Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1998results about How to "Prevent tipping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

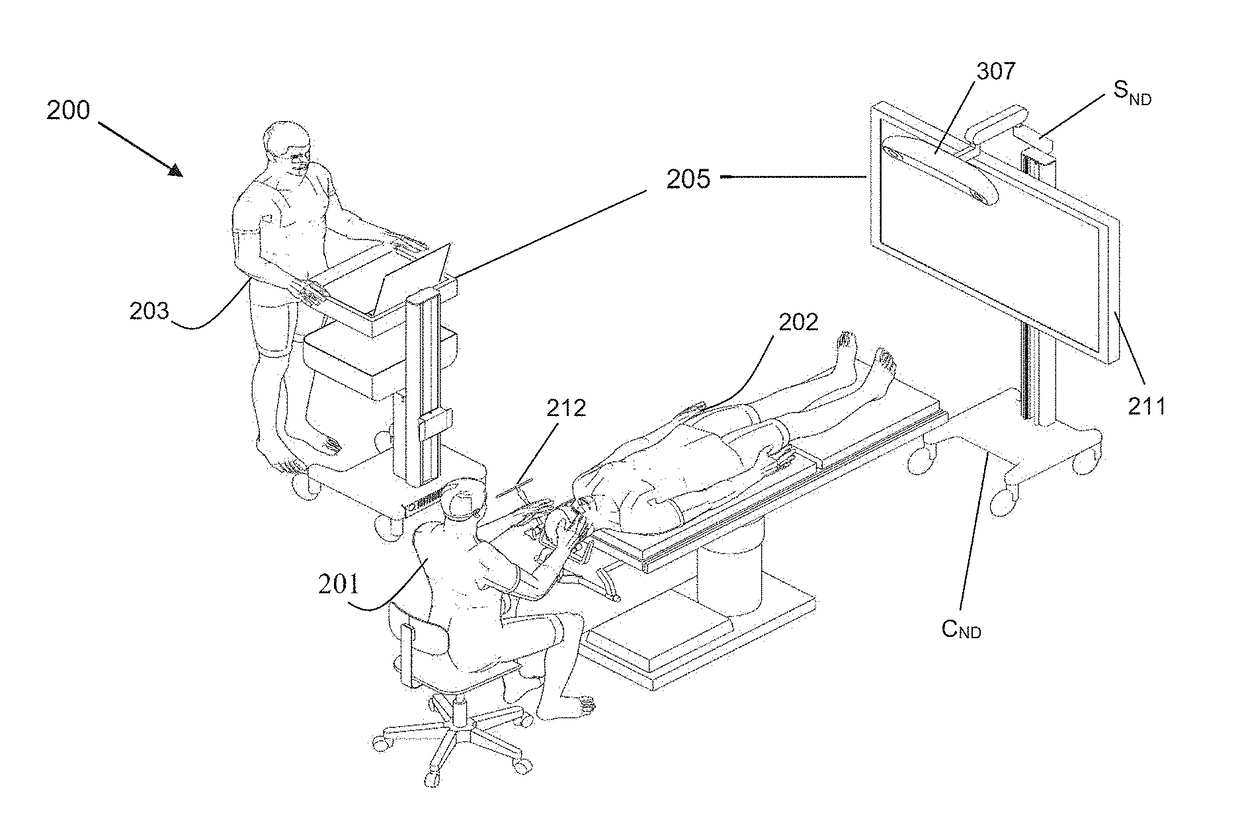

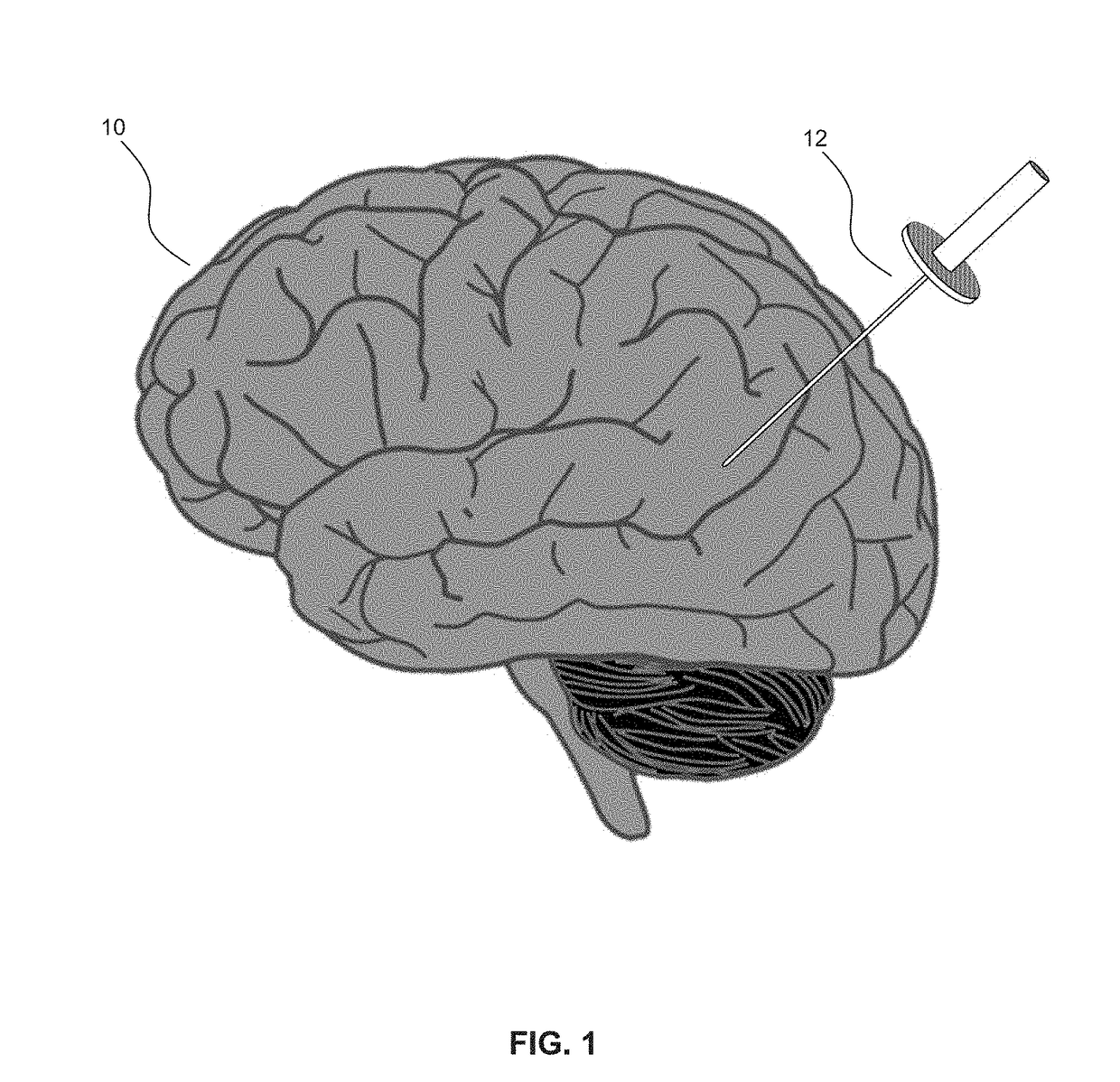

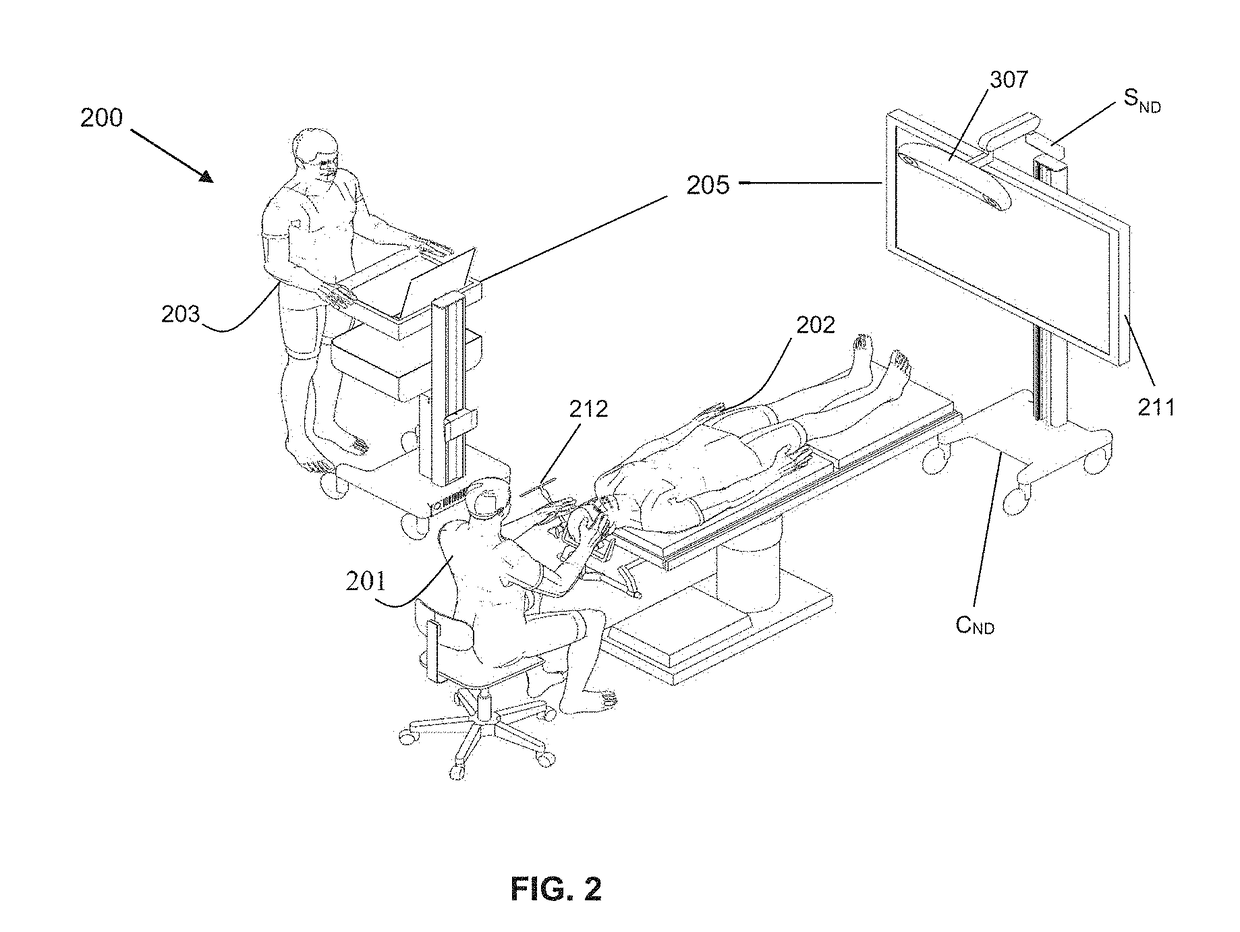

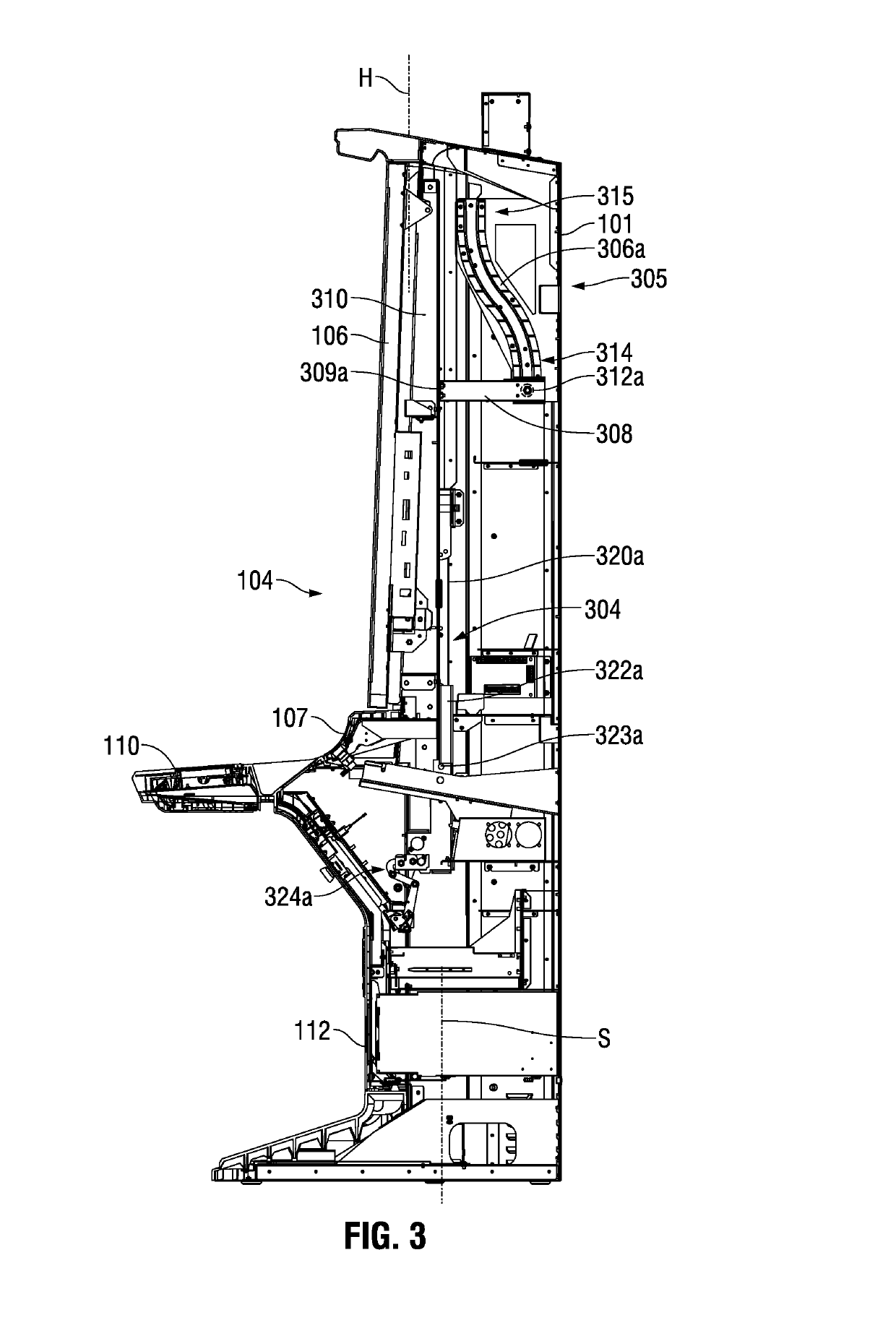

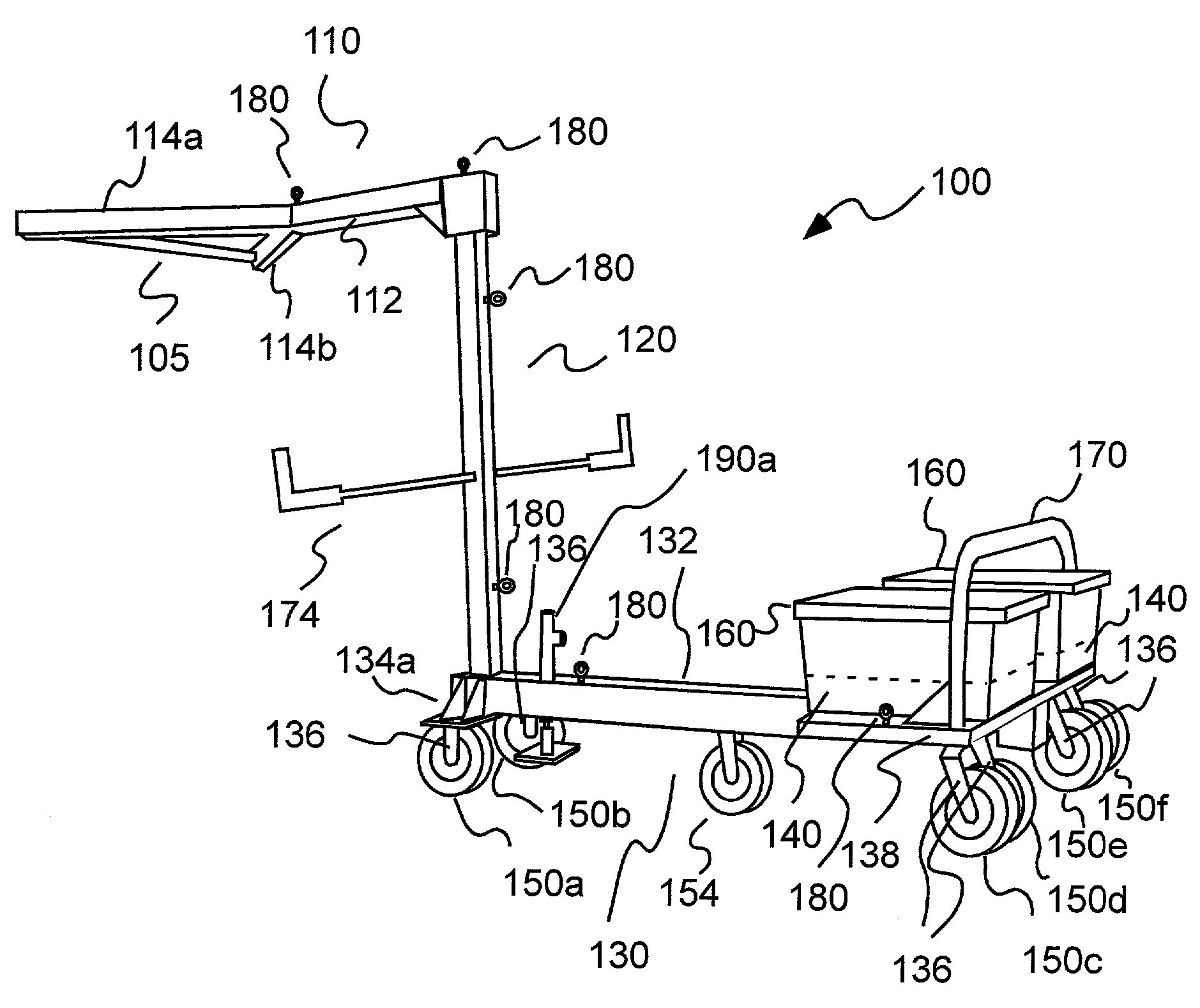

Navigation arm system and methods

InactiveUS20170304020A1Position be accurate and stableFacilitate positioningCannulasSurgical needlesCartStructural stability

A navigation arm system for supporting a navigation device of a navigation system, capable of coupling with a navigation display cart, the navigation arm system involving: an arm assembly configured to position the navigation device, the arm assembly including a first arm linkage having a tension adjustment feature and releasably connectable to the navigation device; a second arm linkage capable of connecting the arm assembly to the navigation display cart; and at least one joint coupling at least the first and second arm linkages; and a locking mechanism configured to maintain a disposition of the arm assembly in relation to the navigation display cart in a locked stored position and a unlocked deployed position, the locking mechanism configured to lockably couple the arm assembly in relation to the navigation display cart, the locking mechanism including a plurality of locking modes, whereby structural stability is providable

