Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

92 results about "Dimethylaminopropylamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dimethylaminopropylamine (DMAPA) is a diamine used in the preparation of some surfactants, such as cocamidopropyl betaine which is an ingredient in many personal care products including soaps, shampoos, and cosmetics. BASF, a major producer, claims that DMAPA-derivatives do not sting the eyes and makes a fine-bubble foam, making it appropriate in shampoos.

Preparation method for self-emulsified cationic epoxy emulsion

InactiveCN103497617ANarrow molecular weight distributionGood flexibilityPolyurea/polyurethane coatingsPaints for electrolytic applicationsEmulsionCarbon chain

The invention discloses a preparation method for self-emulsified cationic epoxy emulsion. The method mainly comprises: using bisphenol A, dodecylphenol and ethoxylatedbisphenol A to perform chain extension on low-molecular-weight epoxy resin to obtain medium-molecular-weight chain-extended epoxy resin; using diethanolamine and N, N-dimethylpropylamine to perform ring-opening amination on chain-extended epoxy resin; and taking a totally-enclosed modified MDI as a curing agent, neutralizing with lactic acid, and emulsifying in deionized water to obtain the self-emulsified cationic epoxy emulsion. According to the epoxy emulsion, tertiary / quaternary amine cationic epoxy resin is taken as the resin main body, and the molecules of the tertiary / quaternary amine cationic epoxy resin have both hydrophobic carbon chains and hydrophilic cationic chain segments, so that the resin molecules have self-emulsifying function, and can be stably emulsified in water without the help of emulsifiers. The provided self-emulsified cationic epoxy emulsion is applicable to preparation of cathodic electrophoretic coatings which has excellent coating performance.

Owner:ZHAOQING UNIV

Cationic viscoelastic surfactant and preparation and application thereof

InactiveCN105080424AExcellent high temperature resistance and shear resistanceGood suspension effectOrganic compound preparationTransportation and packagingFracturing fluid3-MCPD

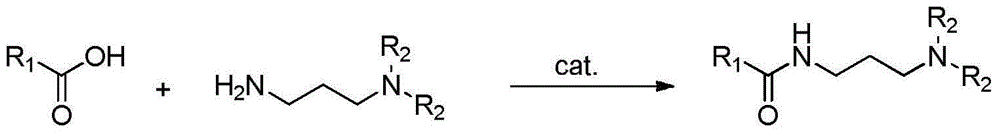

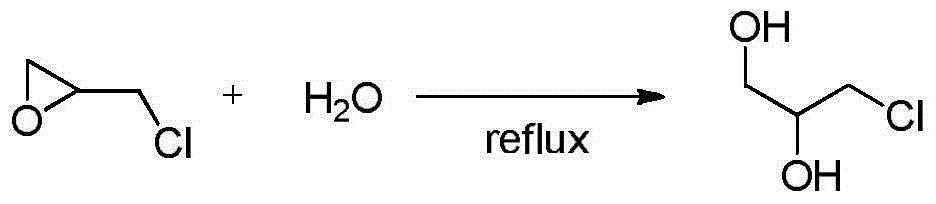

The invention discloses a cationic viscoelastic surfactant and preparation and application thereof. The preparation method of the cationic viscoelastic surfactant comprises the following steps: firstly, mixing long-chain fatty acid with dimethylaminopropylamine according to a certain proportion, adding a catalyst solution to obtain a required amide product intermediate A by a series of reaction; allowing reflux condensation reaction of epoxy chloropropane and water at a certain proportion to be carried out in oil bath of 100 DEG C to obtain colourless and transparent 3-chloro-1,2-propylene glycol aqueous solution, namely an intermediate B; heating the intermediate A in oil bath for melting, and dropwise adding an aqueous solution B to obtain the required viscoelastic surfactant by a series of reaction; the surfactant can be mixed with a potassium chloride solution according to a certain proportion to obtain clean fracturing fluid which is low in cost and excellent in performance, besides, the clean fracturing fluid has excellent high-temperature resistance, shearing resistance, and excellent solid-carrying performance, is automatic and thorough in gel breaking, causes little damage to the reservoir stratum and has the characteristic of wide application range.

