Lightweight concrete block for environment-friendly construction and preparation method thereof

A lightweight concrete and concrete block technology, applied in the field of construction, can solve the problems of reducing and reducing the structural strength and damage life of concrete blocks, and achieve the effects of increasing the strength of the blocks, improving the forming process of the blocks, and increasing the strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

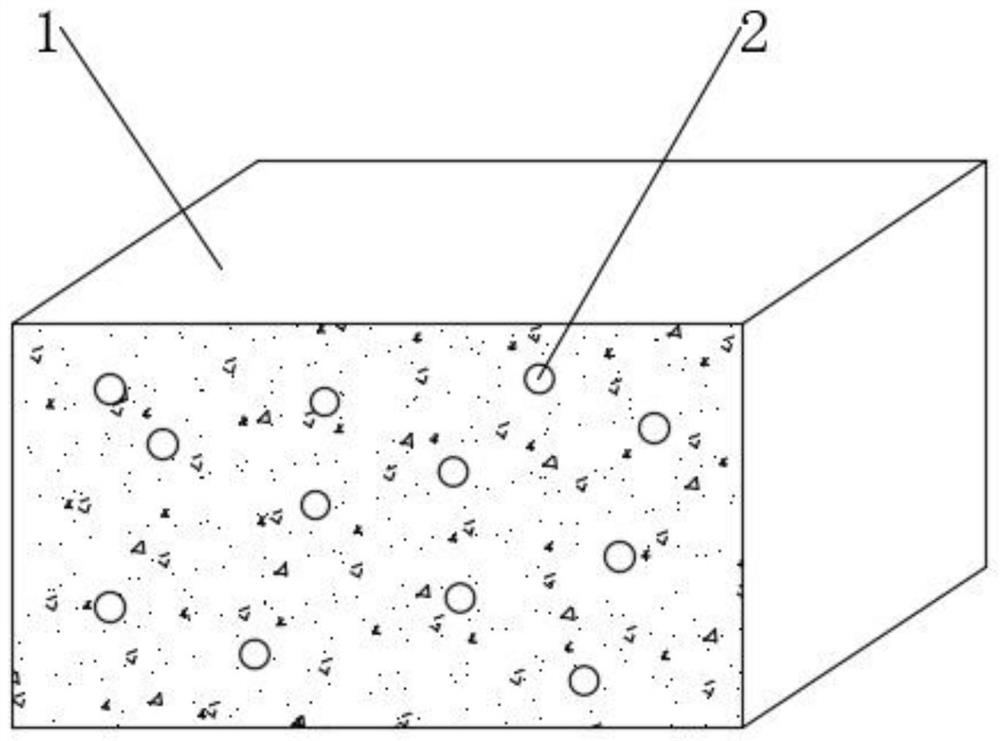

[0043] see figure 1 , a lightweight concrete block for environmental protection construction, comprising a concrete block body 1 and a plurality of self-generating internal vibrating balls 2 embedded in the concrete block body 1, the concrete block body 1 includes the following raw materials in parts by weight: 50 parts of cement, 30 parts of industrial waste residue, 2 parts of water reducer, 1 part of activator, 40 parts of water, 0.3 part of polymer emulsion.