Owner:SYNAPTIVE MEDICAL INC

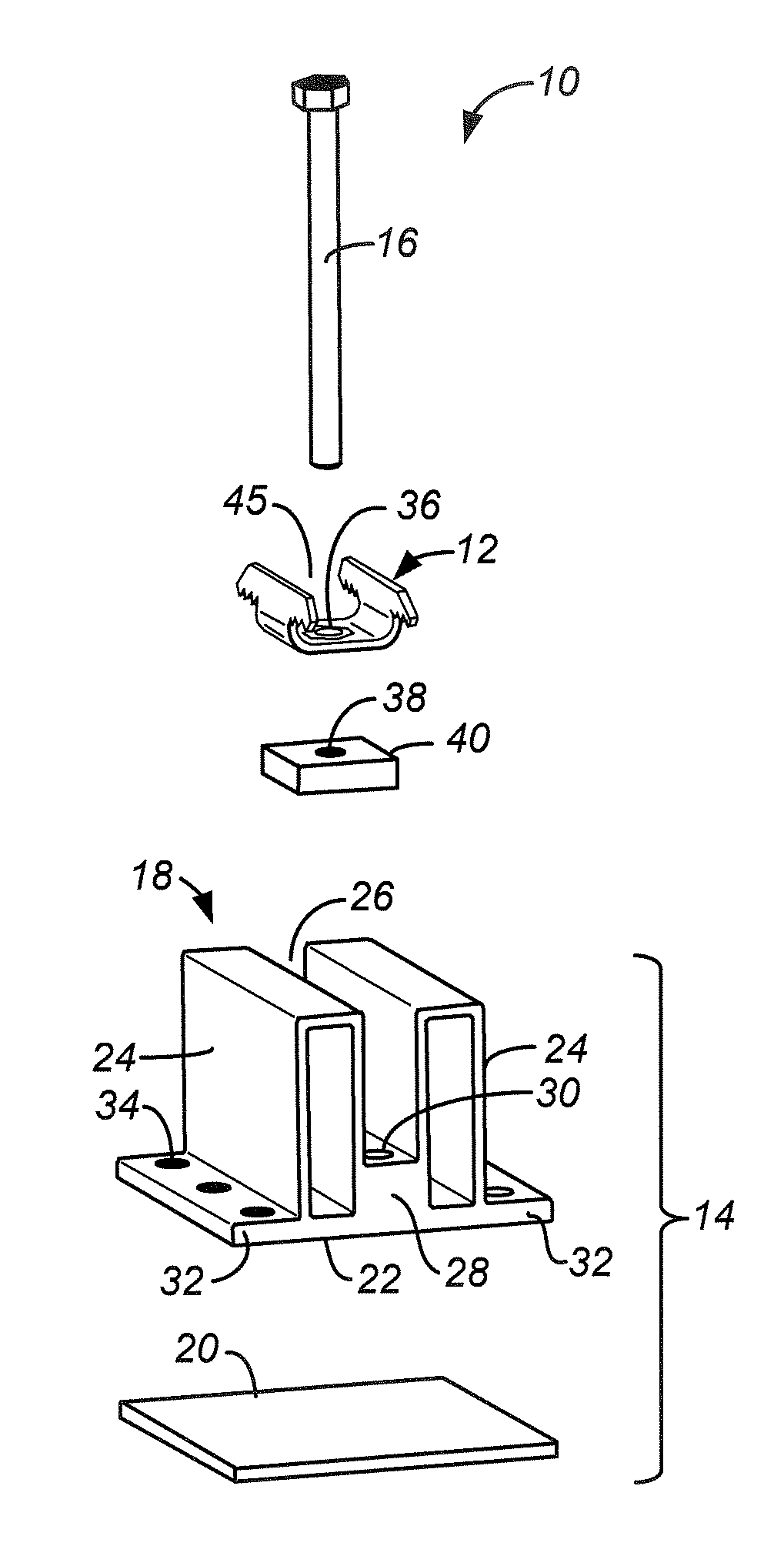

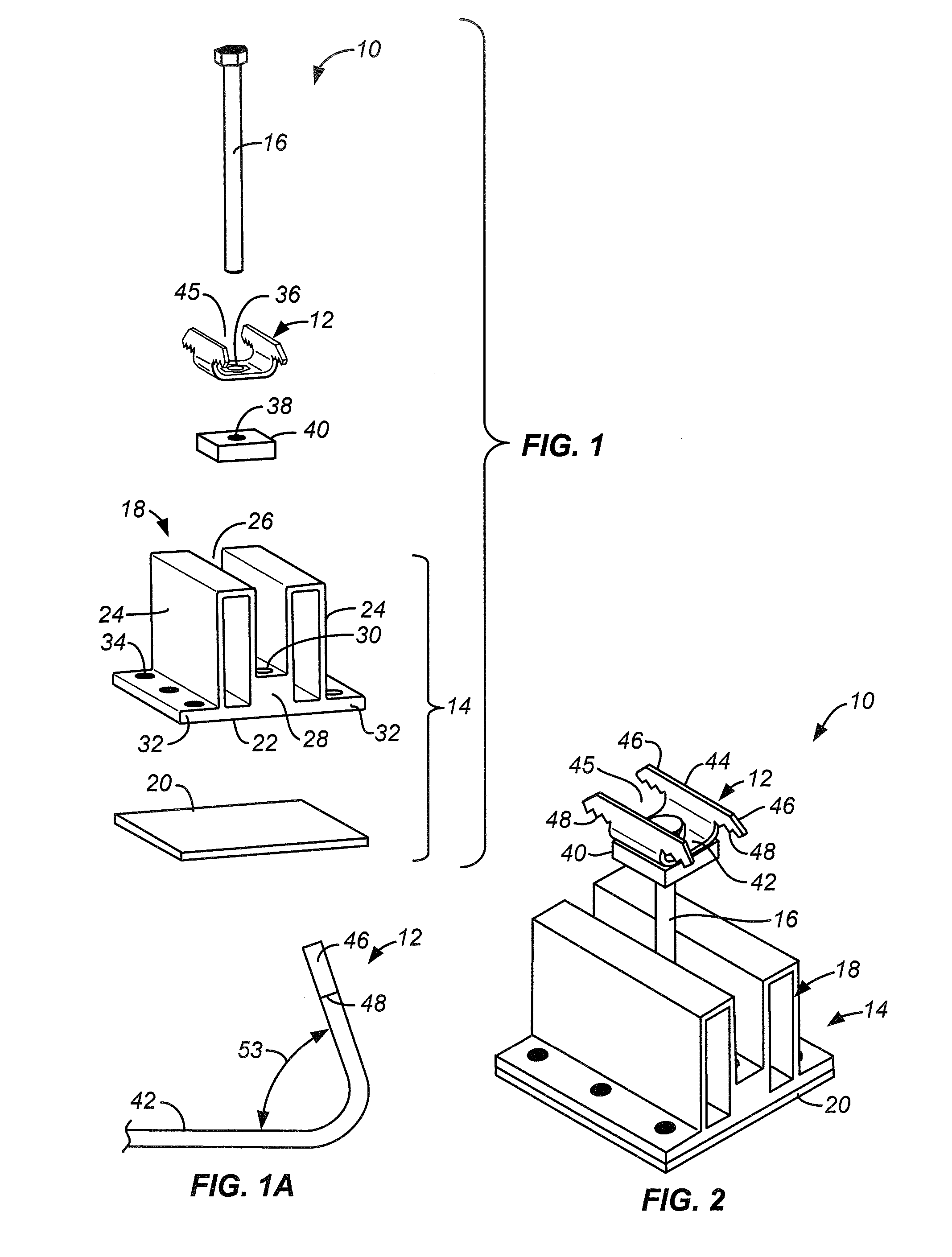

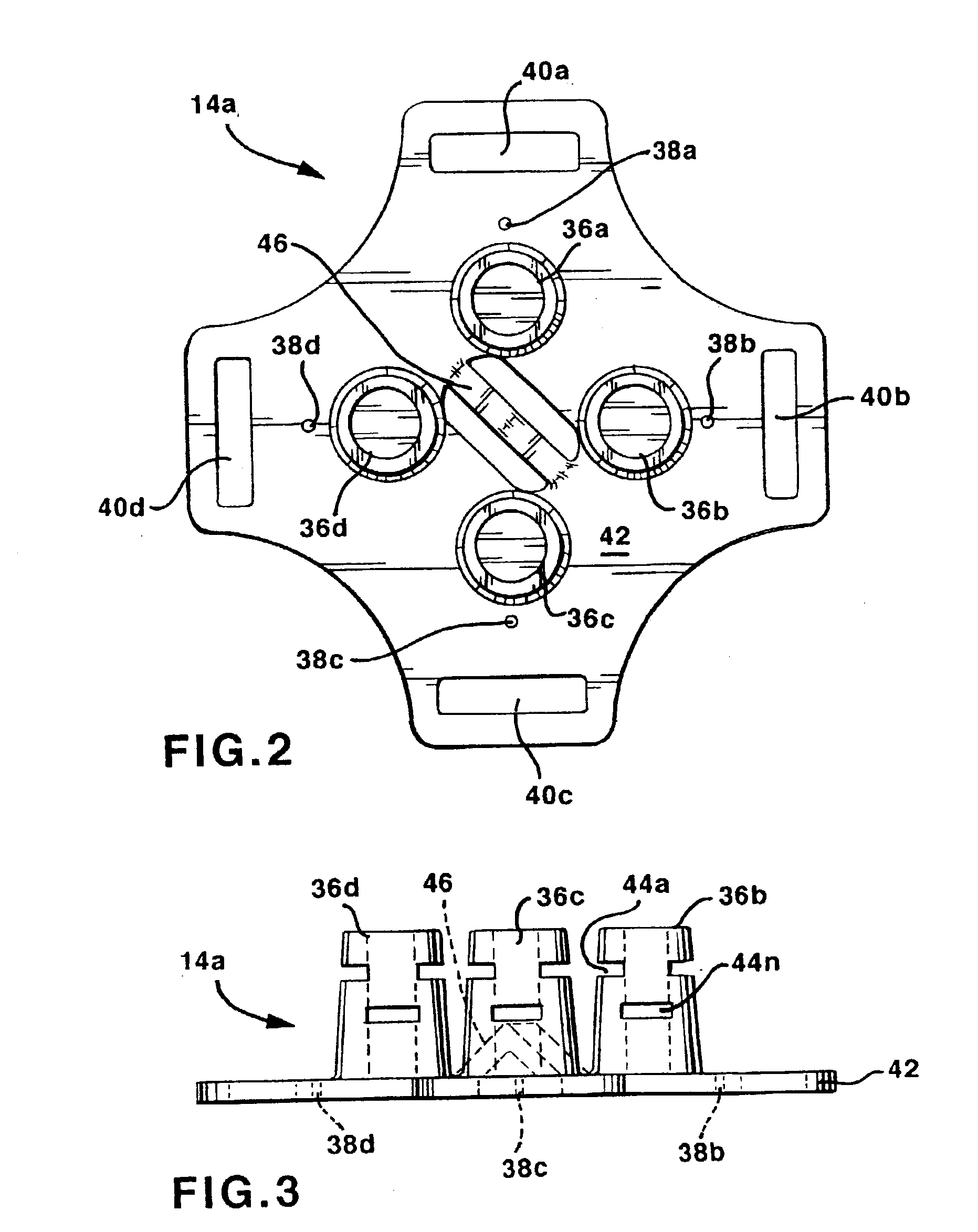

Photovoltaic Module Mounting Clip with Integral Grounding

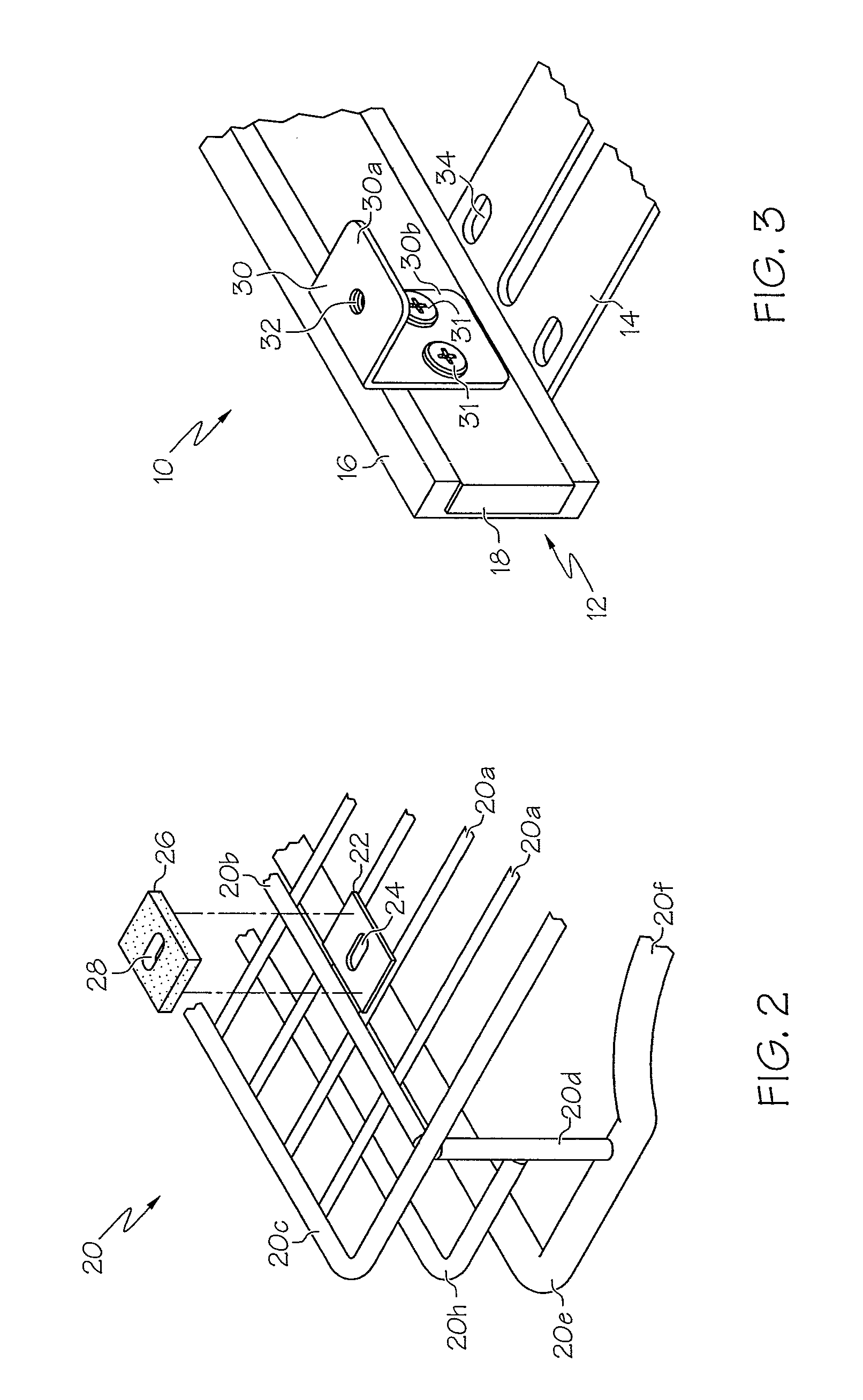

ActiveUS20070212935A1Prevent tippingConsiderable laborPhotovoltaic supportsSolar heating energyAcute angleElectrical and Electronics engineering

An electrically conductive mounting / grounding clip, for use with a PV assembly of the type having an electrically conductive frame, comprises an electrically conductive body. The body has a central portion and first and second spaced-apart arms extending generally perpendicular to the central portion. Each arm has an outer portion with each outer portion having an outer end. At least one frame surface-disrupting element is at each outer end. The central portion defines a plane with the frame surface-disrupting elements pointing towards the plane. In some examples each arm extends from the central portion at an acute angle to the plane.

Owner:SUNPOWER CORPORATION

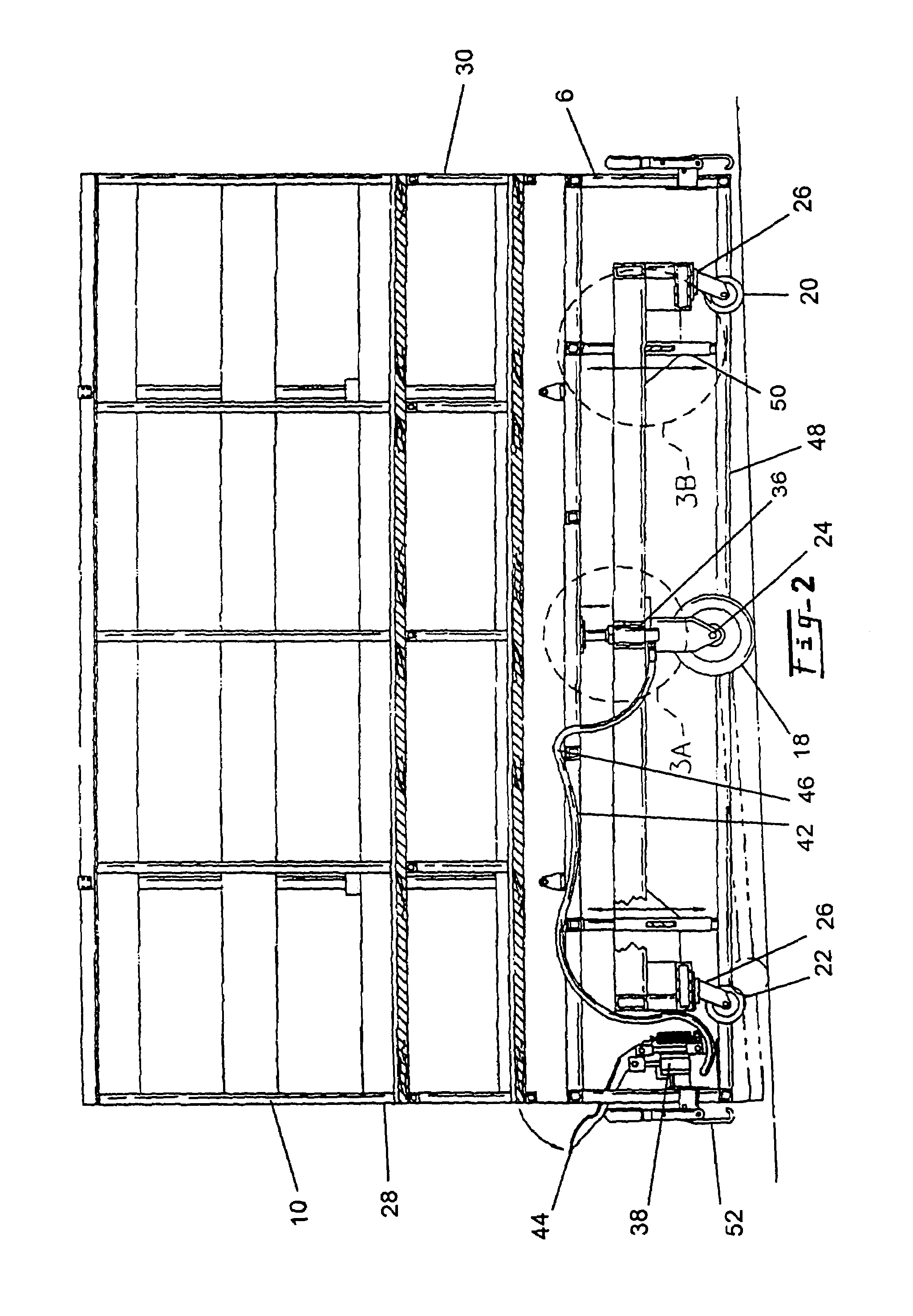

Product management display system with trackless pusher mechanism

A product management display system for merchandising product on a shelf includes using a trackless pusher mechanism that travels along a surface on which product is placed. The pusher mechanism of the invention also includes a pusher paddle and a floor that extends forward of the pusher paddle. A flat coiled spring or other biasing element may be operatively connected behind the pusher paddle and extend across the floor of the pusher mechanism and to the front of the shelf. In use, the product to be merchandised may be placed on the coiled spring and on the floor of the pusher mechanism. With this configuration, the pusher paddle is prevented from tipping or bending backwards during operation. The invention may be used with the merchandising of product on horizontal or non-inclined shelves or surfaces, as well as with gravity-fed systems, or systems that use gravity as a mechanism to urge product toward the front of the shelf.

Owner:RTC IND

Treatment of movement disorders by a combined use of chemodenervating agent and automated movement therapy

InactiveUS20080279896A1Prevent tippingImprove the immunityBacterial antigen ingredientsNervous disorderKinesiotherapyCombined use

The present invention relates to a method of treating a movement disorder in a patient, the method comprising administering a medicament comprising an effective amount of chemodenervating agent to the patient, wherein the patient is subjected to a muscle stimulation therapy, for example an movement therapy or an muscle activation therapy, and the medicament is administered prior to and / or during and / or after the movement therapy and a kit for the treatment of patients suffering from movement disorders comprising a medicament comprising an effective amount of a chemodenervating agent, and a device for carrying out automated movement therapy.

Owner:MERZ PHARMA GMBH & CO KGAA

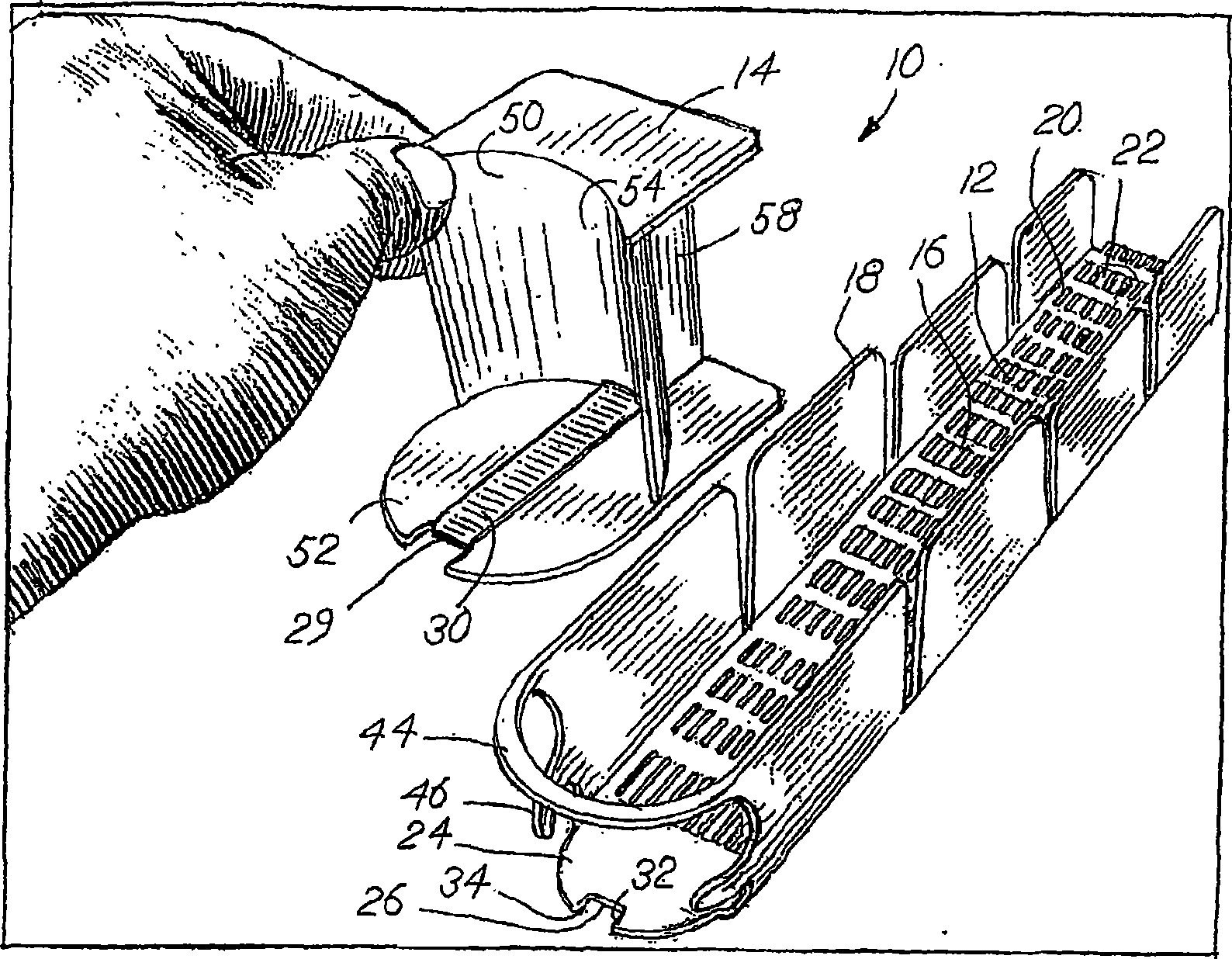

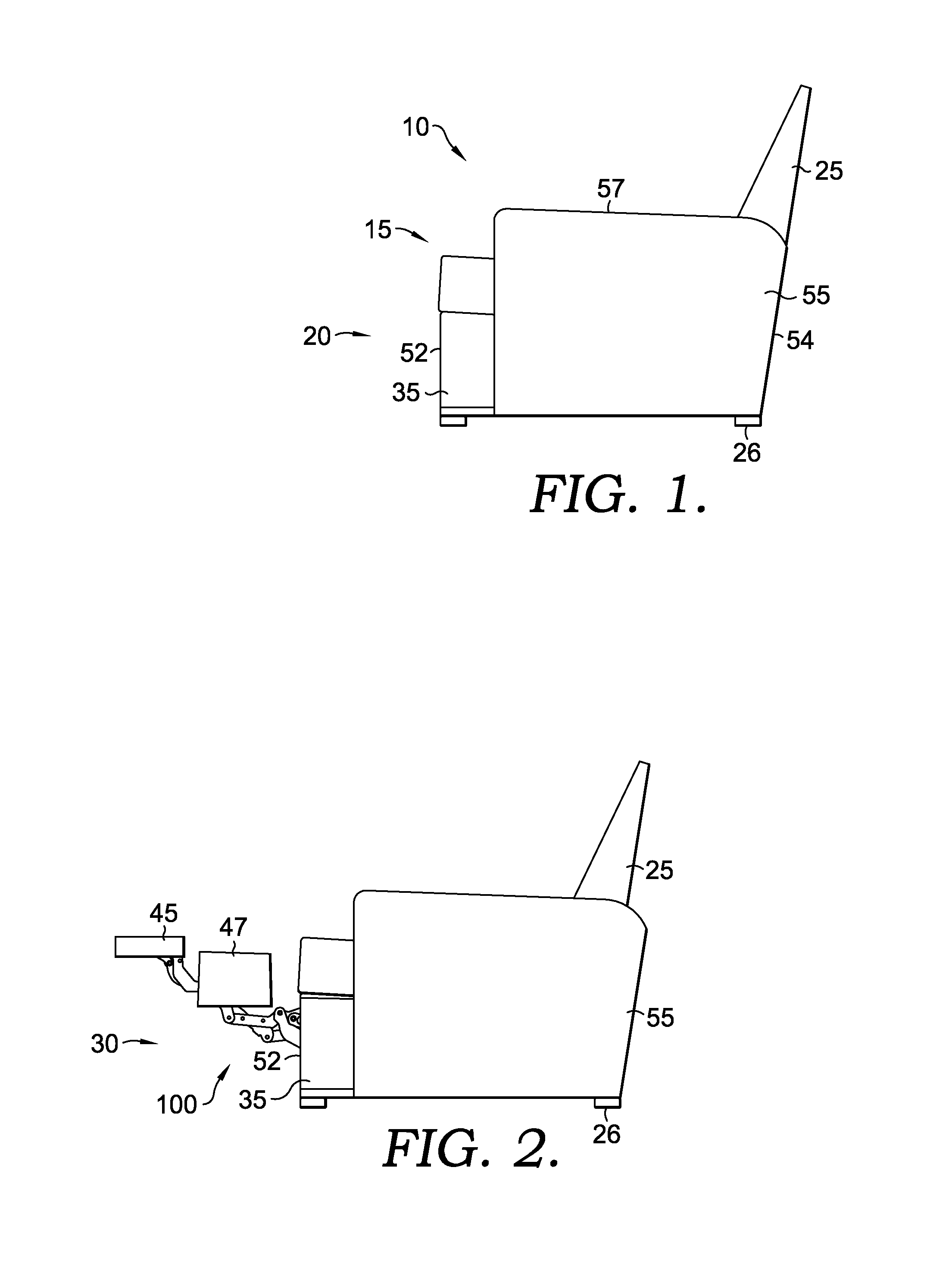

Zero-wall clearance linkage mechanism for providing additional layout

InactiveUS20120049606A1Prevent tippingCost-effectiveControlling membersMechanical apparatusEngineeringLinear actuator

A seating unit that includes a linkage mechanism adapted to adjust between closed, extended, and reclined positions is provided. The linkage mechanism includes a seat-mounting plate mounted to a footrest assembly, a back-mounting link and a rear bellcrank both rotatably coupled to the seat-mounting plate, an activator bar that controls a footrest drive link, and a linear actuator for carrying out automated adjustment of the linkage assembly. In operation, a stroke in a first phase of the linear actuator generates a torque on the activator bar. The footrest drive link converts the torque into a laterally-directed force that pushes the footrest assembly into the extended position. A stroke in the second phase acts to push the activator bar forward and translate the seat-mounting plate forward at a consistent inclination angle. The forward translation causes the rear bellcrank to rotate, thereby biasing the back-mounting link rearward into the reclined position.