Owner:SOUTHWEST PETROLEUM UNIV

Loaded nickel-base bi-component catalyst and application thereof

ActiveCN102188975AInhibitory activityReduce qualityOrganic compound preparationAmino compound preparationActivated carbonDimethylaminopropylamine

The invention discloses a loaded nickel-base bi-component catalyst and an application thereof. The catalyst is prepared by the following steps of: (1) firstly immersing a carrier with a soluble nickel salt solution by adopting an isovolumetric immersion method, then drying and roasting, wherein the carrier is gamma-aluminium oxide, silicon dioxide, molecular sieve or activated carbon; and (2) immersing the product obtained by the step (1) with a soluble transitional metal salt solution of another transitional metal by adopting the isovolumetric immersion method, drying and roasting again, thus the loaded nickel-base bi-component catalyst is obtained, wherein the transitional metal is selected from Fe, Co, Cr, Cu, Zn, Pt, Pd, Ru, Au and Ag. The loaded nickel-base bi-component catalyst disclosed by the invention is applied to preparation of high purity 3-dimethyl amino propylamine by catalytic hydrogenation on 3-dimethyl amino propionitrile, the reaction selectivity is high, and the catalyst can be reused, thus the catalyst is suitable for industrial application.

Owner:ZHEJIANG UNIV OF TECH

Microcrystalline-cellulose-modified rubber material

The invention discloses a microcrystalline-cellulose-modified rubber material composed of the following raw materials, by weight: 3-4 parts of an anti-aging agent BPS, 0.2-0.6 parts of 8-10% sulfuric acid, 26-30 parts of melamine, 5-8 parts of a 37% formaldehyde solution, 7-10 parts of urea, 6-10 parts of microcrystalline cellulose, 1-1.2 parts of isopropanol, 2-3 parts of sulfur, 3-4 parts of maleic anhydride, 210-230 parts of neoprene S40V, 3-4 parts of sodium fluosilicate, 20-26 parts of montmorillonite powder, 5-7 parts of tetrabutyl titanate, 20-24 parts of carbon black, 0.4-1 parts of sodium cinnamate, 2-3 parts of abietinol, 2-4 parts of palm wax, and 1-2 parts of dimethylaminopropylamine. According to the invention, microcrystalline cellulose is processed with the crosslinking effect of maleic anhydride, and is blended with abietinol, such that surface viscosity is improved, material compatibility is promoted, and good antioxidant effect is provided. Microcrystalline cellulose forms a closer network structure in melamine resin formed by melamine, urea and formaldehyde, such that resin viscosity and tensile deformation resistance are well improved, and certain reinforcement and tackifying effects are provided in the rubber material. Therefore, flexural cracking resistance, hot-air aging resistance and stability of the rubber material are improved.

