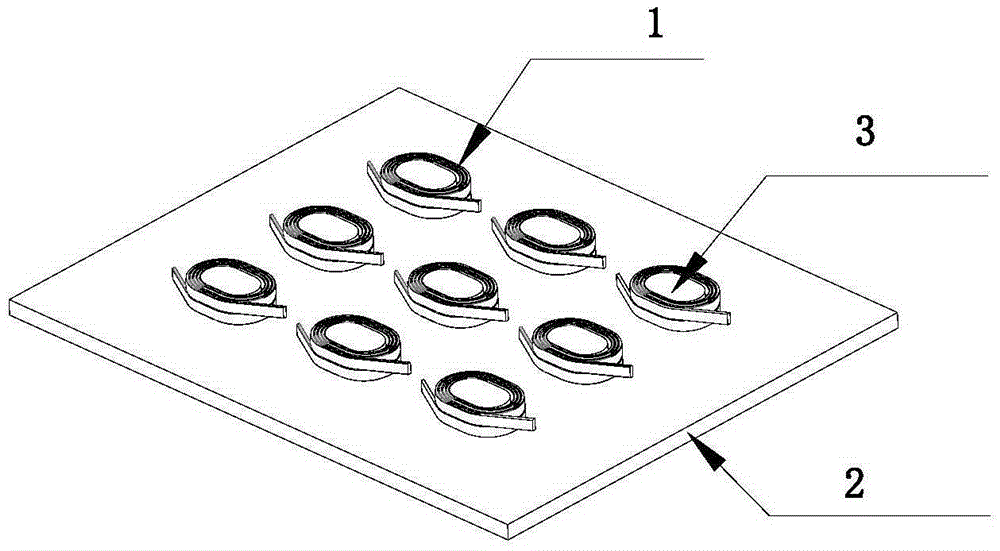

Method for fabricating a solar tile

InactiveUS6906253B2Operational securityReduces cell edgePrinted circuit assemblingCosmonautic vehiclesFlexible circuitsEngineering

The present invention provides a solar tile and method for fabricating the same. The solar tile includes a flexible circuit having at least one electrically conductive path laminated between two insulating sheets. The flexible circuit includes a plurality of openings that are completely through the flexible circuit and define contact locations with the electrically conductive path. The solar tile also includes a plurality of coplanar photovoltaic solar cells that are secured to the flexible circuit so that the contacts are aligned with the openings in the flexible circuit. Further, the solar tile includes a plurality of electrically conductive solder connections located within the openings in the flexible circuit to electrically connect the solar cell contacts and the electrically conductive path. Additionally, in a preferred embodiment, the solar tile includes a single coverslide situated adjacent and covering the plurality of solar cells opposite the flexible circuit.

Owner:GULA CONSULTING LLC

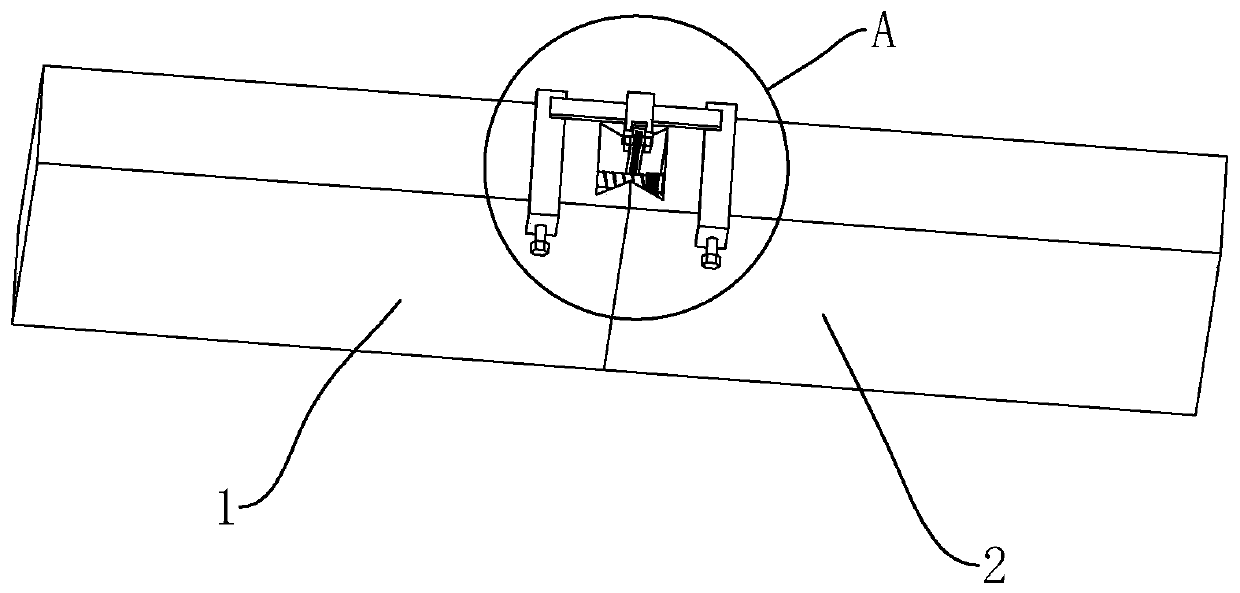

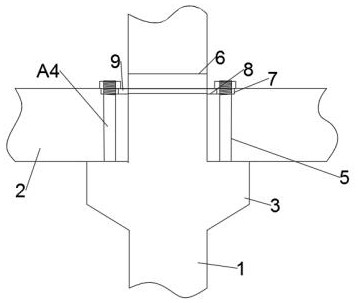

Fabricated building unit and assembly method thereof

The invention discloses a fabricated building unit and an assembly method thereof. The fabricated building unit comprises a first wallboard, a second wallboard and a connection piece used for the first wallboard and the second wallboard. One end face of the first wallboard is provided with a first dovetail groove extending vertically, and the end face, in butt joint with the first wallboard, of the second wallboard is provided with a second dovetail groove corresponding to the first dovetail groove. The connection piece comprises a connection pipe, a threaded rod, a limiting block which is rotationally connected to the end portion of the threaded rod and can rotate under the effect of gravity to a state inn which the limiting block is perpendicular to the threaded rod, and a gear which isfixedly arranged on the threaded rod in a sleeving manner. The connection pipe is preburied in the first wallboard, the connection pipe inwards extends from the groove bottom of the first dovetail groove, the connection pipe is internally provided with an internal thread, and the end portion of the threaded rod is provided with a movable groove for the limiting block to rotate to a state in whichthe limiting block is parallel to the threaded rod. The groove bottom of the second dovetail groove is inwards provided with an insertion hole, the size of the insertion hole can enable the limiting block and the threaded rod to insert in a parallel state, the second wallboard is provided with a movable cavity which communicates with the insertion hole, and the movable cavity can enable the limiting block to rotate to be perpendicular to the threaded rod.

Owner:惠州市鸿泰建筑工程有限公司

Surface mounting inductor manufacture method

InactiveCN105355409AImprove pass rateReduce manufacturing costTransformers/inductances coils/windings/connectionsInorganic material magnetismInsulation layerChemical plating

The invention discloses a surface mounting inductor manufacture method comprising the following steps: firstly preparing an inductor body; carrying out insulation treatment for the surface of the inductor body besides an electrode portion; pre-processing the electrode portion of the inductor body; removing an insulation layer on end portions of two lead wires of a coil in the inductor body; depositing one or more layers of metal conductive layers on the surface of the electrode portion of the inductor body through either a physics vapour deposition technology, or chemical vapor deposition or electroplate and chemical plating technology, the metal conductive layers are the electrode, thus obtaining the surface mounting inductor; the advantages are that the electrode position mode is employed to form the electrode, the electrode can directly grow into form on the electrode portion of the inductor body, and the electrode can be directly deposited on the end portion of the lead wires of the coil in a forming process; the electrode and the lead wires are connected through atom combination so as to provide high connecting integration, thus greatly reducing DC resistance between the lead wires of the coil and the electrode; the DC resistance between the lead wires of the coil and the electrode is relatively small, so the performance of the surface mounting inductor is high.