Owner:L & P PROPERTY MANAGEMENT CO

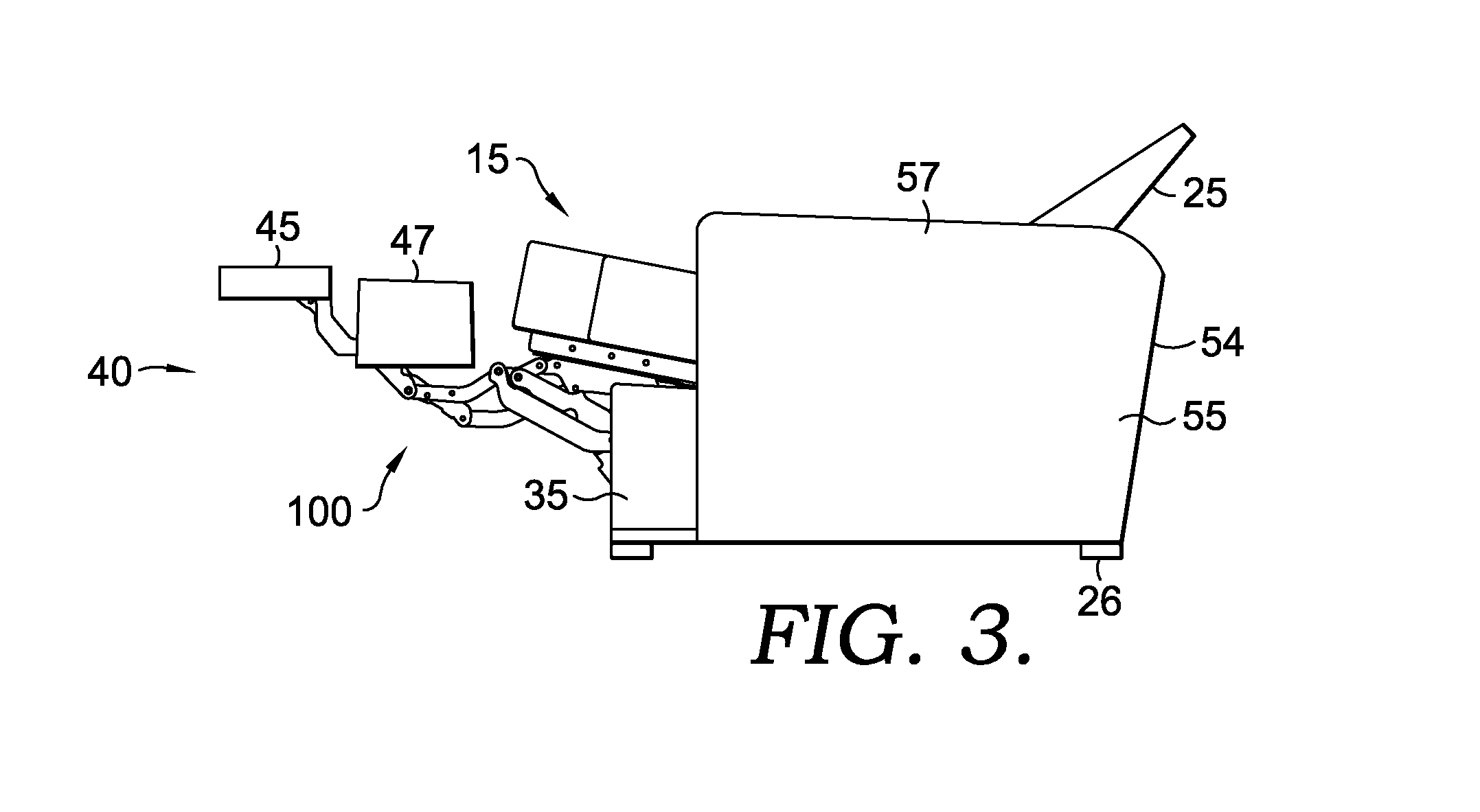

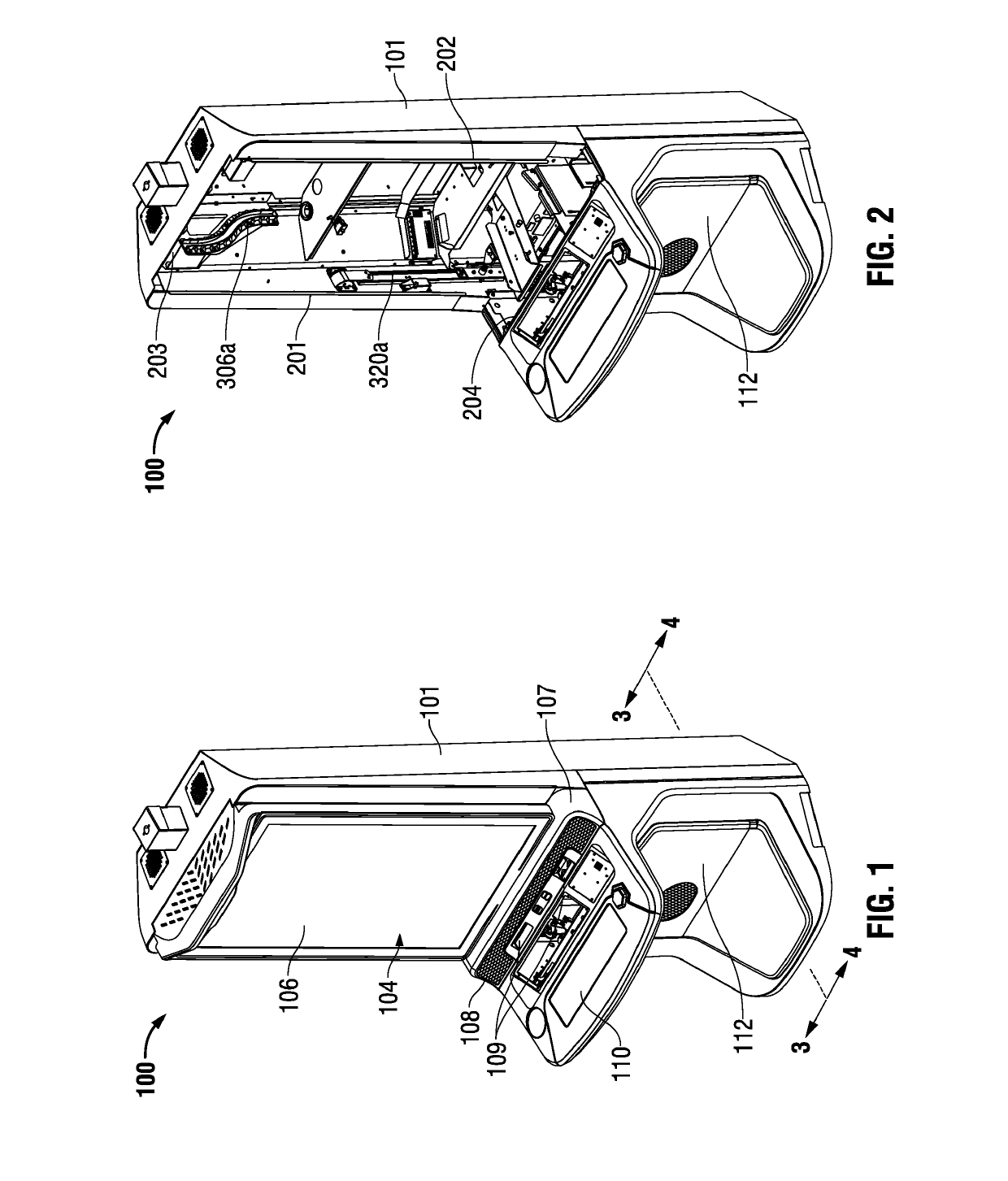

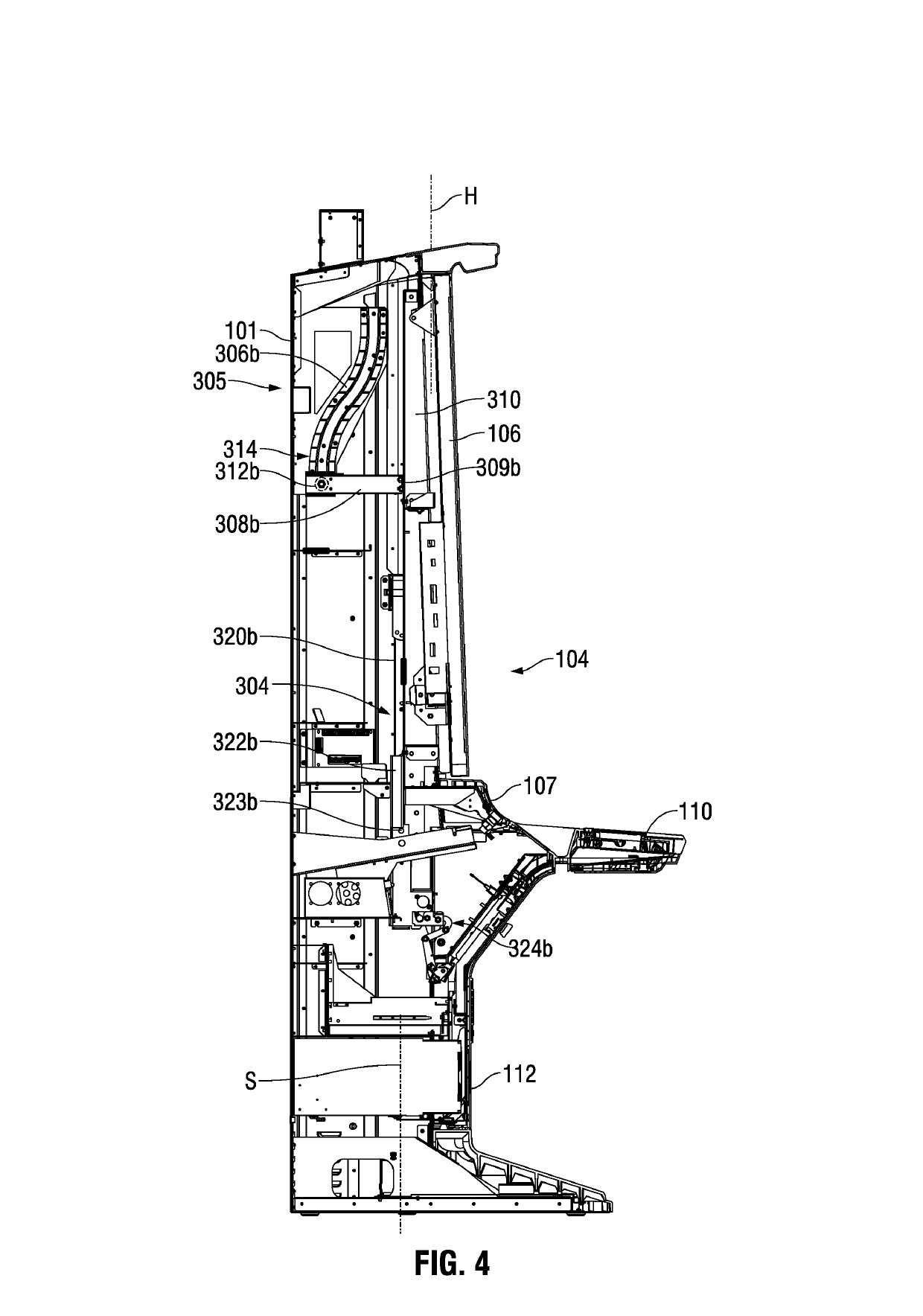

Gaming machine cabinet access structure and method

ActiveUS20190102984A1Prevent tippingSuitable balanceApparatus for meter-controlled dispensingAccess structureEngineering

A gaming machine includes a gaming machine cabinet defining an upper cabinet volume and a cabinet front opening to the upper cabinet volume. A gaming machine panel is mounted on the gaming machine cabinet in a panel operating position in which the gaming machine panel registers with and covers at least a base area of the cabinet front opening. The gaming machine further includes a translation structure connected between the gaming machine panel and the gaming machine cabinet. The translation structure is operable enable the gaming machine panel to be moved from the panel operating position upwardly to a cabinet open position. In this cabinet open position the gaming machine panel remains supported by the gaming machine cabinet and is removed from a base area of the cabinet front opening.

Owner:EVERI GAMES

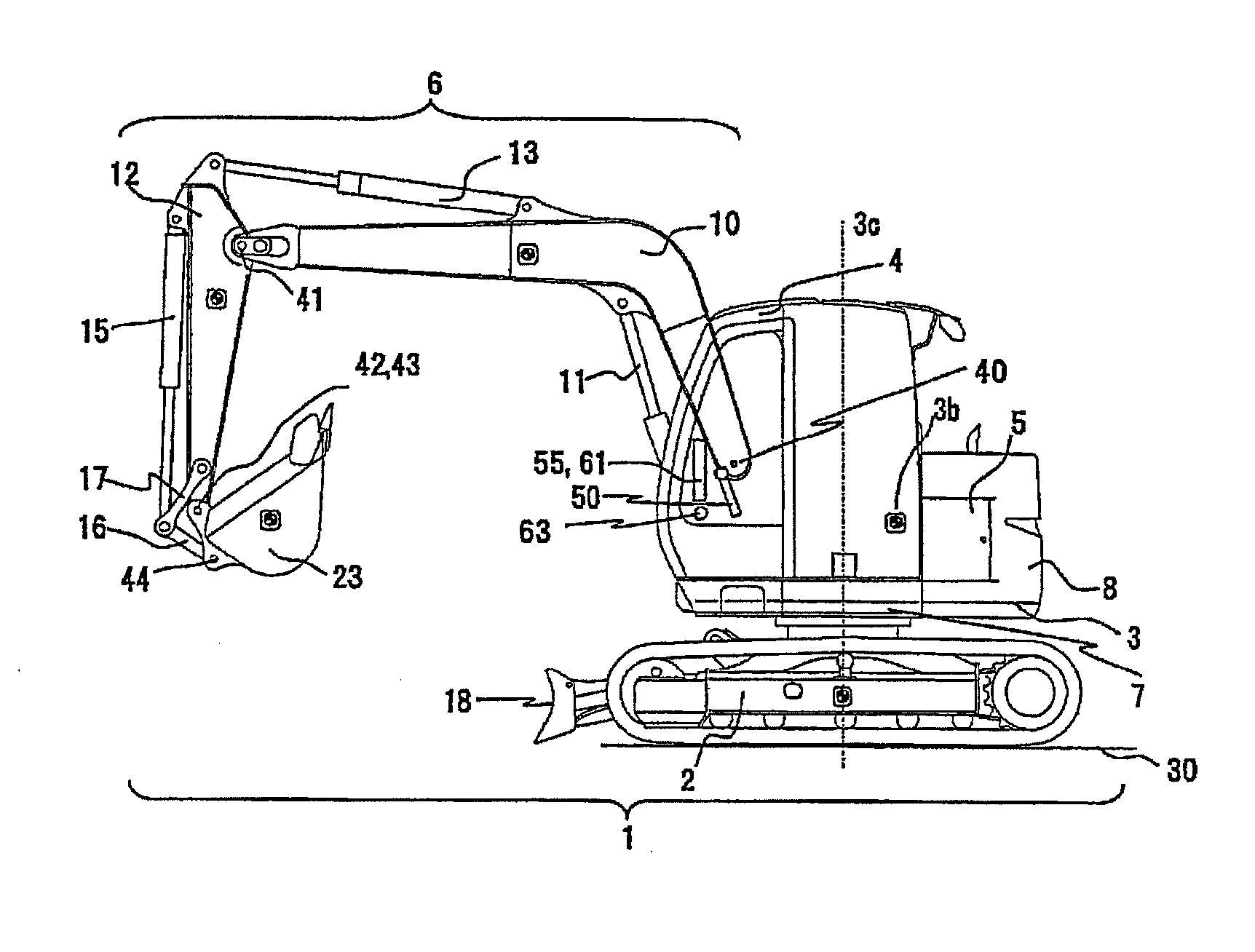

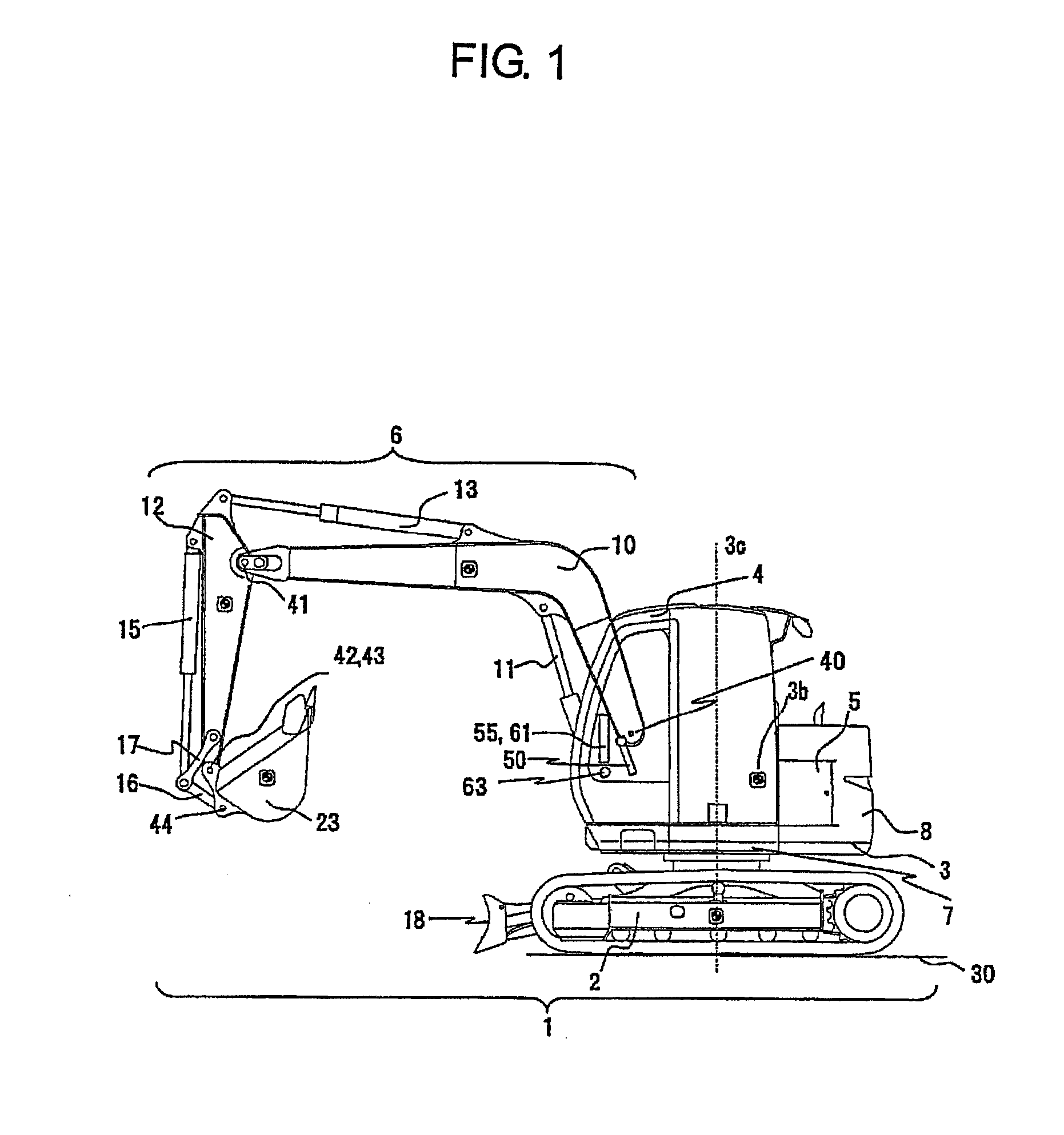

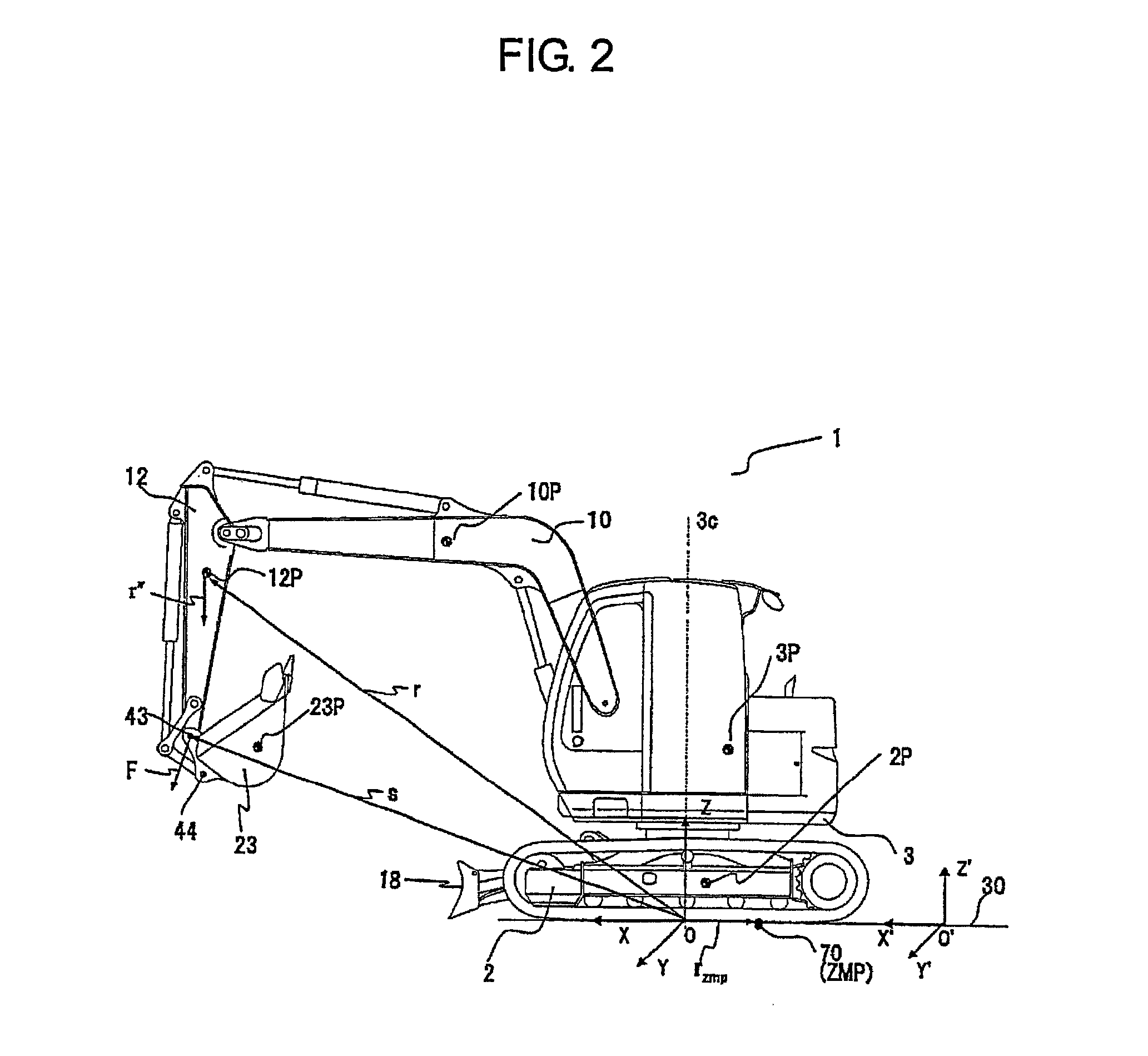

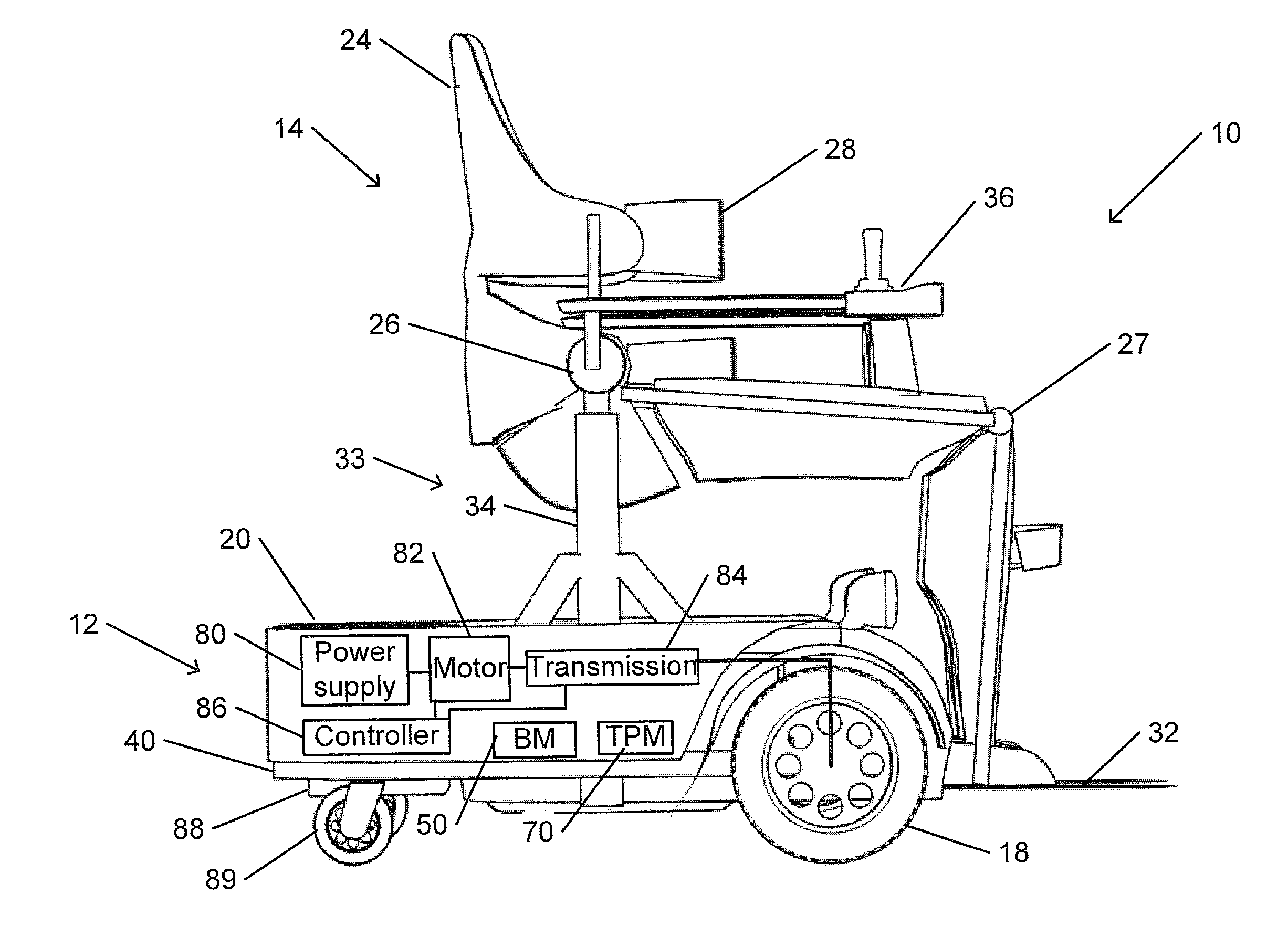

Work machine

ActiveUS20140121840A1Prevent tippingStable jobGeometric CADTemperatue controlDynamic balanceStabilization control

To provide a work machine with high stability in which a dynamic balance can be evaluated easily while the influence of a sudden stop of an travel base, an upperstructure and a work front is taken into consideration.A stabilization control calculation unit (60a) and a command value generating unit (60i) are provided in a control device (60) of the work machine. The stabilization control calculation unit (60a) uses a sudden stop model and position information of each movable portion of the travel base and a machine body including the work front (6) to predict a change of stability until reaching a complete stop when a control lever (50) in an operating state is instantaneously brought back to a stop command position, and calculates a motion limit needed to prevent destabilization from occurring at any time instant until reaching the stop. The command value generating unit (60i) corrects the command information to a drive actuator on the basis of the calculation result of the stabilization control calculation unit (60a).

Owner:NIHON KENKI CO LTD

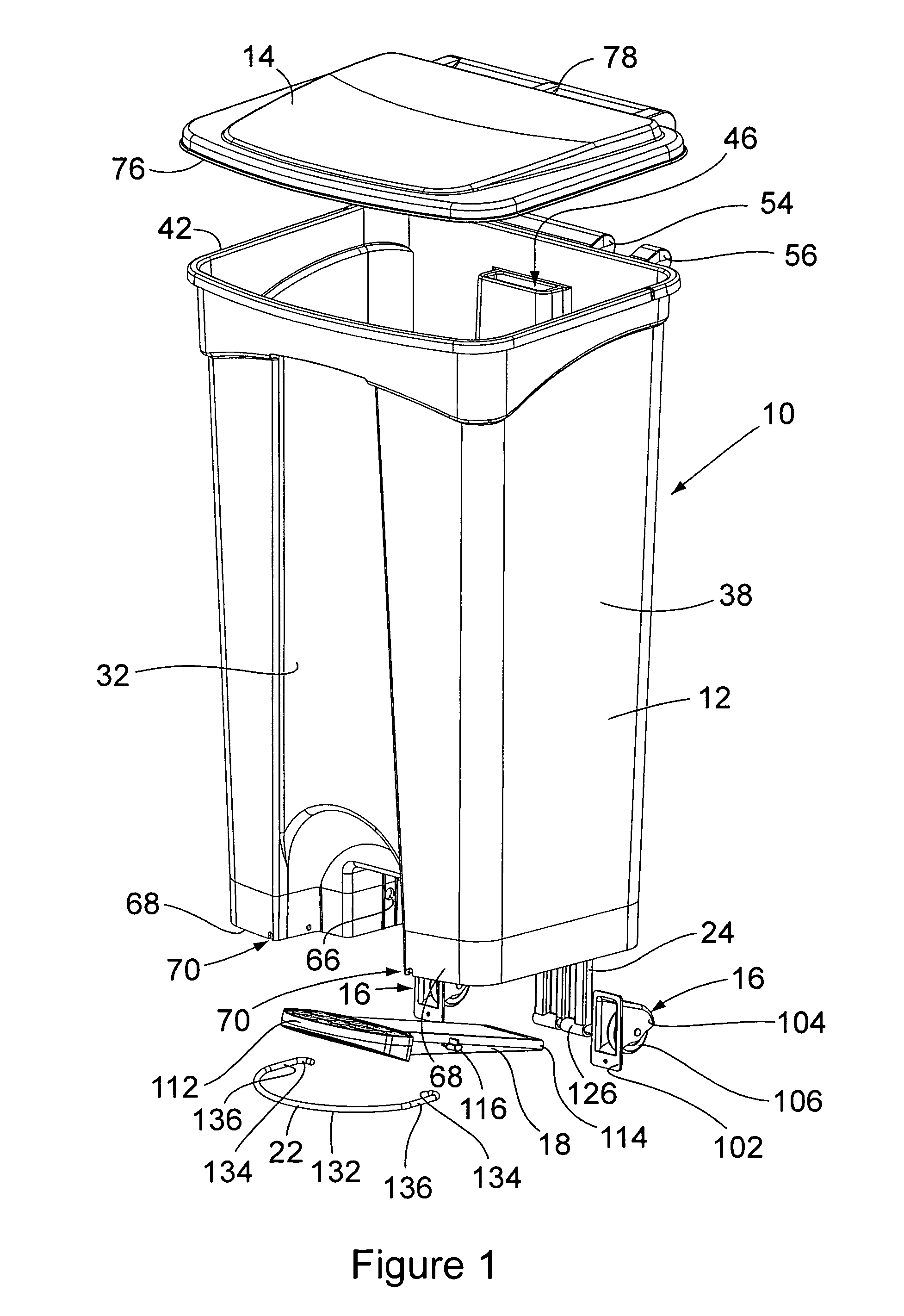

Step-on receptacle with tip prevention

ActiveUS20060103086A1Resisting tendencyEasy constructionCarriage/perambulator with single axisRefuse receptaclesEngineeringThreaded fastener

Owner:AMERICAN PLASTICS LLC

Stacked drawer refrigerator

ActiveUS20050061021A1Function increaseEasy accessLighting and heating apparatusDomestic refrigeratorsEngineeringBottle

A drawer refrigerator, including an evaporator, compressor and condenser, has a partitioned cabinet with two vertically stacked pull-out drawers having drawer bins. A single evaporator is located adjacent both drawer cavities and is partitioned to keep the temperature in both drawer bins approximately equal. The pull-out drawers can have a bottle bin with recesses holding the necks of wine, soda or like bottles. The bottle bin slides on the top edges of the drawer bin at its sides and can be moved front to back. The pull-out drawers can have an underside compartment opening at both sides of the drawer containing a removable storage bin. The pull-out drawers can also have an adjustable divider fence with pairs of lateral and transverse divider rods extending between the side walls and between the door panels and the rear walls of the drawer bins. The rods are coupled by a hub having a hand operated screw knob for locking the position of the fence.

