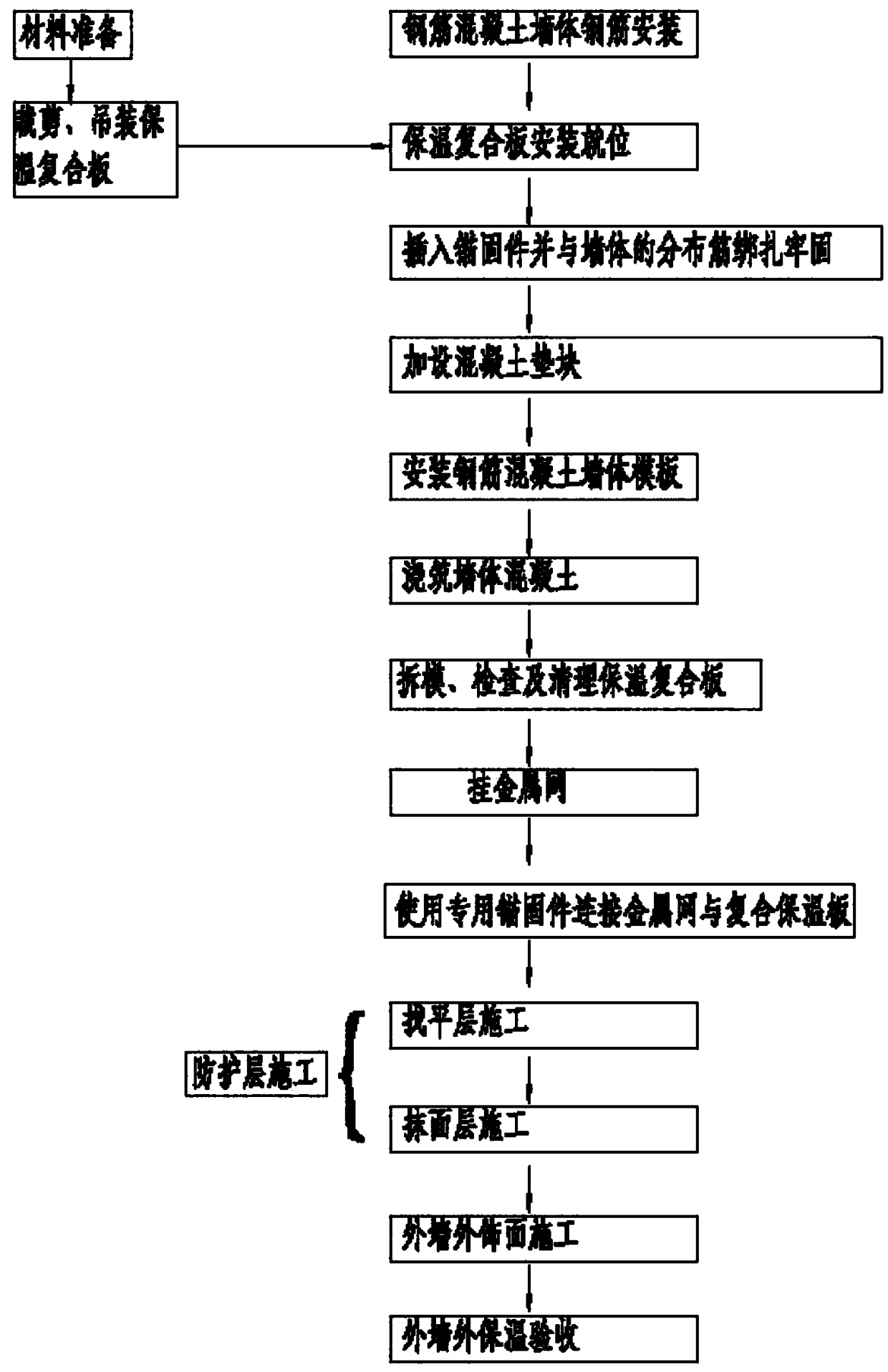

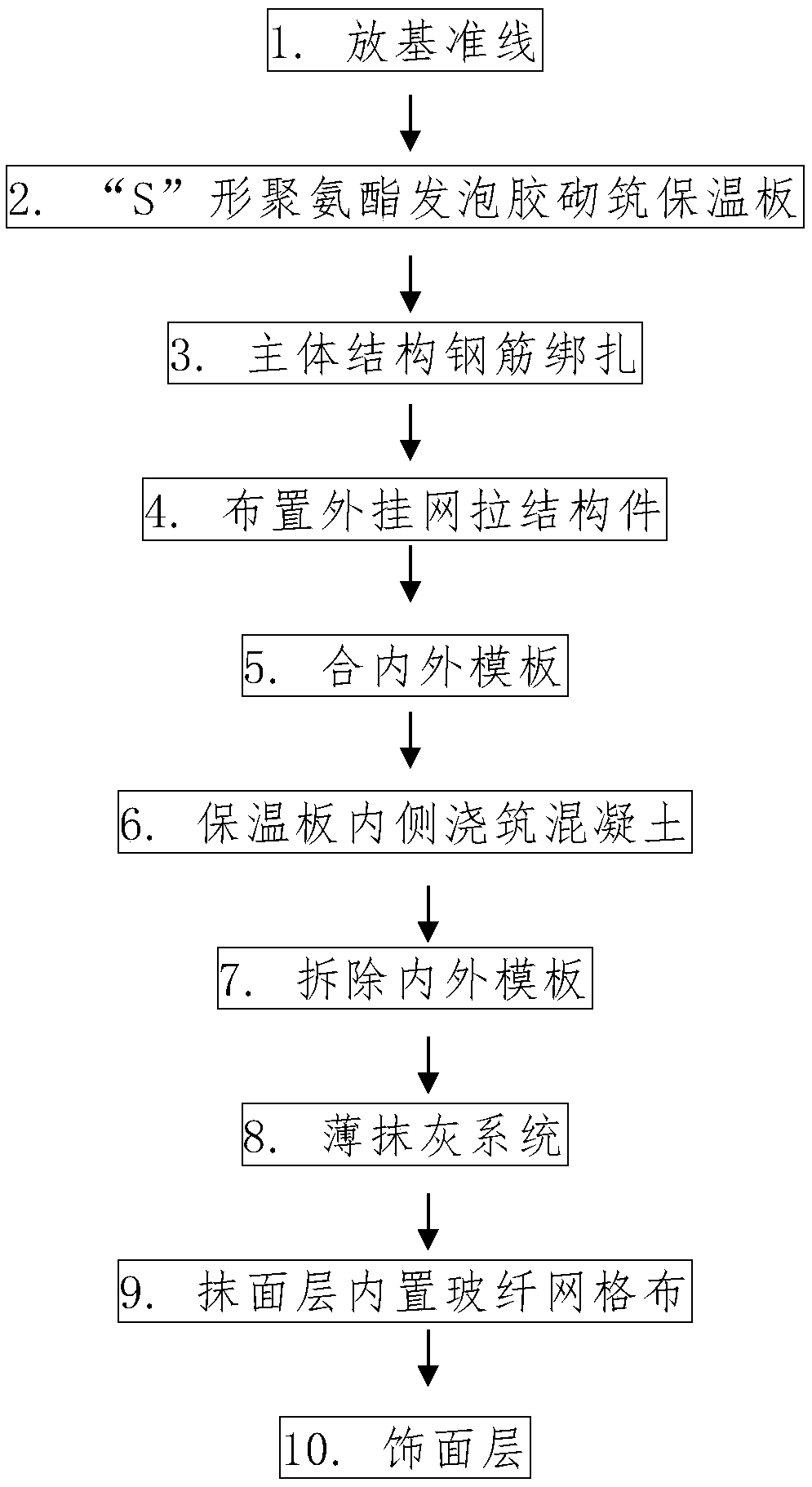

Passive low-energy building external thermal insulation system construction process

A technology for building exterior walls and construction technology, applied in the field of building thermal insulation materials, can solve problems such as unfavorable inner and outer formwork cavity spacing, adjustment, etc., to ensure crack resistance and shedding risk, improve connection integrity, verticality control and formwork Easy and fast adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

