Crown cap reversing device

A technology of reversing device and crown cap, which is applied in the direction of flanged bottle caps, etc., can solve the problems that the correct rate of reversing cannot reach 100%, the speed of cap sorting is reduced, and the normal production is affected, and the effect of reversing is good, The effect of simple structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

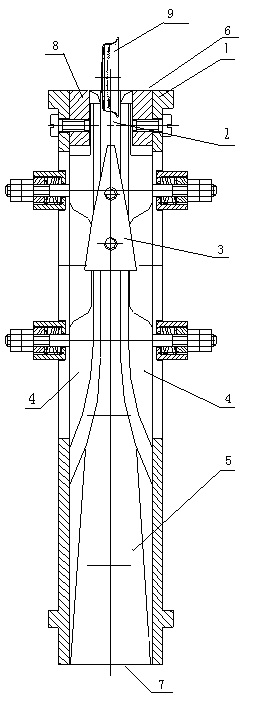

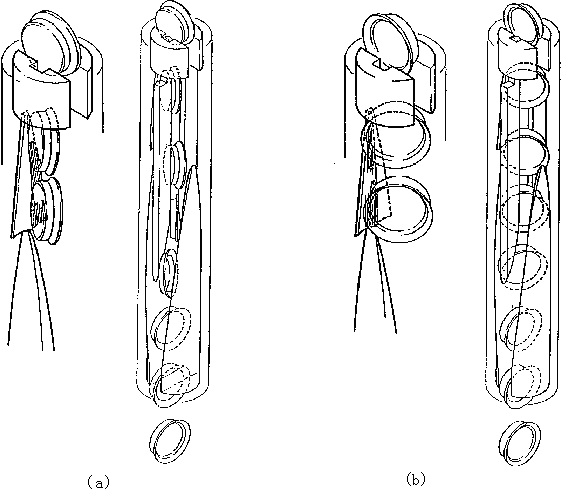

[0015] Embodiment 1 Concrete structure of the present invention (in conjunction with Figure 1-3 )

[0016] The crown cap reversing device of the present invention comprises a cylinder 1, and the cylinder 1 includes a cover inlet 6 and a cover outlet 7, from which the cover inlet 6 to the cover outlet 7 are sequentially arranged with the cylinder body 1 fixedly connected guide port 8, guide slide plate 3 and lower guide plate 5;

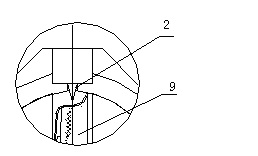

[0017] The guide port 8 includes two symmetrically arranged cylindrical bodies with a bow-shaped cross-section. The guide port 8 also includes a guide key 2 for positioning the entrance direction of the crown cover. The guide key 2 is a cuboid with a side surface a rib located between the columns;

[0018] The upper end of the guide slide 3 is connected with the rib of the guide key 2, and the guide slide 3 is a curved surface with a protrusion in the middle and two wings spread out; this structure makes the skirt of the crown cover slide down alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com