Owner:U LINE CORP A WI CORP

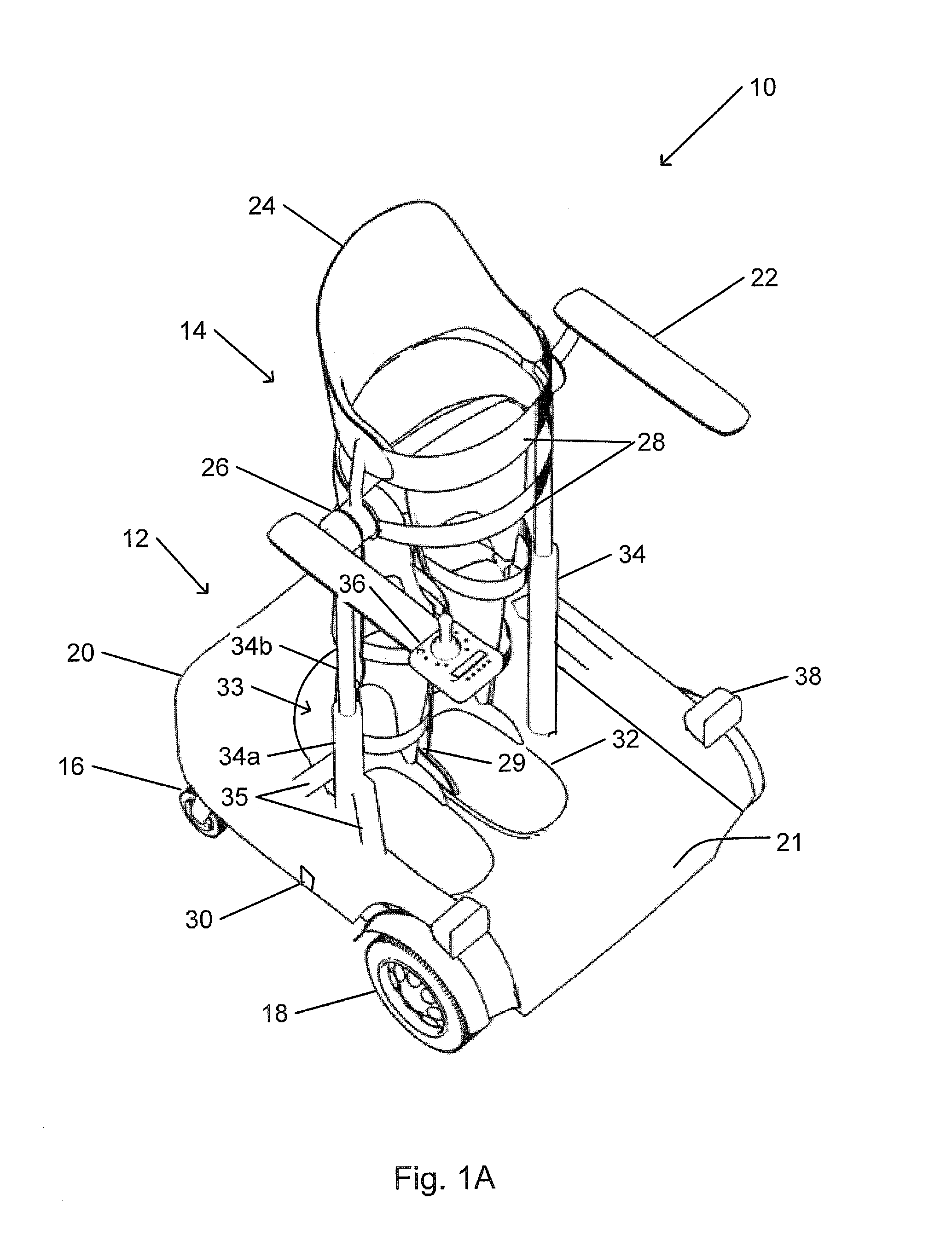

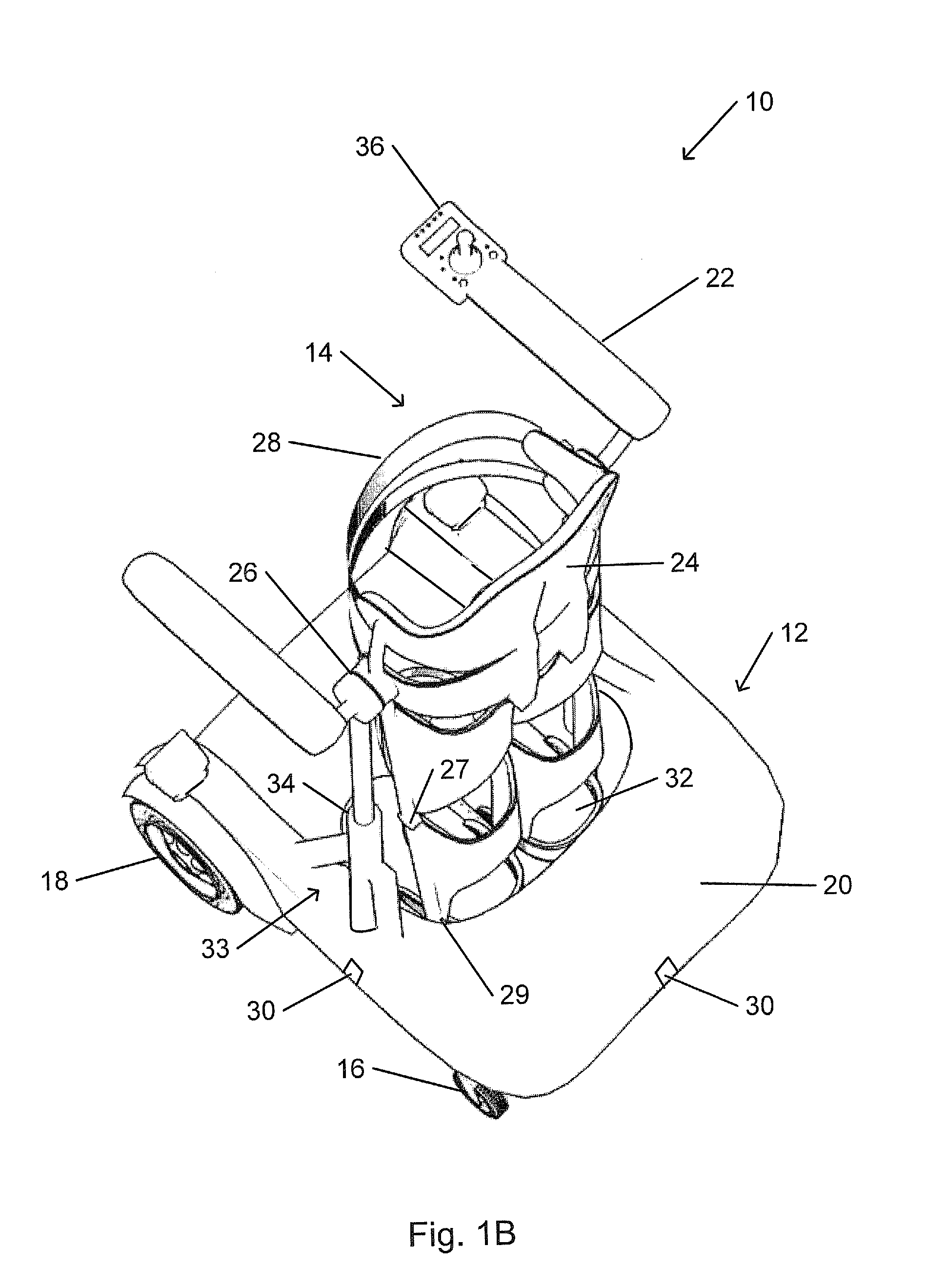

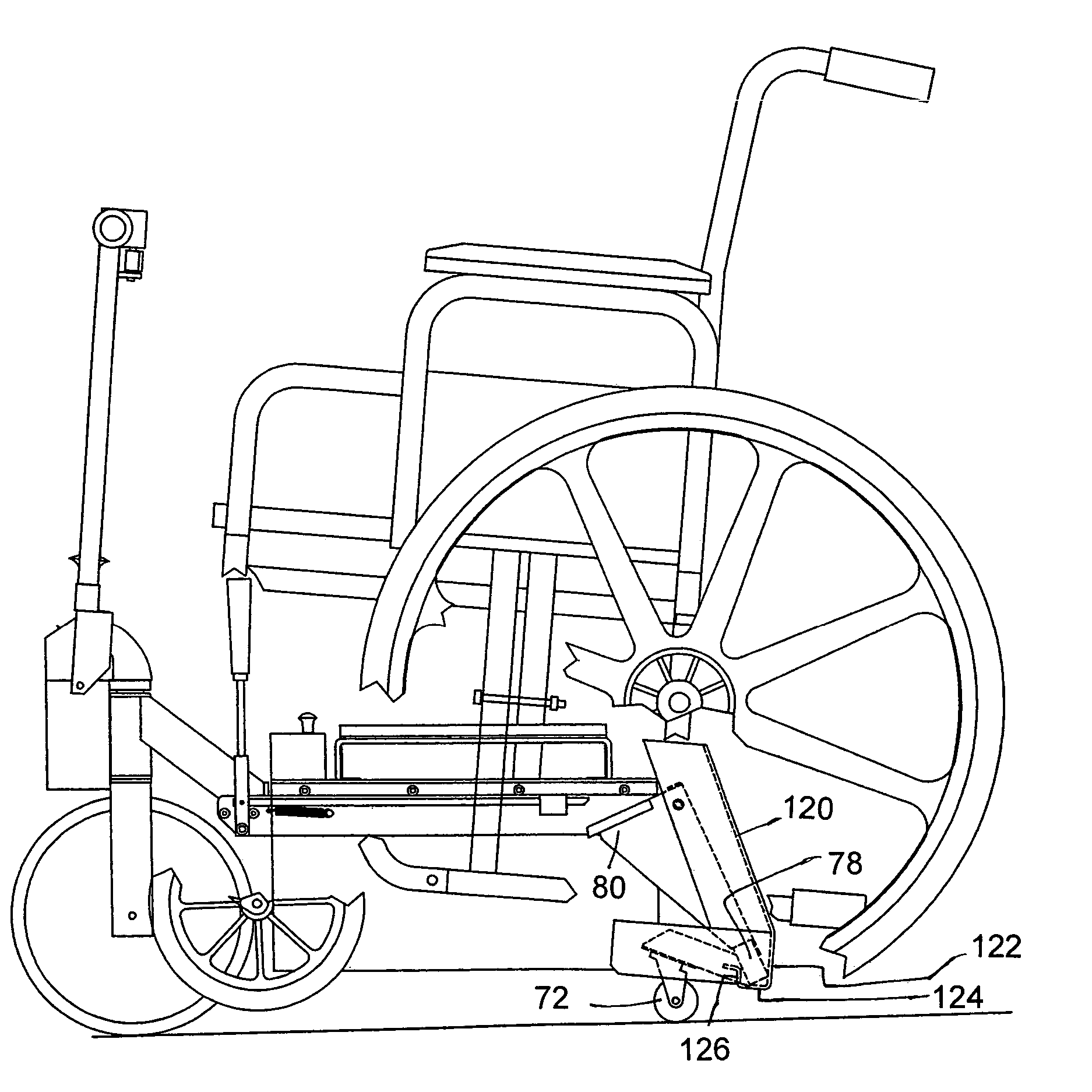

Standing wheelchair

ActiveUS20150060162A1Prevent tippingVehicle fittings for liftingWheelchairs/patient conveyanceStanding PositionsEngineering

A standing wheelchair device includes a wheeled base for enabling the device to move on a supporting surface. A harness assembly includes a plurality of braces for attaching to parts of a body of a user of the device, at least some adjacent braces of being connected by joints. A lifting unit mounted on the base, supports a hip joint of the harness assembly, and is configured to raise or lower the hip joint. When the user is attached to the harness assembly and is in a sitting position, raising a height of the hip joint causes the user to assume a standing position. When the when the user is attached to the harness assembly and is in a standing position, lowering the hip joint causes the user to assume a sitting or reclining position.

Owner:UPNRIDE ROBOTICS

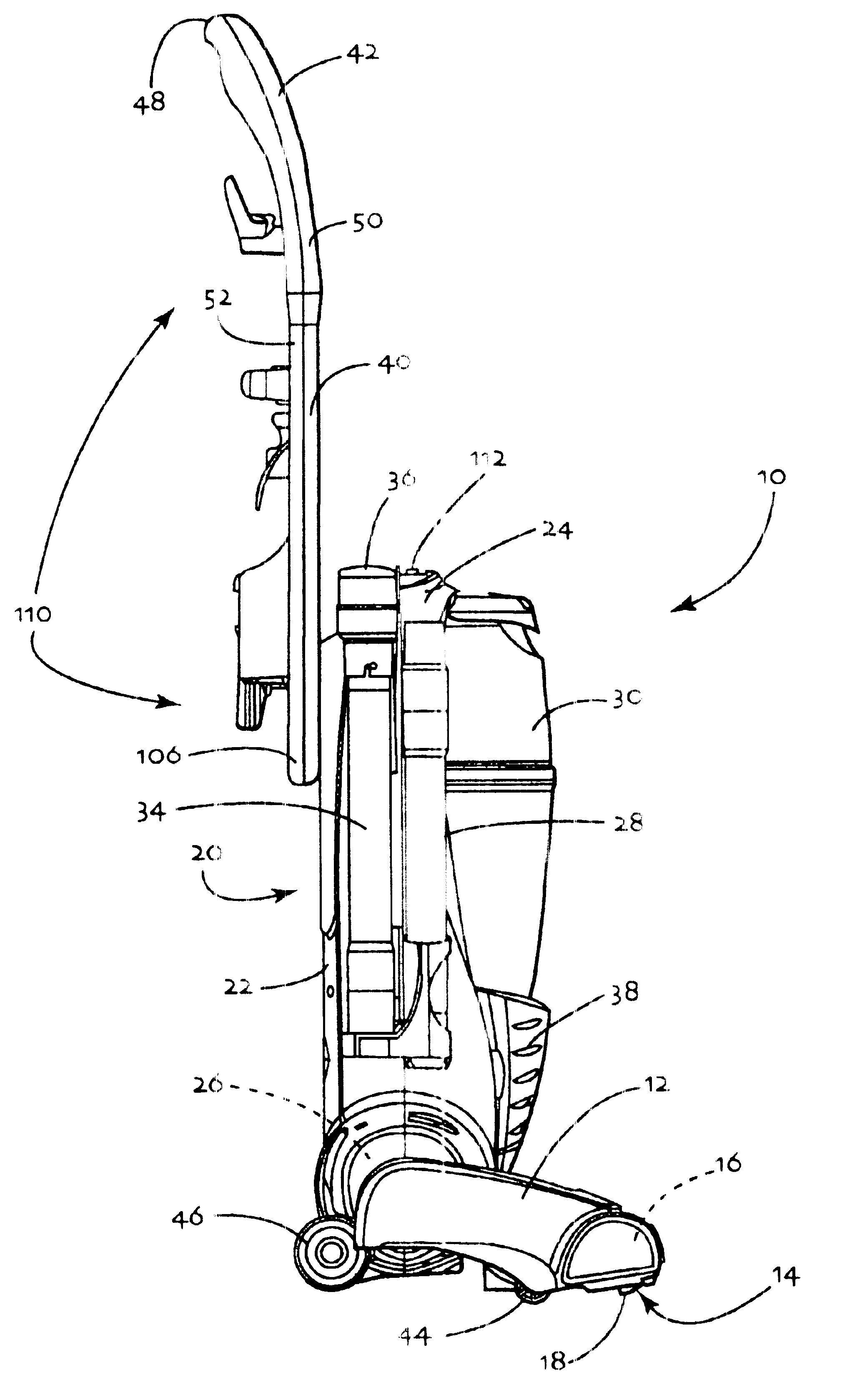

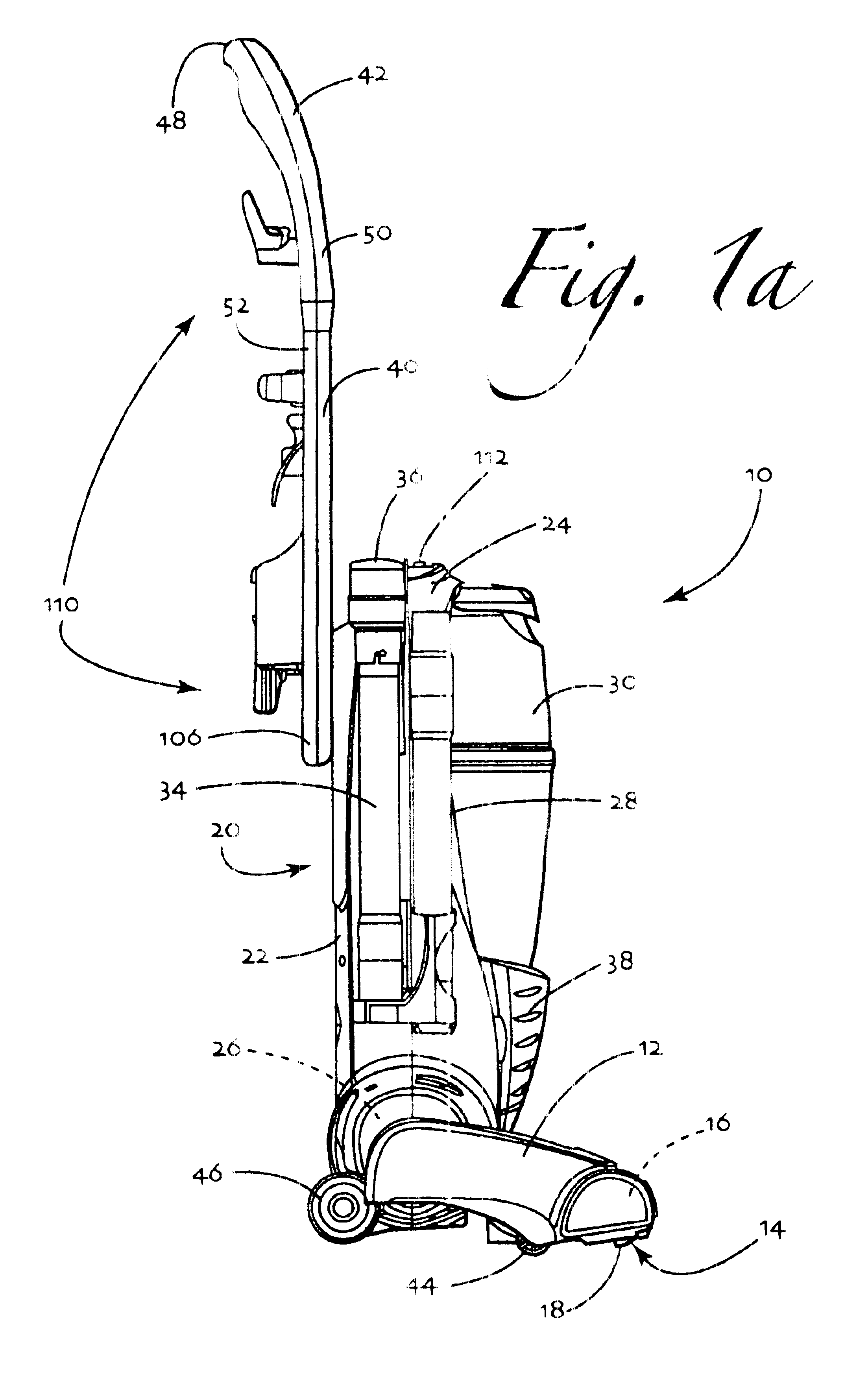

Rotating operating handle for vacuum cleaner

InactiveUS6941615B2Prevent tippingAvoid cleaningCleaning filter meansSuction filtersEngineeringVacuum cleaner

A floor cleaning apparatus includes a nozzle assembly and a canister assembly connected to the nozzle assembly. A suction generator and a dirt collection vessel are carried by the nozzle assembly or the canister assembly. In addition, the vacuum cleaner includes a control handle displaceable between operating and storage positions. A stabilizer on the handle is provided adjacent the floor in the storage position. Engagement of the stabilizer with the floor prevents the vacuum cleaner from inadvertently tipping over rearwardly.