Owner:NINGBO YUNSHENG ELECTRONIC COMPONENTS TECHNOLOGY CO LTD +1

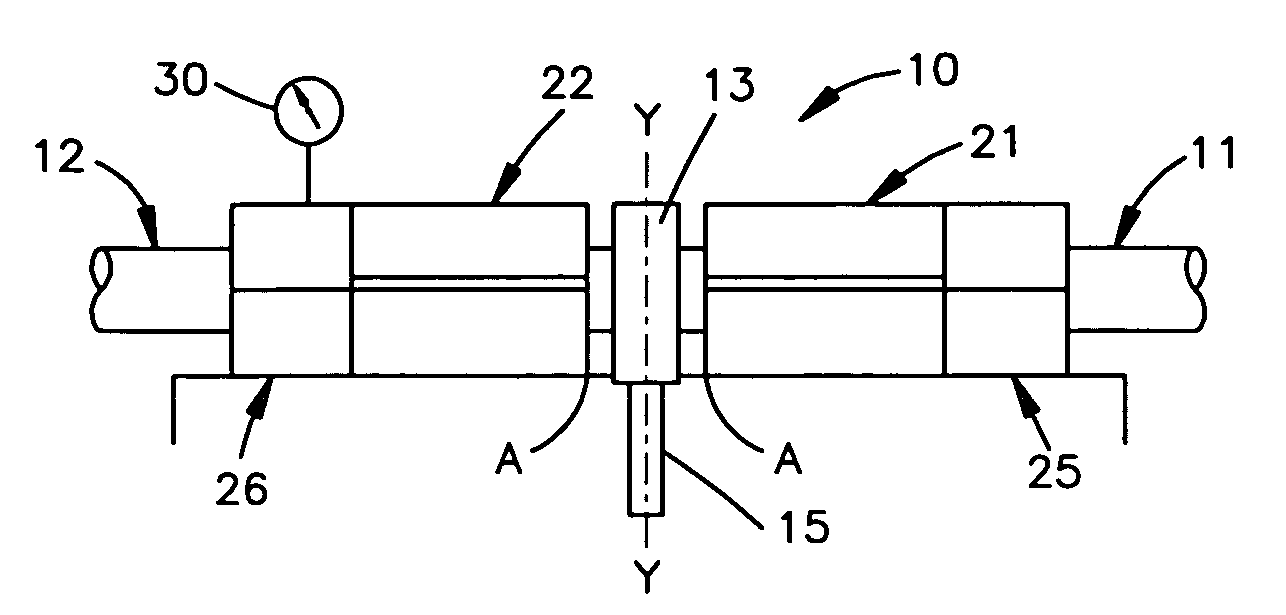

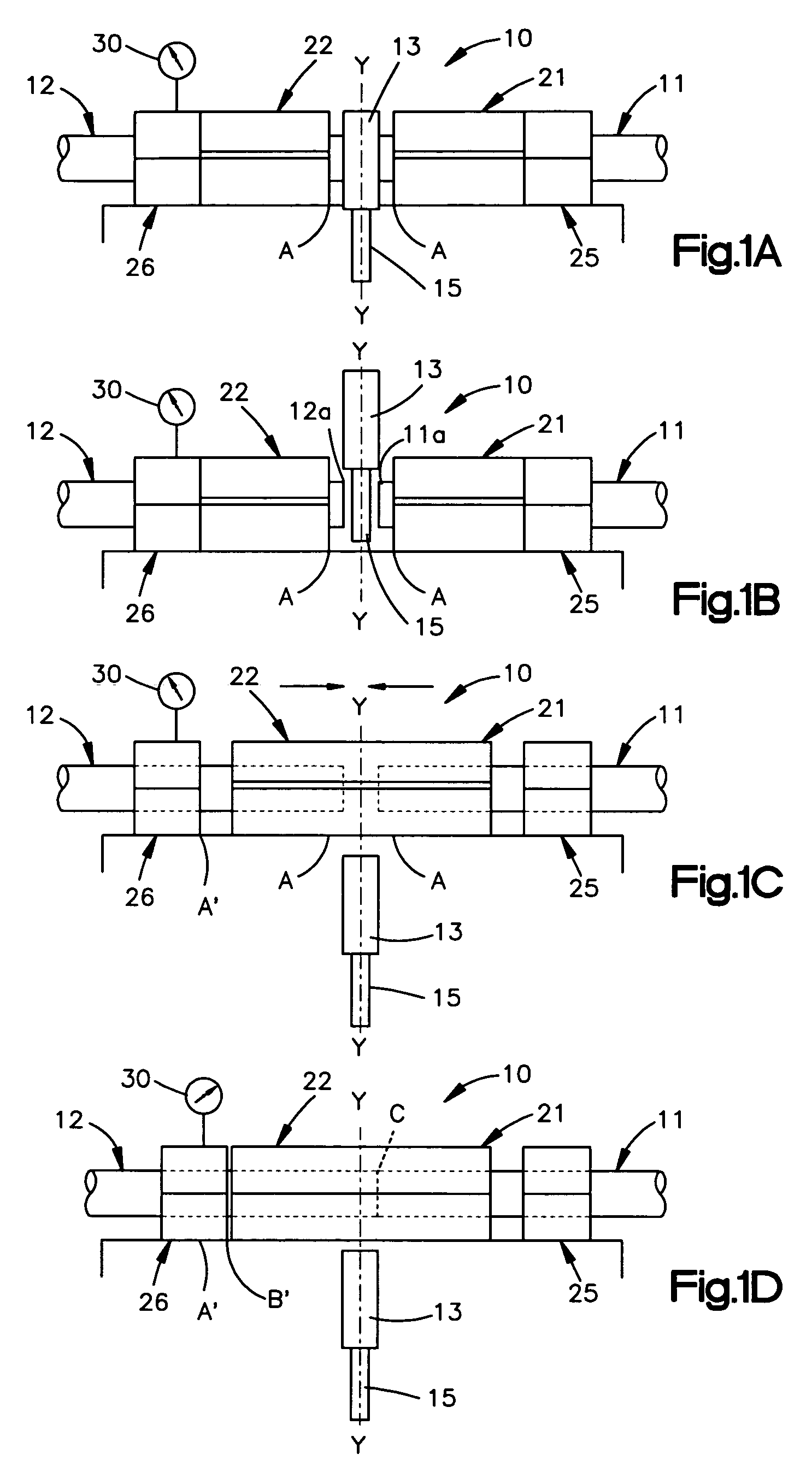

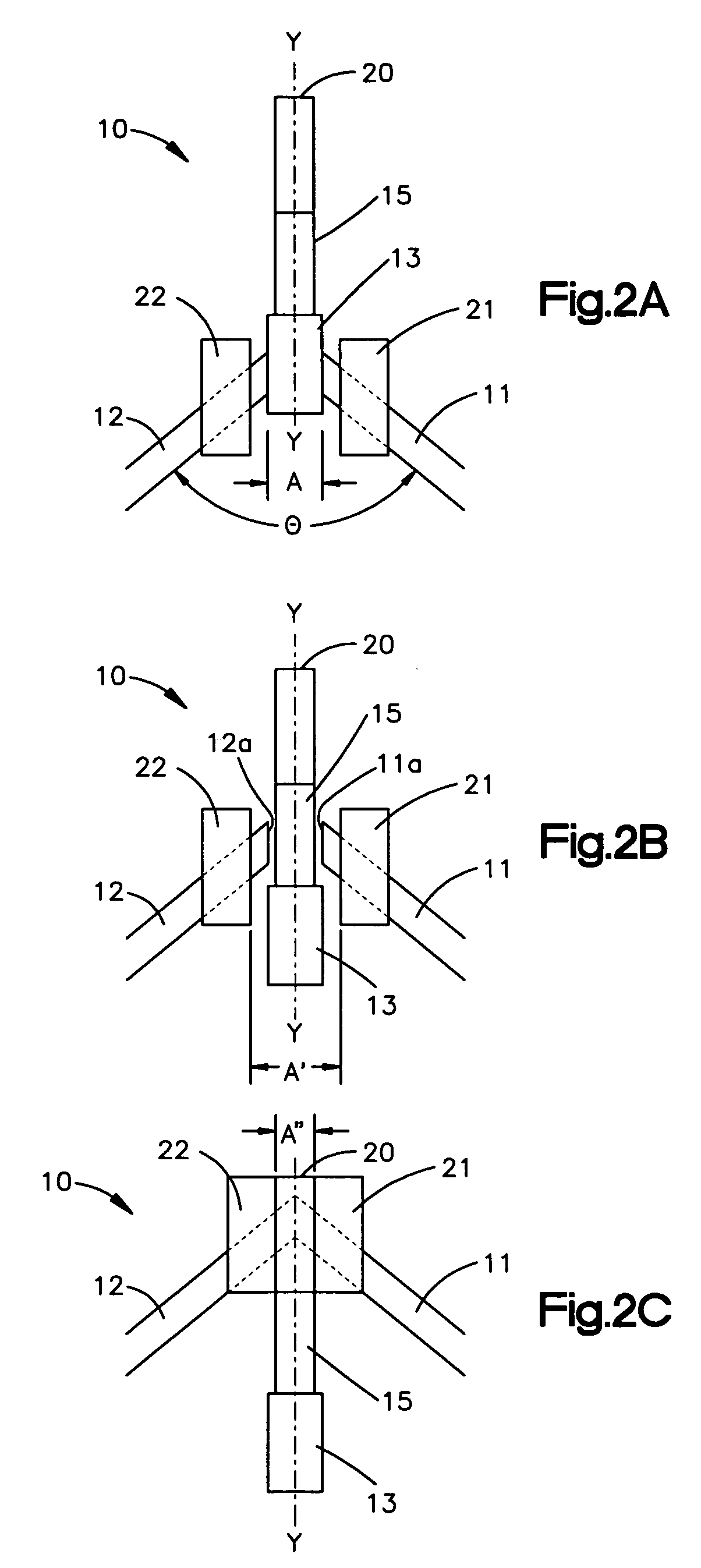

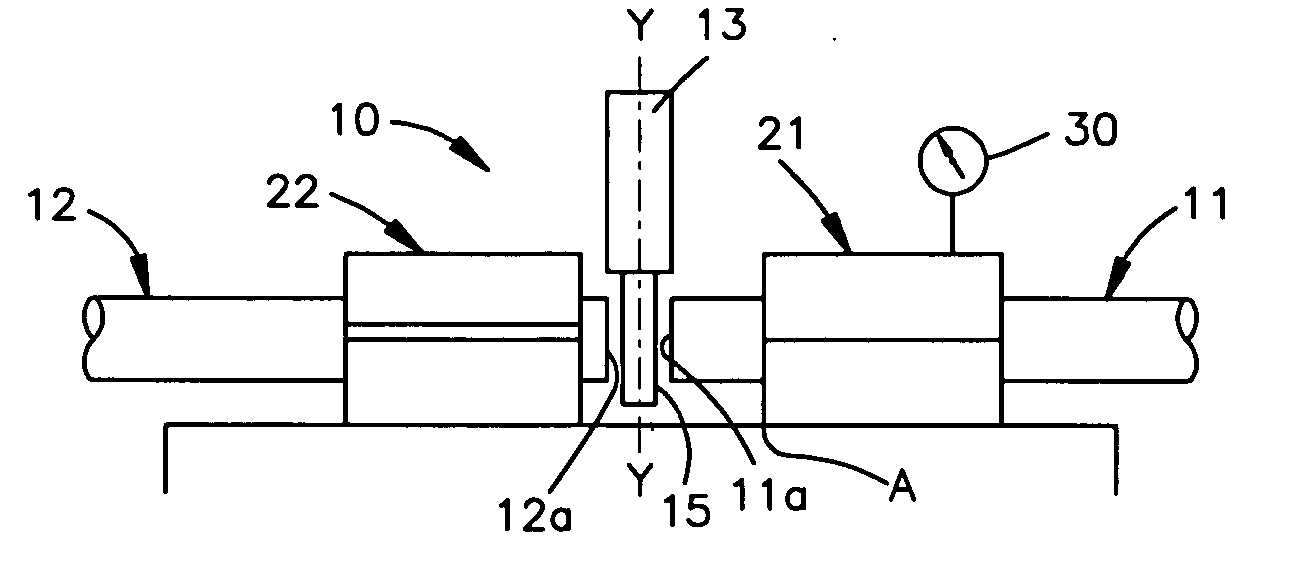

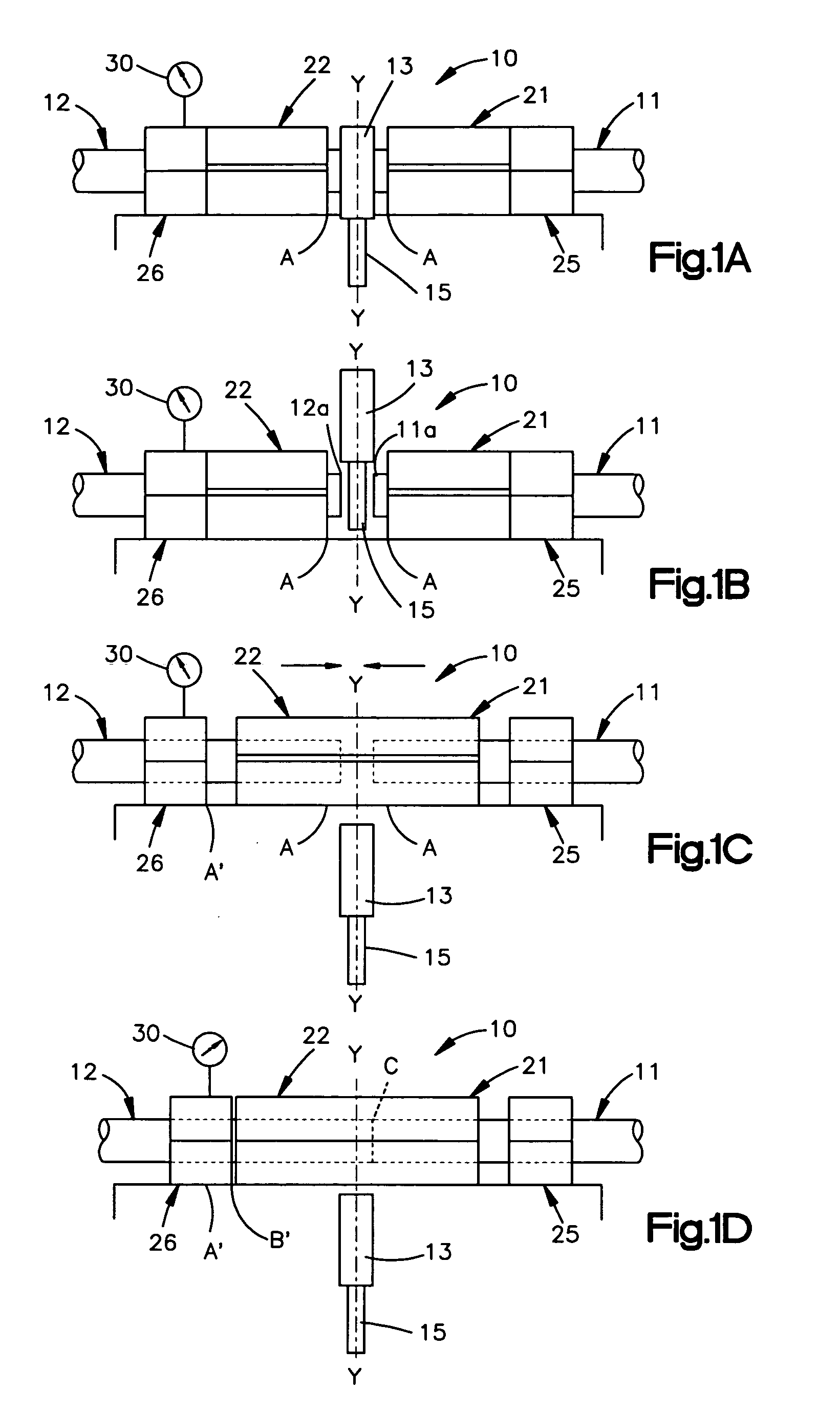

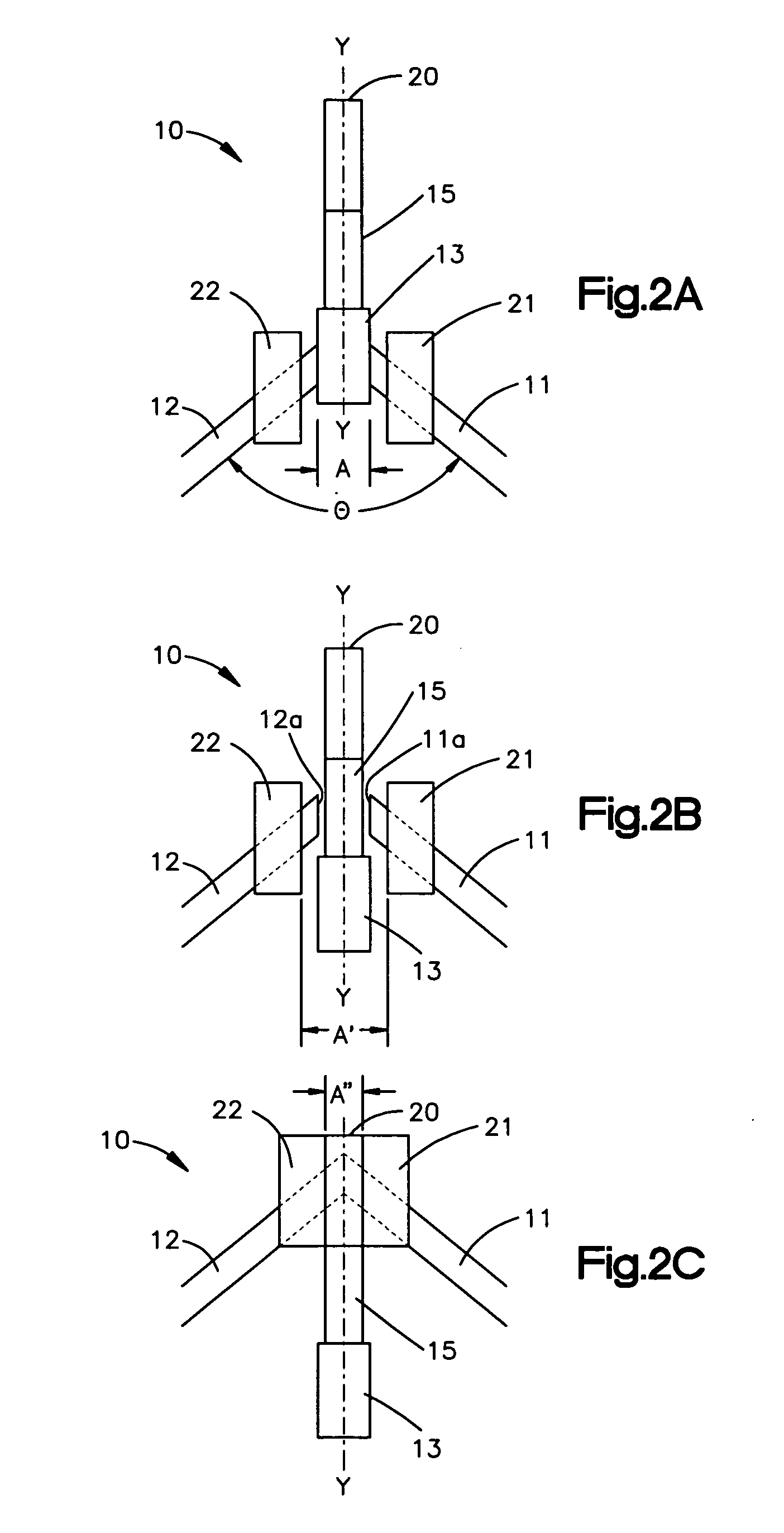

Flashless welding method and apparatus

ActiveUS7503992B2Good lookingHigh strengthEngine sealsLamination ancillary operationsContact pressureEngineering

A method and apparatus for welding two separate ends of an extrusion or two separate extrusion ends to form a flashless extrudate or gasket by having a first and a second mold for supporting and clamping the extrusion ends, and a spacer bar for positioning the extrusion ends to a location within the mold. A heating element elevates the temperature of the extrusion ends to a welding condition, and a clamping device is used for securing the extrusion ends. A flashless welding operation results by inserting and clamping at least one heated extrusion end into a welding mold until an acceptable contact pressure is obtained against the opposing heated extrusion end.

Owner:SPRINGSEAL

Flashless welding method and apparatus

ActiveUS20070181654A1Great offsetGood lookingEngine sealsLamination ancillary operationsContact pressureEngineering

A method and apparatus for welding two separate ends of an extrusion or two separate extrusion ends to form a flashless extrudate or gasket by having a first and a second mold for supporting and clamping the extrusion ends, and a spacer bar for positioning the extrusion ends to a location within the mold. A heating element elevates the temperature of the extrusion ends to a welding condition, and a clamping device is used for securing the extrusion ends. A flashless welding operation results by inserting and clamping at least one heated extrusion end into a welding mold until an acceptable contact pressure is obtained against the opposing heated extrusion end.

Owner:SPRINGSEAL

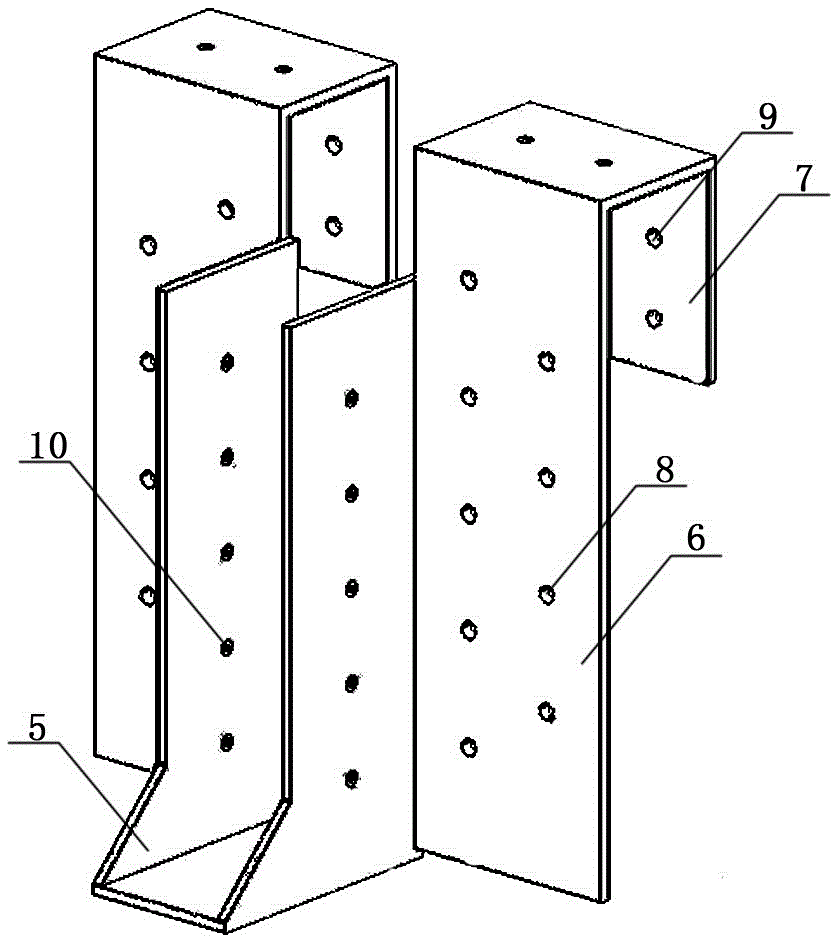

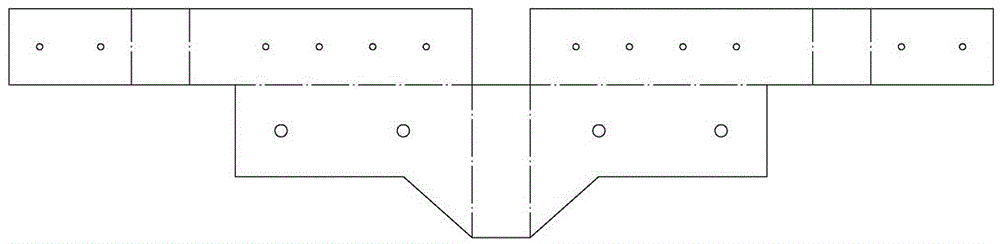

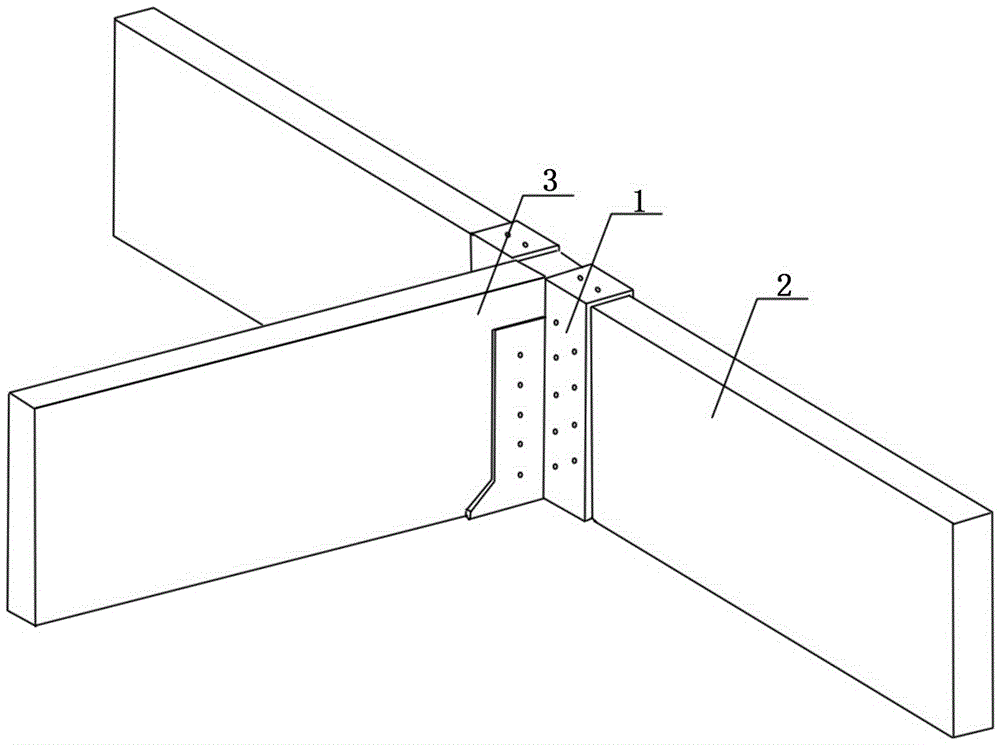

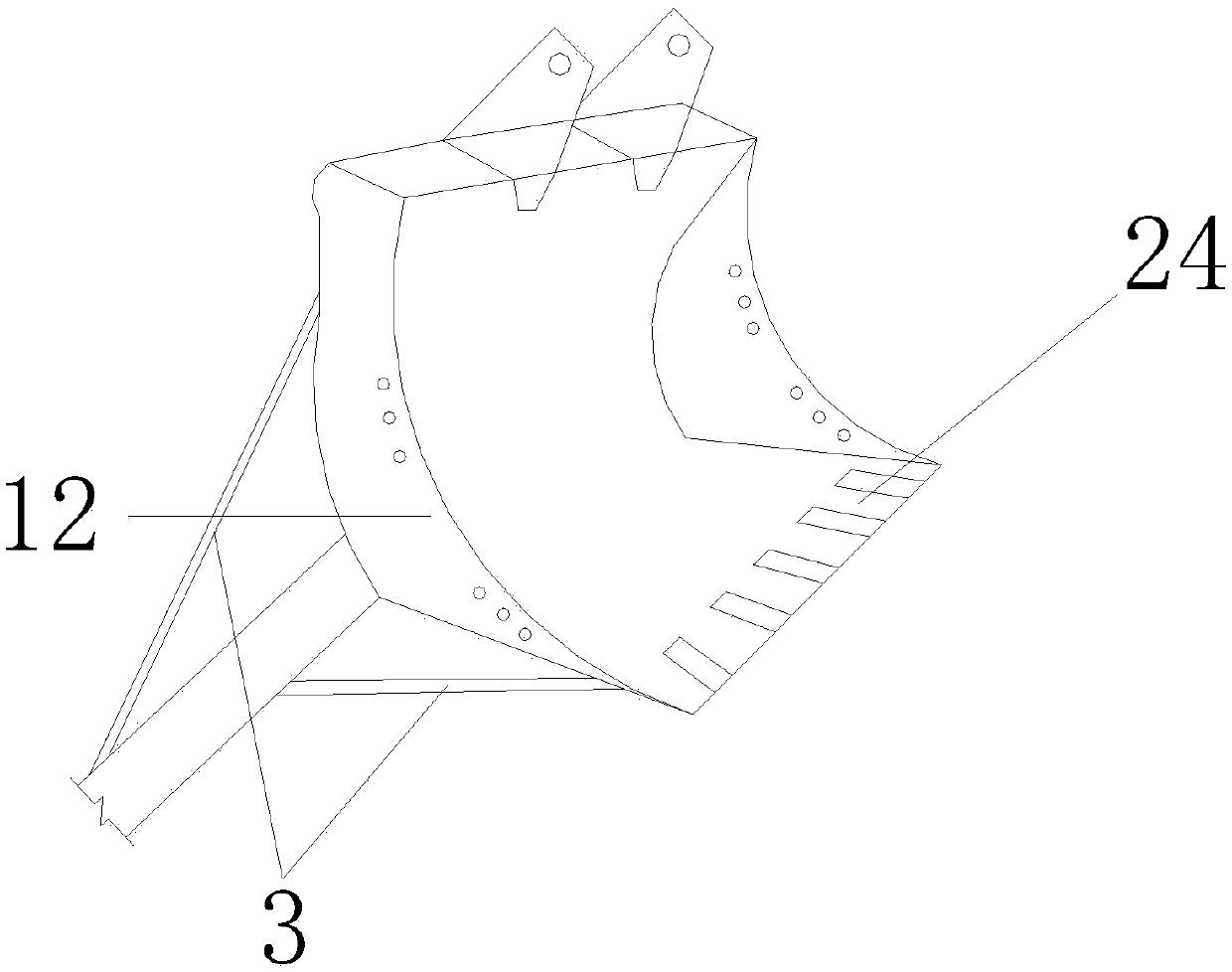

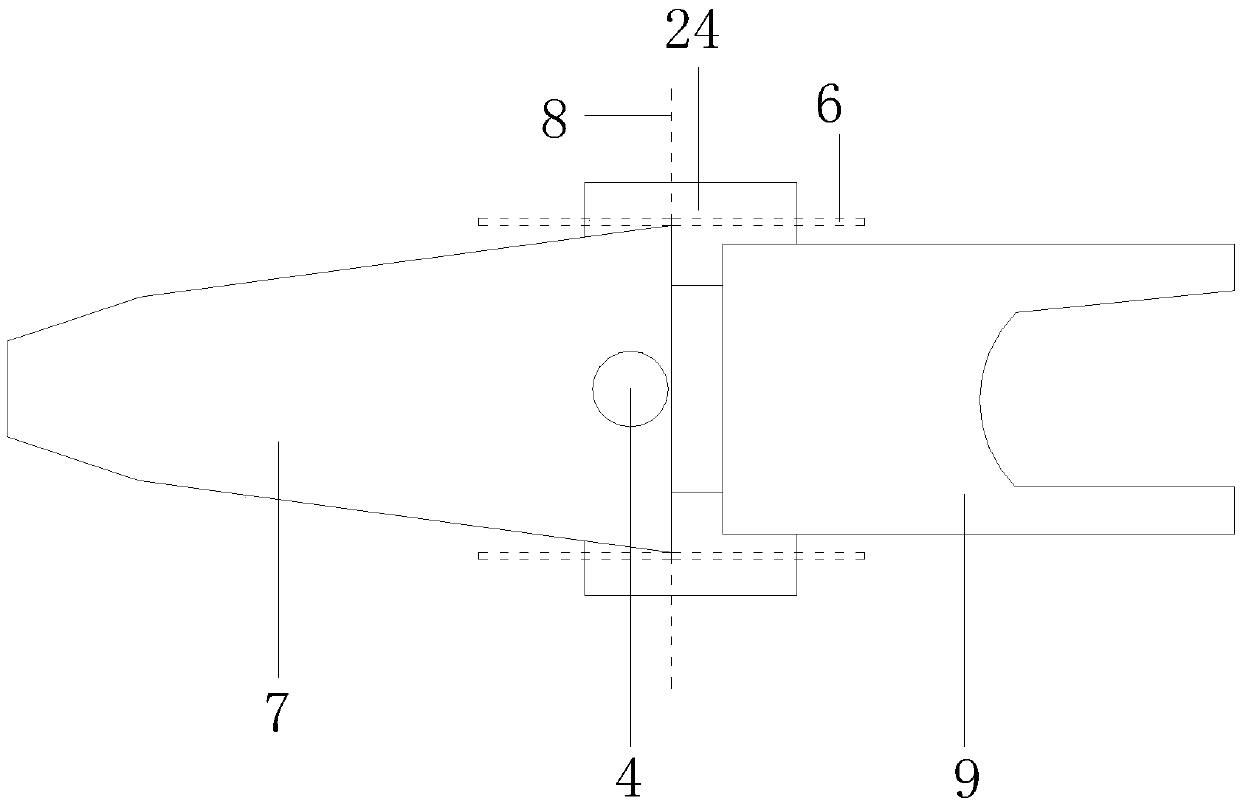

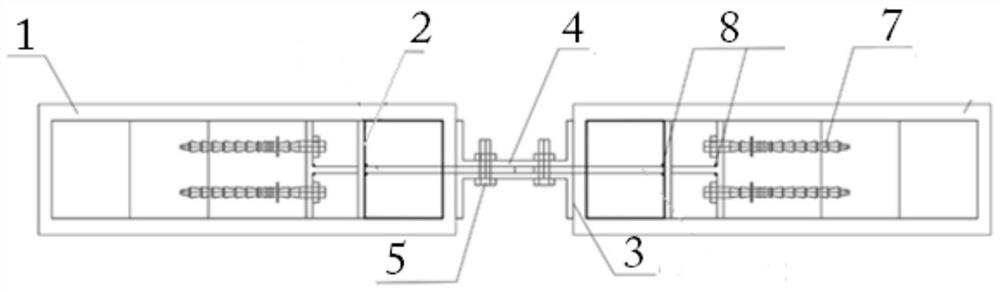

Wood structure anti-shearing connecting element, connecting structure, box body platform structure and construction method

ActiveCN105525681AImprove connection integritySolve the lack of carrying capacityFloorsEngineeringMetal

The invention relates to a wood structure anti-shearing connecting element, a connecting structure, a box body platform structure and a construction method. The connecting element is of an integral structure formed by sequentially and vertically bending a metal plate, and comprises a U-shaped web plate, flanges and hook heads, wherein the flanges symmetrically extend out from the two side surfaces of the web plate; the hook heads are formed by bending from the upper end parts of the flanges in a direction of being opposite to the web plate; and connecting holes are formed in each of the web plate, the flanges and the hook heads. The box body platform structure can be used as a lower part support structure for transforming the ground of a stadium into an ice surface; on the premise of not damaging the original field, the temporary transformation in the functional aspect can be fast completed by using the box body structure; and a technical feasible scheme is provided for transforming the existing ordinary stadium into a winter event stadium. By using the connecting element, the stability of the box body structure is ensured; and the reliability of the structure as a whole lower part supporter is ensured; the construction is simple and fast; the time and the labor are saved; and the construction efficiency and the construction quality can be effectively improved.

