Quick-setting type adjustable gel grouting material and application thereof

A technology of grouting materials and coagulation accelerators, which is applied in the field of building materials, can solve problems such as long coagulation time, and achieve the effects of improving the cohesive force of the hole wall, good economic benefits, and improving compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

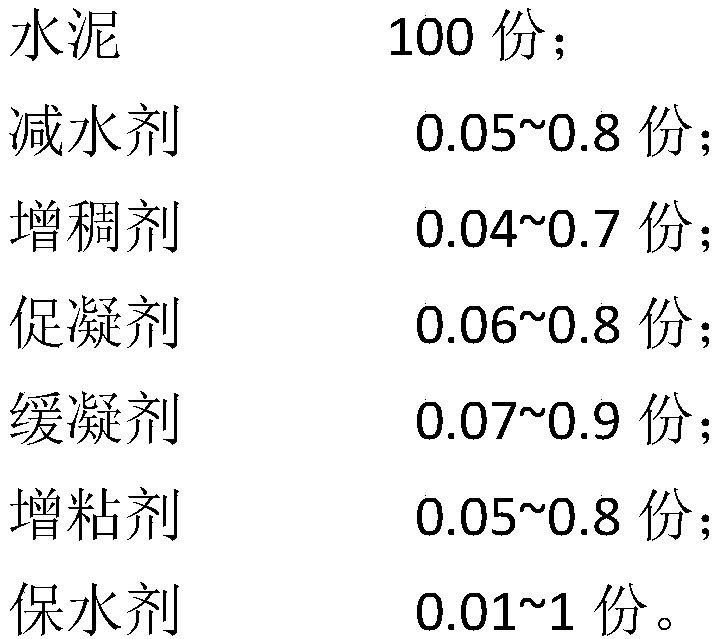

[0024] Add 30 parts of water and 70 parts of river sand / artificial sand / quartz sand to a fast-setting adjustable grouting material of the present invention to obtain a sand-containing slurry body, which specifically includes the following components in parts by weight:

[0025]

[0026]

[0027] In this real-time example, the water reducer is a polycarboxylate water reducer, a melamine water reducer or a naphthalene-based water reducer.

[0028] The thickener is hydroxypropylmethylcellulose or hydroxymethylpropylcellulose.

[0029] The coagulant is lithium carbonate or calcium formate.

[0030] The retarder is boric acid or citric acid or tartaric acid.

[0031] The tackifier is glue essence (PVA or PVE).

[0032] The water retaining agent is polyacrylamide.

[0033] Table 1 shows the test results of various indicators of a fast-setting adjustable-setting grouting material in Example 1.

[0034]

Embodiment 2

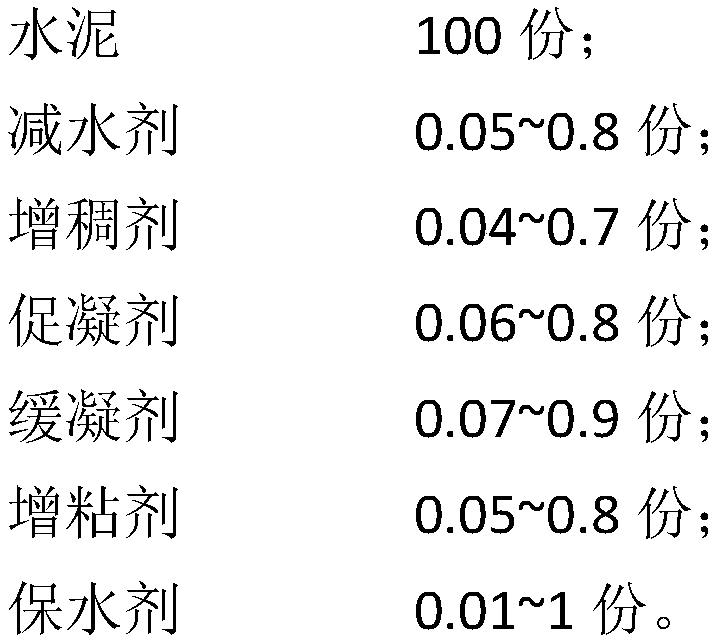

[0036] Add 30 parts of water and 70 parts of river sand / artificial sand / quartz sand to a fast-setting adjustable grouting material of the present invention to obtain a sand-containing slurry body, which specifically includes the following components in parts by weight:

[0037]

[0038] The cement is sulphoaluminate cement.

[0039] The water reducer is polycarboxylate water reducer, melamine water reducer or naphthalene water reducer.

[0040] The thickener is hydroxypropylmethylcellulose or hydroxymethylpropylcellulose.

[0041] The coagulant is lithium carbonate or calcium formate.

[0042] The retarder is boric acid or citric acid or tartaric acid.

[0043] The tackifier is glue essence (PVA or PVE).

[0044] The water retaining agent is polyacrylamide.

[0045] Table 2 shows the test results of various indicators of the fast-setting anchor grouting material in Example 2.

[0046]

Embodiment 3

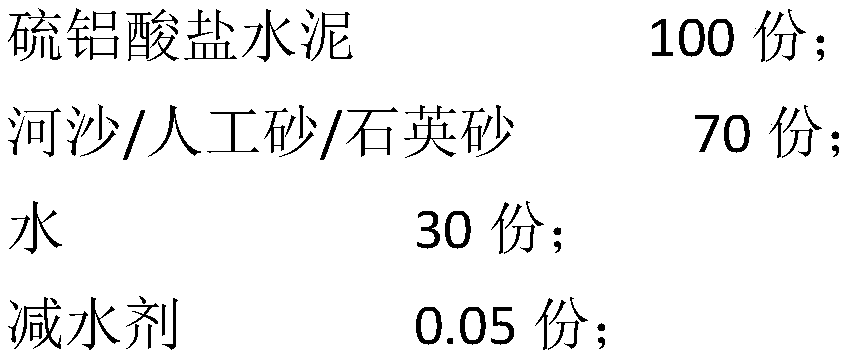

[0048] Add 30 parts of water and 70 parts of river sand / artificial sand / quartz sand to a fast-setting adjustable grouting material of the present invention to obtain a sand-containing slurry body, which specifically includes the following components in parts by weight:

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com