Owner:PANASONIC OF NORTH AMERICA

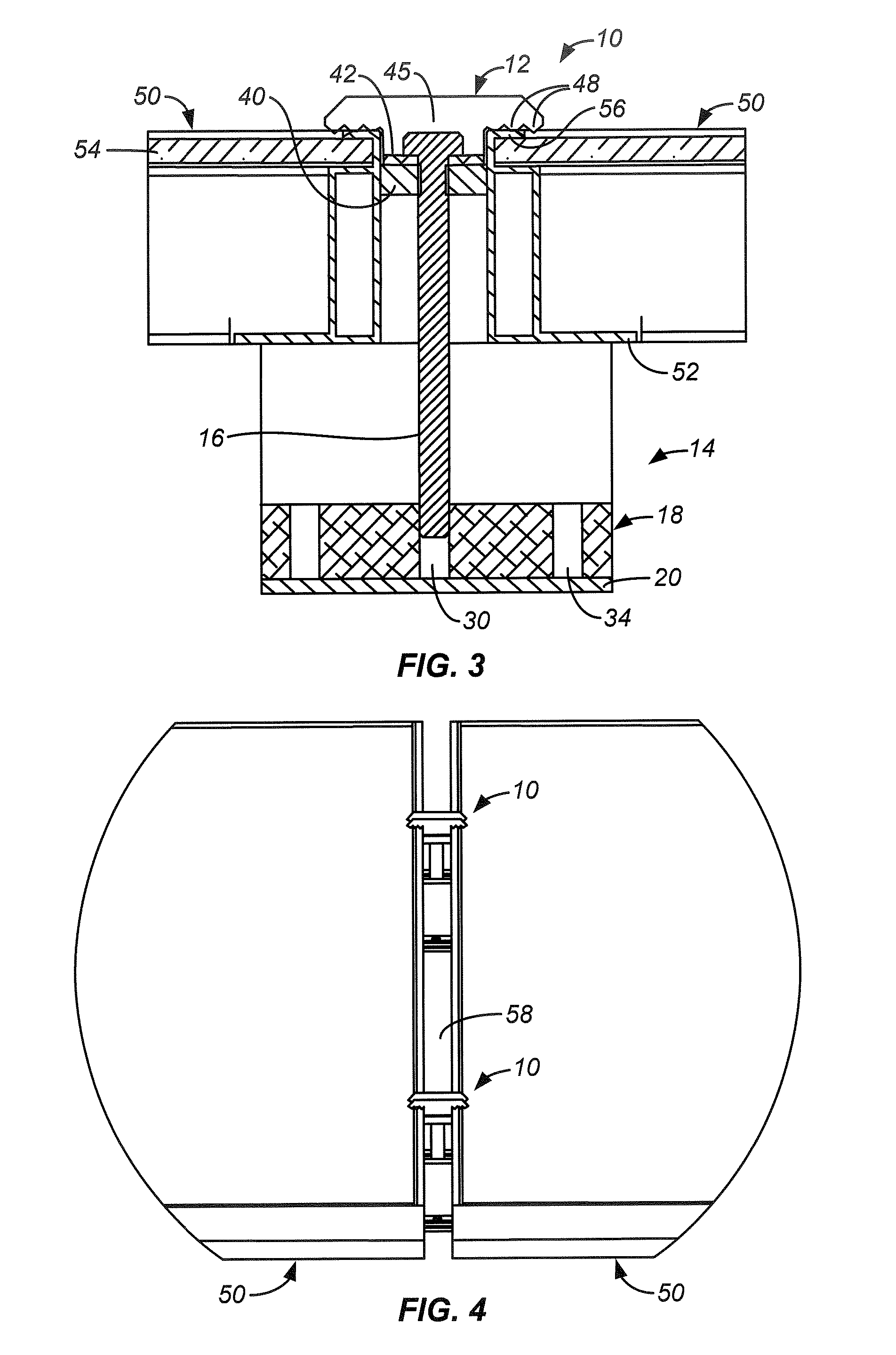

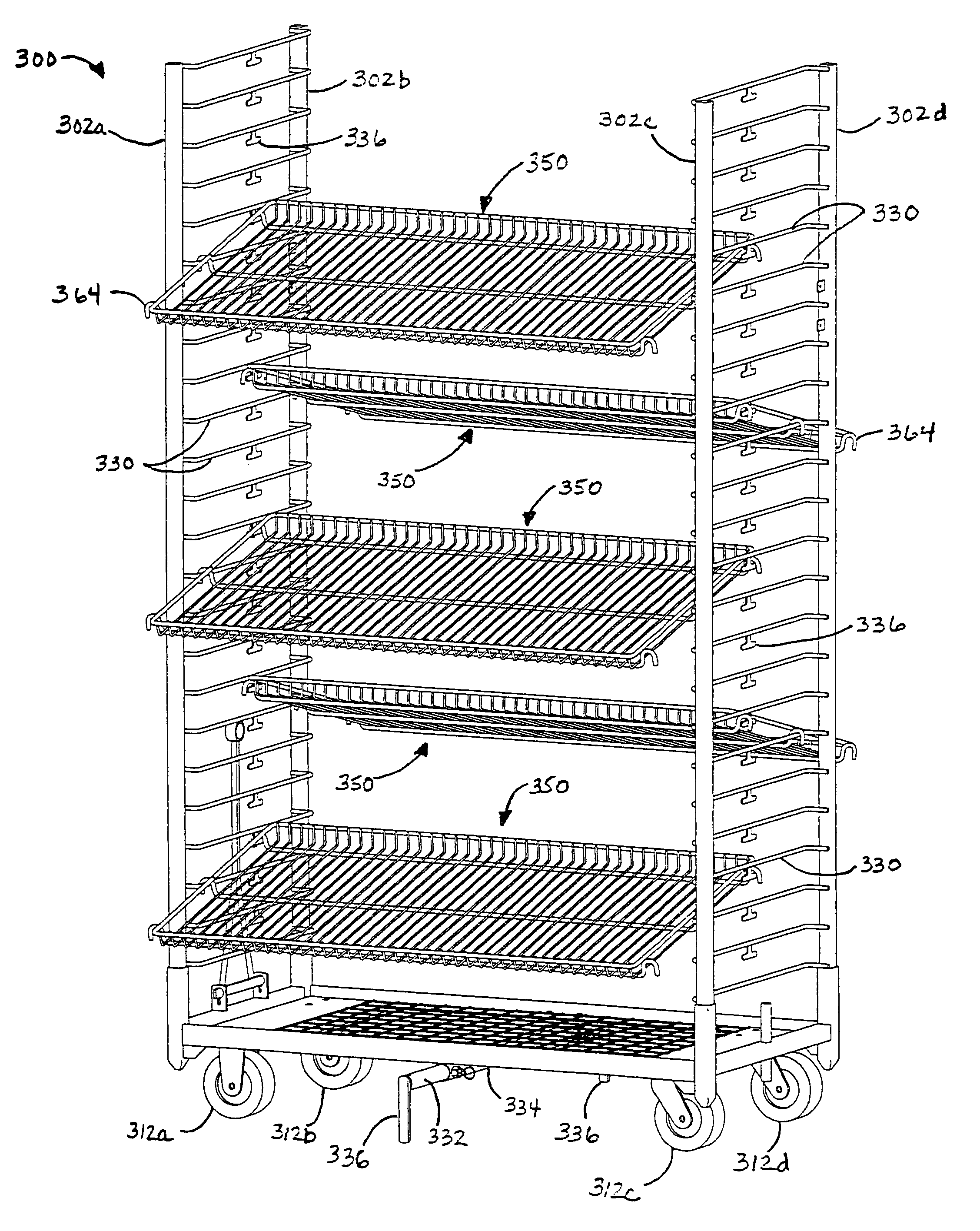

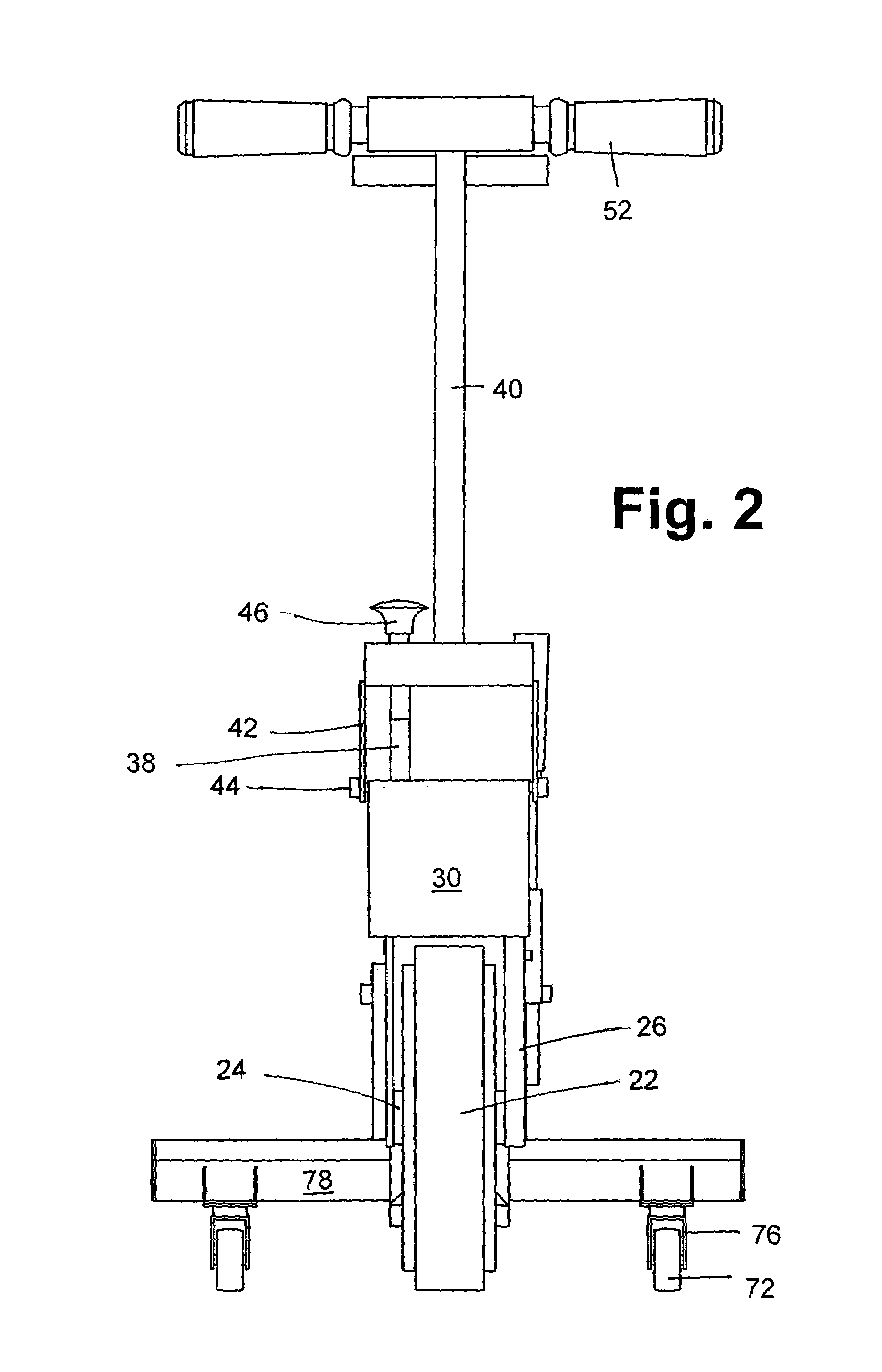

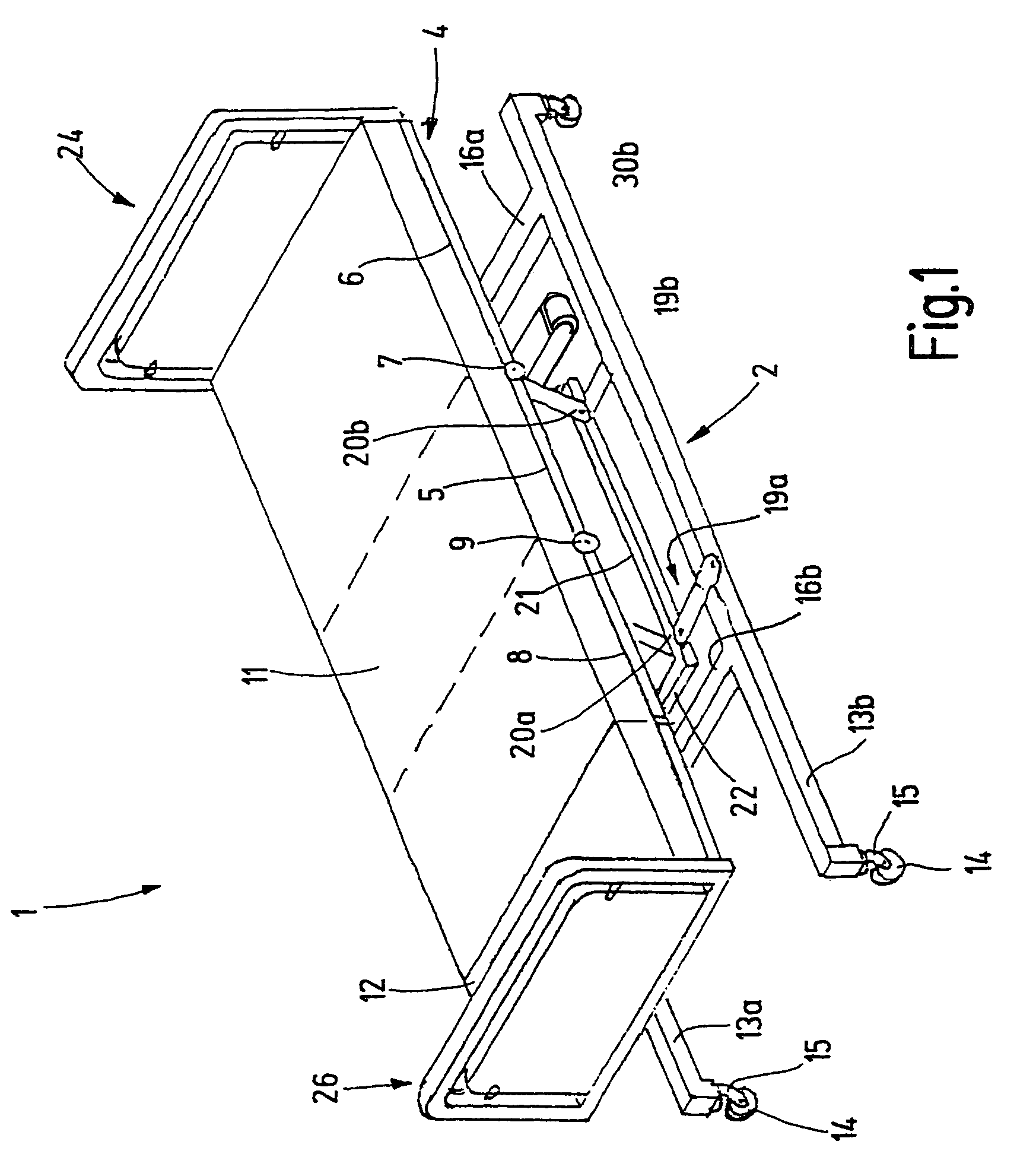

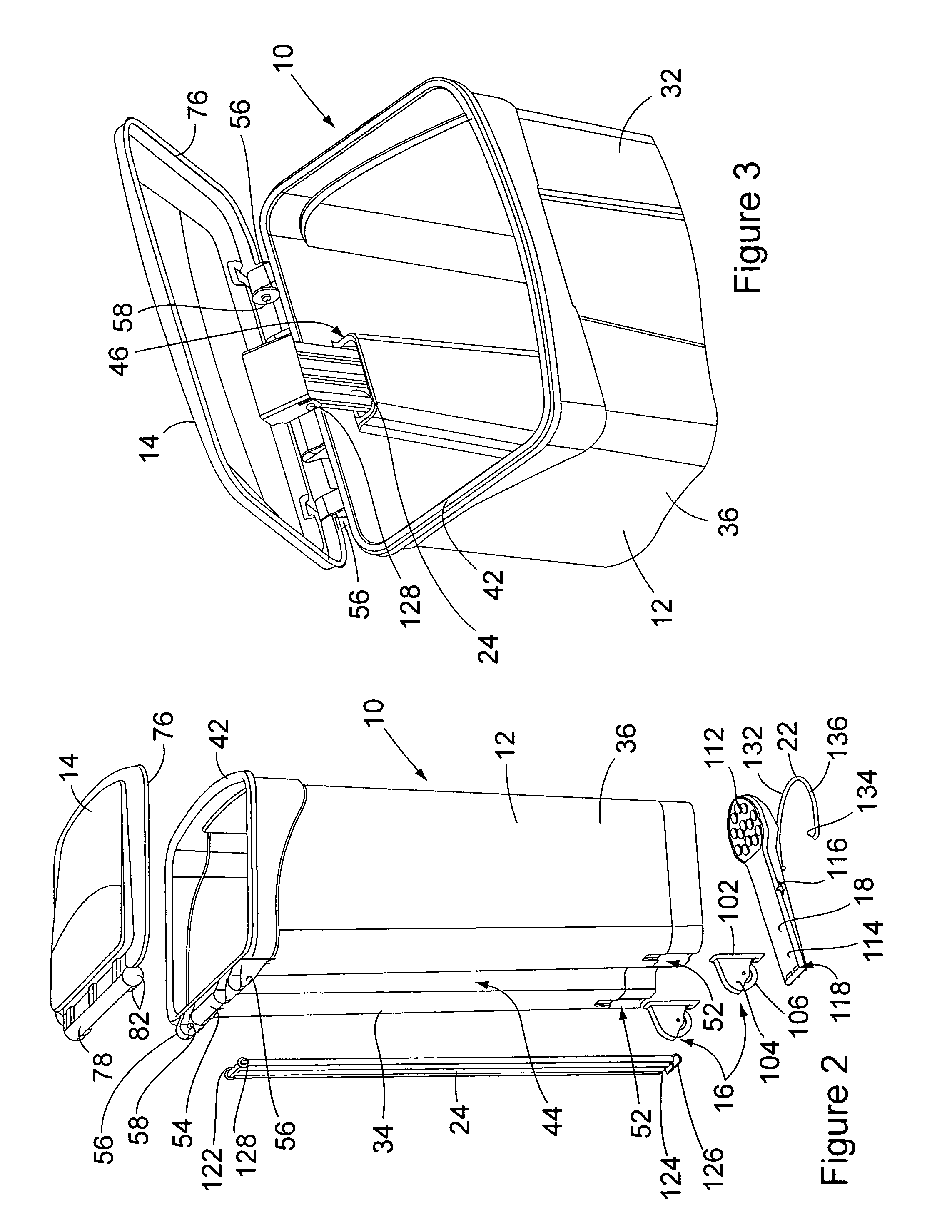

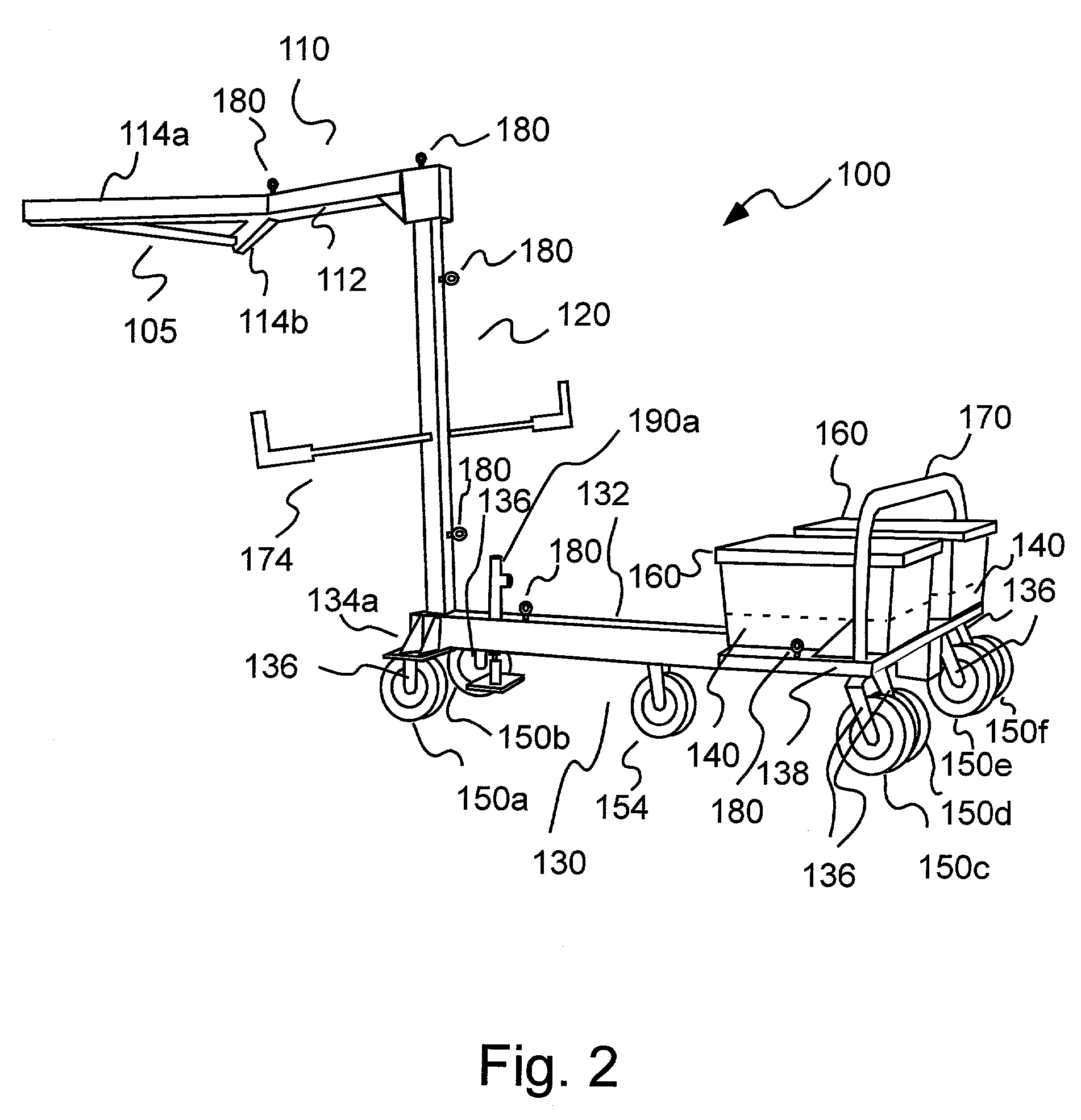

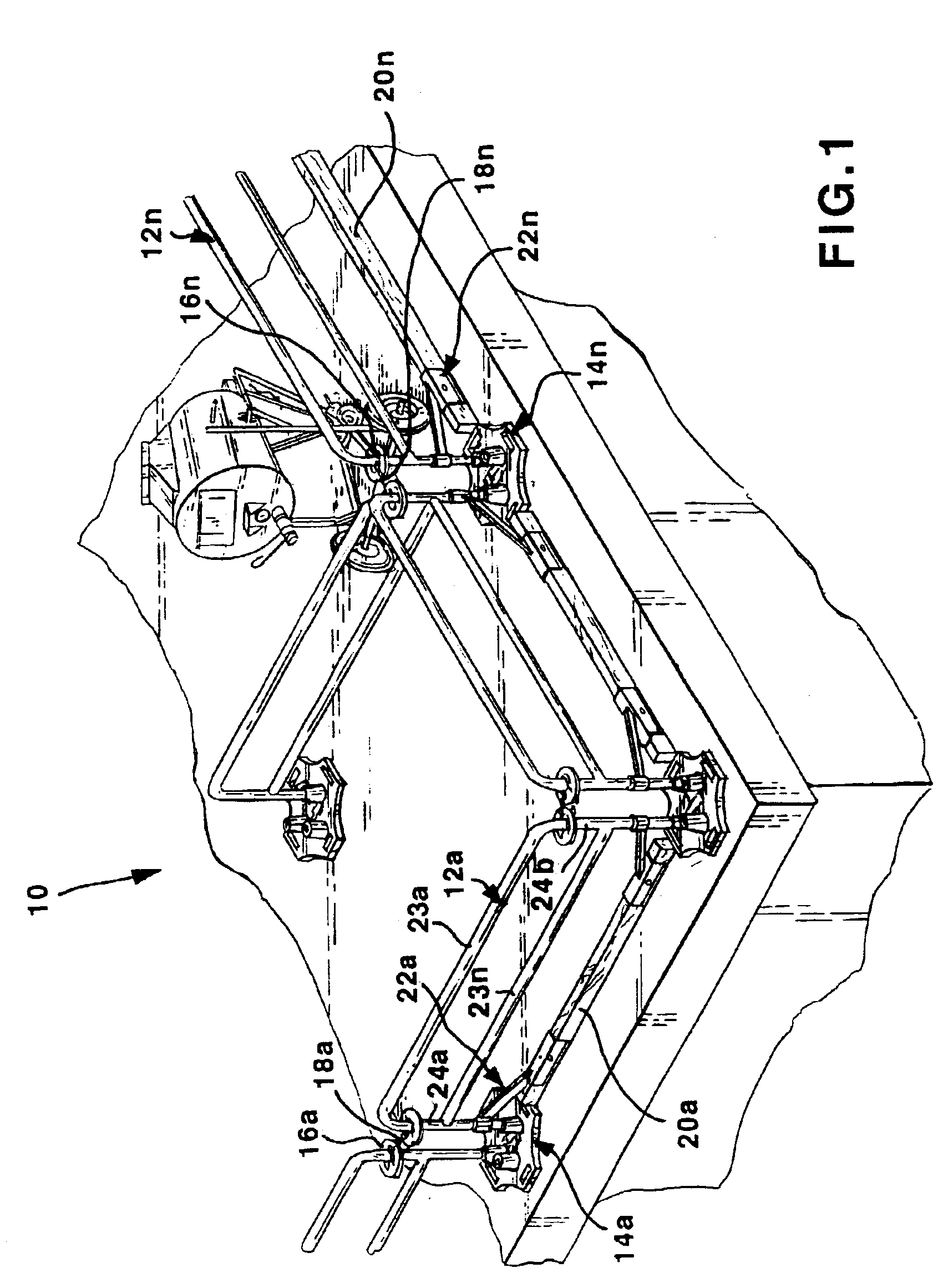

Rack for transportation and display of plants

A rack assembly for transportation and display of potted plants and similar articles. The rack includes vertical supports, and a plurality of trays that are slidingly supported on the posts. The trays are extensible from a retracted position in which the trays are arranged in compact, vertically spaced relationship for transportation, to a deployed position in which the trays extend on opposite sides in an alternating arrangement with increased vertical spacing, and are tilted to a downwardly angled orientation so that the plants can be readily viewed and accessed by customers and other personnel. The posts and trays are mounted on a mobile frame that includes stabilizer legs which prevent the assembly from tipping when the trays are in the deployed position. The posts and trays are removable from the frame, and can be broken down for storage.

Owner:VANDERHOEK WIEBE S +1

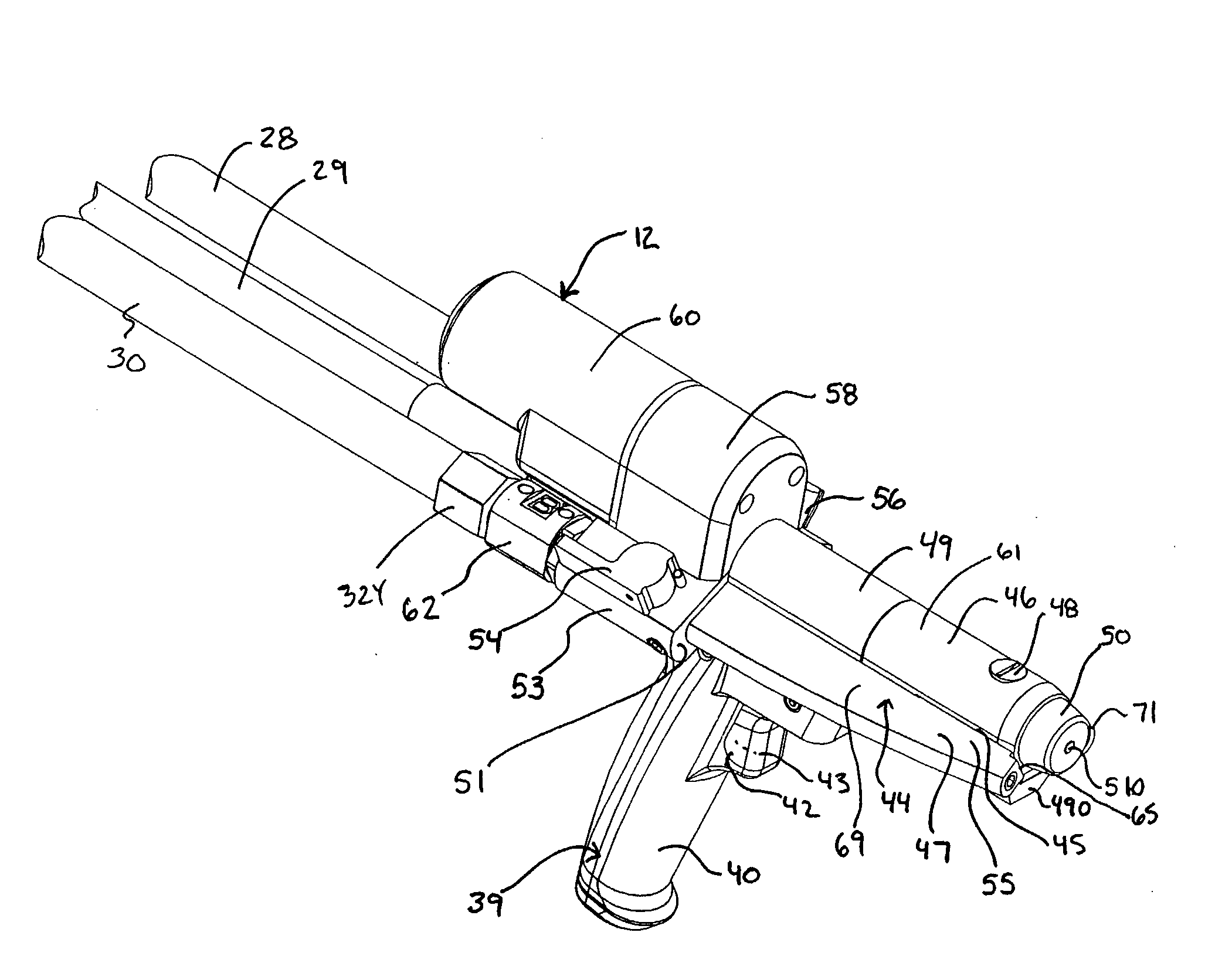

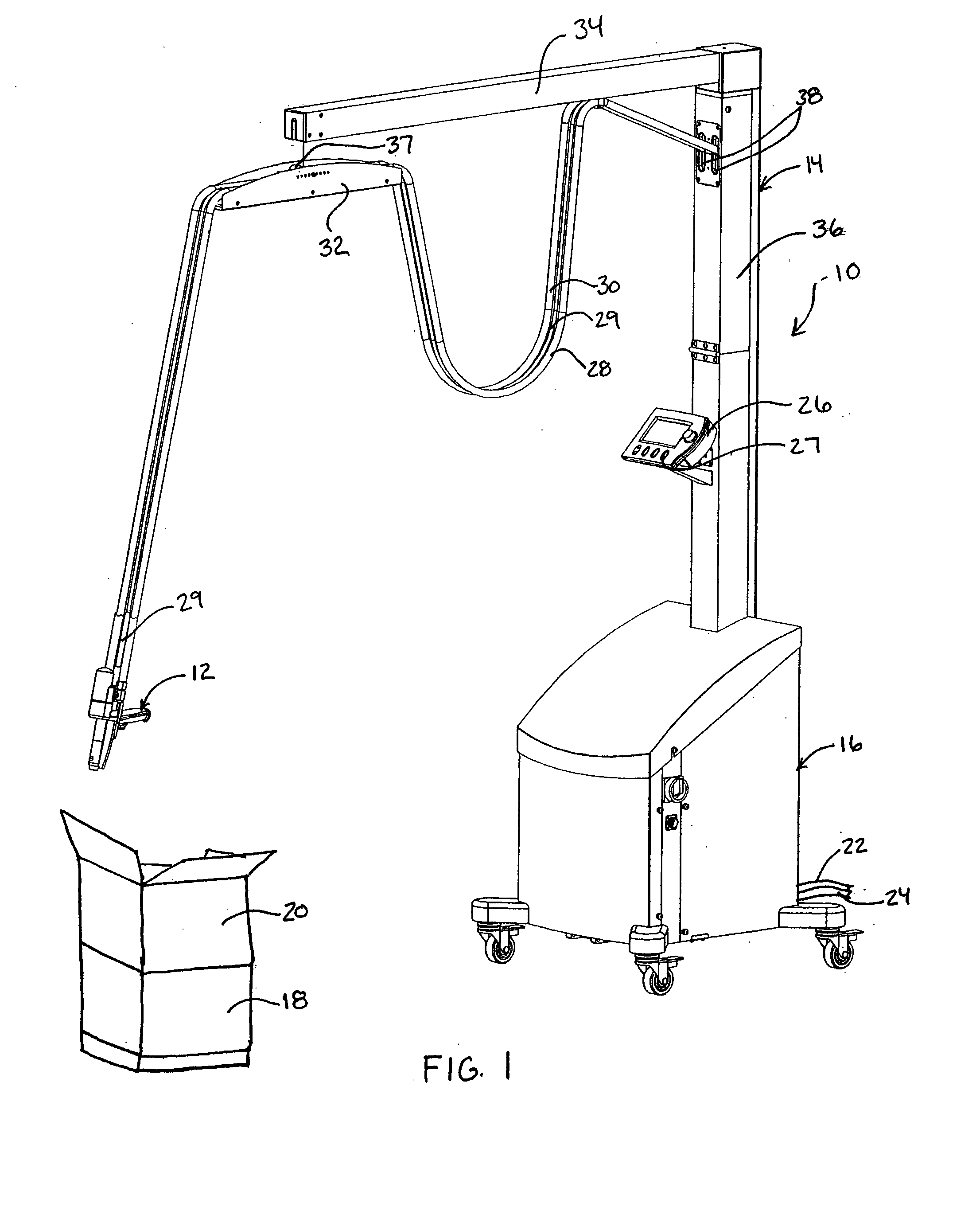

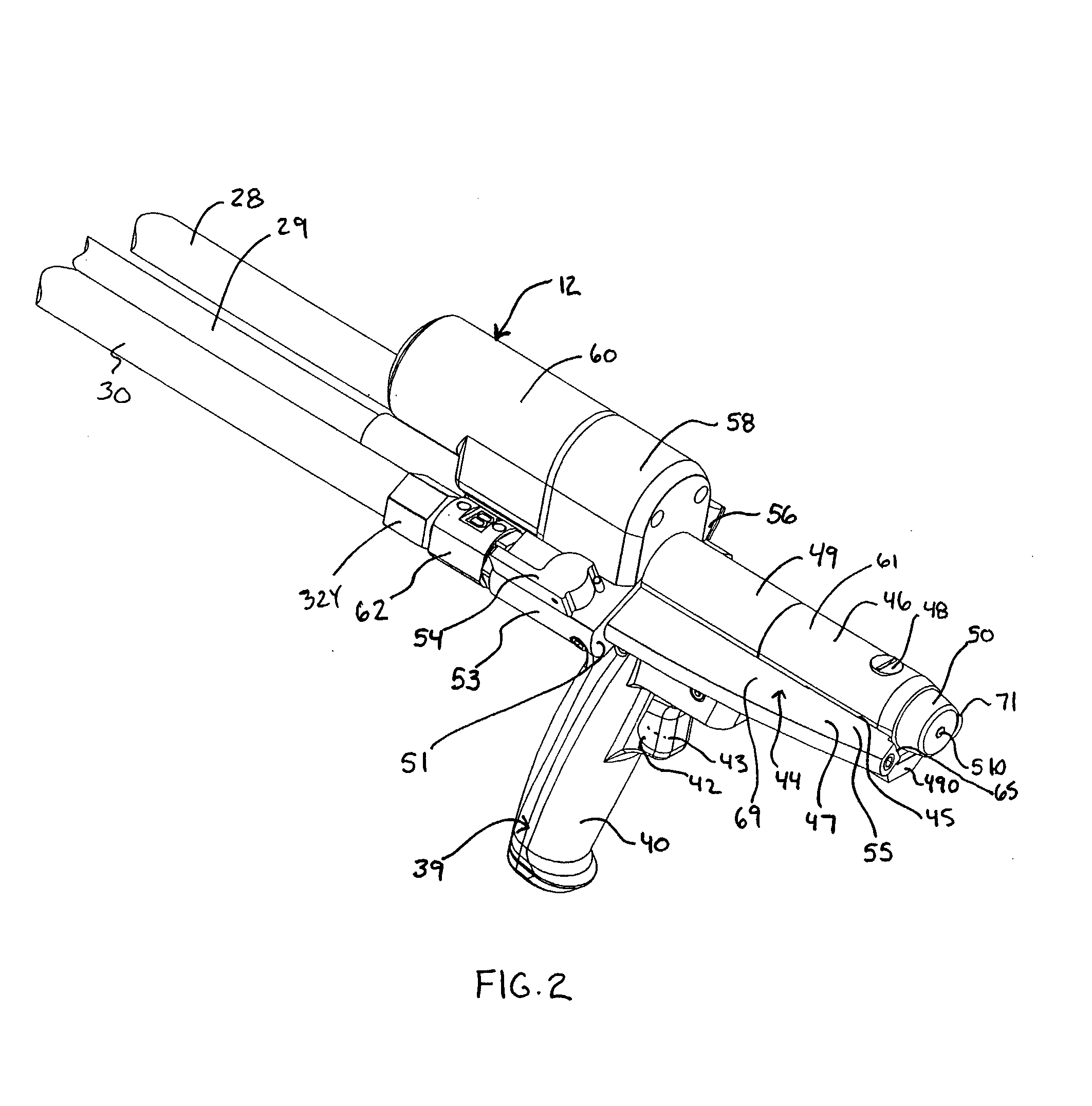

Hand Held Dispenser

ActiveUS20080135579A1Minimize downtimeEasy to disassembleLiquid flow controllersLarge containersTemperature controlHand held