Owner:BEIJING NAT AQUATICS CENT CO LTD +3

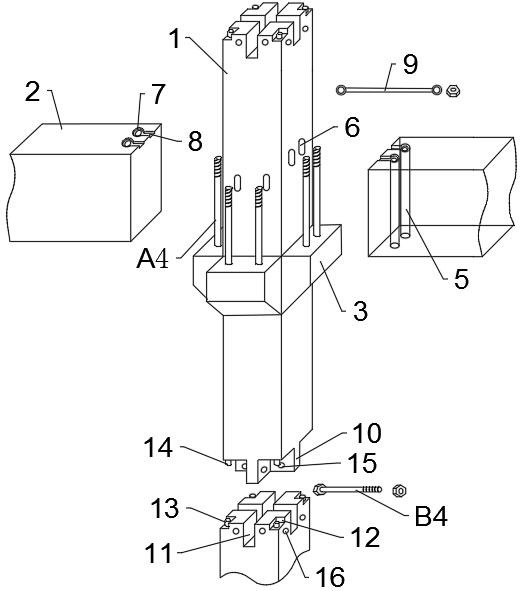

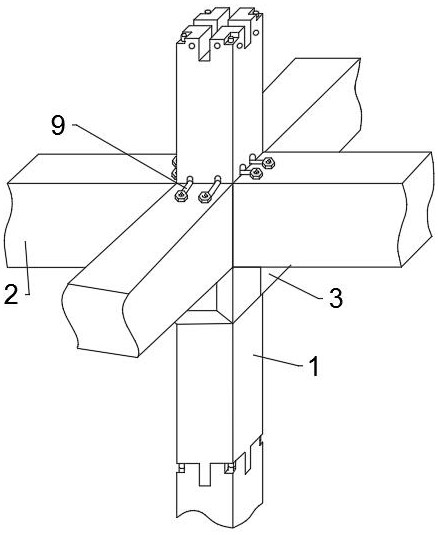

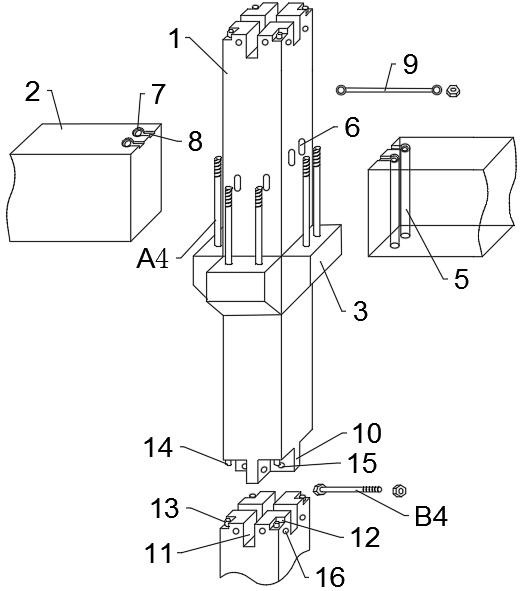

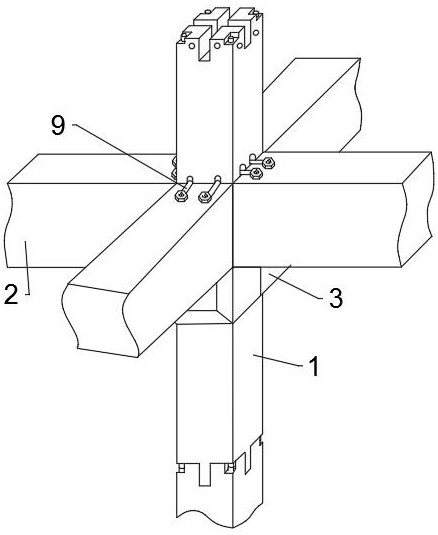

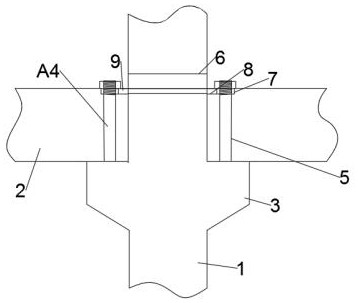

Novel assembly type connecting joint

ActiveCN111677107AImprove stabilityQuality improvementBuilding constructionsStructural engineeringMechanical engineering

The invention discloses a novel assembly type connecting joint. The novel assembly type connecting joint comprises a prefabricated bracket column and prefabricated beams, and further comprises screw rods, first through holes, grooves, tie rods and second through holes, wherein the screw rods are fixed to brackets and parallel to the prefabricated bracket column, the ends of the prefabricated beamsare placed on the brackets and connected with the brackets in a bolt fit mode, the first through holes are formed in the end parts, corresponding to the screw rods, of the prefabricated beams in a penetrating mode, the grooves are formed in the surfaces of the end parts of the prefabricated beams and comprise first grooves formed in the upper ends of the first through holes, the diameters of thefirst grooves are larger than the diameters of the first through holes, the grooves further comprise second grooves perpendicular to the width direction of the prefabricated beams, one ends of the second grooves communicate with the first grooves, the other ends of the second grooves extend to the edges of the end parts, circular rings are arranged at the two ends of rod bodies of the tie rods, the sizes of the rod bodies are matched with the sizes of the second grooves, the outer diameters of the circular rings are matched with the size of the first grooves, the inner diameters of the circular rings are the same as the diameters of the first through holes, and the second through holes are formed in the mode of being parallel to the width direction of the prefabricated bracket column in apenetrating manner.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

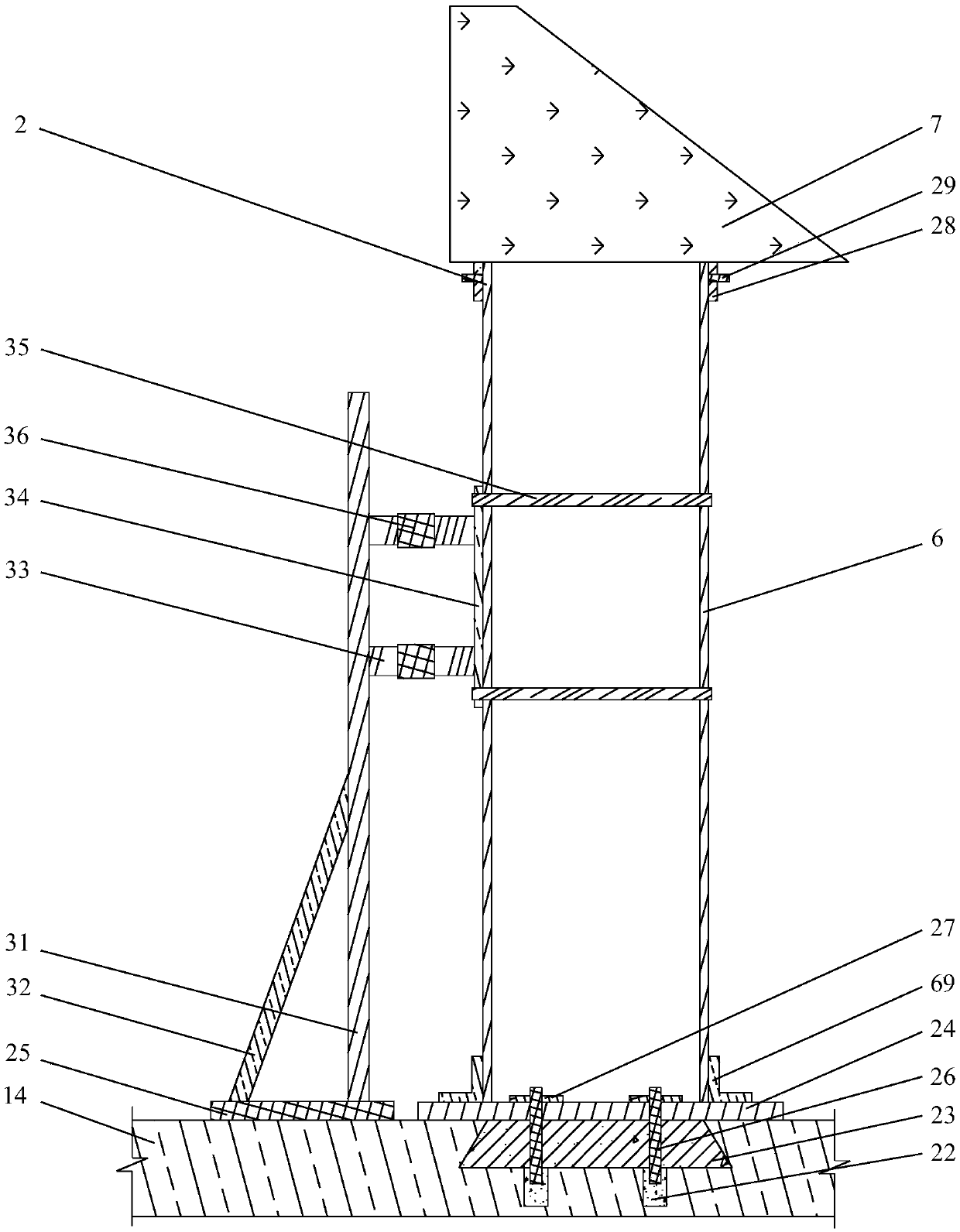

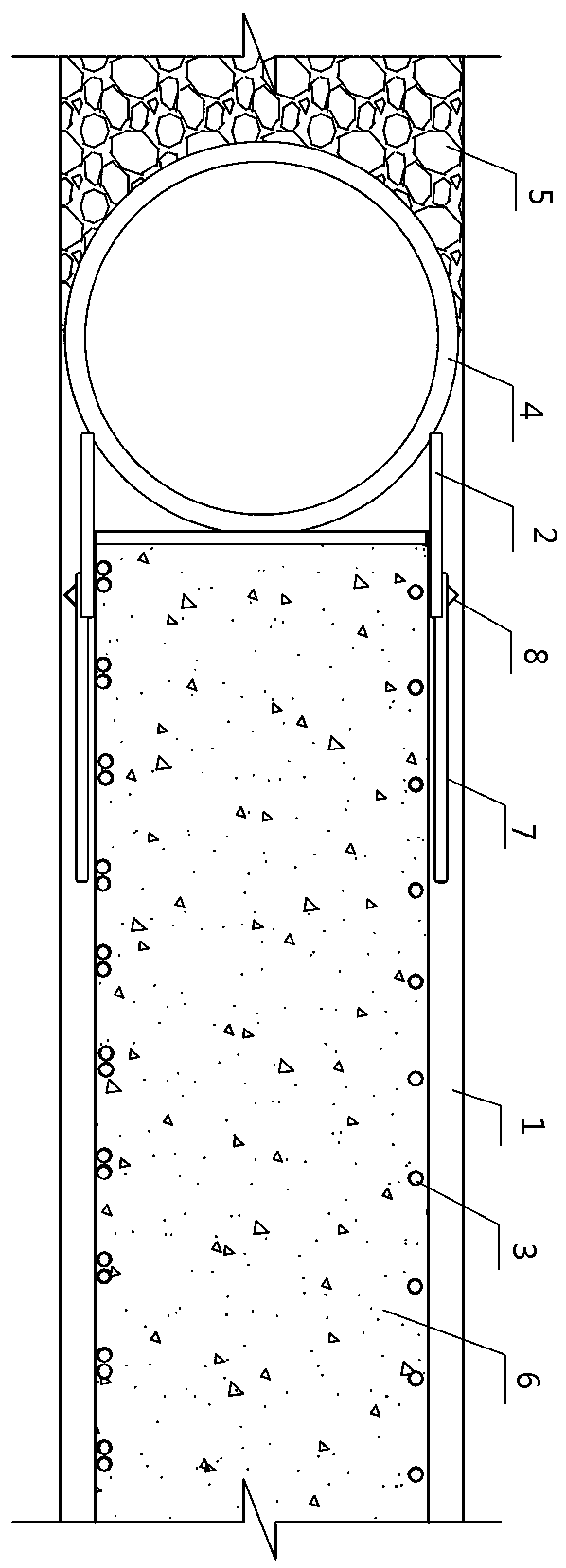

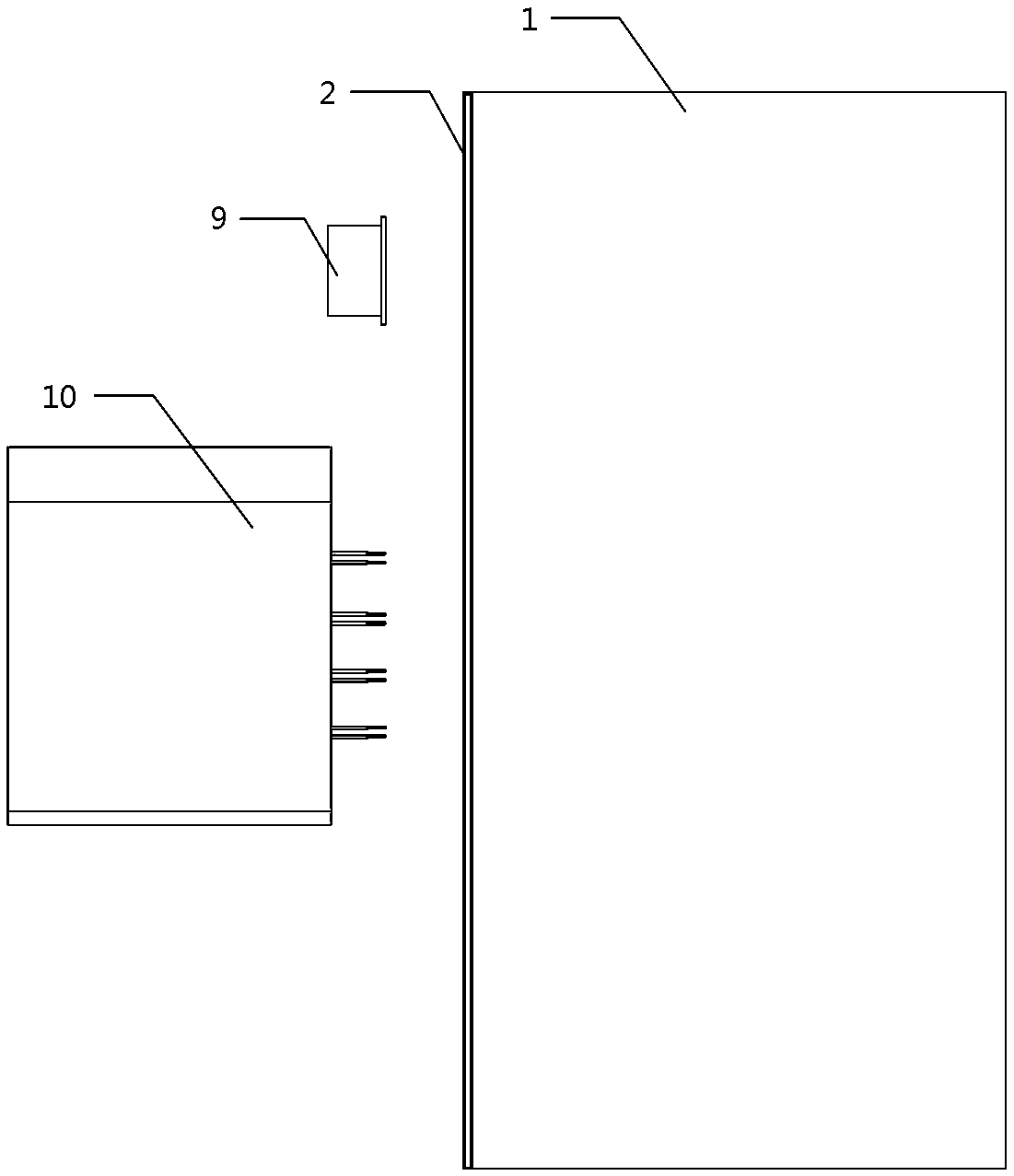

Suspension and protection system for water supply pipe crossing foundation pit and construction method

ActiveCN109629576AEnsure safetyFast and efficient excavationPipe supportsExcavationsReinforced concreteEconomic benefits

The invention relates to a suspension and protection system for a water supply pipe crossing a foundation pit and a construction method. The system is characterized by comprising a water supply pipe area foundation pit excavation auxiliary sizing device; a pile-beam integrated suspension supporting beam placing system; a unit assembly type suspension and protection system for the water supply pipecrossing the foundation pit; a rigid cast-in-situ concrete base and light roof covering backfill system for the water supply pipe crossing the foundation pit. The invention belongs to the field of underground engineering, effectively protects the integrity of a water supply pipe crossing the foundation pit, improves the construction safety, solves the integral stability problem of the suspensionsupporting structure consisting of a supporting pile and a reinforced concrete lintel, and obviously improves the construction efficiency, the construction process is simple and feasible. And good technical and economic benefits can be obtained when the system is applied to practical projects.

Owner:浙江恒鸿建设有限公司

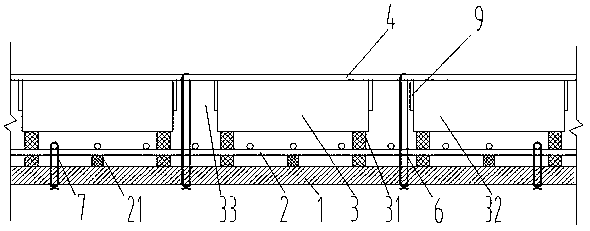

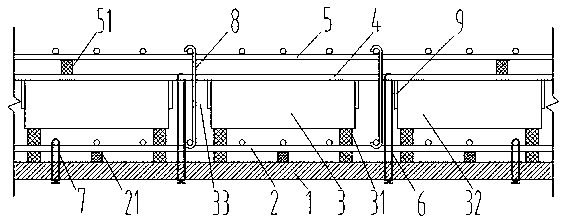

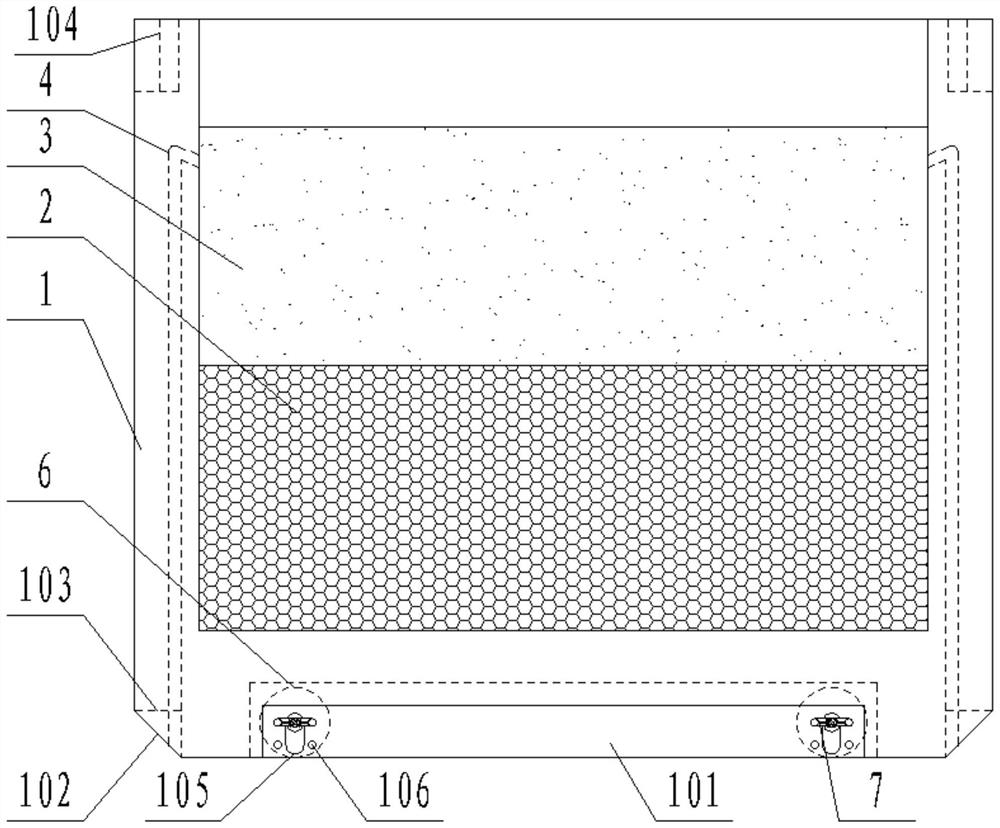

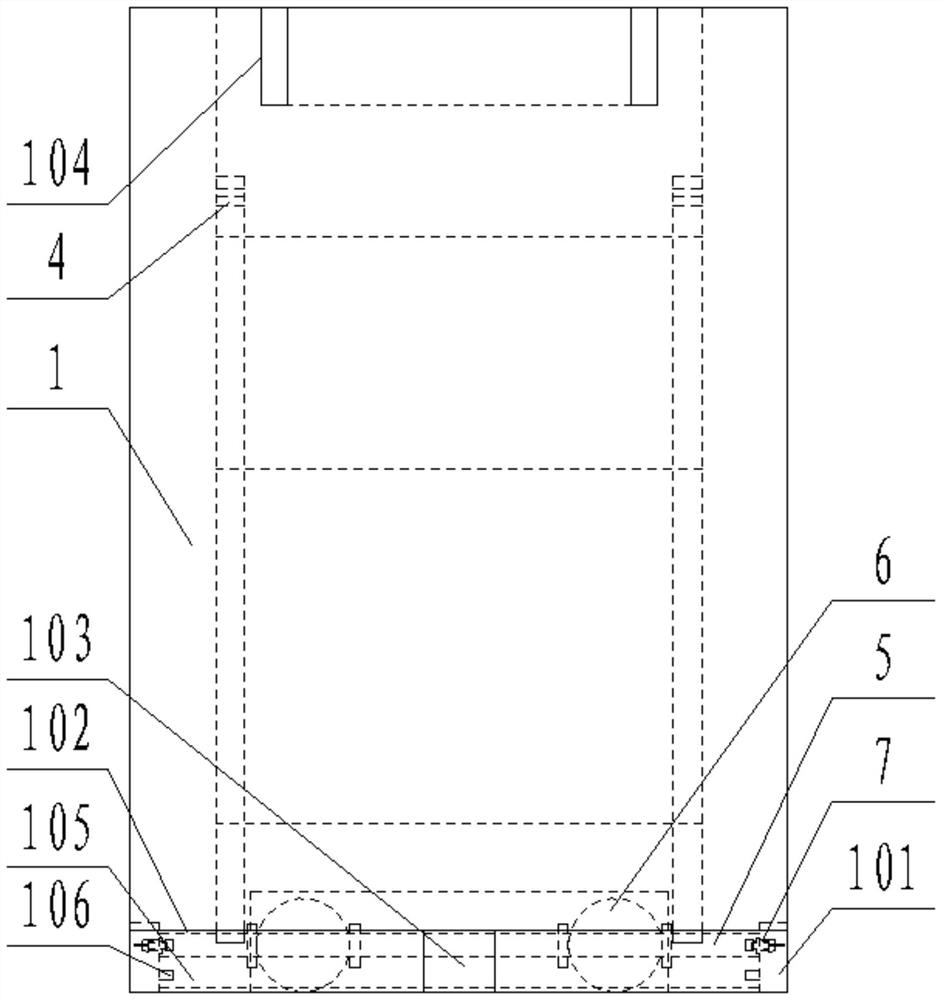

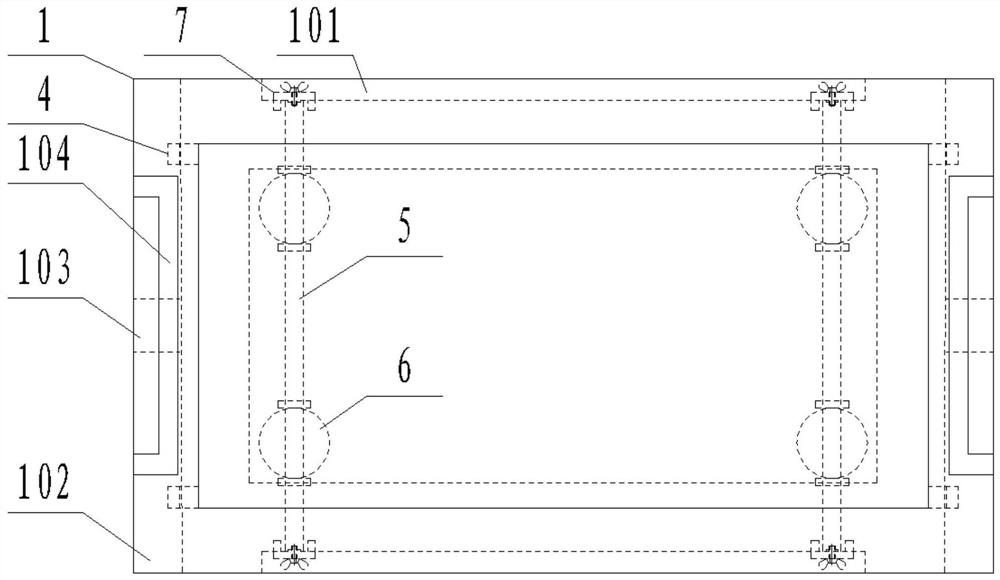

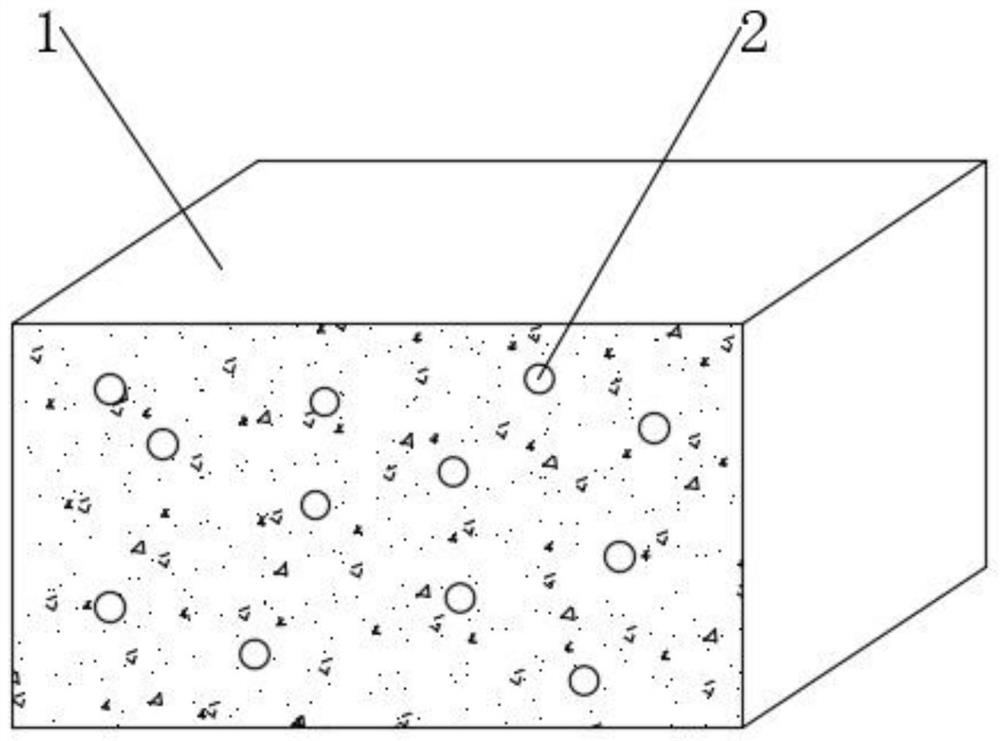

Construction method facilitating guarantee of hollow floor structural size

The invention relates to a construction method facilitating guarantee of hollow floor structural size. The construction method comprises the following steps that S1, a horizontal bottom formwork is laid; S2, a plurality of bottom layer steel bar cushion blocks are arranged on the bottom formwork, and a bottom steel bar layer is laid; S3, a plurality of second connecting pieces are used for connecting the bottom steel bar layer with the bottom formwork; S4, a plurality of placeholder box body cushion blocks are arranged on the bottom formwork, and a placeholder box body layer is laid; S5, an anti-floating steel bar layer is laid on the placeholder box body layer, and the anti-floating steel bar layer is supported by the placeholder box body layer; S6, a plurality of first connecting piecesare used for connecting anti-floating layer and the bottom formwork; S7, a plurality of top layer steel rib cushion blocks are arranged on the placeholder box body layer, and a top steel bar layer islaid; and S8, a plurality of third connecting pieces are used for connecting the top steel bar layer and the bottom steel bar layer. The anti-floating steel bar layer and the first connecting pieces are used for preventing placeholder box body tilting float after concrete slurry pouring, components in the floor are effectively fixed to guarantee the structure size of the floor to meet design sizerequirements and improve floor quality.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