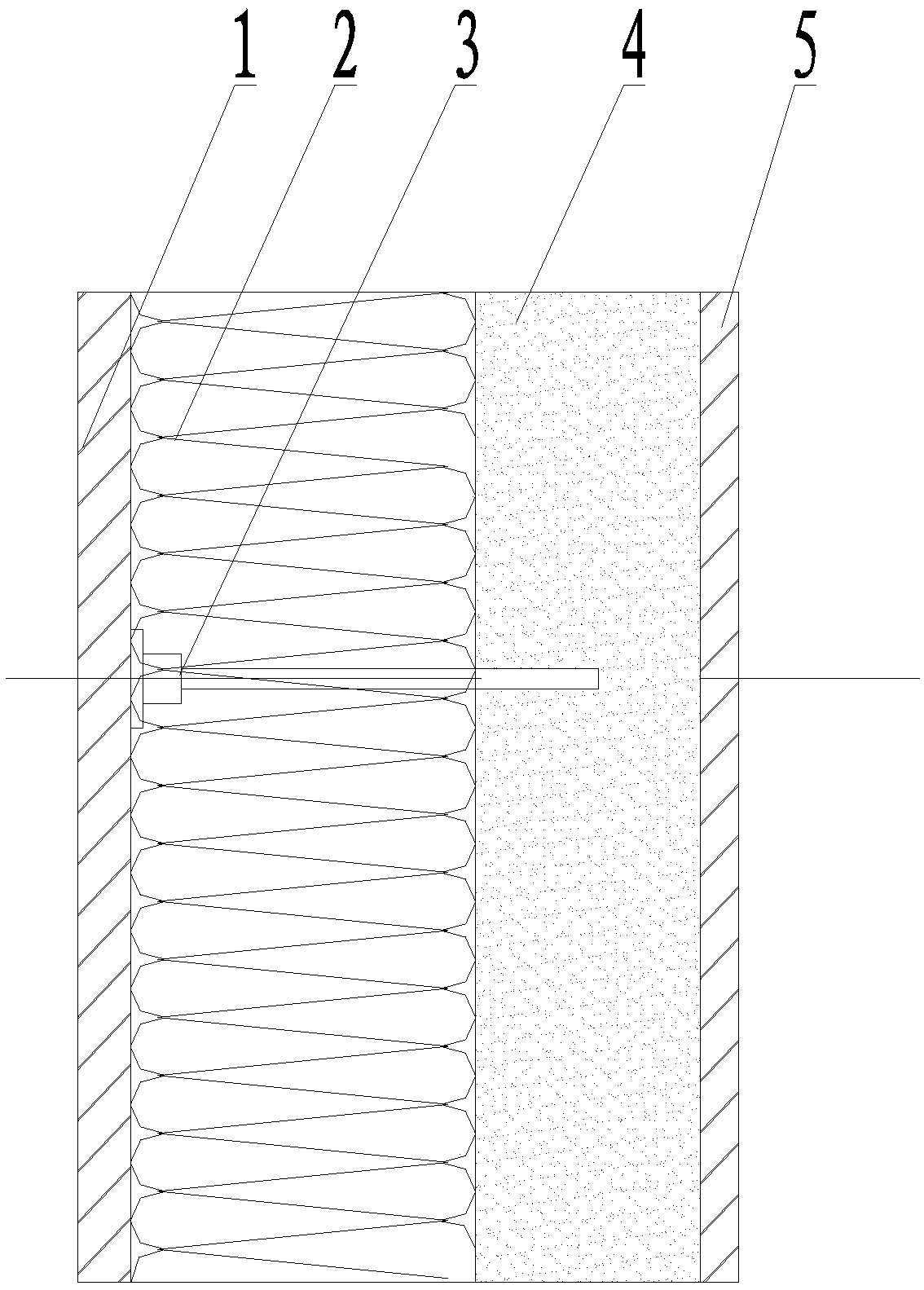

[0046] In view of the fact that the thickness of the insulation layer required by low-energy buildings is very large, generally up to 300mm, the purpose of the present invention is to provide an improved process suitable for thicker insulation boards. The main idea adopted by the inventor is to adjust the insulation layer to double Layers, and the connection form of each insulation layer with the protective layer and the main structure adopts different processes to adjust the matching of the physical properties of the materials of each structural layer, which can effectively solve the problems of thermal insulation system cracking, falling off, and the same life as the building.

[0047] Although the aforementioned application of the present inventor has realized the integrated construction of the insulation layer and the main structure at the same time, the effectiveness of the sticking and anchoring has been effectively solved, and the same life span of the building and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com