A hand held dispenser system with associated dispensed material supply assembly as in separate source chemical foam precursor feeding into, for example, streamlined chemical passageways preferably each comprised of, in series, a castellated swivel hose filter, a valve assembly housing, a wing extensions of a manifold, which manifold supports a high efficiency drive system and is supported by a handle that provides for a compact assembly and receives a rugged trigger assembly. The manifold design provides for elongated filter and, temperature controlled cartridge heater insertion. There is further provided in a preferred embodiment a readily releasable electric source feed line plug connection at the butt end of the dispenser. The dispenser is well suited for the dispensing of methane foam as in a product packaging setting.

Owner:PREGIS INTELLIPACK CORP

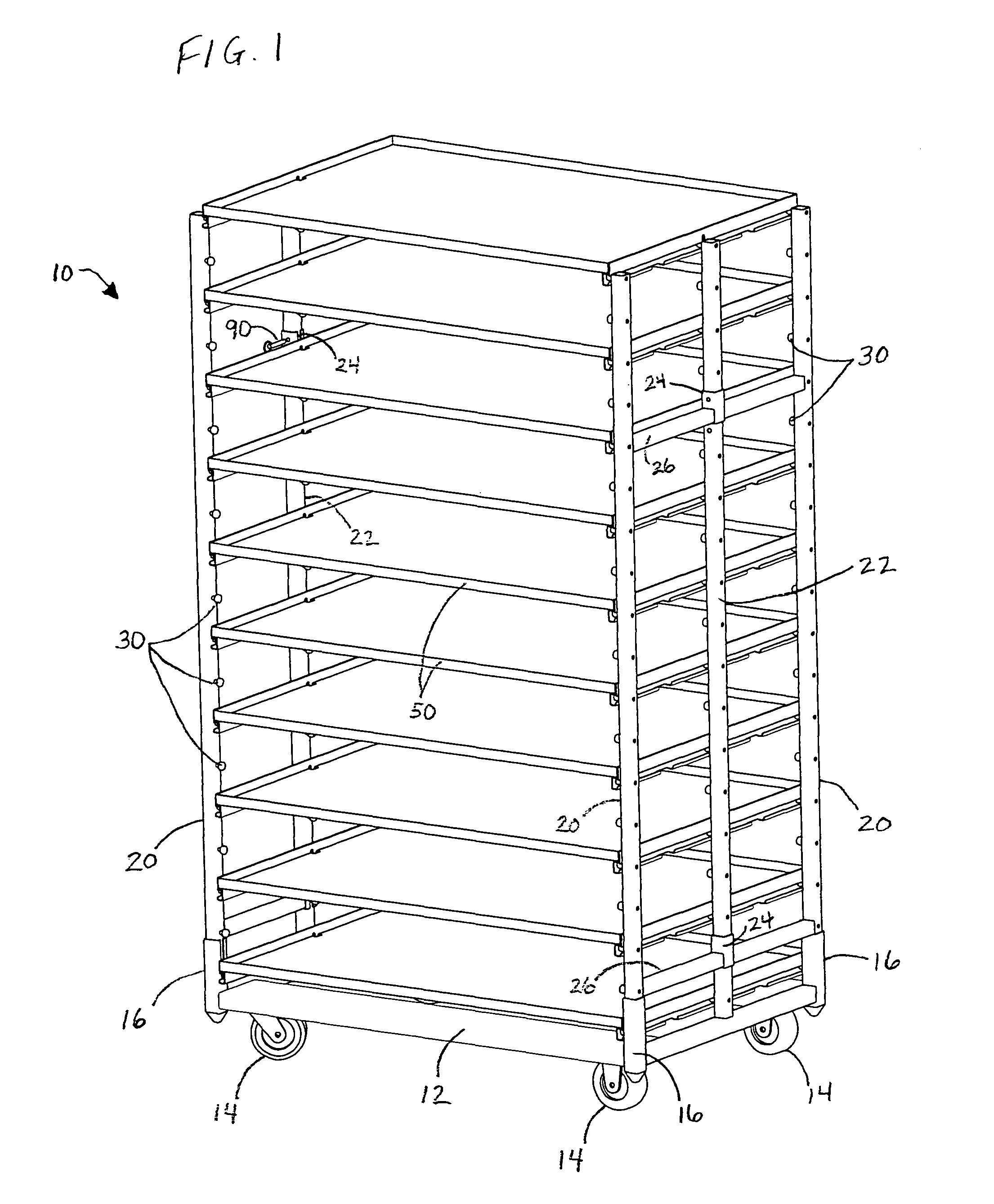

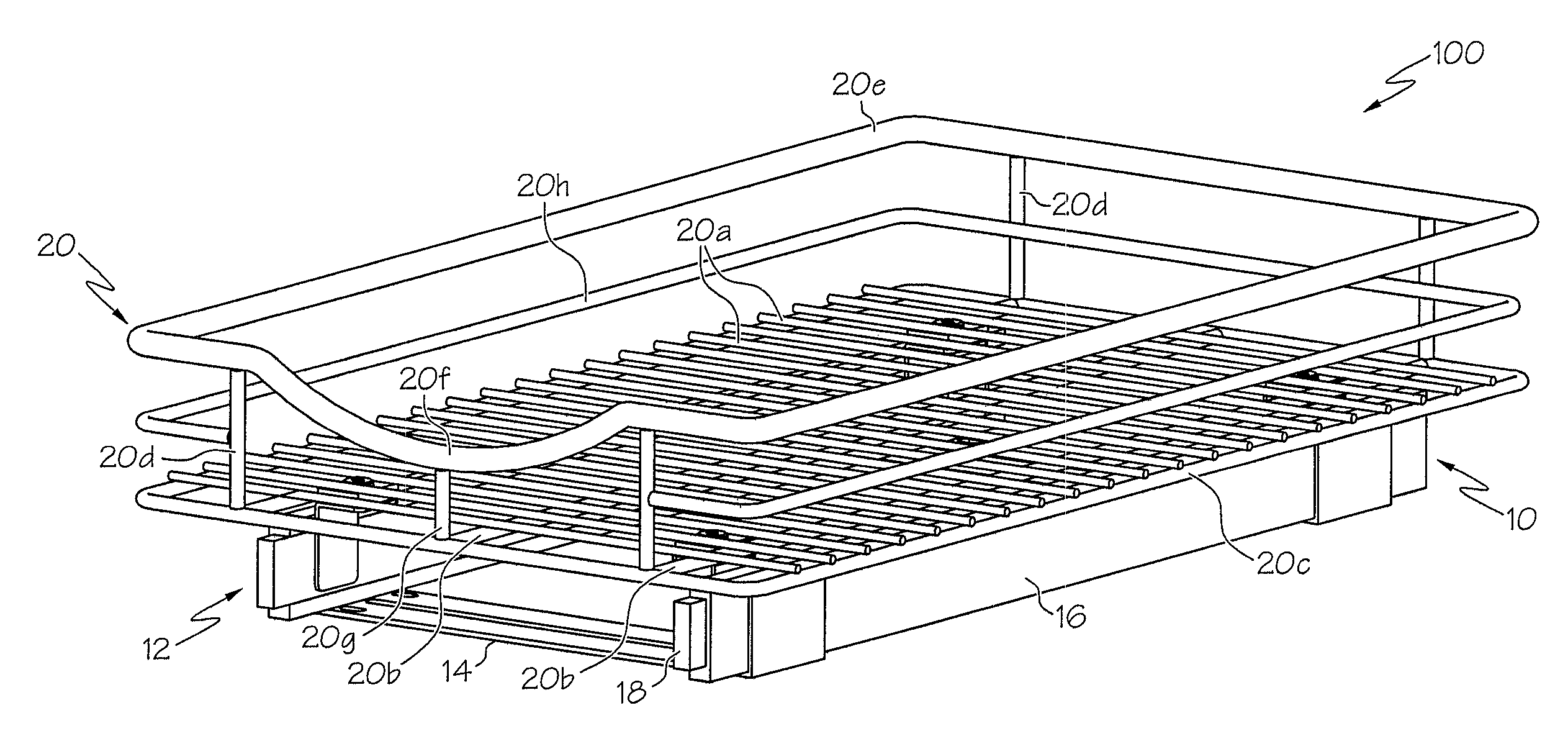

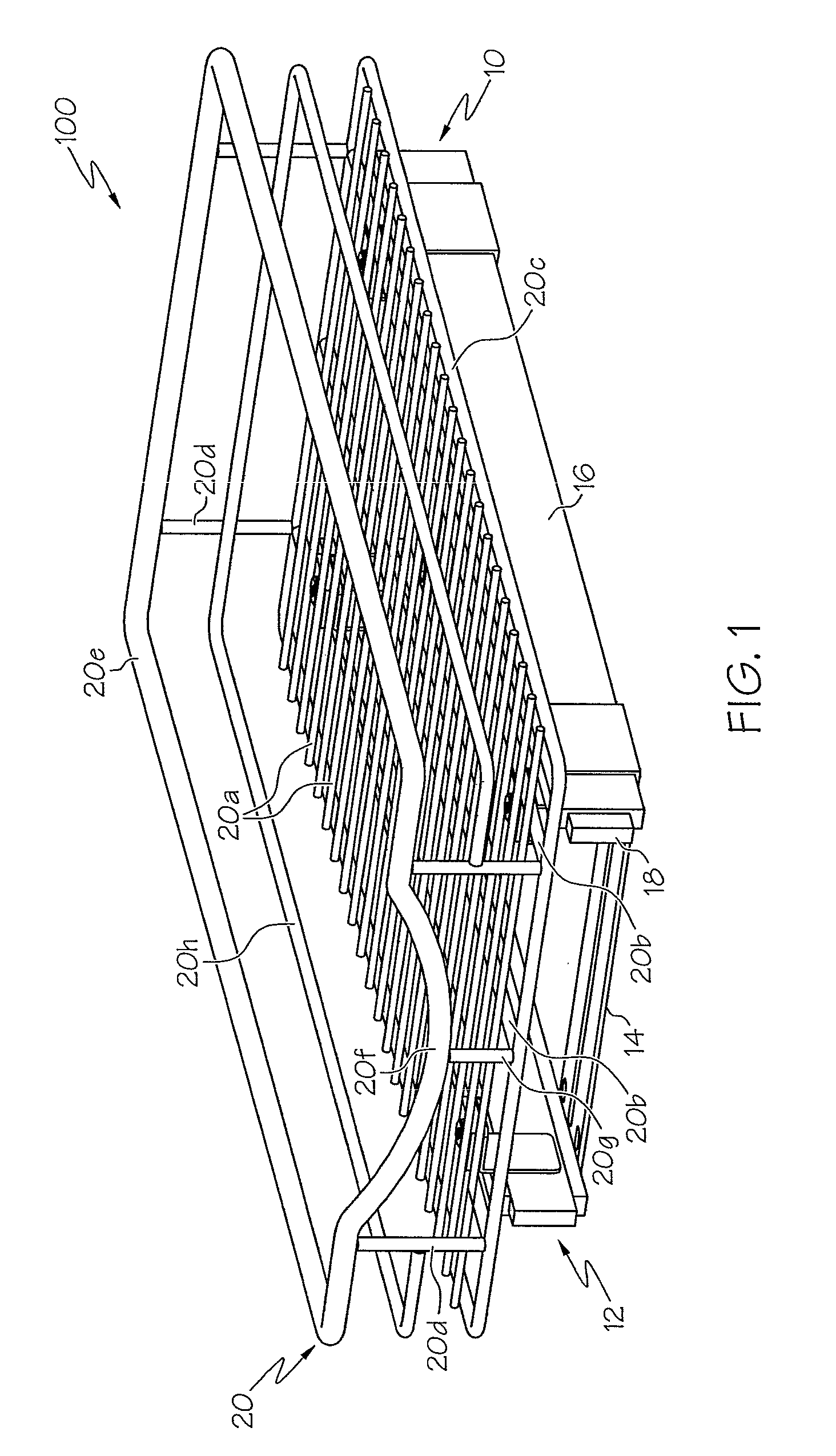

Glide mechanism for roll out drawers and other items

A slide frame mechanism for a rollout accessory such as a wire drawer has two or more ball-bearing glides in a vertical orientation. Each of the glides includes a glide mount with a threaded aperture and cross-bars attached to extend between the glides. The accessory has a plurality of mounting tabs. Shoulder screws with partial threads pass through the accessory mounting tabs and threadably engage the threads of the slide mount apertures to secure the accessory to the glides. A compressible pad is positioned between the accessory mounting tabs and the glide mounts to provide a floating suspension which reduces binding of the glides when the accessory is rolled in and out. The screws fit loosely through oversized openings in the mounting tabs to allow limited movement of the accessory relative to the glides in a horizontal plane for further reduction of binding. Drawer dividers are constructed to detachably fit on drawers to provide separate compartments.

Owner:LYNK

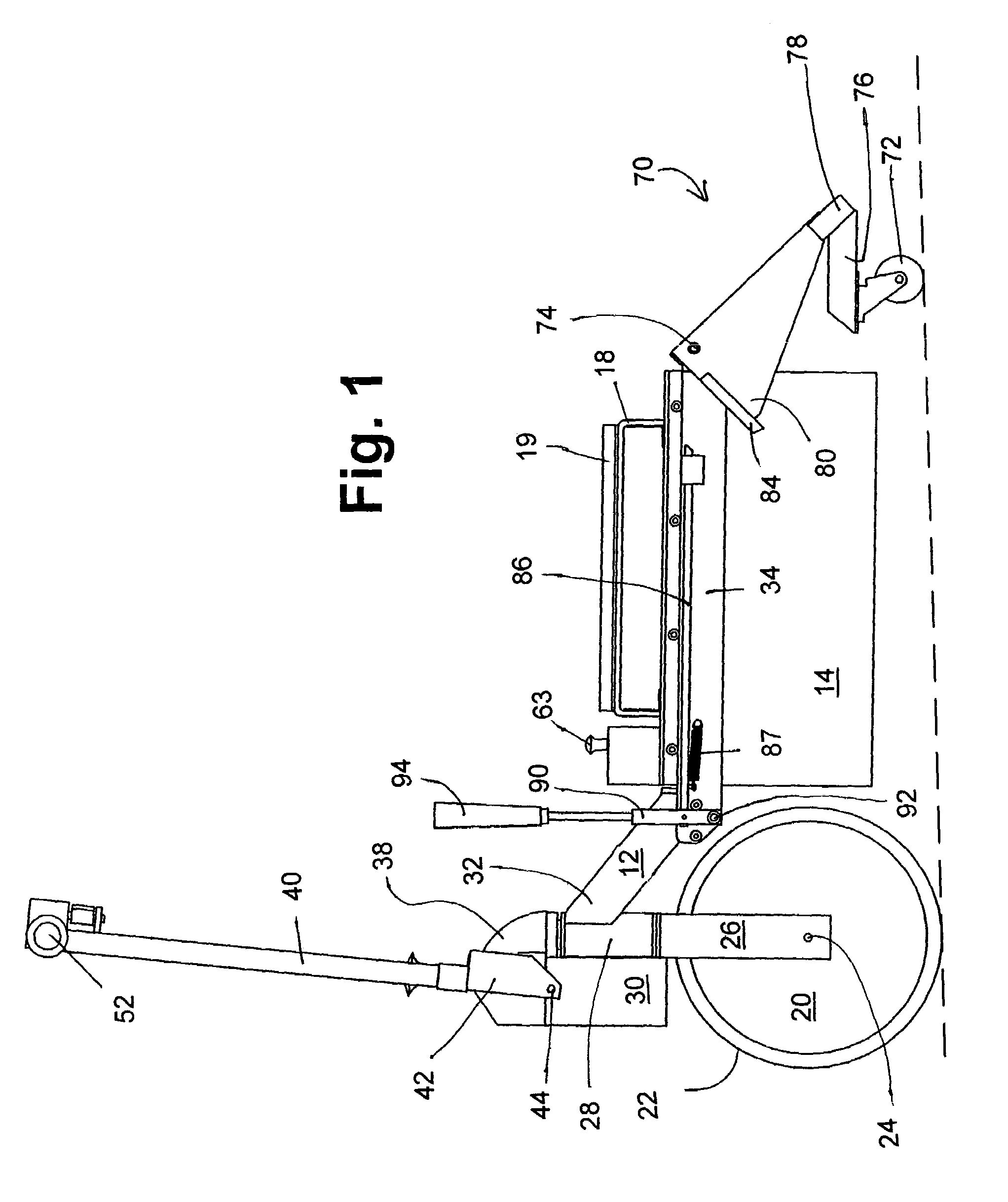

Wheel chair apparatus and method

InactiveUS7117967B2Easy passSpace minimizationDC motor speed/torque controlWheelchairs/patient conveyanceWheelchairDrive wheel

A wheel chair drive apparatus includes a frame having a wheel mount, a battery mount, and a control shaft mount. A drive wheel has a drive motor incorporated within the drive wheel. A battery is in operative communication with the drive motor via a detachable jack. A battery housing is dimensioned to mount in the battery mount of the frame and has a handle. A control shaft pivotably mounted on the control shaft mount, so that it has a stow position, and operating position, a user entry position and a table use position. A caster lever is pivotably mounted to the frame, so that it has a rolling position and an engaged position. The caster lever is disposed to engage a receiving seat on a wheel chair. A locking lever is releasably biased toward a position locking the caster lever in the engaged position.