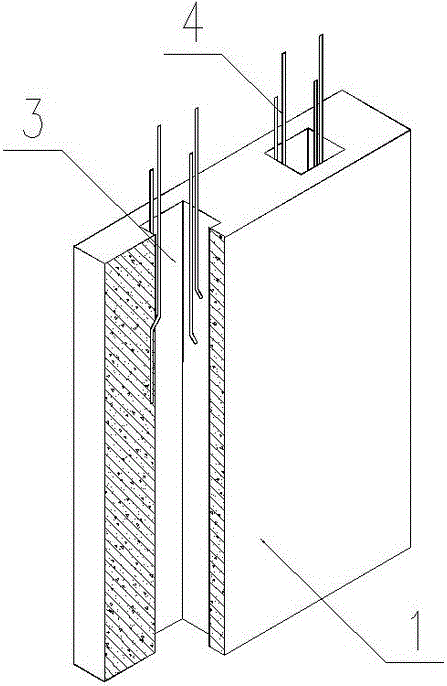

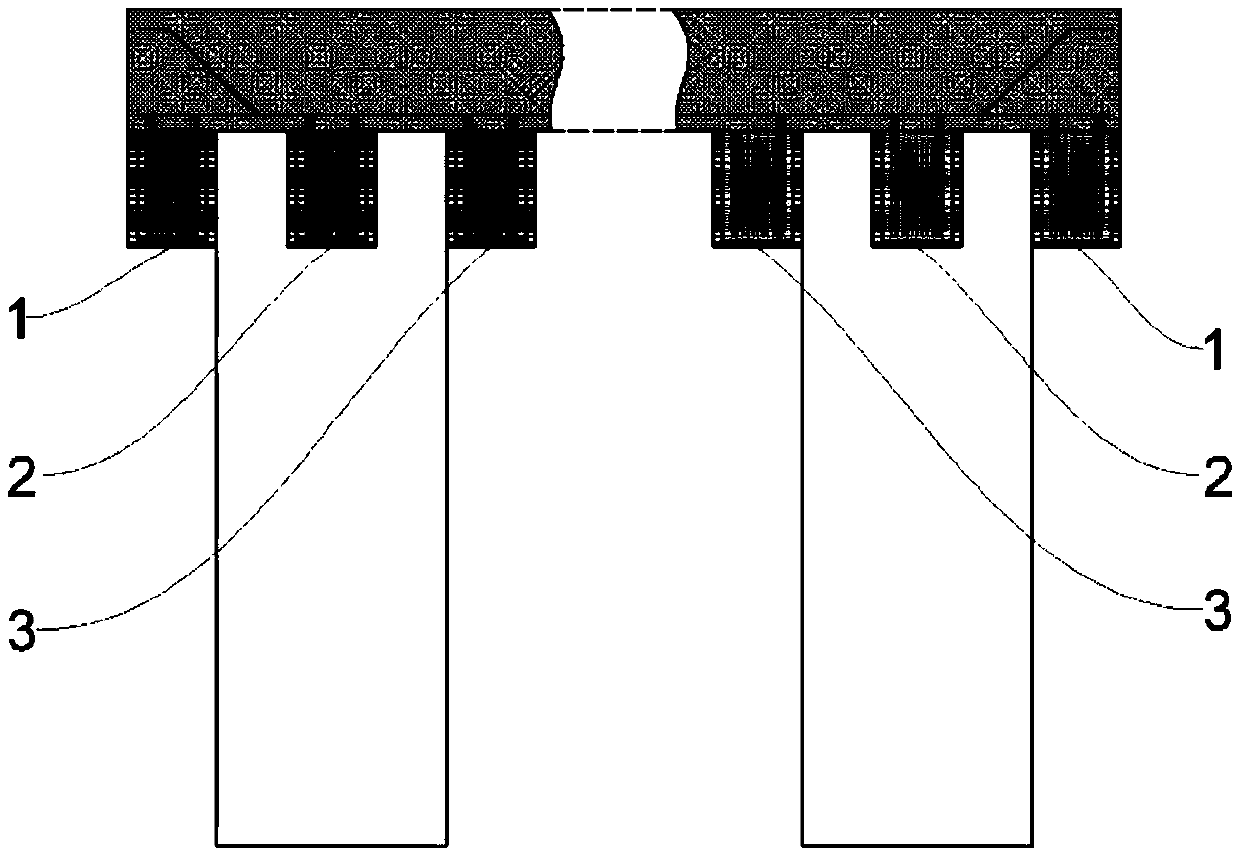

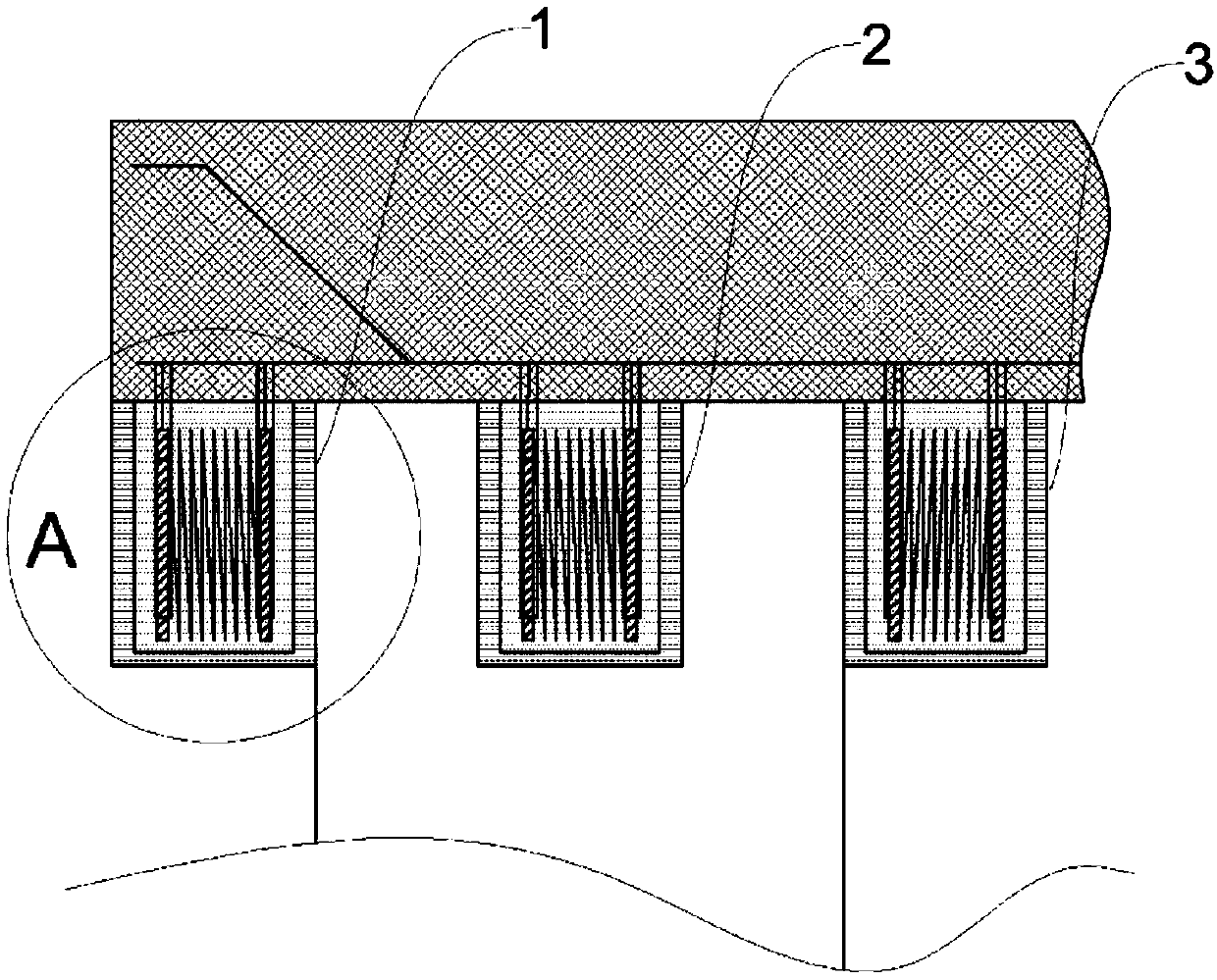

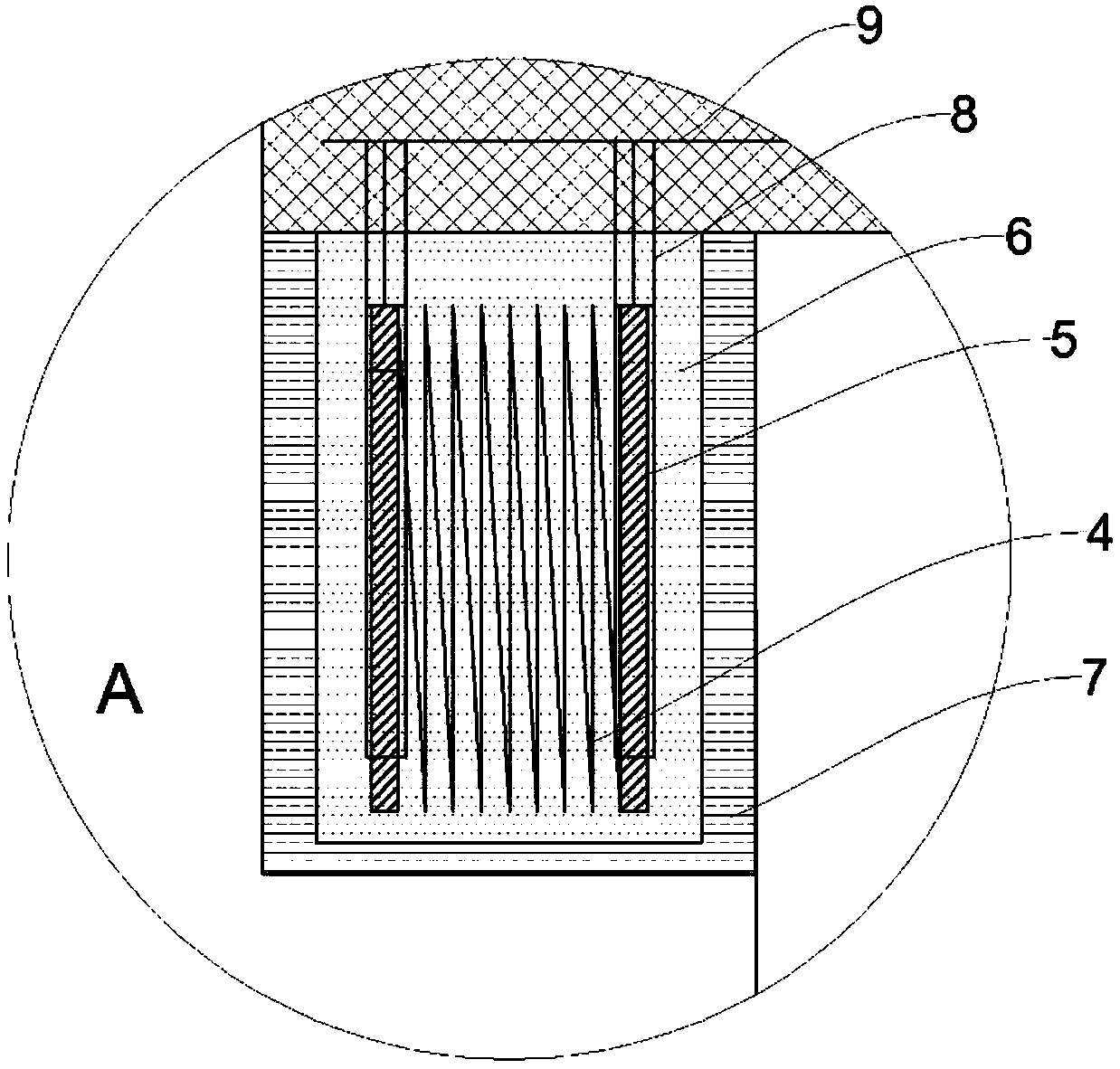

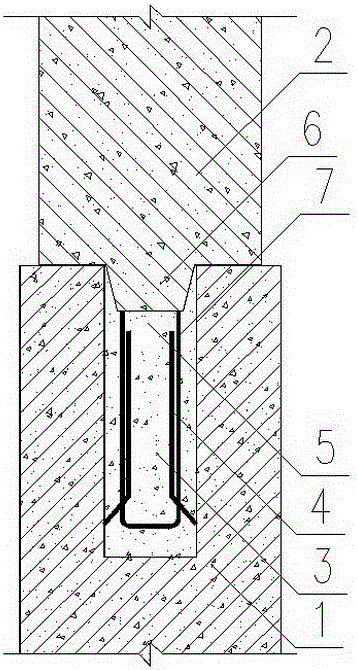

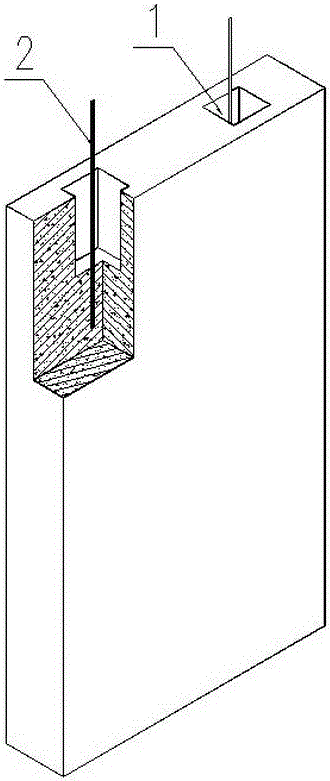

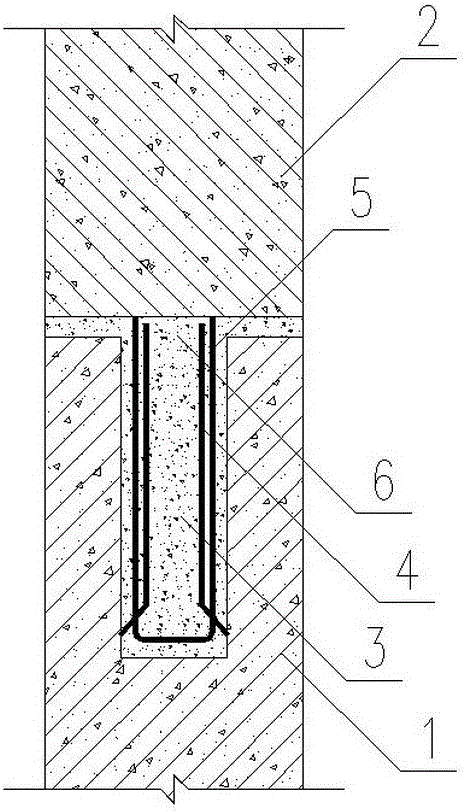

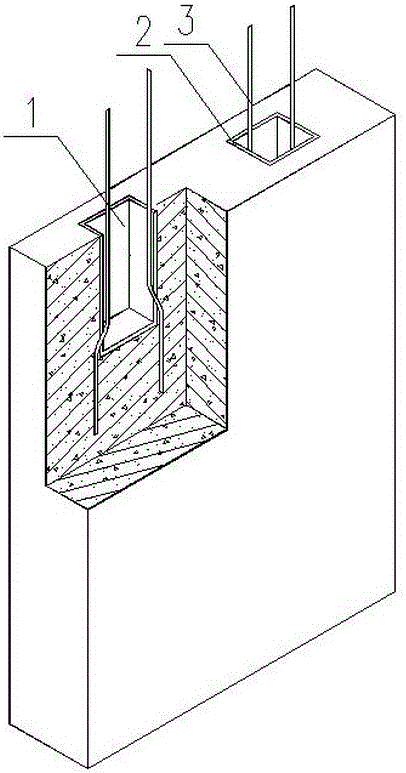

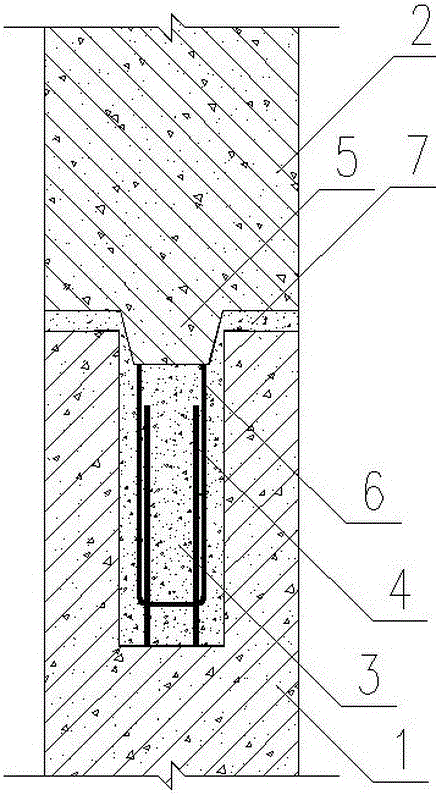

Prefabricated reinforced concrete component connecting method

InactiveCN106245786AImprove connection integrityDirect forceBuilding constructionsReinforced concreteRebar

The invention relates to a method for connecting prefabricated reinforced concrete members, belonging to the technical field of prefabricated concrete structures. The connection method connects the first prefabricated concrete member and the second prefabricated concrete member as a whole, and it is characterized in that at least one through hole is opened on the first prefabricated reinforced concrete member, and a steel bar is arranged in the hole, and the steel bar Anchored in the concrete of the side wall of the hole; there is a concrete protrusion on the second prefabricated reinforced concrete member, and the end of the protrusion extends out of the anchoring steel bar; the first prefabricated reinforced concrete member and the second prefabricated reinforced concrete member are installed, and the first prefabricated reinforced concrete member is installed. The protrusions of the two prefabricated reinforced concrete components are all or partially extended into the hole; between the first prefabricated reinforced concrete component and the second prefabricated reinforced concrete component, the hole is filled with concrete or grouting material.

Owner:初明进

Prefabricated anti-seismic beam and beam node

ActiveCN109680869AImprove integrityImprove reliabilityGirdersProtective buildings/sheltersArchitectural engineeringTransverse wave

The invention discloses a prefabricated anti-seismic beam and a beam node, and belongs to the technical field of prefabricated buildings. At least one side of two ends of the beam is provided with a protruding outer wing, middle wing and inner wing; the middle wing is inserted into a connection column, and the outer wing and the inner wing abut against two sides of the connection column respectively; compression springs which are perpendicular to the connection column are arranged in the outer wing, the middle wing and the inner wing, buffer boards are connected with two sides of each compression spring, and the buffer boards are fixedly connected with beam main reinforcement through stirrups; the outer wing, the middle wing and the inner wing are filled with graphene foam. Compared with the prior art, the prefabricated anti-seismic beam and the beam node have the advantage that through simple beam end node structure and interior structure modification, the absorption and buffer capability of the beam node of transverse waves caused by earthquakes is greatly improved, so that the anti-seismic property of a building is improved.