Owner:FUYANG ANGU BOILER PRESSURE VESSEL MFG

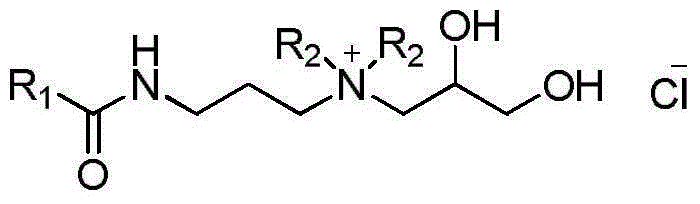

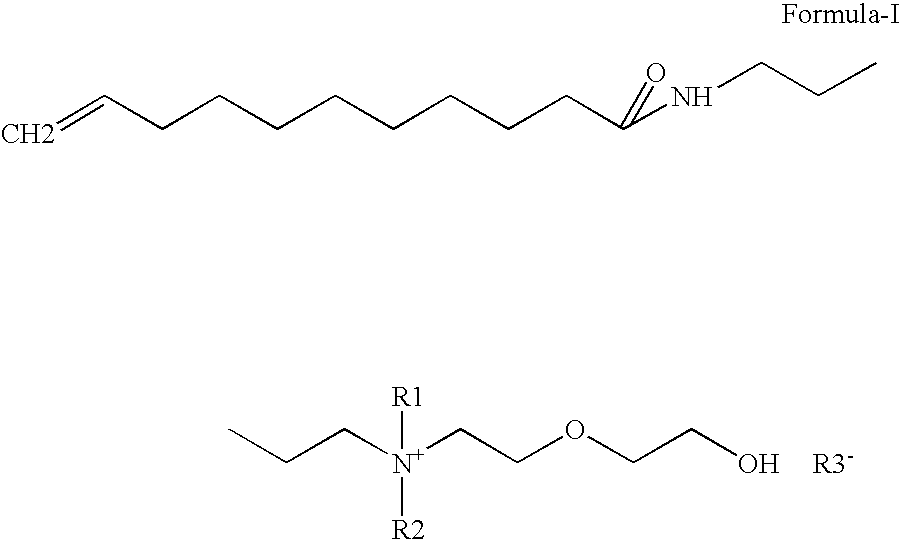

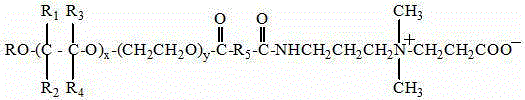

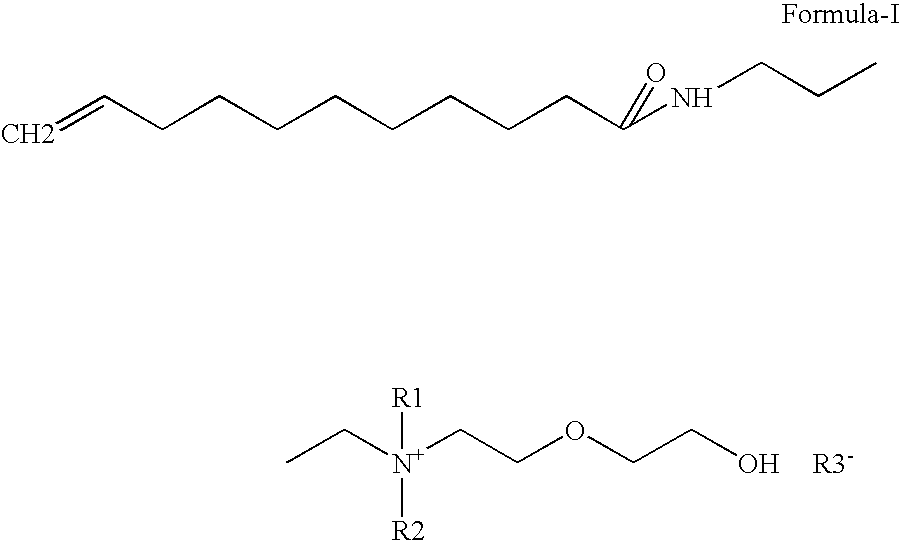

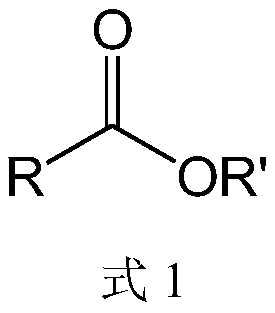

Water-soluble anti-dandruff compounds and compositions thereof

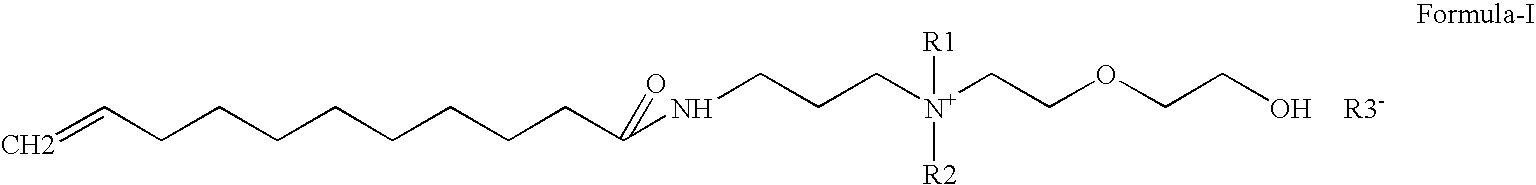

InactiveUS20060182696A1More anti-dandruff activityGood water solubilityCosmetic preparationsCationic surface-active compoundsPersonal careWater dispersible

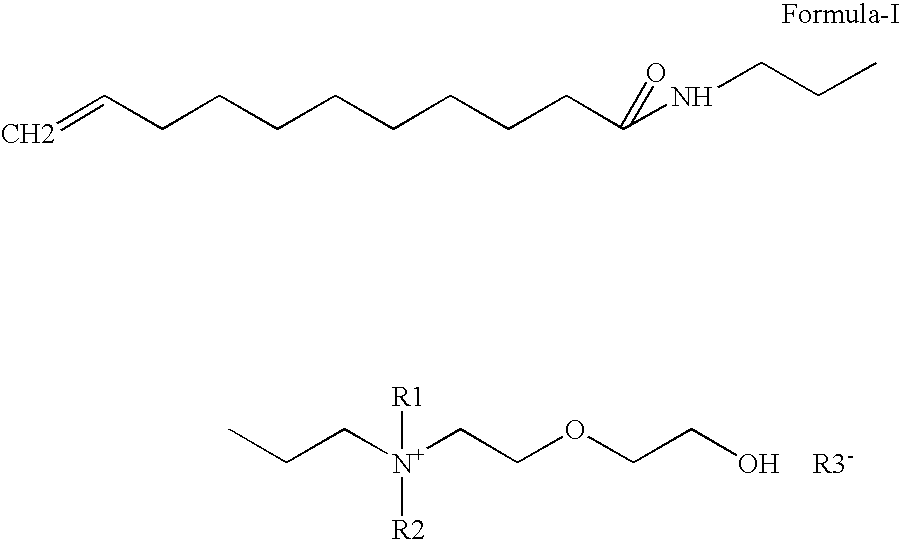

Water-soluble and water dispersible undecylenic amido propyl dimethyl hydroxyl ethoxy ethyl ammonium undecylenate compounds of formula I having anti-dandruff, preservative and sunscreen activity wherein R1, R2 are from C1-C6 carbon atoms, R3 is undecylenic acid, amino group is selected from dimethyl amino propyl amine. Personal care compositions comprising compounds of formula I

Owner:GALAXY SURFACTANTS

Low pressure process for manufacture of 3-dimethylaminopropylamine (dmapa)

InactiveCN1747925AHigh selectivityOrganic compound preparationAmino compound preparationPtru catalystHydrogenation process

An improved process for the production of 3-dimethylaminopropylamine in high purity from N,N-dimethylaminopropionitrile utilizing a low pressure hydrogenation process is described. The basic process comprises contacting the nitrile with hydrogen at low pressure in the presence of a catalyst under conditions sufficient to effect the conversion of the nitrile to the primary amine product.