Owner:MIDAMERICA ELECTRONICS CORP

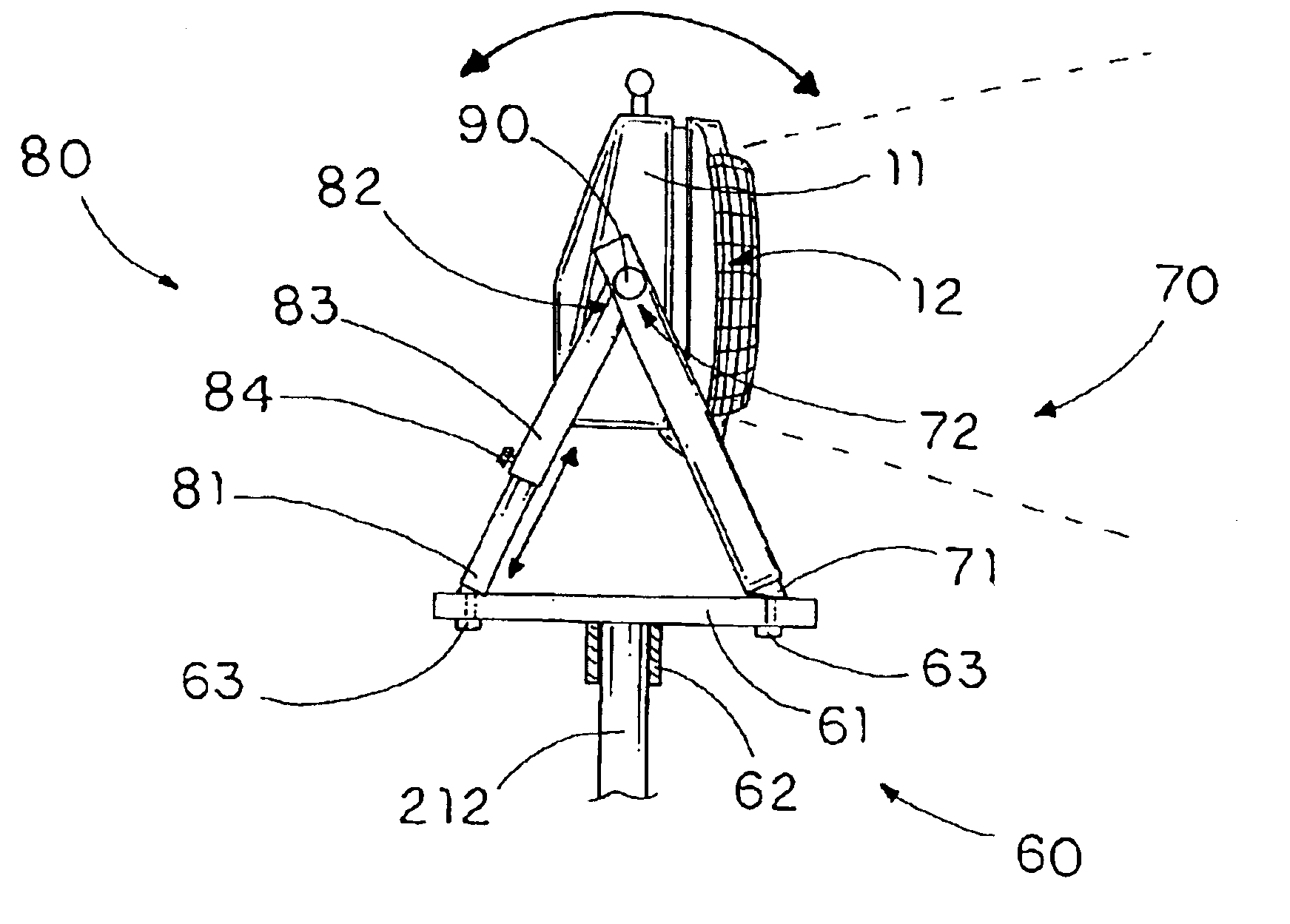

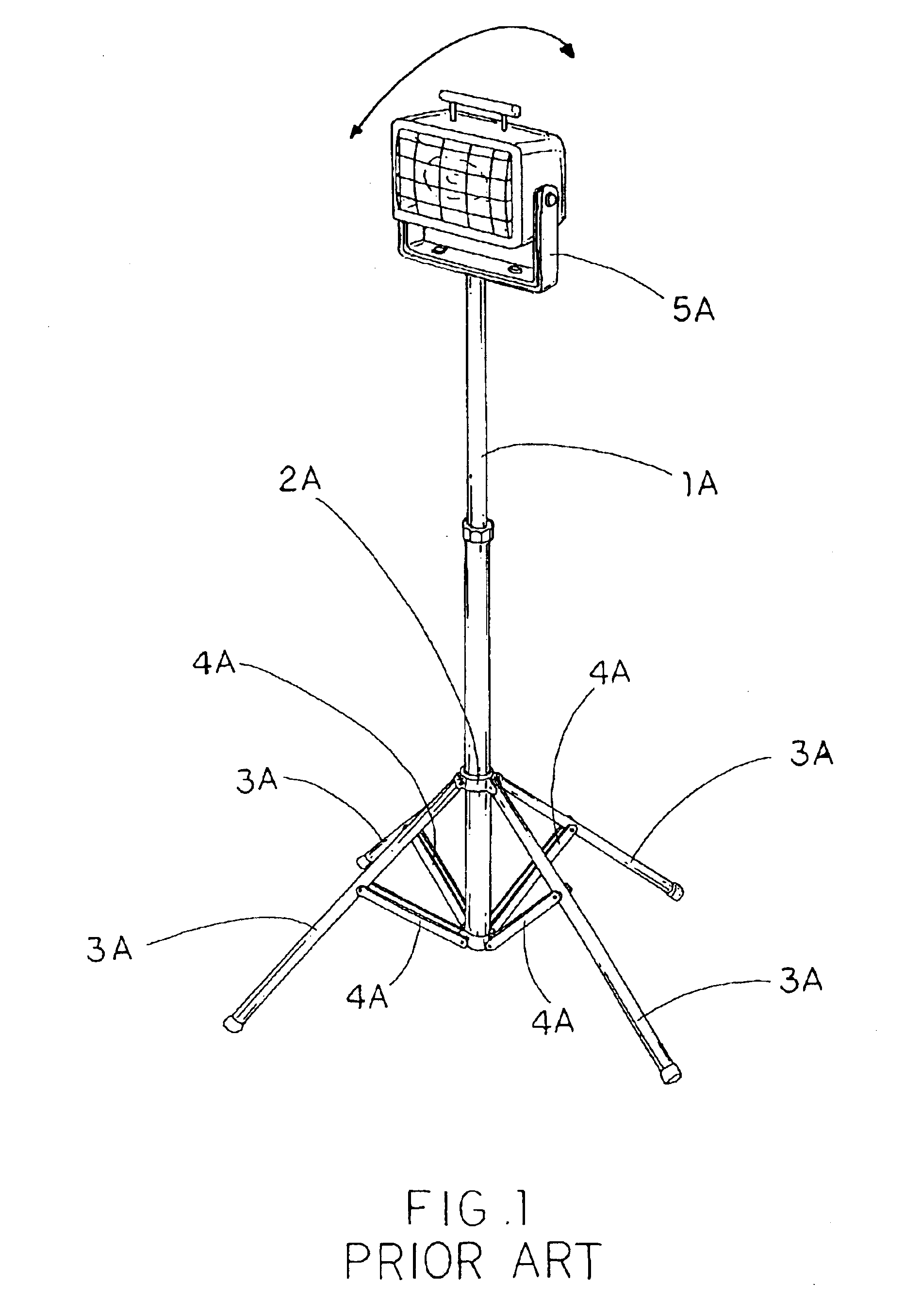

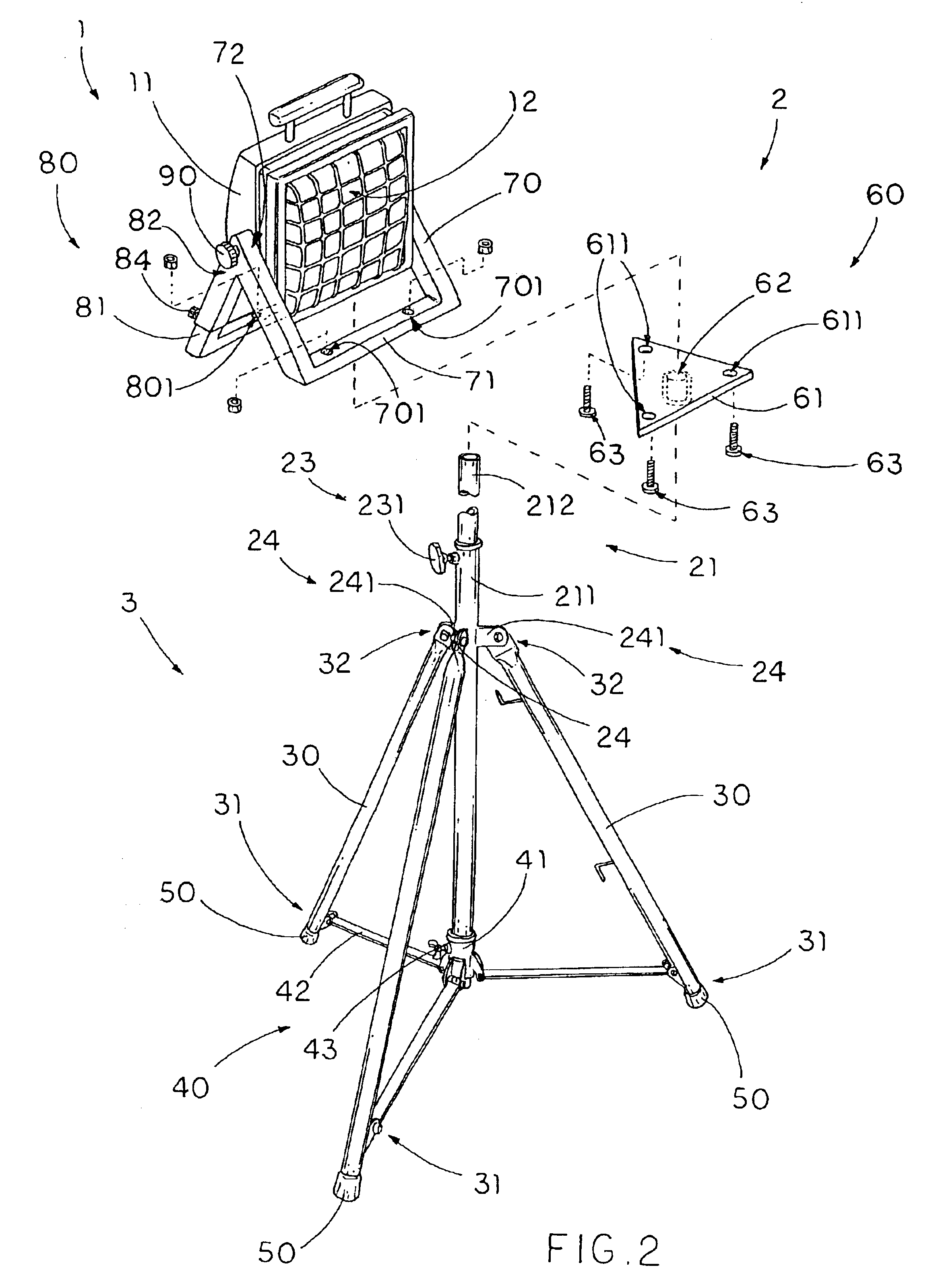

Worklight

InactiveUS6877881B2Prevent tippingEasy to foldCoupling device connectionsNon-electric lightingBraced frameEngineering

A worklight includes a worklight housing for receiving a light source therein and a worklight stand including a U-shaped supporting leg having a lower supporting base and two upper hinge ends pivotally connected to the worklight housing, and a U-shaped pivot leg having a lower standing base and two upper pivot ends, wherein the two hinge ends of the supporting leg are pivotally connected with the two pivot ends of the pivot leg respectively. The worklight stand further includes a foldable stand and a supporting frame, which is supported on foldable stand, detachably mounted to the supporting base of the supporting leg and the standing base of the pivot leg in space apart manner such that the worklight housing is substantially supported on the supporting frame and is elevated via the foldable stand in a stable manner.

Owner:TSAO FRANK

Motorcycle stand

InactiveUS6241104B1Minimize tire slippageMore compactTravelling carriersCycle standsHands freeEngineering

A motorcycle stand designed for hands-free operation that enables the rider to safely park a motorcycle in a secured, upright position without the aid of another individual and without having to dismount from the motorcycle. The motorcycle stand includes: rigid base; adjustably attached ramp; ramp-locking device; wheel stop; pairs of adjustably attached and opposing wheel supports; and a multitude of anti-skid pads. The wheel supports guide the wheel into the parking position and engage the sides of the front wheel. The weight of the motorcycle ensures the front wheel is engaged in the motorcycle stand such that the motorcycle cannot be moved forward, backward, or tipped from side-to-side. The steep inclination of the ramp and a locking device prevent the parked motorcycle from accidentally rolling backward and out of engagement with the motorcycle stand, even when the motorcycle is parked on an inclined surface. The position of the ramp and wheel supports can be adjusted to accommodate wheels of different widths and diameters. The stand is sized and configured such that it does not interfere with the motorcycle's front fender, brake rotor, and lower fairing. The stand is light weight, of simple and inexpensive construction, and easy to transport, operate, and deploy.

Owner:KRAUS TERRENCE DONALD

Rotating bed with improved stability

Owner:BARTHELT HANS PETER

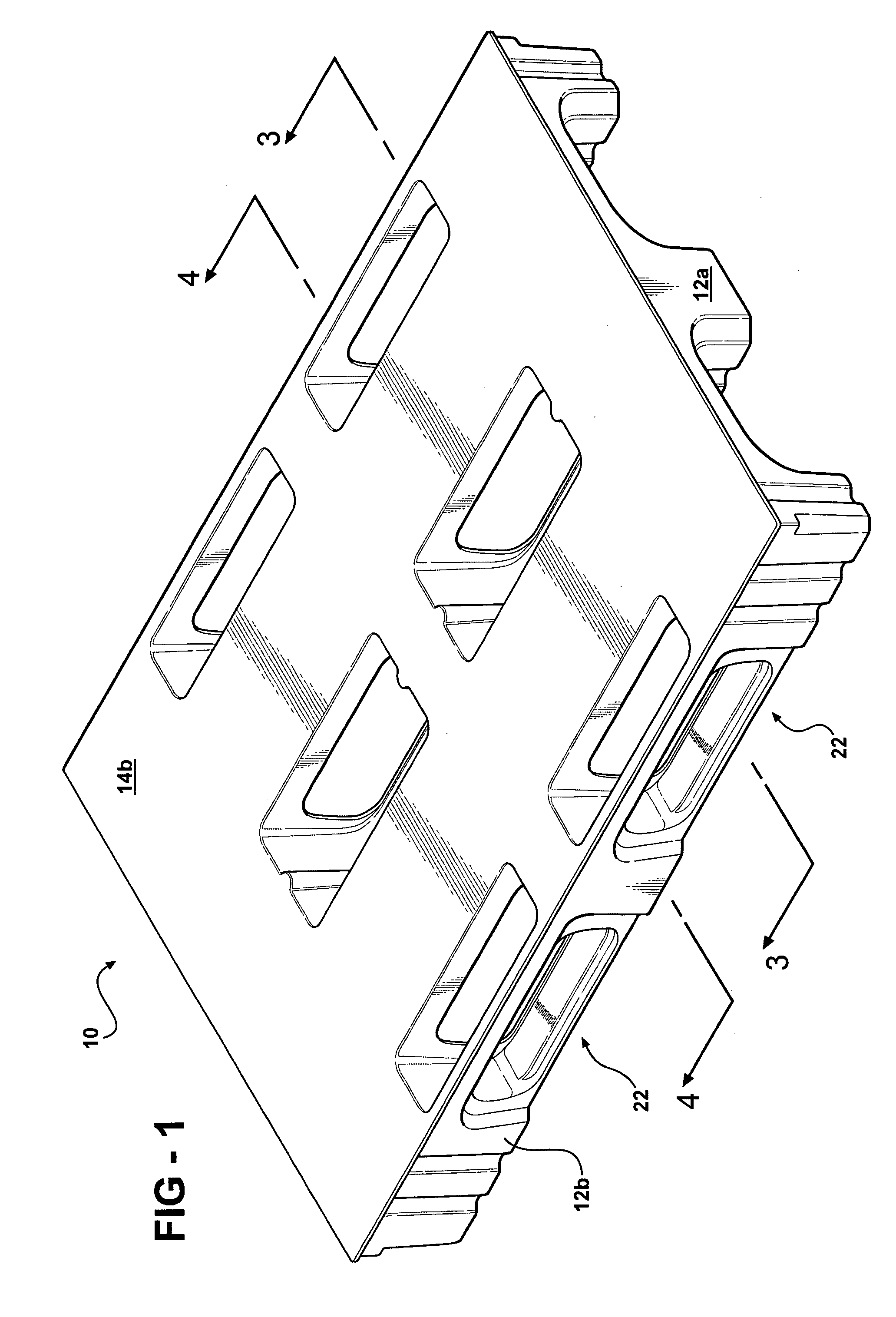

Twin sheet pallet

ActiveUS20060075939A1Prevent tippingFacilitates firm positive receiptRigid containersEngineeringPallet

A twin sheet plastic pallet comprising an upper plastic sheet and a lower plastic sheet selectively fused to the upper sheet. The lower sheet has a generally rectangular configuration, including sidewalls and end walls, and includes a plurality of separate parallel upwardly opening longitudinally extending U-shaped grooves extending from end to end of the sheet and a plurality of downwardly opening U-shaped grooves interspersed between the upwardly opening grooves and opening in the end walls of the sheet. The upper sheet defines a top wall, defining the platform surface of the pallet, and a plurality of upwardly opening U-shaped protrusions extending downwardly from the top wall and sized to nest within the upwardly opening grooves of the lower sheet, whereby with the upper sheet positioned over the lower sheet and the protrusions positioned in the upwardly opening grooves, the sheets may be fused together to form double thickness U-shaped wall structures at the interfaces of the protrusions and the upwardly opening grooves. The pallet further includes a pair of longitudinally extending metallic beams positioned between the upper and lower sheets, and laterally aligned slots are formed in the U-shaped wall structures to allow passage of the forks of a forklift truck.

Owner:SHUERT TECH

Step-on receptacle with tip prevention

ActiveUS7530578B2Easy constructionPrevent tippingCarriage/perambulator with single axisRefuse receptaclesEngineeringThreaded fastener

Owner:AMERICAN PLASTICS LLC

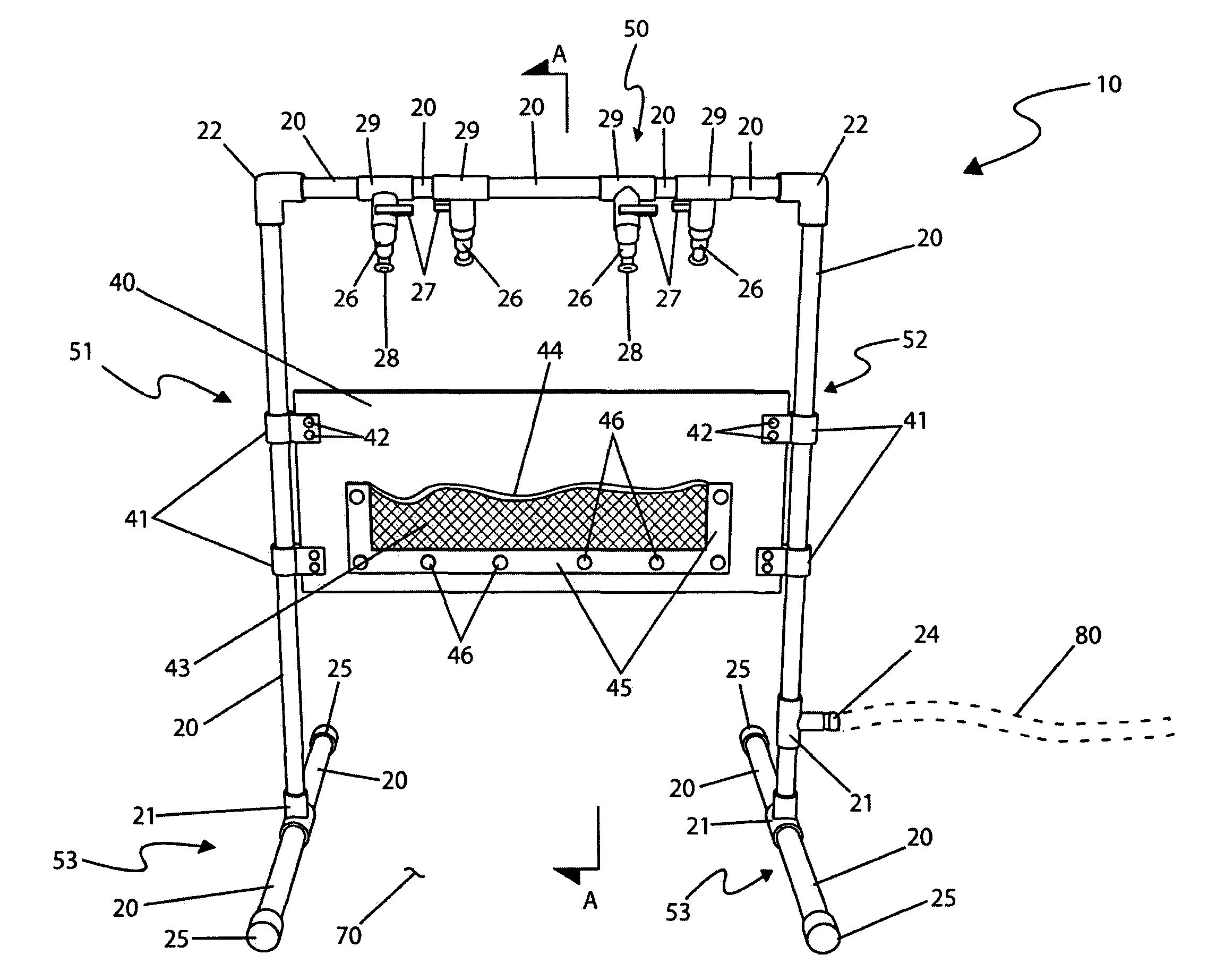

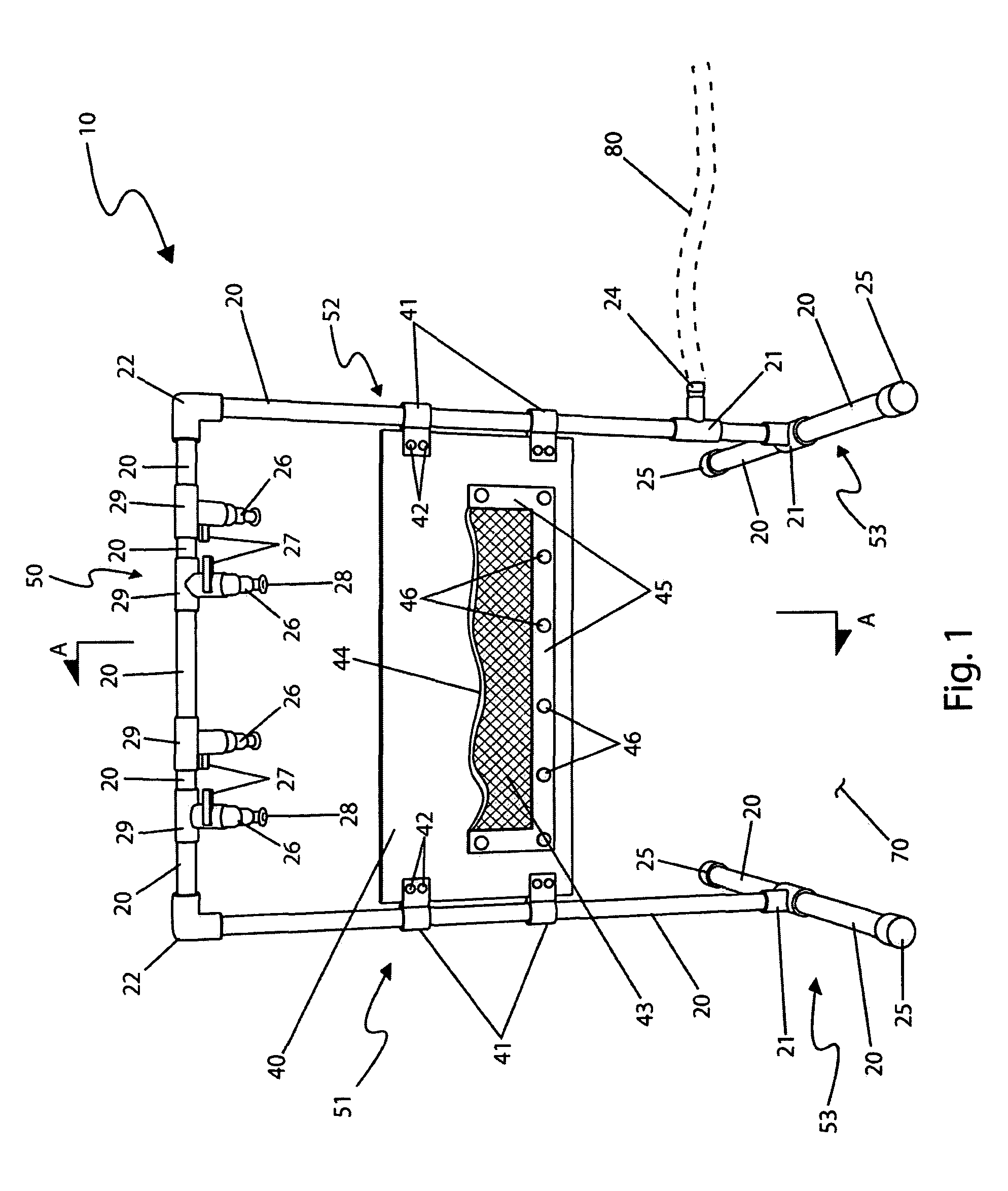

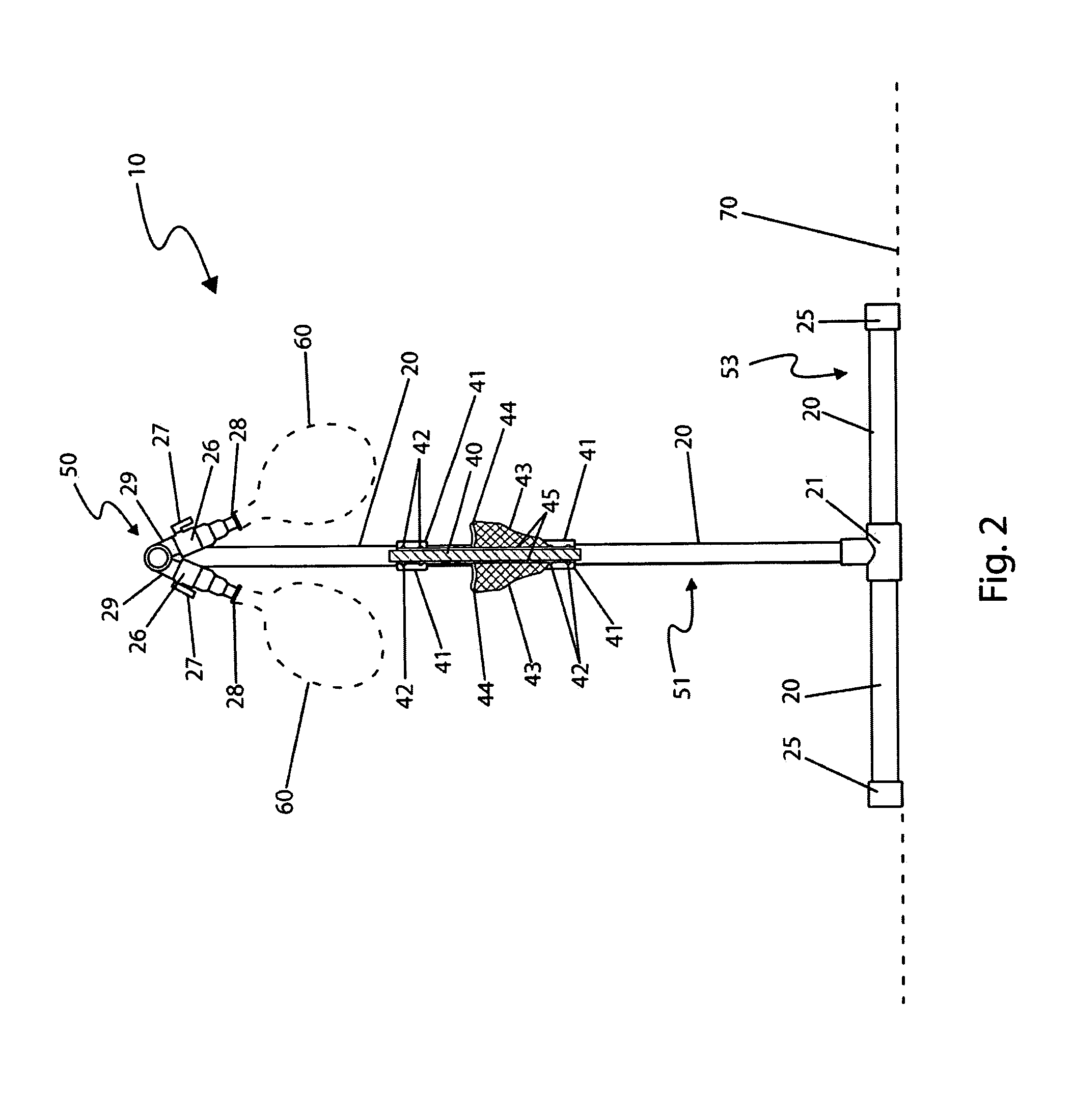

Filling station for water-based toys

InactiveUS8037906B1Prevent slidingPrevent tippingAmusementsAquatic toysWater basedPolyvinyl chloride

An apparatus designed to fill multiple water balloons and other water-based toys at the same time is herein disclosed. The apparatus takes the form of a large stand approximately thirty-four (34) inches high and twenty-four (24) inches wide made using polyvinylchloride (PVC) piping and fittings. The apparatus is supported across the bottom using two (2) “T”-shaped legs, also made of PVC pipe. A water connection to a standard garden hose is provided on one (1) leg near the bottom. Four (4) angled valves are provided across a top portion, such that up to four (4) users can use the apparatus simultaneously to refill water-based toys such as squirt guns or water balloons. When finished at each station, each user can easily turn off an individual valve, thus avoiding the wasting of water.

Owner:GRILLO EDWARD J

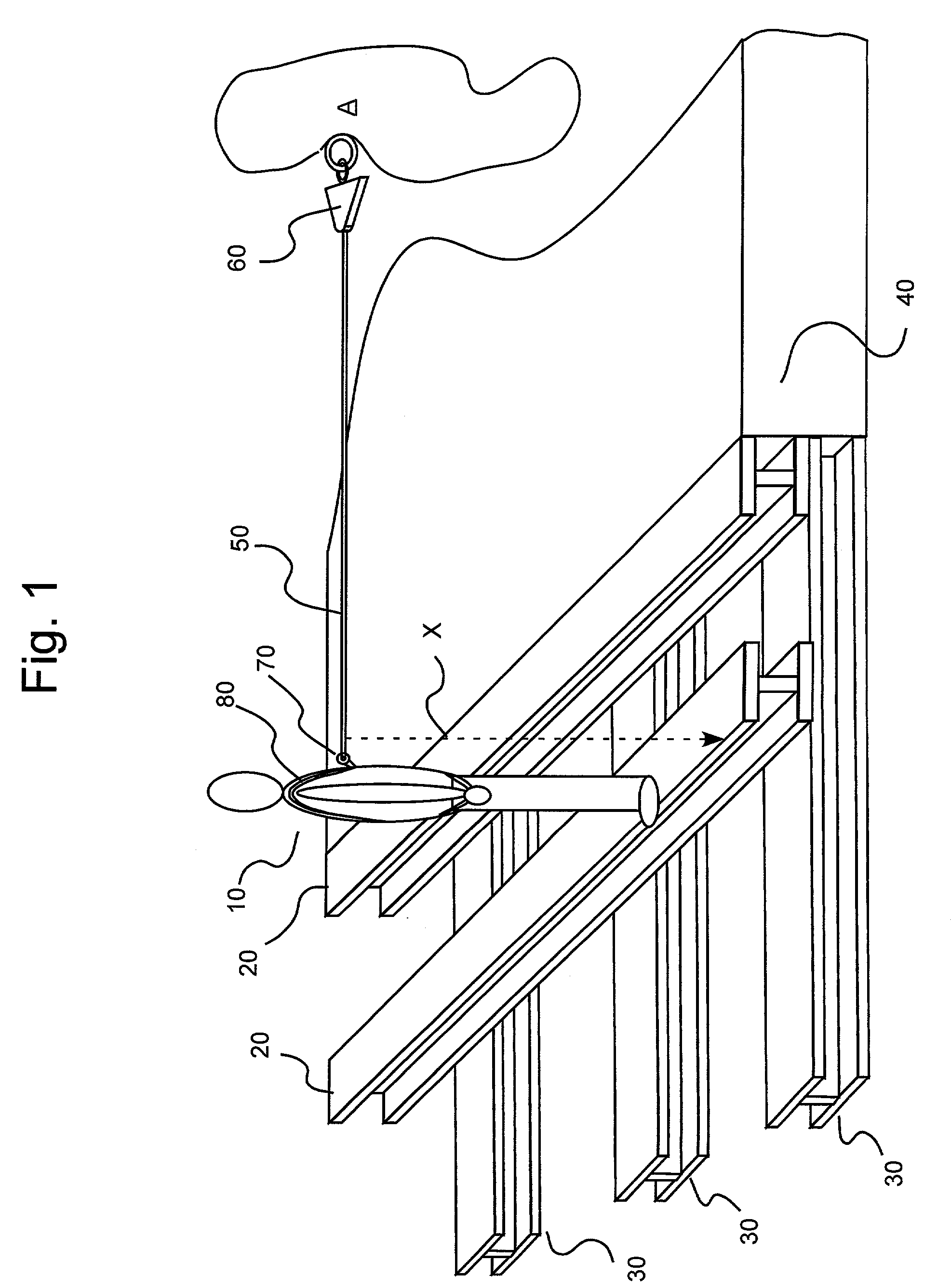

Anchor point devices, systems and methods for use in fall protection

InactiveUS7032710B2Enhanced fall protectionPrecise positioningSafety beltsMountaineeringFall protectionEngineering

An anchoring system includes an anchor member to anchor the lifeline and at least one extending unit to extend the anchor member out to a working position beyond (horizontally) and above (vertically) an edge to provide for an overhead anchoring point. The anchoring system preferably further includes a support to which the extending unit is attached. The support immobilizes the overhead anchoring system so that the anchor member remains at the working position (even in the case of a fall by the worker). A method of anchoring a fall protection lifeline for use by a worker working at or beyond an edge includes the steps: elevating an anchor member to position the lifeline above the head of a worker and supporting the anchor member at the working position. The method can also include the step of extending the anchor member to a working position horizontally beyond and above the edge.