Owner:宁波云创建筑工程技术有限公司

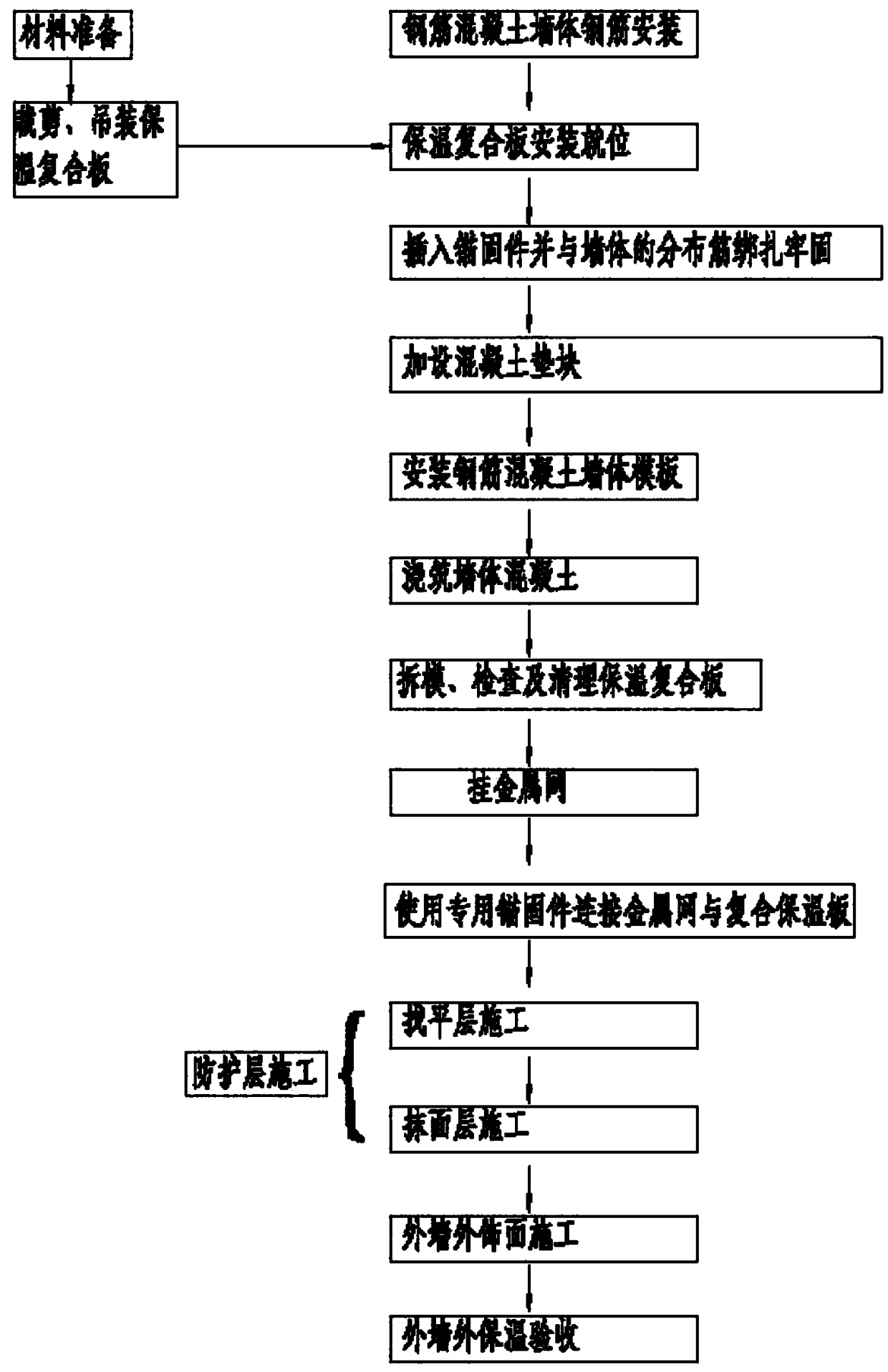

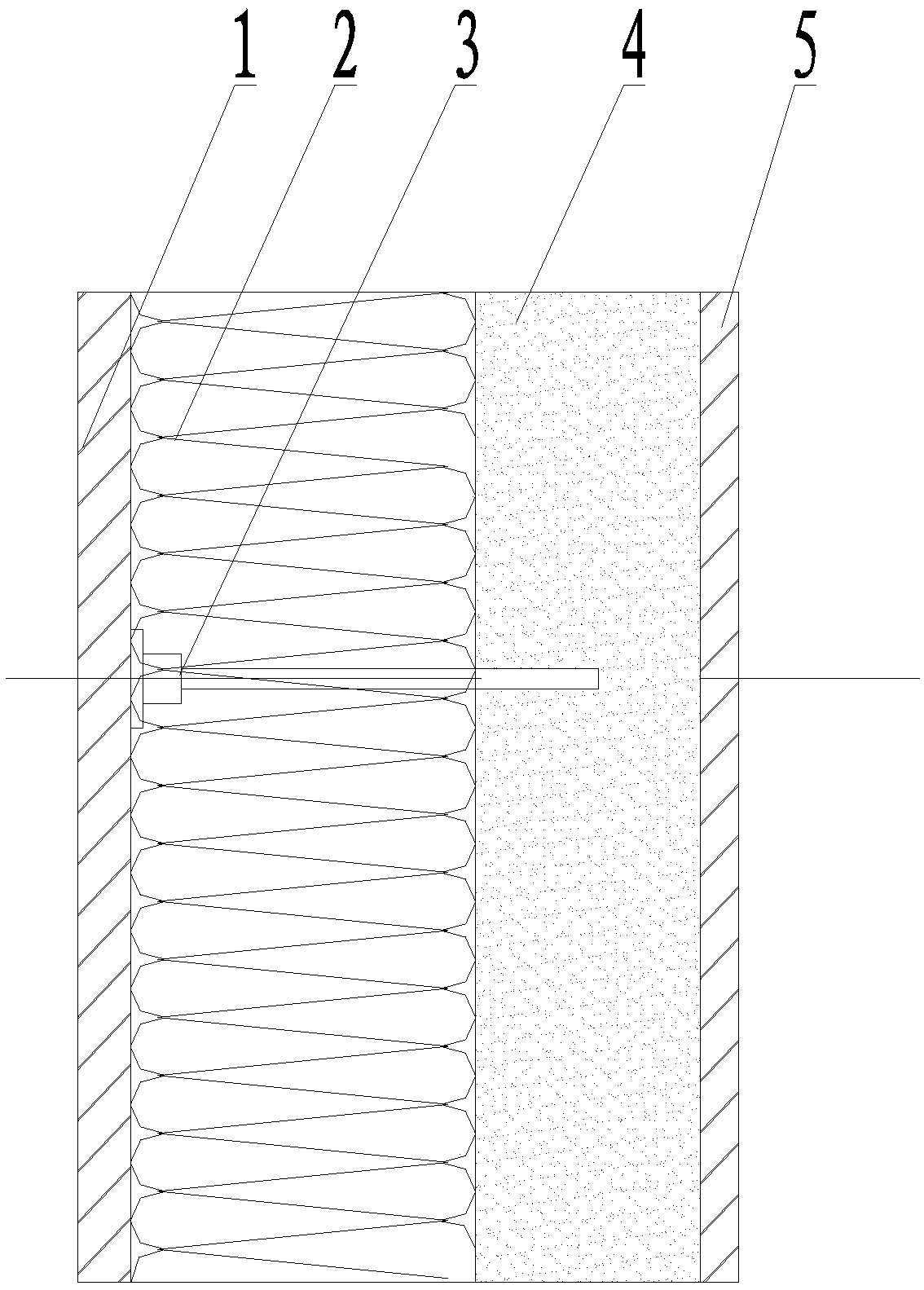

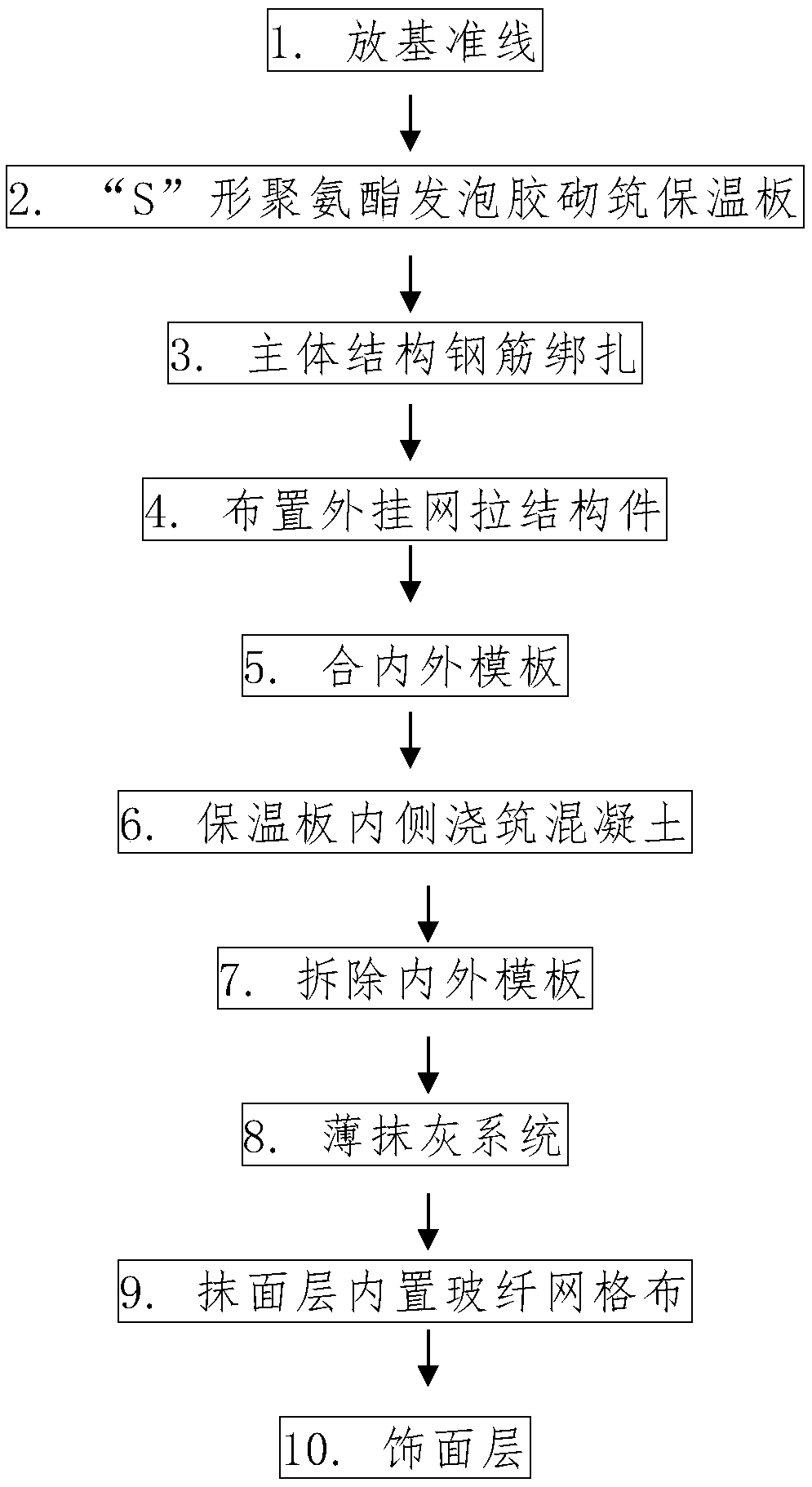

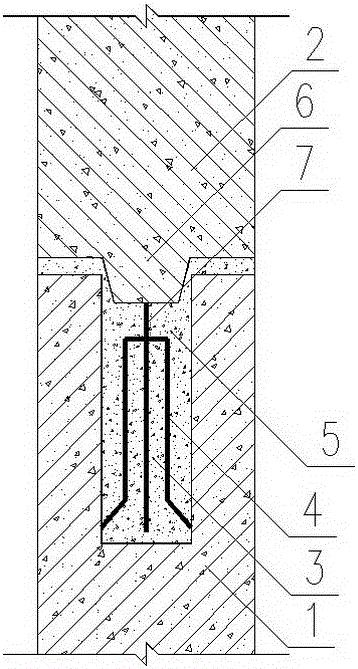

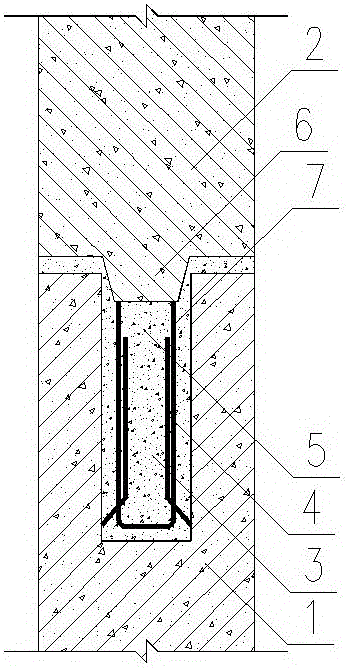

Passive low-energy building external thermal insulation system construction process

InactiveCN109024936ASticky anchor effectiveness solutionRealize the buildingClimate change adaptationPassive housesThermal insulationArchitectural engineering

The invention discloses a passive low-energy building external thermal insulation system construction process that is different from an existing process described on the graph; the process comprises the following steps: laying warming plates into a thermal insulation wall, and building a reinforcement mat and casting same with the thermal insulation wall into one body. The single layer insulationstructure integrated technology firstly lays the thermal insulation wall, and then deploys the main structure steel bars; verticality control and template adjustment and calibration are fast.

Owner:HEBEI SANKAISHENFA SCI & TECH CORP LTD

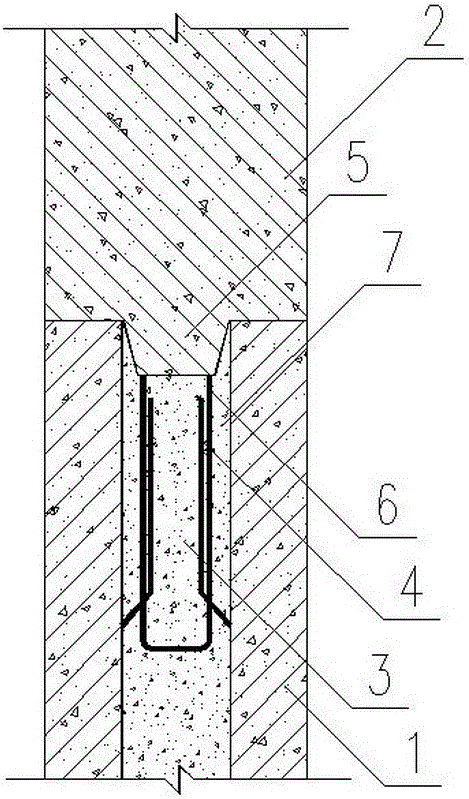

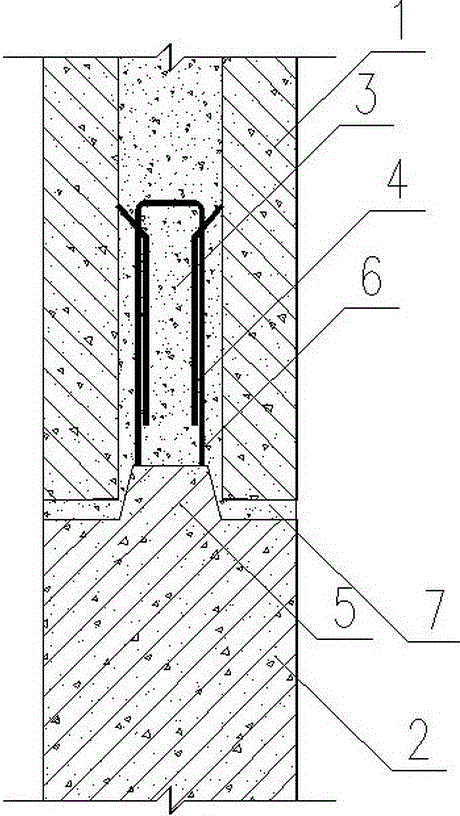

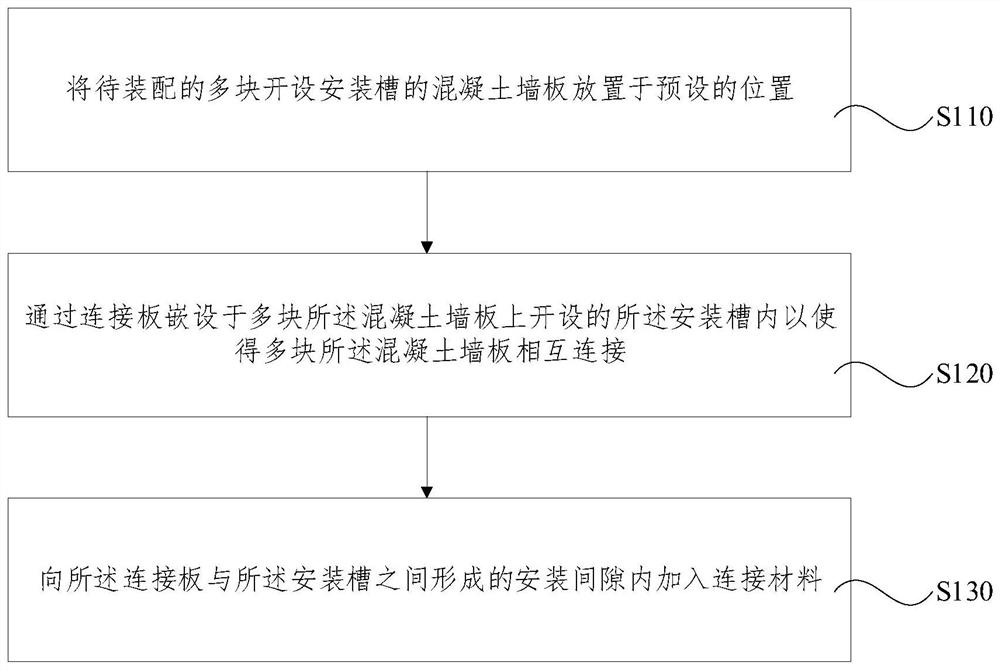

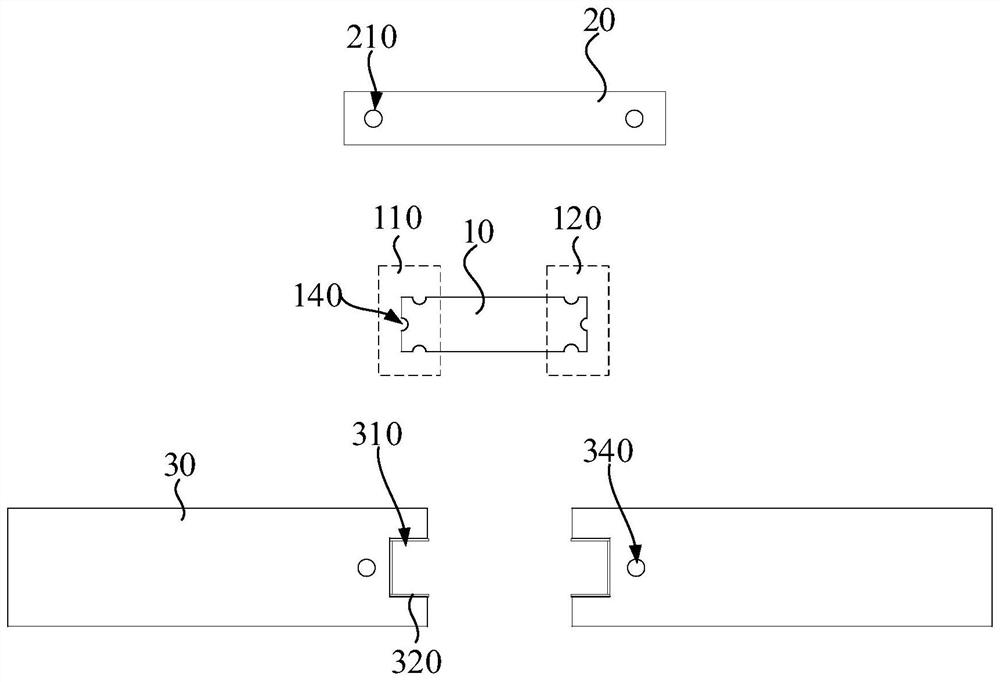

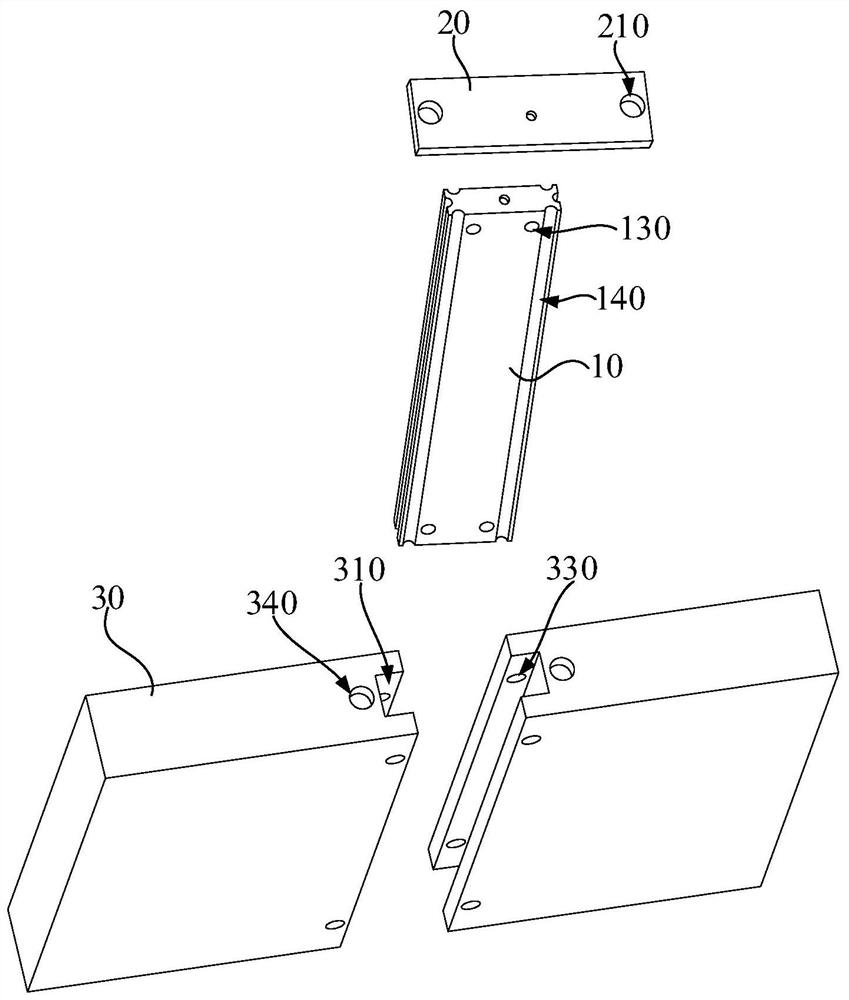

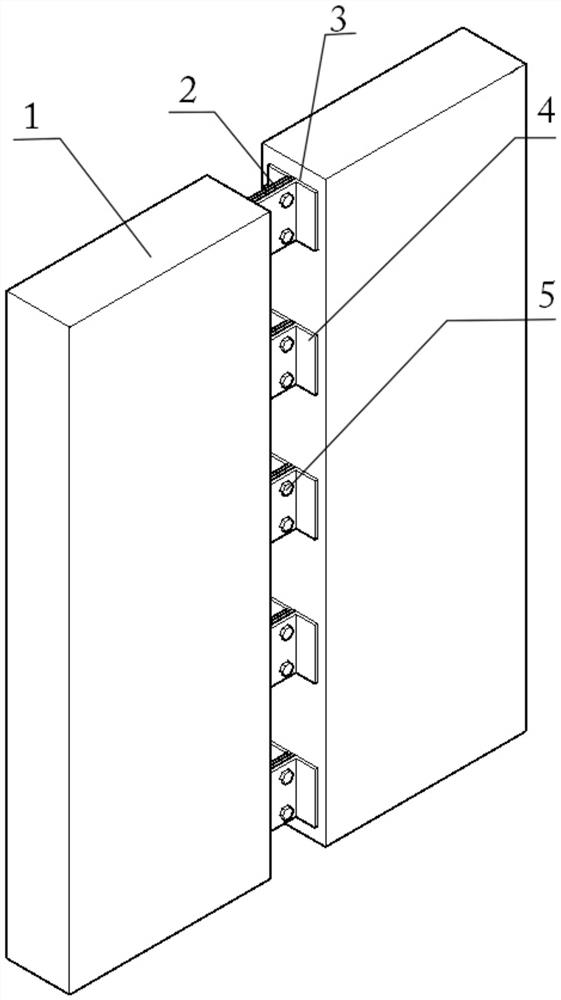

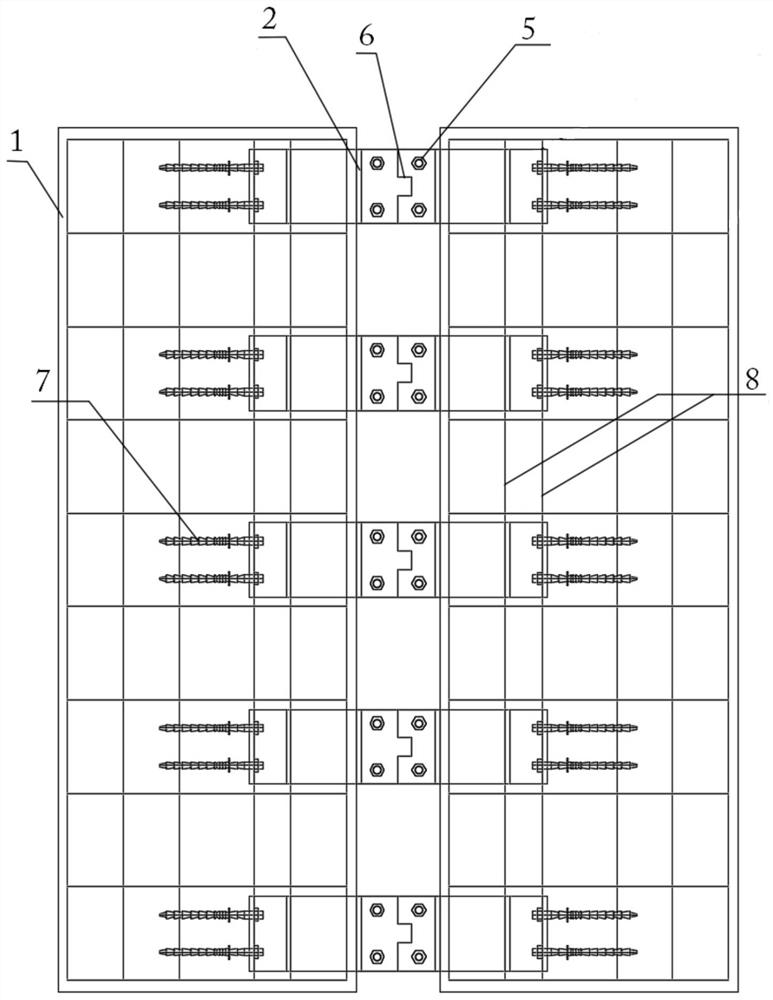

Prefabricated concrete dry-type connection method and prefabricated concrete wall

PendingCN113216449AImprove connection integritySimple structureWallsBuilding material handlingWall plateMechanical engineering

The invention provides a prefabricated concrete dry-type connecting method and a prefabricated concrete wall. The prefabricated concrete dry-type connecting method comprises the steps that a plurality of to-be-assembled concrete wallboards with mounting grooves are placed at preset positions; connecting plates are embedded into the mounting grooves formed in the multiple concrete wallboards, so that the multiple concrete wallboards are connected with one another; and a connecting material is added into mounting gaps formed between the connecting plates and the corresponding mounting grooves. Through the mode, a plurality of concrete wallboards are connected through the connecting plates, the connecting materials are added into the mounting gaps formed after connection so as to further reinforce the connecting integrity of the concrete wallboards; and the connecting plates are matched with the mounting grooves, so that the structure is simple, disassembly and assembly are convenient, high precision is not needed, the defect that in the prior art, a dry-type connecting method is high in manufacturing and installation precision requirement is overcome, and therefore popularization and implementation are convenient.

