Construction method of concrete diaphragm wall in mucky soil body with high water content

A technology for concrete cut-off walls and muddy soil, applied in the field of concrete, can solve the problems of easy sinking of concrete cut-off walls, influence of concrete cut-off wall bearing capacity, and long concrete setting time, so as to shorten the final setting time and achieve final The effect of shortening the setting time and reducing the elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

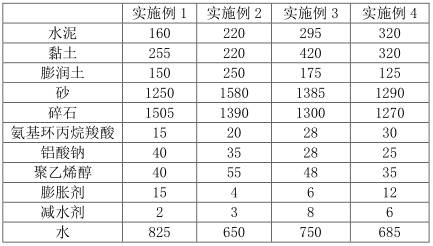

Embodiment 1-4

[0064] A method for constructing a concrete cutoff wall in muddy soil with high water content, comprising the following steps:

[0065] (1) Build guide wall: Use surface grouting to reinforce the foundation and prevent seepage in the loose layer, and then use a small excavator to excavate the guide wall in the loose layer. The width of the guide wall is 95cm, and the top of the guide wall The surface is 10cm above the ground;

[0066] (2) Preparation of wall-fixing mud: Use rotary drill to make holes, then add Neptune polymer mud to stir, mix well, and set aside;

[0067] (3) Hole forming and slotting: the rotary drill rides directly on the guide wall to drill holes, the stress point on the upstream side is 1.2m away from the notch, and the construction is continuous for 24 hours. The hole forming time of each hole is controlled within 3 hours, and the hole forming time is certain Finally, the impact drill should follow up in time to drill the small wall and clear the hole to r...

Embodiment 5

[0077] The difference from Example 4 is that 12kg of polypropylene fibers and 15kg of nano-silicon dioxide are uniformly mixed in advance, and then added to step (7) to mix uniformly with other components.

Embodiment 6

[0079] The difference from Example 4 is that 20kg of polypropylene fibers and 8kg of nano-silica are uniformly mixed in advance, and then added to step (7) to mix uniformly with other components.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com