Owner:SPERIAN FALL PROTECTION

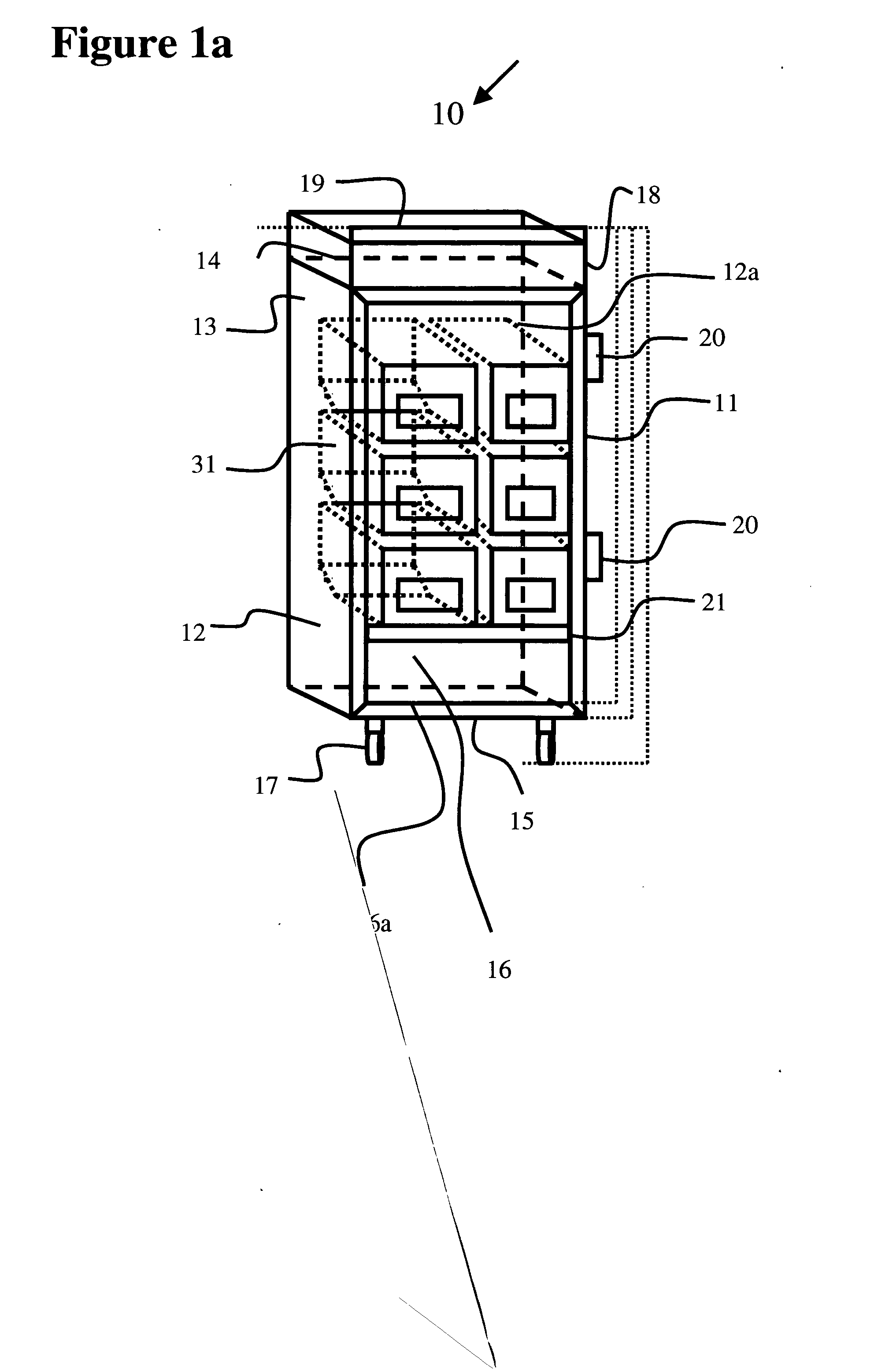

Candy pick & mix merchandiser system

InactiveUS20070080175A1Small footprintReliable deliveryRacksMovable measuring chambersVertical stabilityEngineering

A candy pick and mix merchandiser system has a small foot print. Depth adjustable merchandiser vessels have an array of vertically stackable candy delivery bins of varying sizes and configurations. A tongue and groove attachment means attaches and interlocks the vertically stackable candy delivery bins to form a stacked configuration wherein the bins are stacked one over another in an interlocked array. Vertical stability strengthener means strengthen the interlocked array of vertically stacked candy bins. The vertical stability strengthener means comprise a plurality of male and female plugs adapted for insertion into a plurality of vertically and horizontally parallel and side-by-side flush perforations in frontal lower corners of vertically disposed left and right acrylic panels of said bins. The candy delivery bins are front or rear loading. Funnel and rake bins in which a rake passes through a narrow aperture in the funnel minimize entry of contaminants into the bin. Other candy delivery configurations include stackable scoop bin, stackable tongue bin, and stackable open bin.

Owner:WORLDS SWEETEST FUN

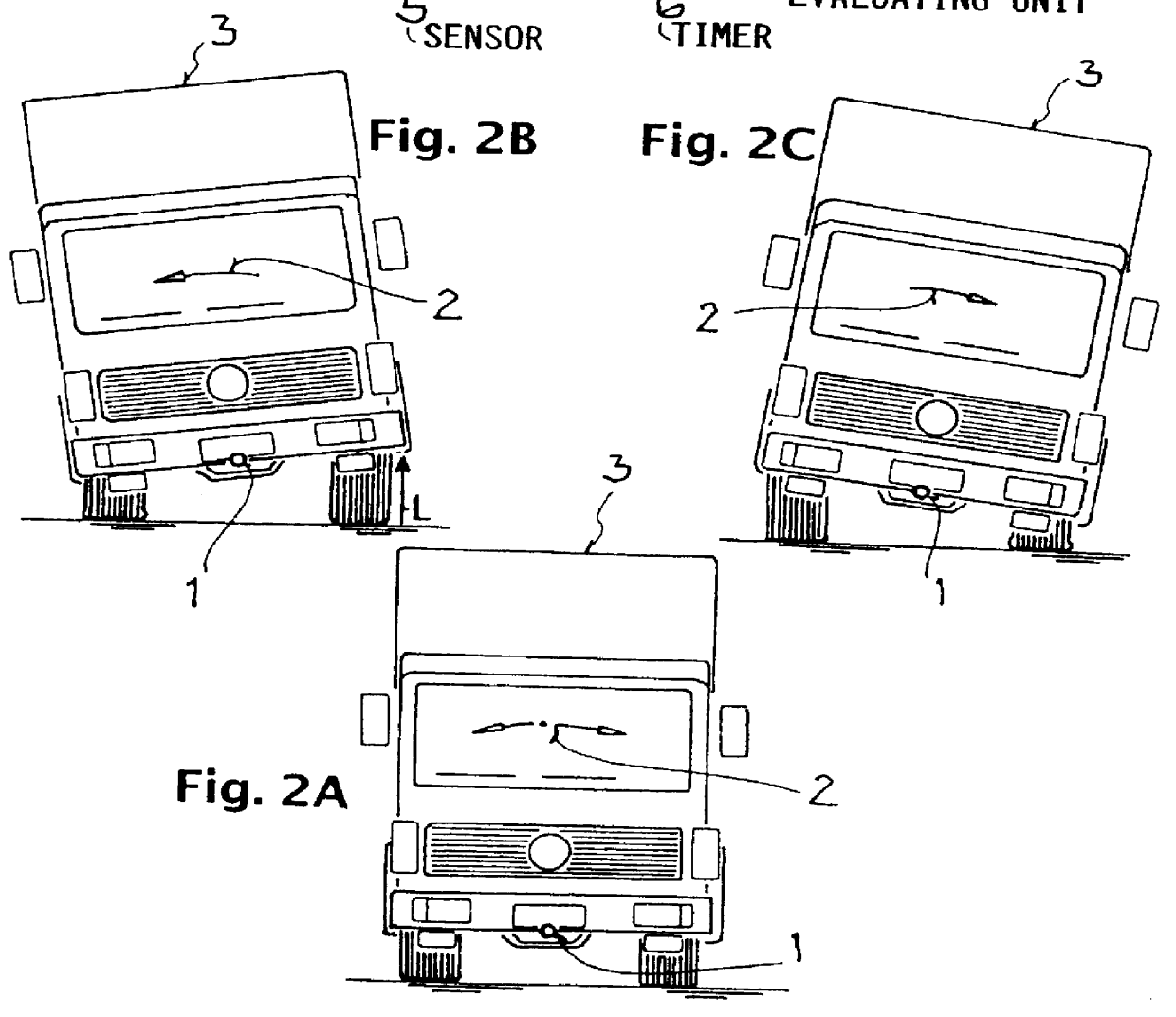

Method and apparatus for determining oscillation values and other vehicle-specific quantities of a vehicle

InactiveUS6157295AAccurately and unambiguously calculateReliable estimateVehicle testingPedestrian/occupant safety arrangementRolloverDriver/operator

A method and an apparatus determine the frequency or the period of the natural characteristic oscillation of a vehicle, and therefrom determine the mass of the vehicle and provide a warning if a dangerous oscillation condition exists which could lead to a tipping or rollover of the vehicle. The evaluation is carried out while the vehicle is driving. The apparatus includes a sensor such as a rotation rate sensor, a timer, an evaluating unit, and a warning unit. The method involves measuring the time interval between two characteristic features of the oscillation measured by the sensor, such as zero crossings, minimum points or maximum points of the angular velocity of the oscillation, and then calculating the period and / or the frequency of the oscillation from the measured time interval. Then the moment of inertia and / or the mass of the vehicle can be determined from the period or frequency. Also, if the period or frequency is out of a safe range, a warning is triggered to indicate to the driver of the vehicle that a rollover danger exists.

Owner:DAIMLER AG

Zero-wall clearance linkage mechanism for providing additional layout

InactiveUS8573687B2Prevent tippingCost-effectiveControlling membersMechanical apparatusEngineeringLinear actuator

A seating unit that includes a linkage mechanism adapted to adjust between closed, extended, and reclined positions is provided. The linkage mechanism includes a seat-mounting plate mounted to a footrest assembly, a back-mounting link and a rear bellcrank both rotatably coupled to the seat-mounting plate, an activator bar that controls a footrest drive link, and a linear actuator for carrying out automated adjustment of the linkage assembly. In operation, a stroke in a first phase of the linear actuator generates a torque on the activator bar. The footrest drive link converts the torque into a laterally-directed force that pushes the footrest assembly into the extended position. A stroke in the second phase acts to push the activator bar forward and translate the seat-mounting plate forward at a consistent inclination angle. The forward translation causes the rear bellcrank to rotate, thereby biasing the back-mounting link rearward into the reclined position.

Owner:L & P PROPERTY MANAGEMENT CO

High-speed carding machine

InactiveCN102995167AGuaranteed stabilityGuaranteed speedCarding machinesEngineeringUltimate tensile strength

A high-speed carding machine comprises a base and a vibration wool feeding machine, a high-speed carding device and an automatic three-position barrel changing device which are connected with one another sequentially. The vibration wool feeding machine in the high-speed carding machine utilizes a translational vibration plate and a baffle to push textile raw materials uniformly, and moreover, the falling and outputting speeds of the textile raw materials are increased. A shaft seat of the high-speed carding machine is arranged on a breast cylinder wallboard and a large cylinder wallboard, so that the phenomenon that the positions of a breast cylinder and a large cylinder are changed relatively to the positions of a working roller and a wool stripping roller due to the high-speed rotation is avoided, the production quality is ensured, a suction pipe is arranged to suck the textile raw materials and reduce air flow which is generated by high-speed rotation, and the operation stability and high speed of the carding machine are ensured. The automatic three-position barrel changing device can control rotating wheels to change collection barrels, so that the high-speed carding machine is simple in structure and the labor intensity of the working personnel is reduced; and a U-shaped guardrail can ensure that the operation tracks of the collection barrels are stable when the collection barrels are changed, so that the whole barrel changing operation is carried out stably, and the collection barrels are prevented from tipping over during the barrel changing process.

Owner:青岛诚利佳机械有限公司

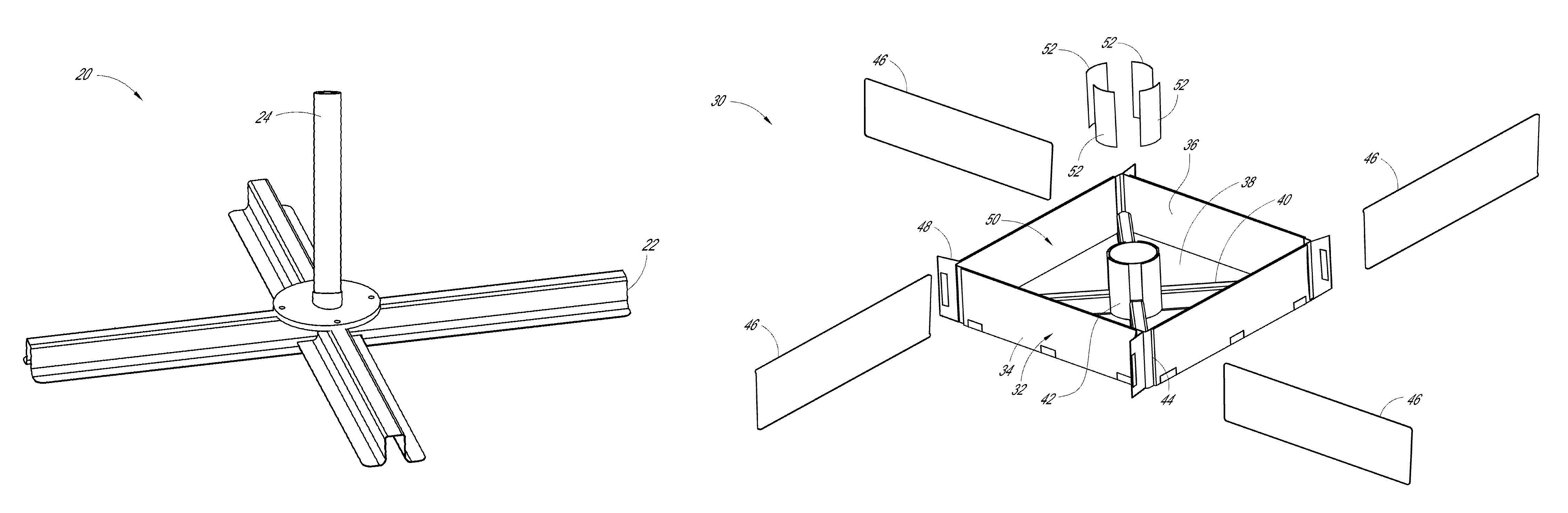

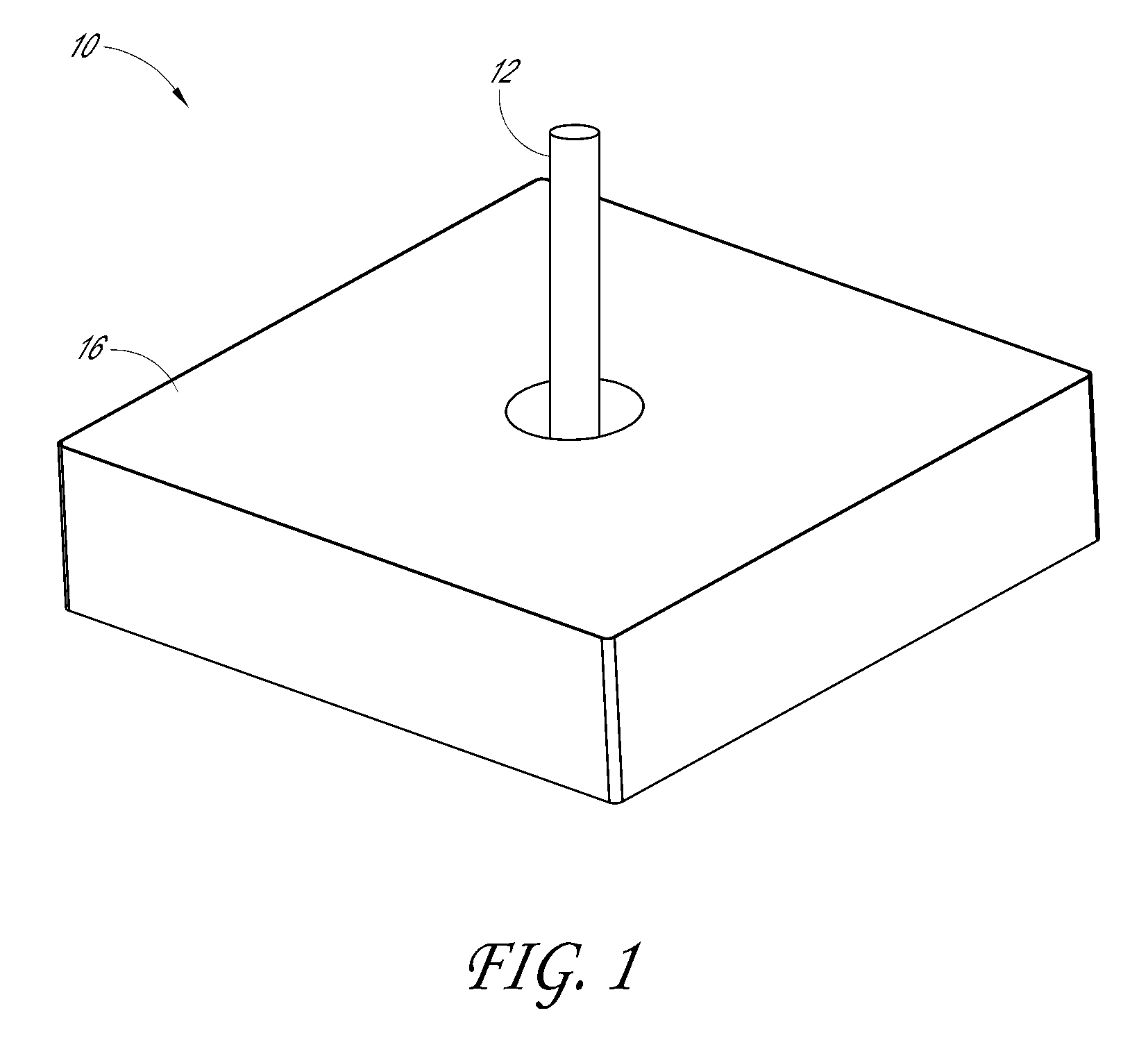

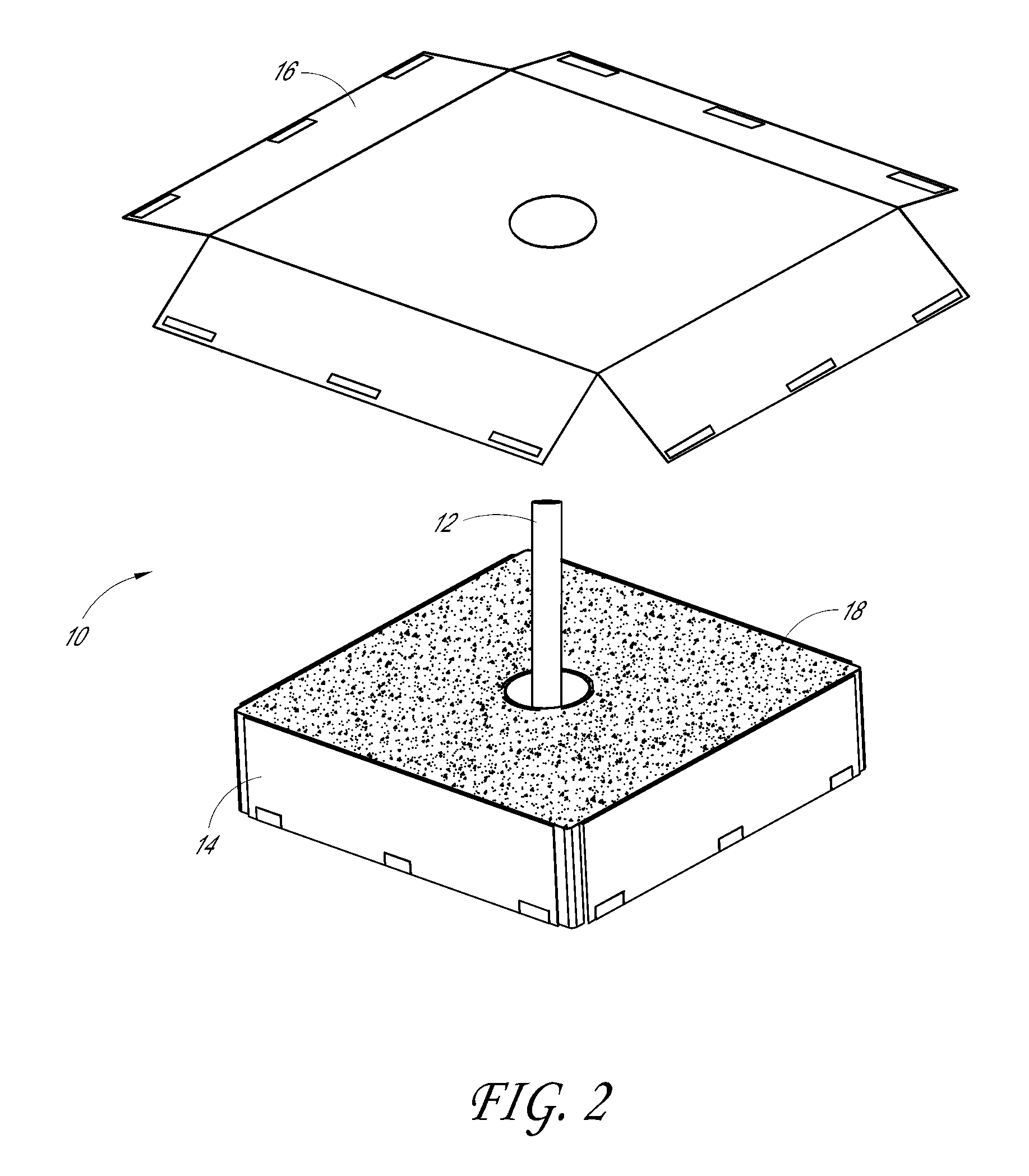

Shape retaining foldable umbrella base

ActiveUS9540840B2Easy transport and storage and packagingCost-effectiveWalking sticksUmbrellasEngineeringMechanical engineering

A foldable umbrella base may include a cross-piece having a ground engaging portion and an upright receptacle configured to receive an umbrella pole. The foldable umbrella base may also include a foldable container comprising a ballast retaining space configured to receive and retain a ballast material. The foldable umbrella base may also include a foldable cover configured to be disposed over the foldable container to enclose the foldable container and cross-piece while permitting the umbrella pole to extend therethrough. A first plurality of retainers may be coupled to a side surface of the foldable container may be configured to receive and hold a corresponding first plurality of rigid members such that the first plurality of retainers can provide structural support to the foldable container, whereby the foldable container can retain a shape upon receiving the ballast.

Owner:OLIVER JOEN AN MA

Nozzle for floor vacuum cleaner

The invention relates to a vacuum cleaner nozzle, which includes: a suction head (1); a suction tube connecting piece (2), which is movably attached to the suction head or a suction channel around an axis of rotation, and the suction channel is rotatably connected to the suction head; a sliding bottom (3), which includes at least one lower suction groove (4) limited by the suction edge; and retractable bearing and sealing elements for sucking slippery floors, which include a front bearing strip (5) with or without air-permeable openings (15) arranged above the suction groove (4) along the dust suction direction. The front strip (5) is vertically adjustable or rotatably mounted on a supporting member (6) and fixed in the suction head (1), and the supporting member is actuated by means of aswitching element (7) available at the suction head. According to the invention, a separately selectable auxiliary device (10) is provided for sucking debris. Using the auxiliary device, a ground clearance of more than 2 mm is set between the floor surface to be cleaned and the already extended front strips (5) for sucking dust on smooth floor, while retaining the pivoting movement of the suctionhead (1), and the flow cross section of the opening (15) in the front strip (5) is changeable or not.

Owner:威赛有限公司

Cart for large slabs

InactiveUS7004483B1Easy to maneuverSmooth rotationGlass plate transportationUnderstructuresGranolithicEngineering

The Invention is a cart for moving slabs of stone, such as marble and granite. In a first embodiment, main wheel support the weight of the slabs while front and rear end wheel prevent tipping of the cart. A hydraulic system withdraws the wheels, rendering the cart stationary. In a second embodiment, a main wheel carriage is clamped directly to a slab and bears its weight while smaller front and rear end wheel carriages clamped to the slab prevent tipping of the slab. The wheel arrangement of both embodiments allows the heavy slabs of stone to be readily maneuvered and rotated.

Owner:MARBLE CRAFTERS

Gate section and base for a safety rail system

InactiveUS6845970B1Enough weightEnough massFencingBuilding material handlingEngineeringMechanical engineering

An improved gate section and base for a portable safety rail system which utilizes cast iron bases and hinged gate sections. The improved base includes four post receivers, recessed handles with smooth edges, and stacking recesses. The improved gate section incorporates a single pull double latching mechanism which includes two durable and robust latches each with its own manual operating tab but also a manual operating handle whereby both latches can be operated simultaneously.

Owner:TRACTEL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com