Owner:BEIJING UNIVERSITY OF CIVIL ENGINEERING AND ARCHITECTURE

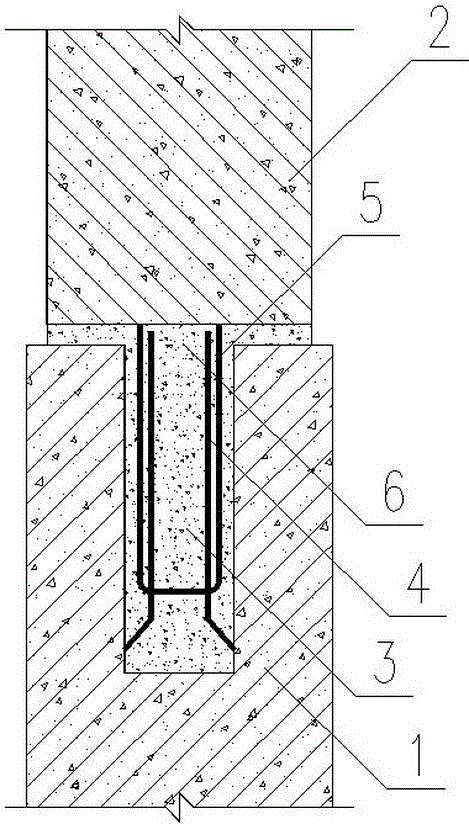

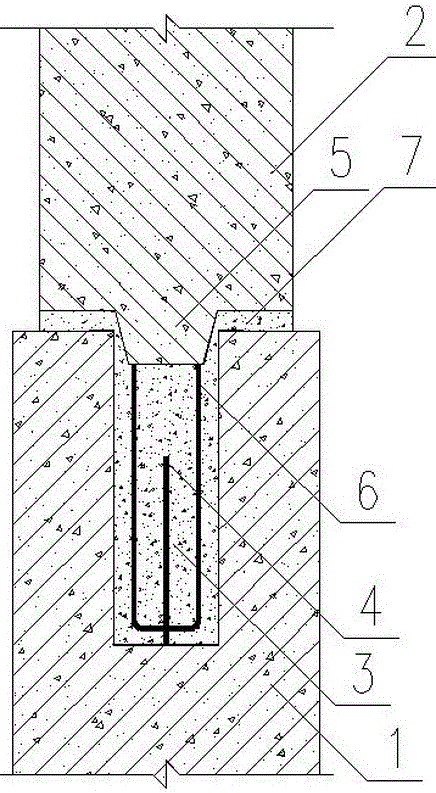

Connecting method of precast reinforced concrete members

InactiveCN106223477AGuaranteed integrityEasy constructionBuilding constructionsReinforced concreteEngineering

The invention relates to a connecting method of precast reinforced concrete members, and belongs to the technical field of precast concrete structures. The connecting method is used for connecting a first precast reinforced concrete member and a second precast reinforced concrete member into a whole. The connecting method is characterized in that at least one groove is formed in the first precast reinforced concrete member, and the groove is filled with the retarding mortar; a reinforcement bar is arranged in the groove, and is anchored into concrete at the side wall of the groove; a concrete bulge is arranged on the second precast reinforced concrete member, and the end part of the bulge extends out of the anchored reinforcement bar; the first precast reinforced concrete member and the second precast reinforced concrete member are installed, and all or part of the bulge of the second precast reinforced concrete member extends into the groove; after the retarding mortar is cured, the first precast reinforced concrete member and the second precast reinforced concrete member are connected into a whole.

Owner:初明进

Structure of pressure-resistant oil tank and manufacturing method thereof

The invention relates to a structure of a pressure-resistant oil tank and a manufacturing method thereof. According to the main points of the technical scheme, the manufacturing method of the pressure-resistant oil tank comprises the following steps that S1, a connection part is installed, an installation rod is inserted into a sleeve from one end of a matching disc during installation, and a gapis reserved between an installation disc and the matching disc; S2, the connection part is fed into a blow molding mold through a feed part, a blow molding machine blows out a molten parison, the parison is put into the mold, and the blow molding mold is closed; S3, the installation disc makes contact with the parison and presses the parison into a shaft hole, a pressing driving part pushes a shaft sleeve to move along the shaft hole and rotates at the same time, and the shaft sleeve pushes the installation disc to abut against the matching disc; and S4, the blow molding mold is opened, the feed part is taken out from the blow molding mold, then the blow molding mold is closed again, the mold is opened again after the parison is cooled, and the effect that connection strength and stabilitybetween an anti-wave plate and the inner wall of the pressure-resistant oil tank are improved is achieved.

Owner:德安福(天津)汽车技术有限公司

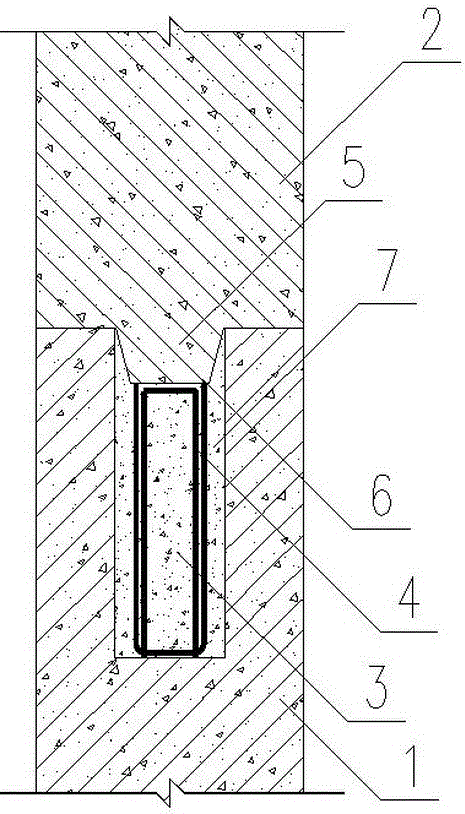

Prefabricated concrete member and manufacturing method thereof

InactiveCN105904587AImprove connection integrityFirmly connectedStrutsConstruction materialFiber-reinforced compositeRebar

The invention relates to a prefabricated concrete member and a manufacturing method of the prefabricated concrete member and belongs to the technical field of prefabricated concrete structures. At least one discontinuous hole is formed in the prefabricated concrete member. Rebars anchored into concrete at the bottoms of the holes are arranged in the holes. The manufacturing method of the prefabricated concrete member includes the steps that the holes are manufactured through inner dies of steel pipes or fiber-reinforced composite pipes, the bottoms of the inner dies are sealed and provided with the holes, and the rebars penetrate the holes. By the adoption of the prefabricated concrete member, the stress performance of the prefabricated concrete structure is improved.

Owner:初明进

Prefabricated shear wall vertical joint connecting structure and construction method thereof

PendingCN113898092ASo as not to damageReduce repair costsWallsProtective buildings/sheltersButt jointArchitectural engineering

The invention discloses a prefabricated shear wall vertical joint connecting structure and a construction method thereof, and relates to the technical field of prefabricated concrete shear wall vertical joint connecting structures in civil construction. The prefabricated shear wall vertical joint connecting structure mainly structurally comprises shear walls, embedded profile steel and connecting pieces. The embedded profile steel is partially embedded in the shear walls, the embedded profile steel on the two shear walls is in butt joint through a rabbet, and the butt joint position is covered with the connecting pieces. The invention further provides a construction method of the prefabricated shear wall adopting the vertical joint connecting structure. The prefabricated shear wall vertical joint connecting structure is good in shock resistance, easy to install and convenient to maintain.

