Quick-hardening inorganic waterproof plugging material

An inorganic cementitious material, waterproof plugging technology, applied in the field of building materials, can solve the problems of lack of inorganic waterproof plugging materials, unsatisfactory construction effect, long mixing time, etc., and achieve the effect of shortening the final setting time and waterproof plugging. Good, high-intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Accurately weigh 64kg of low-alkalinity sulfoaluminate cement with a strength of 43Mpa, 25.3kg of quartz sand with a mesh number of 1000, 10kg of composite early-strength agent, 0.5kg of latex powder, 0.2kg of cellulose, and 10kg of composite early-strength agent 4kg of Li in 2 CO 3 , 3kg of Al 2 (SO 4 ) 3 and 3kg of CaO;

[0046] (2) Add each component in the stirring tank, turn on the mixer, the stirring speed is 800 rpm, and stir for 3 minutes;

[0047] (5) Take a sample to test the coagulation time. If the coagulation time is less than 30s, the finished product can be obtained if the test is qualified.

Embodiment 2-5 and comparative Embodiment 1-4

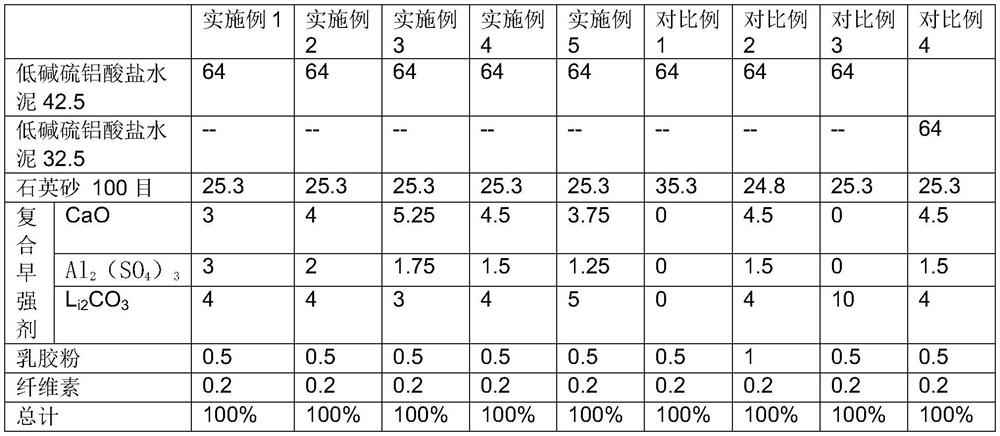

[0049] In order to simplify the description, the preparation parameters of Inventive Examples 2-5 and Comparative Examples 1-4 are listed in Table 1, and the parameters not listed in the table are the same as in Example 1.

[0050] Table 1 embodiment preparation parameter table

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com