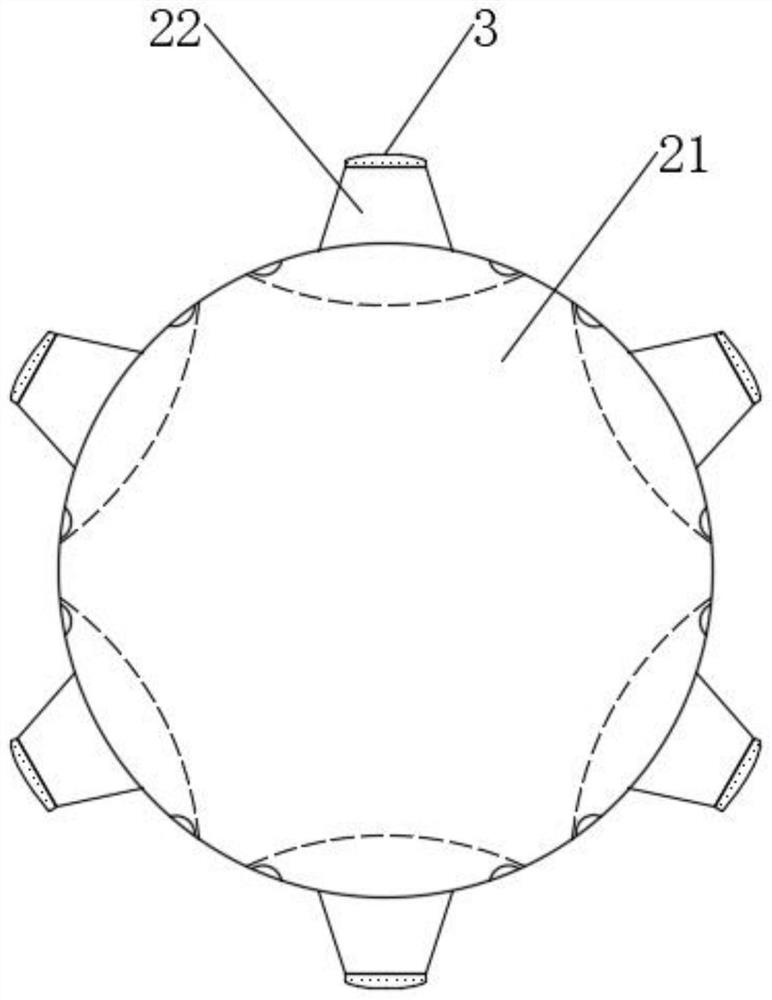

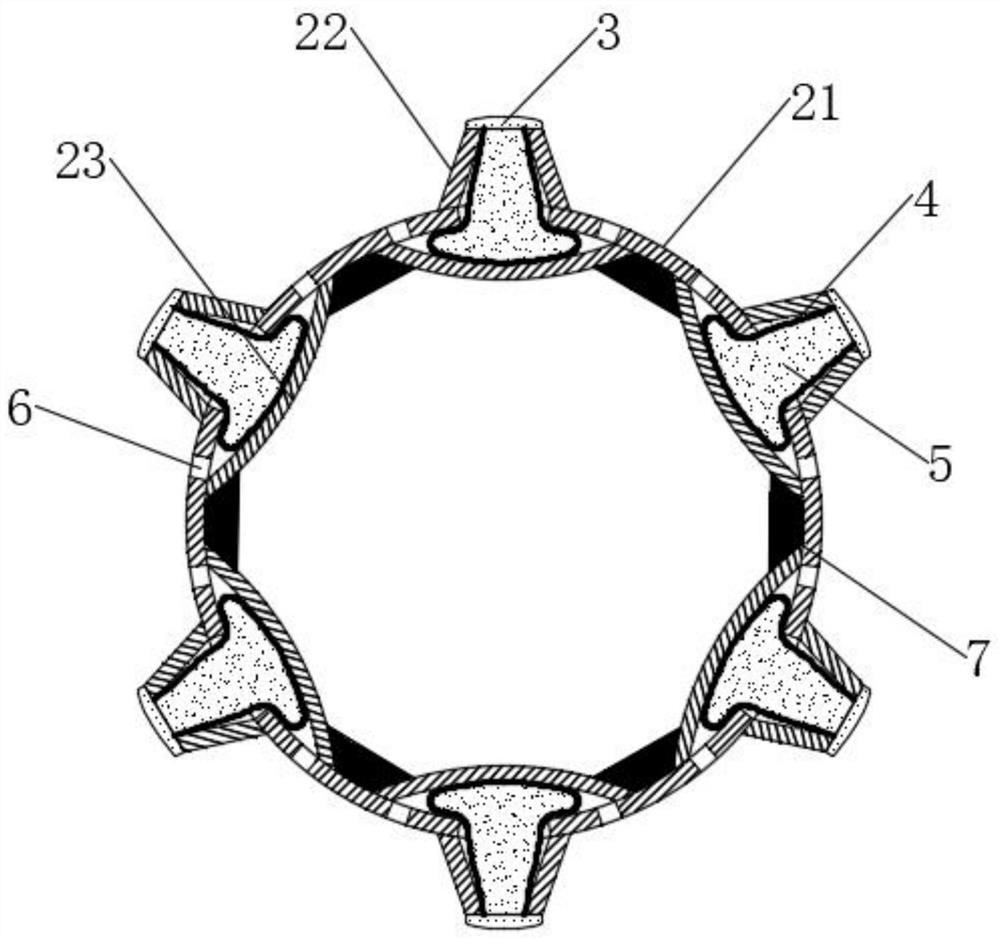

[0044] see Figure 2-4 The self-generating inner vibration ball 2 includes a hollow reinforced sphere 21 and a plurality of gas-generating outer buckets 22 evenly connected to the outer ends of the hollow reinforced sphere 21, the outer ends of the gas-generating outer buckets 22 are connected with a sealing layer 3, and the inner ends of the hollow reinforced sphere 21 Connected with a plurality of inner arch plates 23 matched with the gas-generating outer bucket 22, the inner end of the gas-generating outer bucket...

Embodiment 2

[0058] see figure 1 , a lightweight concrete block for environmental protection construction, comprising a concrete block body 1 and a plurality of self-generating internal vibrating balls 2 embedded in the concrete block body 1, the concrete block body 1 includes the following raw materials in parts by weight: 60 parts of cement, 40 parts of industrial waste residue, 3 parts of water reducer, 2 parts of activator, 45 parts of water, 0.6 part of polymer emulsion.

[0059] A preparation method of lightweight concrete blocks for environmental protection construction, comprising the following steps:

[0060] S1. Weigh the raw materials of the concrete block body 1, mix them evenly, and pour them into the block mold;

[0061] S2. Put an appropriate amount of self-generating inner vibrating balls 2 into the block mould, and heat the mold to 80°C, so that the slurry in the mould will stop and generate gas;

[0062] S3. After the static stop of the slurry, the green body is obtaine...

Embodiment 3

[0066] see figure 1 , a lightweight concrete block for environmental protection construction, comprising a concrete block body 1 and a plurality of self-generating internal vibrating balls 2 embedded in the concrete block body 1, the concrete block body 1 includes the following raw materials in parts by weight: 70 parts of cement, 50 parts of industrial waste residue, 5 parts of water reducer, 4 parts of activator, 50 parts of water, and 0.8 part of polymer emulsion.

[0067] A preparation method of lightweight concrete blocks for environmental protection construction, comprising the following steps:

[0068] S1. Weigh the raw materials of the concrete block body 1, mix them evenly, and pour them into the block mold;

[0069] S2. Put an appropriate amount of self-generating inner vibrating balls 2 into the block mould, and heat the mold to 90°C, so that the slurry in the mould stops and gasses;

[0070] S3. After the static stop of the slurry, the green body is obtained, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com