Owner:CHINA RAILWAY CONSTR GROUP

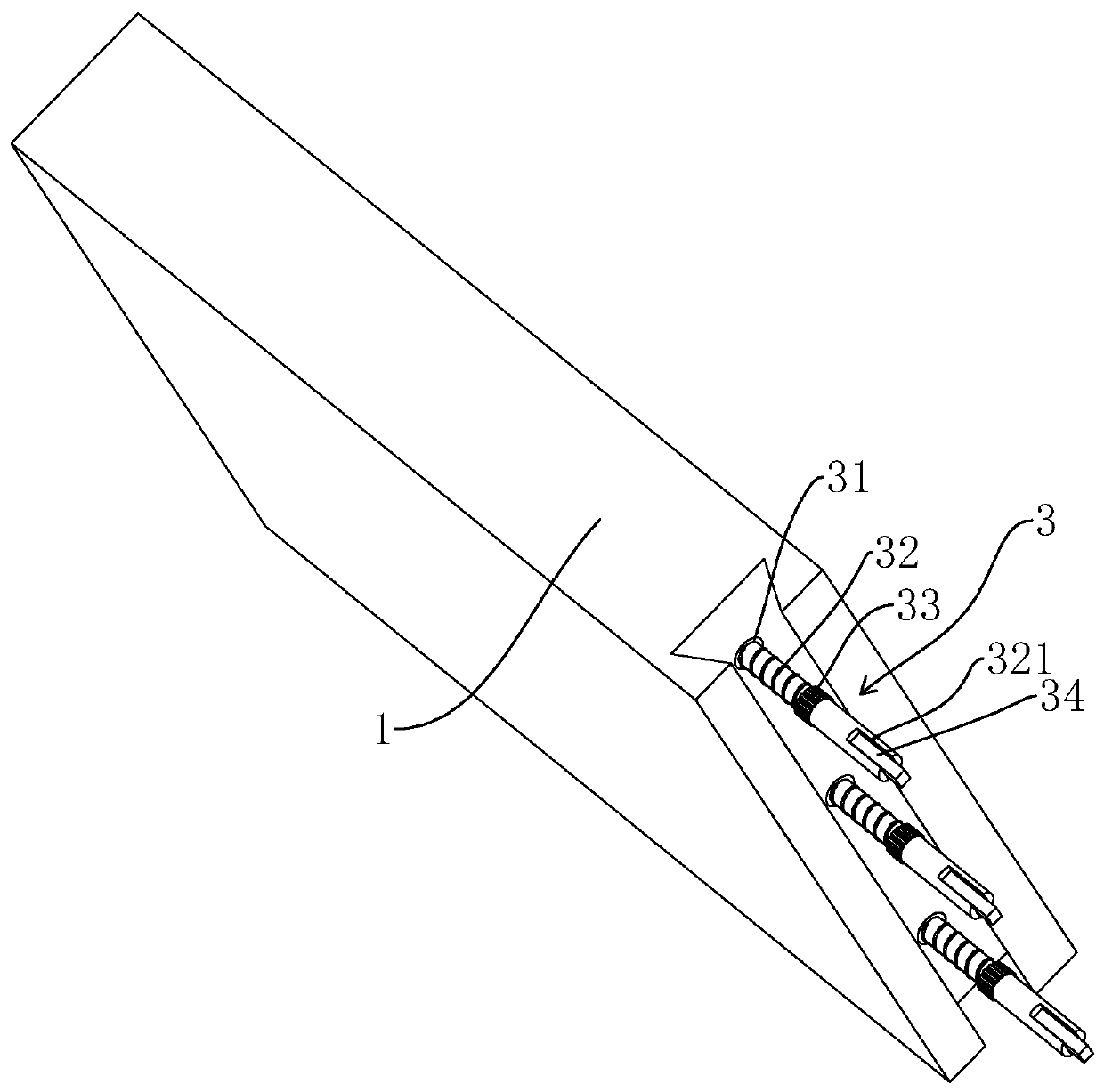

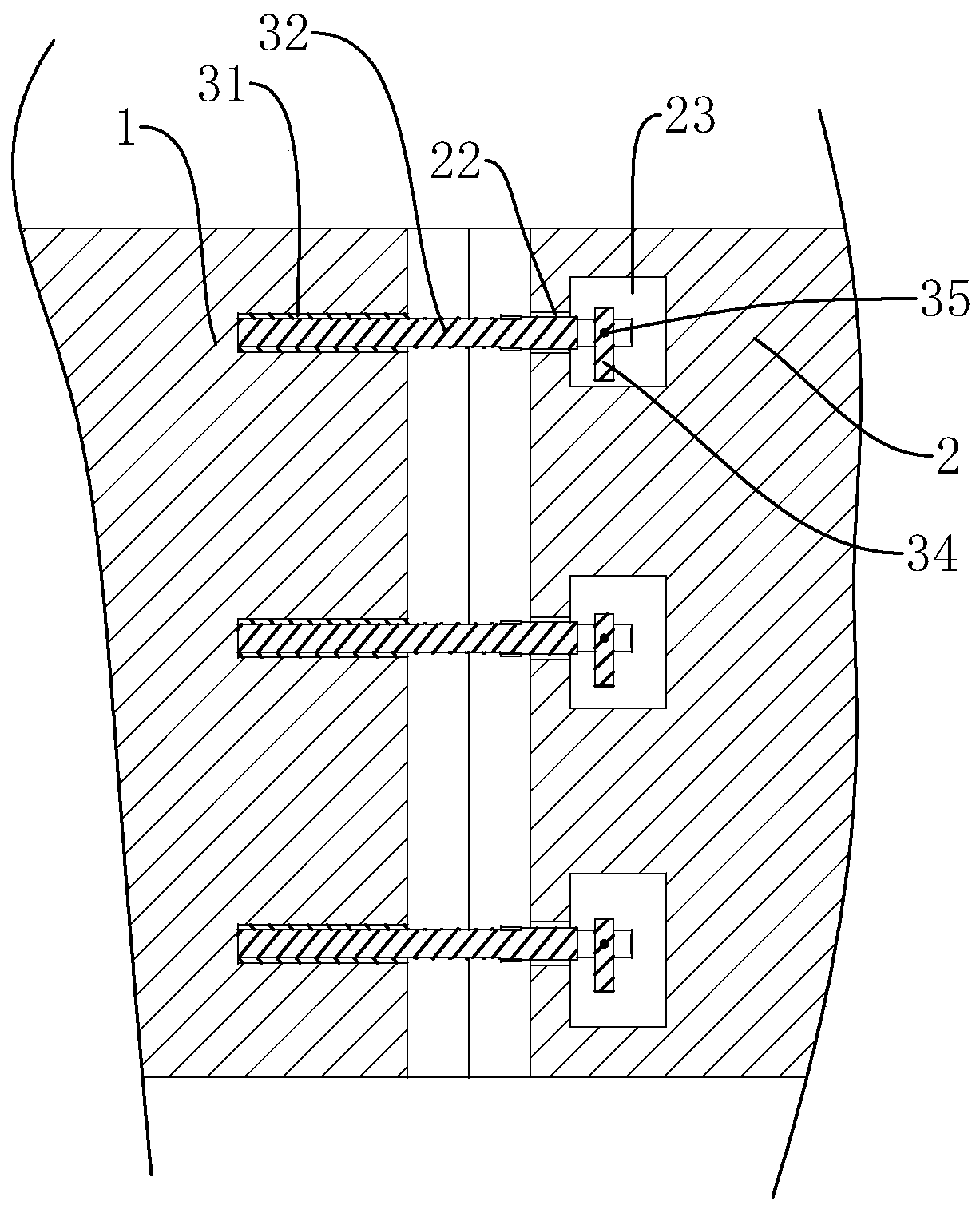

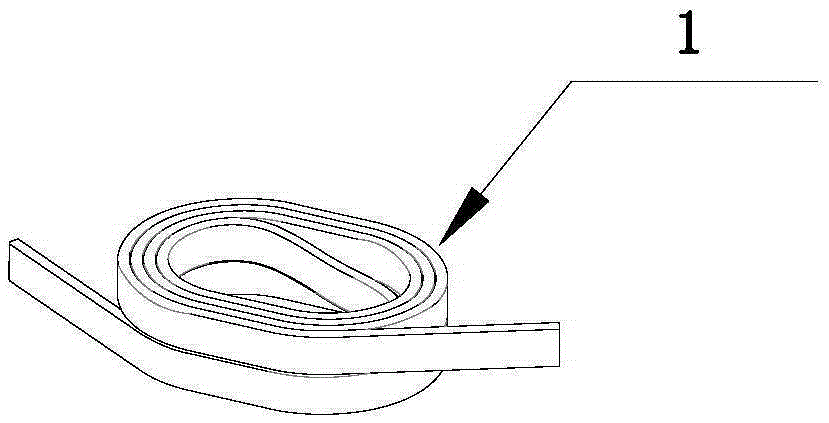

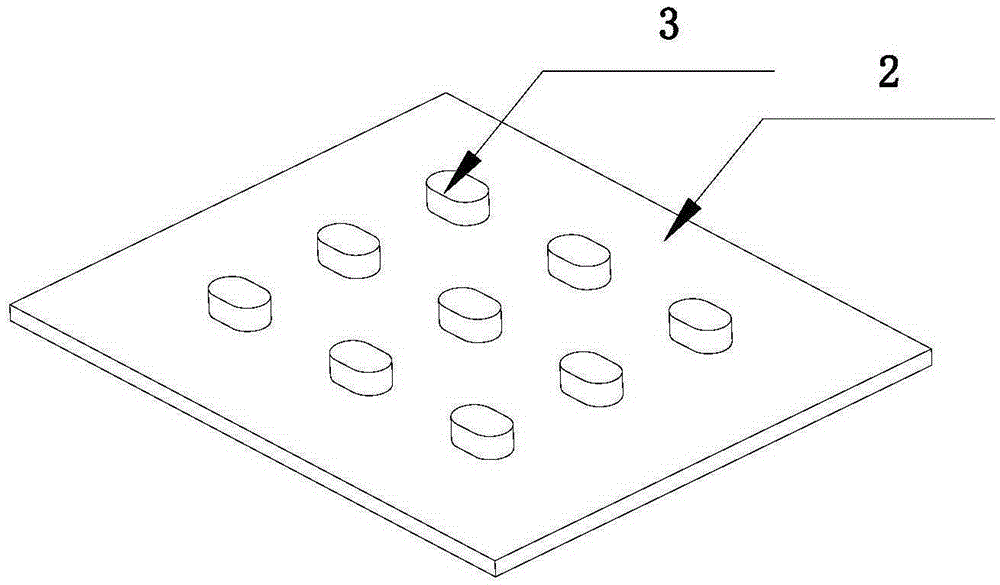

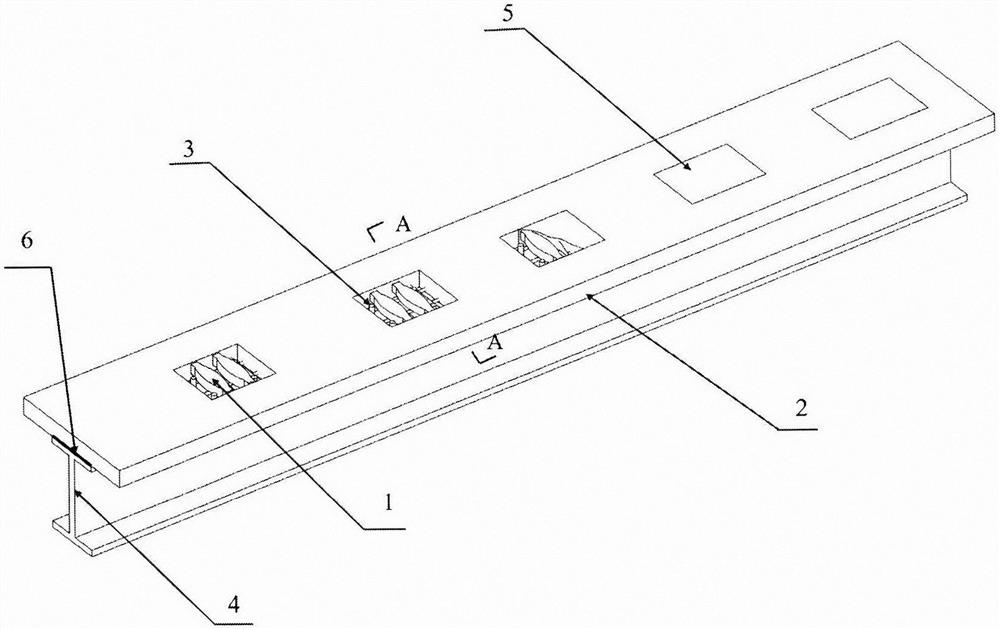

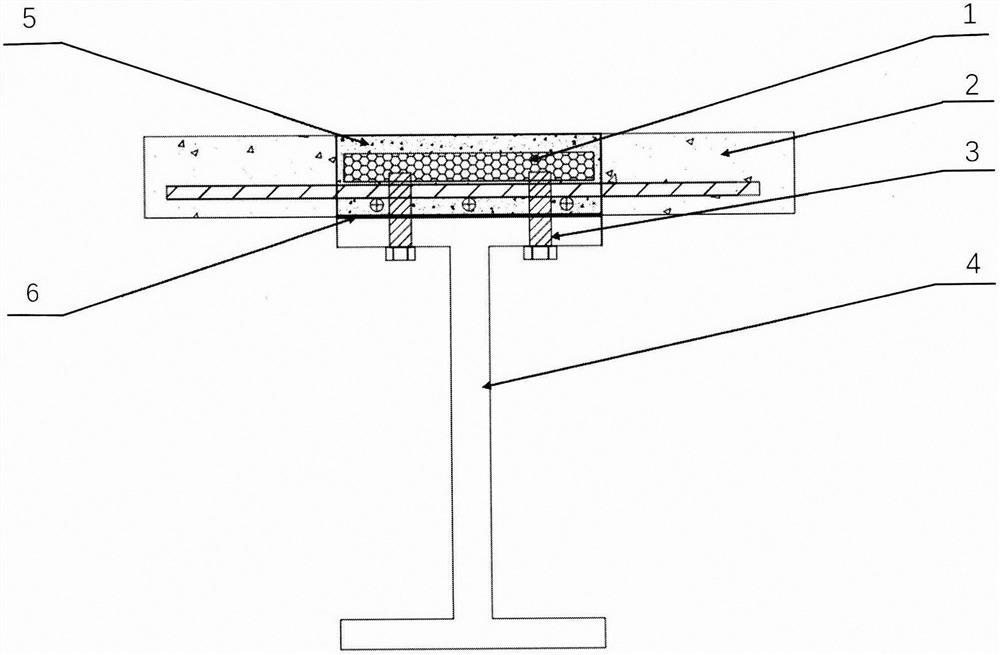

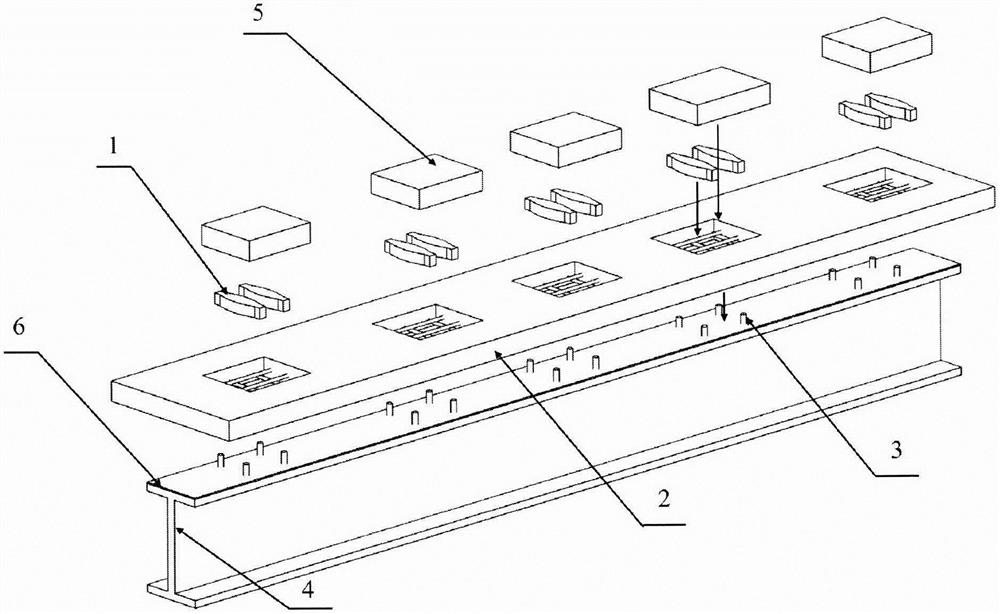

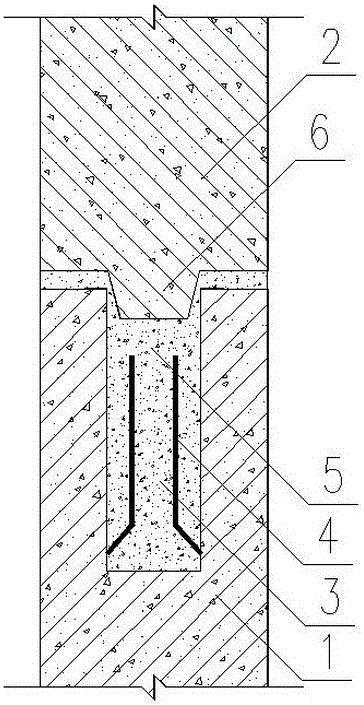

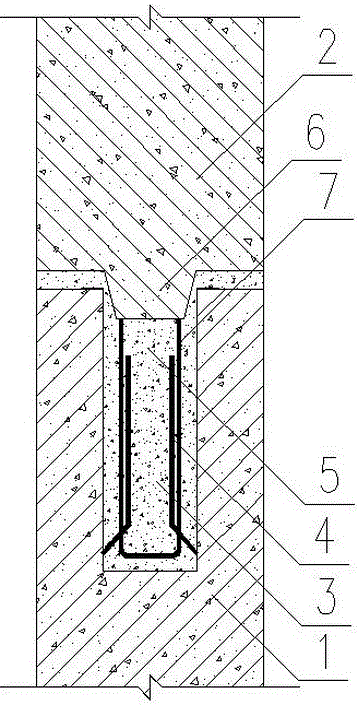

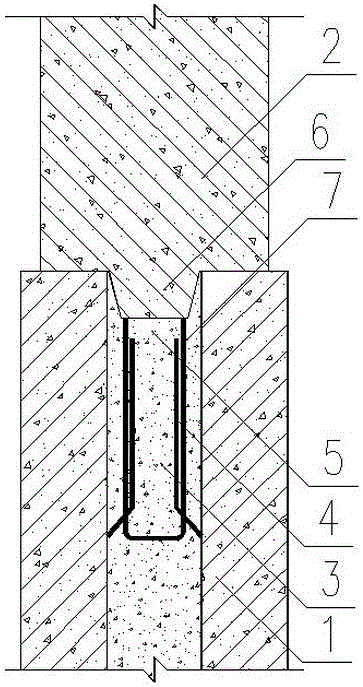

Structure for improving ductility of fabricated composite structure and construction method

PendingCN114673259AConvenient construction methodIncrease profitBuilding constructionsRebarAdhesive cement

The invention belongs to the field of structural engineering, and particularly relates to a structure for improving ductility of a fabricated composite structure and a construction method. The structure is composed of a prefabricated defect block (1), a locally hollowed reinforced concrete slab (2), a shear connector (3), an FRP profile (4), a post-cast UHPC (5) and a chemical adhesive (6). The prefabricated defect block (1) is arranged in the locally hollowed reinforced concrete slab (2) and is connected with the FRP section bar (4) through the shear connecting piece (3) and the chemical adhesive (6). By means of the prefabricated defect blocks (1) and the post-cast UHPC (5), the bearing capacity and the overall rigidity of the structure are improved, meanwhile, the assembly type structure is connected more tightly in the pressing process, and ductility is remarkably enhanced. The locally hollowed reinforced concrete slab (2) can be used as a template of the post-cast UHPC (5), so that the cost is saved, the construction difficulty is reduced, and the technicality and the operability are high.

Owner:NANJING FORESTRY UNIV

Prefabricated reinforced concrete member and manufacturing method thereof

InactiveCN105926827AImprove connection integrityDirect forceConstruction materialStrutsReinforced concreteMetal foil

The invention relates to a prefabricated reinforced concrete member and a manufacturing method thereof, and belongs to the technical field of prefabricated concrete structures. The prefabricated reinforced concrete member is internally provided with at least one hole. The holes are internally provided with rebars anchored in concrete on the side walls of the holes. The top of each hole is provided with metal foil for sealing the hole. According to the provided manufacturing method of the prefabricated reinforced concrete member, the holes are manufactured by adopting an inner formwork of a steel pipe or a fiber reinforced composite pipe, groove channels are formed in the surface of the inner formwork, and the rebars are placed in the groove channels. By means of the prefabricated reinforced concrete member and the manufacturing method thereof, the mechanical performance of the prefabricated concrete structures is improved.

Owner:初明进

Connection method of prefabricated reinforced concrete components

InactiveCN106223471AGuaranteed integrityEasy constructionBuilding constructionsReinforced concreteEngineering

The invention relates to a connection method of prefabricated reinforced concrete components and belongs to the technical field of a prefabricated reinforced concrete structure. The connection method includes that a first prefabricated reinforced concrete component and a second prefabricated concrete component are integrally connected. The connection method is characterized in that at least one hole is formed in the first prefabricated reinforced concrete component, rebar is arranged in the holes, and the rebar is anchored in concrete of side walls of the holes; anchor-connected rebar extends out from the second prefabricated reinforced concrete component; the first prefabricated reinforced concrete component is mounted, the concrete or grouting materials are filled in the holes, the second prefabricated reinforced concrete component is mounted, and anchor-connected rebar of the second prefabricated reinforced concrete component is extended into the holes.

Owner:初明进

Prefabricated component

InactiveCN105888121AImprove connection integrityDirect forceConstruction materialRebarPrecast concrete

Owner:初明进

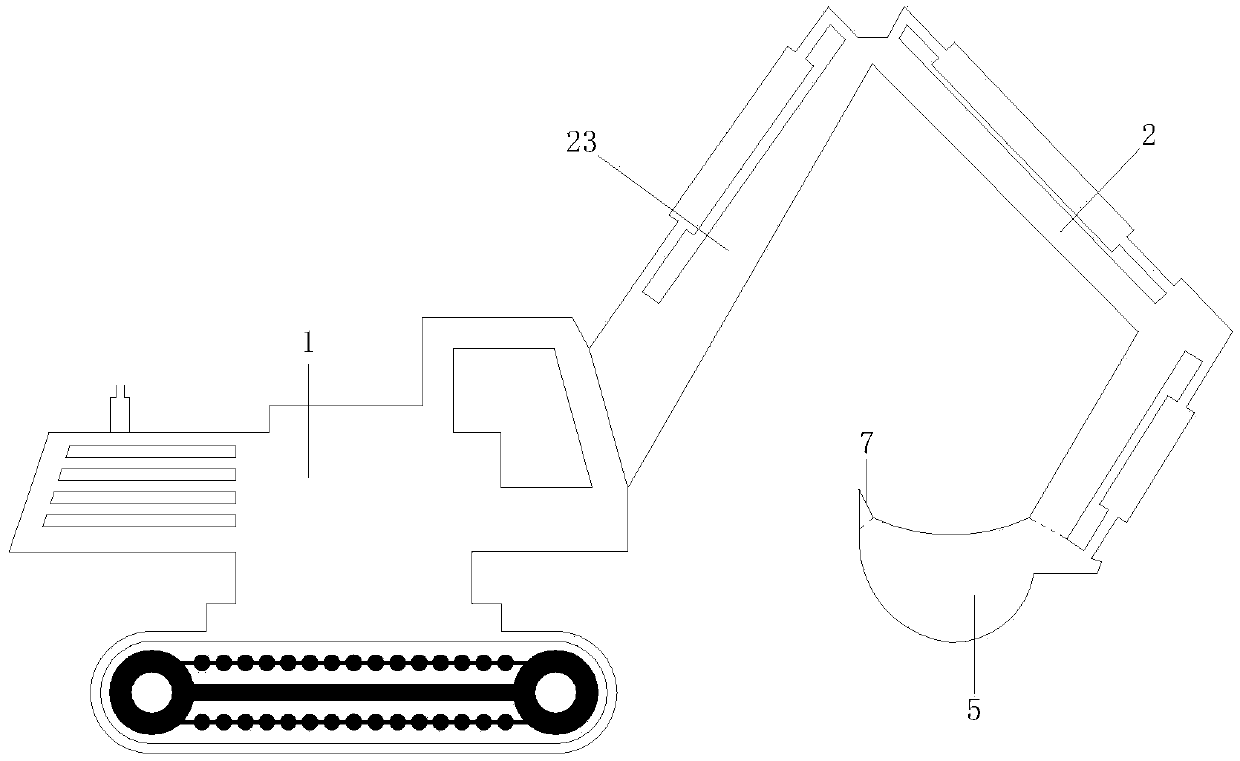

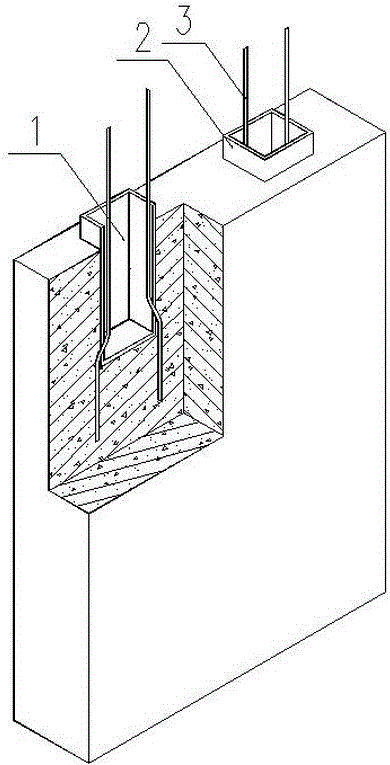

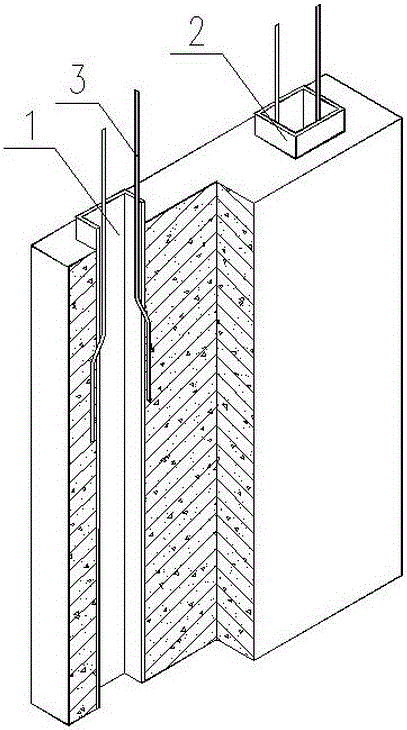

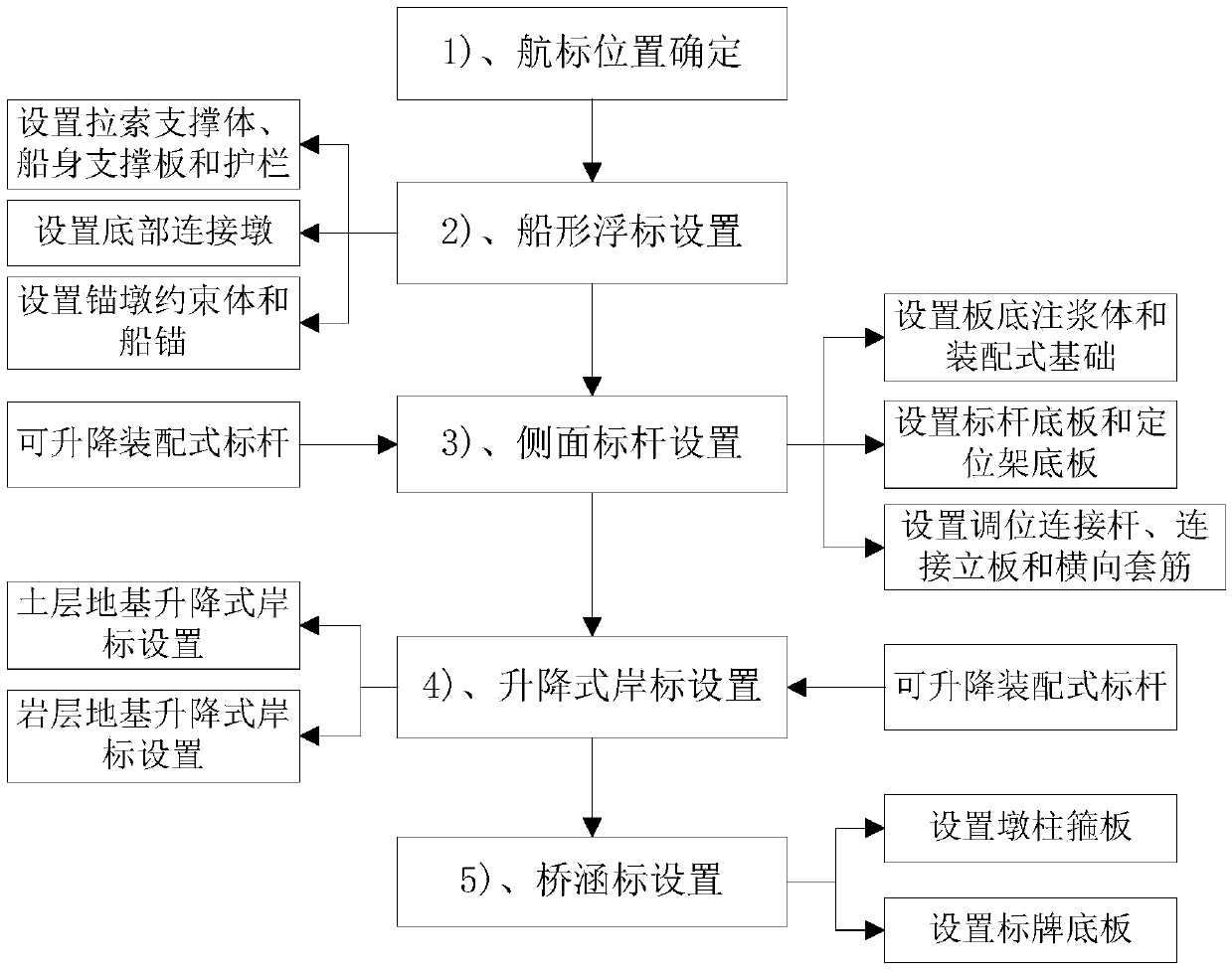

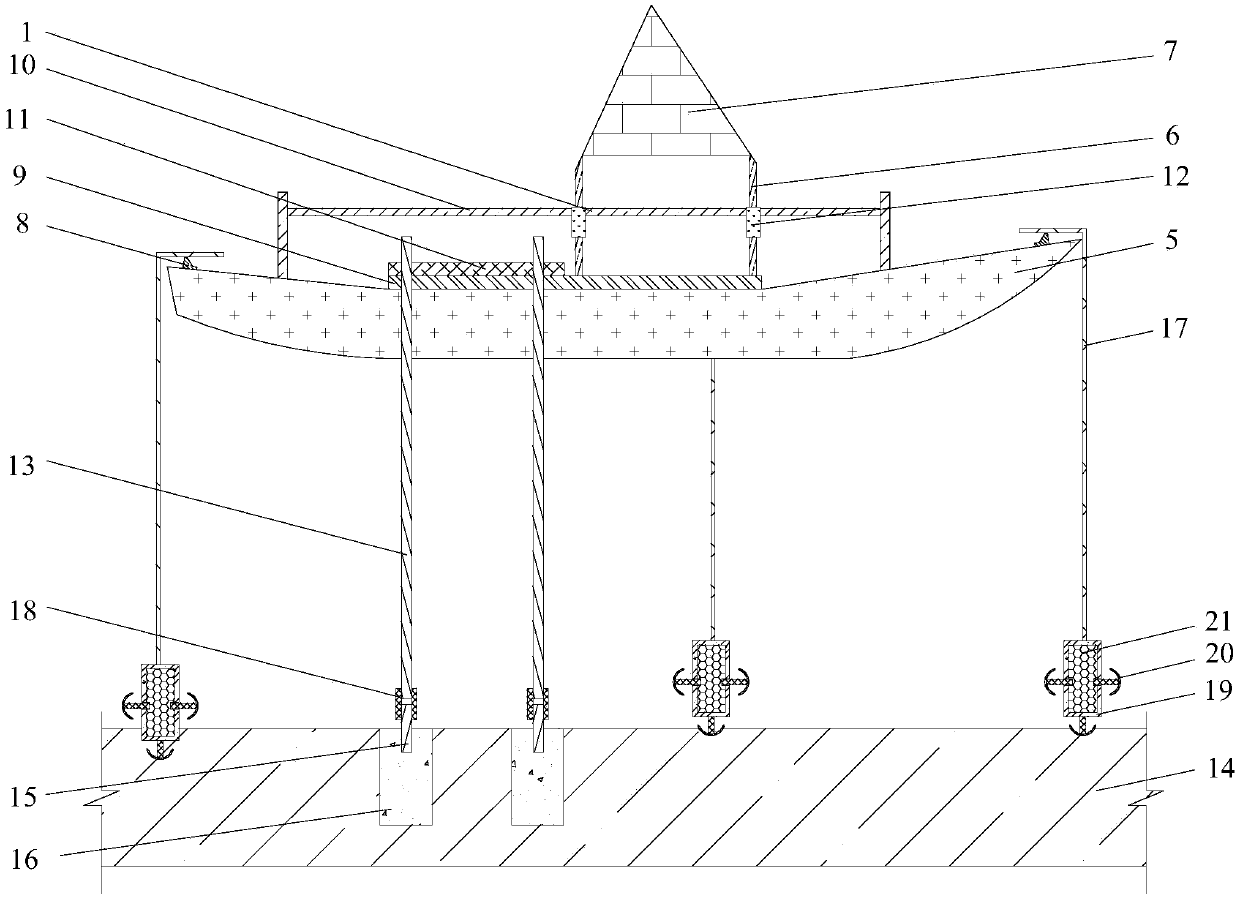

Construction method of navigation mark system

ActiveCN109572935AImprove connection strengthImprove stabilityWaterborne vesselsBuoysSoil propertiesStructural engineering

The invention relates to a construction method of a navigation mark system. The construction method of the navigation mark system comprises the steps of: 1) determining the position of a navigation mark; 2) arranging a ship-type buoy; 3) arranging a side surface pole beacon; 4) arranging a lifting type shore beacon; and 5) arranging a bridge opening mark. The construction method of the navigationmark system has the beneficial effects that the connecting strength of the ship-type buoy and a foundation soil layer is high, the stability of a mark boat is good, and the field positioning is convenient; the pole beacon positioning accuracy of the side surface pole beacon is high, the field mounting of an assembled foundation is convenient, and the connecting integrity of the assembled foundation and the foundation soil layer is good; the lifting type shore beacon adopts different connecting modes according to the soil property situations of the foundation soil layer, the field constructionof the structure is convenient, and the application range is wide; the connection between the bridge opening mark and a pier stud is convenient, the connecting strength of the bridge opening mark andthe pier stud is high, the connecting and positioning of the structure are accurate, and the wind-resistant performance is good.

Owner:HANGZHOU JIANGRUN TECH LIMITED

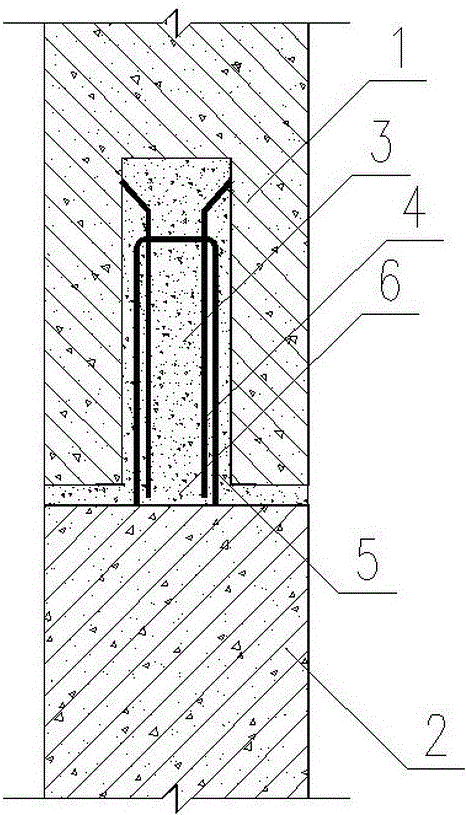

Prefabricated reinforced concrete component connecting method

InactiveCN106223483AGuaranteed integrityEasy constructionBuilding constructionsReinforced concreteRebar

The invention relates to a prefabricated reinforced concrete component connecting method, and belongs to the technical field of prefabricated concrete structures. The method includes the step of integrating a first prefabricated reinforced concrete component and a second prefabricated reinforced concrete component, and is characterized in that at least one hole is formed in the first prefabricated reinforced concrete component, filled with retarded adhesive mortar and internally provided with reinforcing steel bars, the reinforcing steel bars are anchored in concrete of the side walls of the holes, concrete protrusions are arranged on the second prefabricated reinforced concrete component, the first prefabricated reinforced concrete component and the second prefabricated reinforced concrete component are installed, the protrusions of the second prefabricated reinforced concrete component completely or partly extend into the holes, and the first prefabricated reinforced concrete component and the second prefabricated reinforced concrete component are integrated after retarded adhesive mortar is cured.

Owner:初明进

Connecting method of prefabricated concrete member

InactiveCN106193324AGuaranteed integrityEasy constructionBuilding constructionsRebarPrecast concrete

Owner:初明进

An ornamental flower box structure for horticultural plant cultivation

InactiveCN110149954BEasy to adjustEasy to discharge stagnant waterReceptacle cultivationCotton padEngineering

Owner:磐安县双申工艺品有限公司

Underground diaphragm wall I-shaped steel joint water stop control structure and construction method thereof

PendingCN111206566AGuarantee the quality of water stopInhibition formationArtificial islandsUnderwater structuresSlurry wallWater stop

The invention discloses an underground diaphragm wall I-shaped steel joint water stop control structure and a construction method thereof, and relates to the field of building construction. The underground diaphragm wall I-shaped steel joint water stop control structure comprises an underground diaphragm wall groove section, an I-shaped steel joint, a steel reinforcement cage, concrete, a port locking pipe and back pressing broken stones; the cross section of the I-shaped steel joint faces upwards, and the I-shaped steel joint is vertically arranged in the underground diaphragm wall groove section; the steel reinforcement cage is welded to one side face of a web of the I-shaped steel joint; the concrete is poured to the steel reinforcement cage and poured into the underground diaphragm wall groove section; the cross section of the port locking pipe faces upwards, and the port locking pipe is vertically and closely attached to the other side face of the web of the I-shaped steel joint;the other side of the port locking pipe is filled with the back pressing broken stones; and a pair of slurry stop plates are symmetrically welded to the outer side of a flange plate of the I-shaped steel joint, and slurry stop pressing strips are welded to the outer sides of the inner ends of the slurry stop plates. According to the underground diaphragm wall I-shaped steel joint water stop control structure and the construction method thereof, the problems that in an existing underground diaphragm wall I-shaped steel joint construction water stop method, round flowing of the concrete is difficult to control, the water stop quality is difficult to control, a large amount of manpower and construction period are consumed, and the construction efficiency is low are solved.

Owner:CHINA CONSTR FIRST GROUP THE FIFTH CONSTR +1

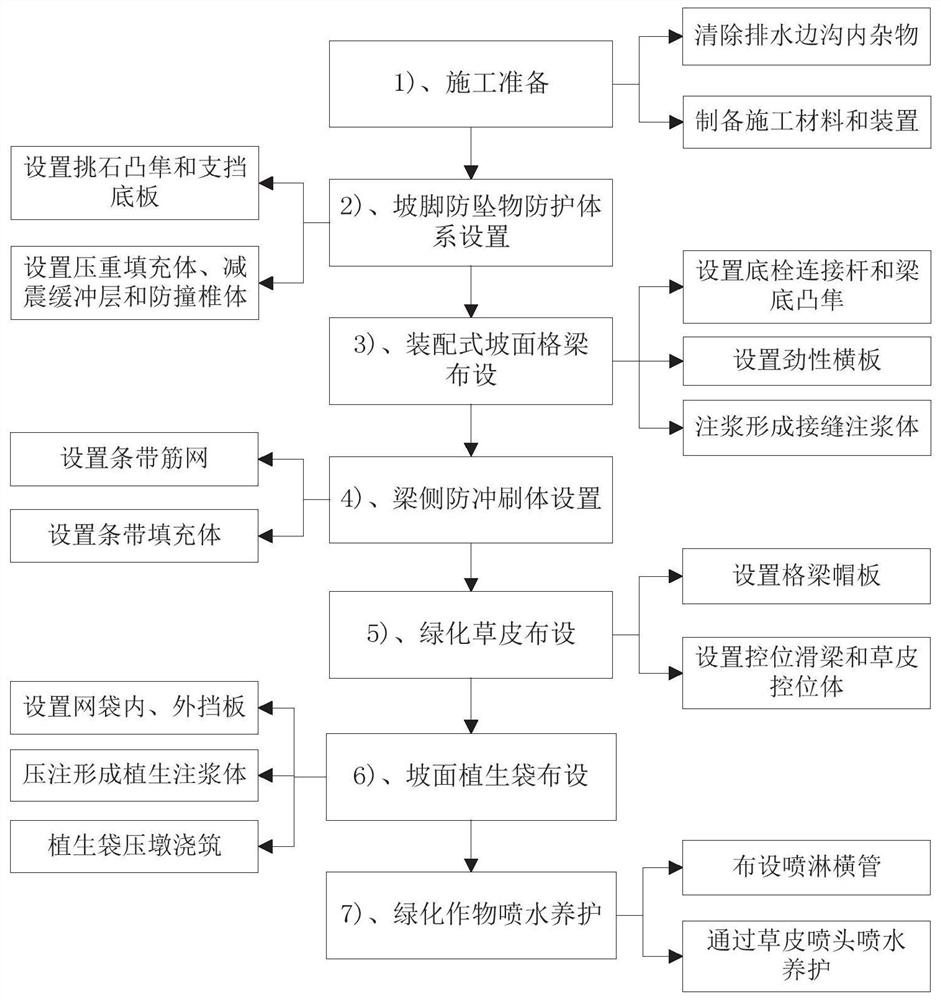

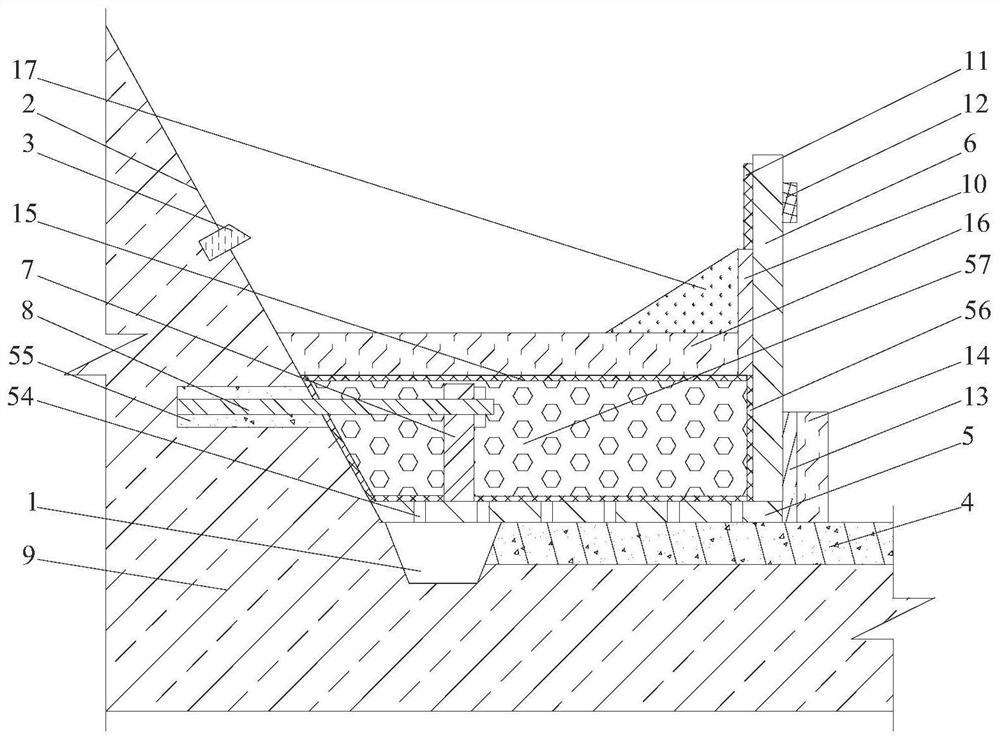

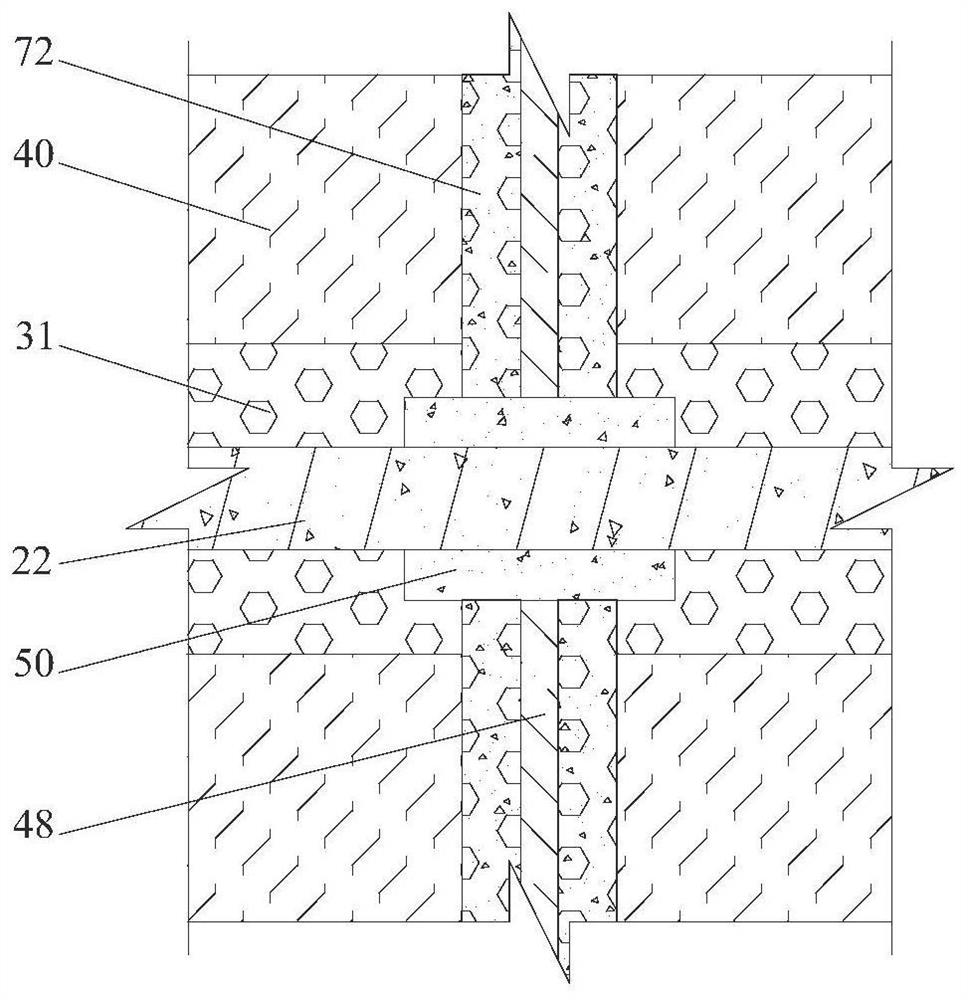

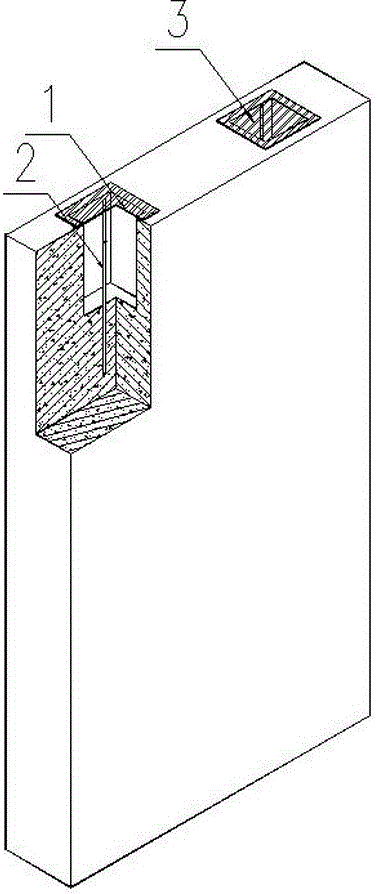

Construction method for slope ecological protection

ActiveCN112726642APlay the role of picking stones to dissipate energyReduce impactClimate change adaptationExcavationsEnvironmental resource managementStructural engineering

The invention relates to a construction method for slope ecological protection. The construction method comprises the steps that 1, sundries in an adjacent drainage side ditch are removed, and materials and devices needed by construction are prepared; 2, 1-2 rows of stone-picking tenons are arranged on the free face of the slope face of a slope; 3, a weight filling body, a damping buffer layer and an anti-collision pile body are sequentially arranged on the upper surface of a supporting and blocking bottom plate; 4, a slope soil body is excavated, and a lattice beam arranging groove is excavated in the slope soil body; and 5, a lattice beam cap plate is arranged on the upper surface of a slope face lattice beam, and the lattice beam cap plate and the slope face lattice beam are firmly connected through cap plate fastening bolts. The construction method has the beneficial effects that the impact force in the falling process of rolling stones is further reduced; the stability of the supporting and blocking bottom plate and a supporting and blocking outer column and the connection integrity of a vegetation mesh bag and the slope soil body are effectively improved; the connection strength between the slope face lattice beams can be improved; and the difficulty of moving of a turf position control body and positioning of greening turf and the difficulty of filling of a mesh bag filling body are effectively reduced.

Owner:湖北省路桥集团有限公司

Prefabricated reinforced concrete member and manufacturing method thereof

InactiveCN105926829AImprove connection integrityFirmly connectedConstruction materialStrutsReinforced concreteMetal foil

The invention relates to a prefabricated reinforced concrete member and a manufacturing method thereof, and belongs to the technical field of prefabricated concrete structures. The prefabricated reinforced concrete member is internally provided with at least one non-through hole. The holes are internally provided with rebars anchored in concrete at the bottoms of the holes. The top of each hole is provided with metal foil for sealing the hole. According to the provided manufacturing method of the prefabricated reinforced concrete member, the holes are manufactured by adopting an inner formwork of a steel pipe or a fiber reinforced composite pipe, the bottom of the inner formwork is sealed and provided with a hole, and the rebars penetrate through the hole. By means of the prefabricated reinforced concrete member and the manufacturing method thereof, the mechanical performance of the prefabricated concrete structures is improved.

Owner:初明进

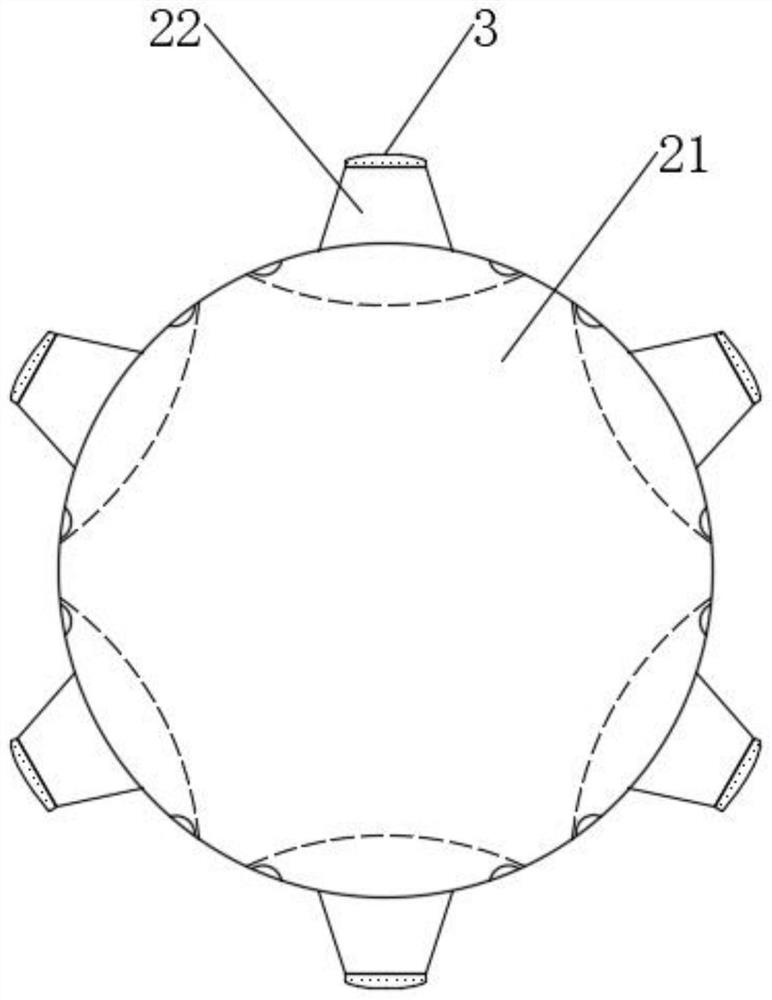

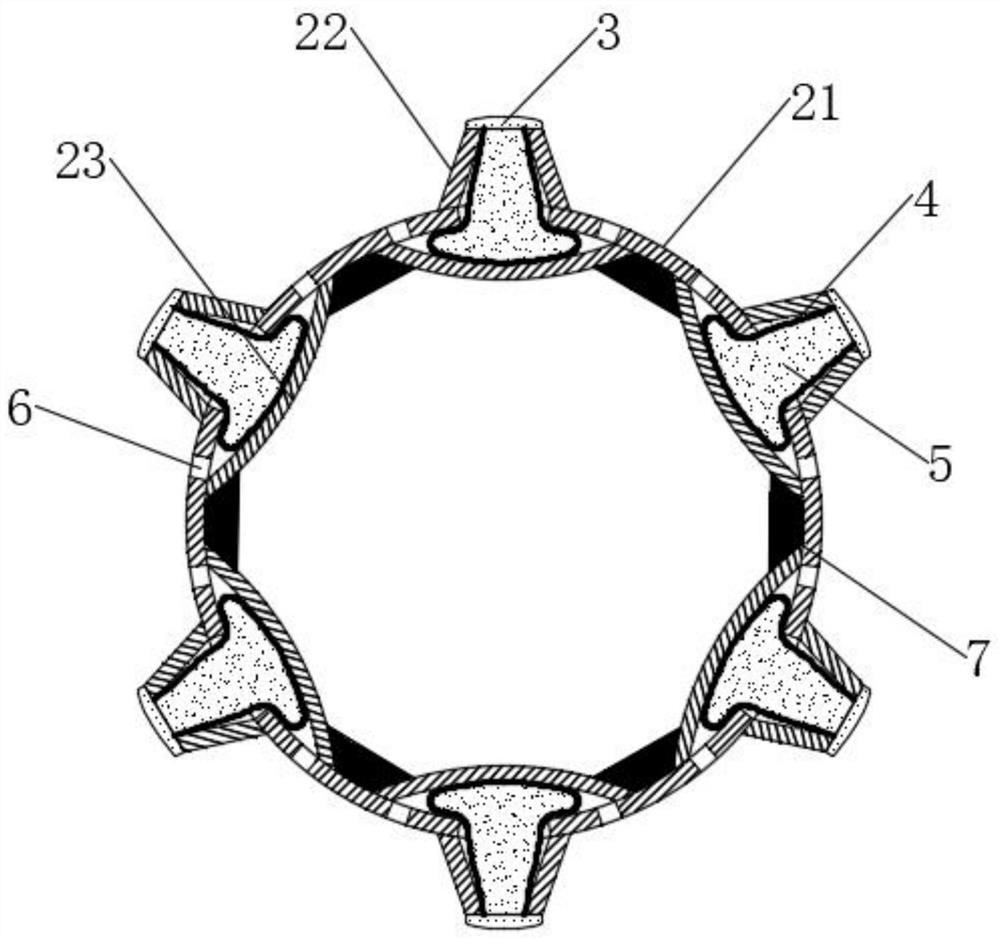

Lightweight concrete block for environment-friendly construction and preparation method thereof

InactiveCN112010666AImprove liquidityImprove uniformityConstruction materialCeramic shaping apparatusArchitectural engineeringStructural engineering

The invention discloses a lightweight concrete block for environment-friendly construction and a preparation method of the lightweight concrete block. The invention belongs to the technical field of buildings. According to the invention, an innovative mode of throwing the spontaneous gas inner vibrating ball can be realized, based on the magnetic repulsion effect, the magnetic particles are autonomously and uniformly distributed in the slurry, then, the gas generation action is triggered under the heating action, the built-in gas-forming powder begins to be heated and decomposed to release gas, the natural gas is released into the slurry along a gas-forming outer hopper on the natural gas-forming inner vibrating ball, fine and uniform air holes are formed, the concrete building block has aporous structure, the traditional gas generating material is replaced, meanwhile, when the spontaneous gas inner vibrating ball releases gas, high frequency vibration is formed in the slurry so thatthe fluidity and uniformity of the slurry are improved, thus indirectly improving the strength of the block. According to the self-aerated concrete block, the self-aerated inner vibration ball is arranged in the slurry, high-frequency vibration is formed in the slurry, the fluidity and uniformity of the slurry are improved, the strength of the block is indirectly improved, the self-aerated inner vibration ball and the block can form a tight whole, the strength of the block is further improved, a large pore channel is reinforced, and a block forming process is greatly improved.

Owner:成都鑫筑博建材有限公司

An assembled connection node

ActiveCN111677107BImprove stabilityQuality improvementBuilding constructionsStructural engineeringMechanical engineering

The invention discloses a novel assembled connection node. It includes prefabricated corbel columns and prefabricated beams, and also includes screw rods fixed on the corbels and parallel to the prefabricated corbel columns, and the ends of the prefabricated beams rest on the corbels and are fitted by bolts Connection; through the first through hole corresponding to the screw rod at the end of the prefabricated beam; the groove is opened on the surface of the end of the prefabricated beam, including the upper end of the first through hole with a diameter larger than The first groove of the first through hole also includes a second groove perpendicular to the width direction of the prefabricated beam, one end of the second groove communicates with the first groove, and the other end extends to the The edge of the end; the two ends of the tie rod shaft are set as rings, the size of the shaft matches the second groove, the outer diameter of the ring matches the size of the first groove, and the inner diameter The diameter of the first through hole is the same as that of the first through hole; the second through hole is opened parallel to the width direction of the prefabricated corbel column.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com