Owner:SOLUTIA INC

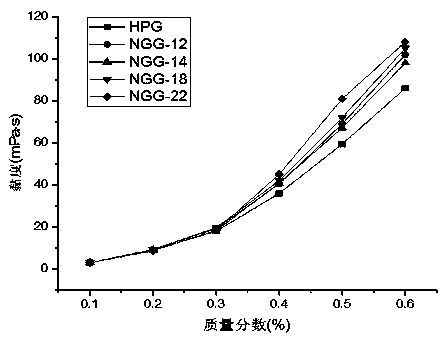

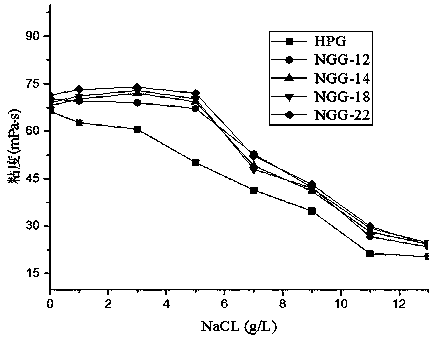

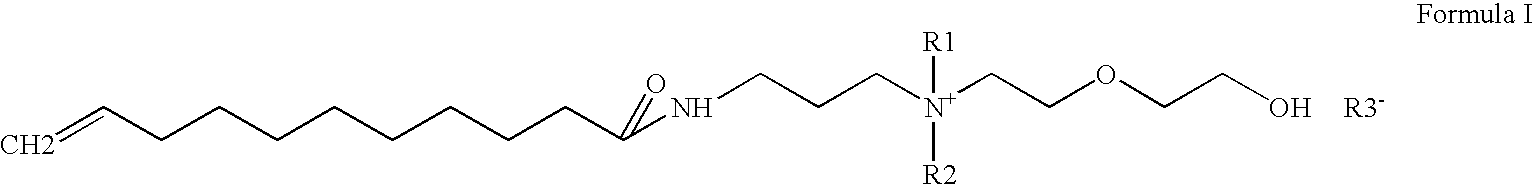

Zwitterionic hydrophobic modified guar gum and preparation method thereof

The invention discloses zwitterionic hydrophobic modified guar gum which is characterized in that the structural formula of the zwitterionic hydrophobic modified guar gum is shown in the specification, wherein R1 is a long-chain organicacid, concretely a long-chain saturated acid with a carbon chain of 6-14 or a long-chain unsaturated acid with a carbon chain of 18-22. The invention also disclosesa preparation method of the guar gum. The preparation method comprises the following steps: introducing an anionic monomer into the guar gum to form an anionic guar gum modified product; preparing awater-soluble amphiphilic cationic hydrophobic monomer from hydrophobic long chain, 3-dimethylaminopropylamine and epoxy chloropropane; and introducing the water-soluble amphiphilic cationic hydrophobic monomer into the anionic guar gum modified product to form an amphoteric hydrophobic modified product. The special electrostatic interaction and hydrophobic association of zwitterions are fully utilized to endow the guar gum molecular chain with special dispersity and rheological property, so that the disclosed guar gum has excellent solubility, tackifying property, temperature resistance and salt resistance.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Impact and cracking resistant material for combustion gas pipelines

The invention discloses an impact and cracking resistant material for combustion gas pipelines. The material comprises, by weight, 40-60 parts of high density polyethylene, 30-40 parts of ethylene propylene diene monomer, 20-30 parts of acrylonitrile-butadiene-styrene copolymer, 30-40 parts of carbon black, 1.8-2.6 parts of modified montmorillonite, 0.9-0.13 parts of modified carbon nanotubes, 20-30 parts of nonyl cyclohexanedicarboxylate, 20-30 parts of methyl acetylricinoleate, 15-20 parts of ammonium polyphosphate, 10-15 parts of zinc borate, 5-8 parts of red phosphorus, 1-3 parts of di-tert-butyl peroxide, 0.4-0.6 parts of dimethylaminopropylamine, 0.1-0.3 parts of a promoter CZ, 2-4 parts of a Ca / Zn composite stabilizer, 1-2 parts of zinc stearate, 1-2 parts of butylmercaptooxo stannane, 0.5-1 part of an antioxidant D, 0.3-0.5 parts of an antioxidant RD and 1-3 parts of polyethylene wax. The material has the advantages of good impact resistance and high toughness.

Owner:安徽宁国市高新管业有限公司

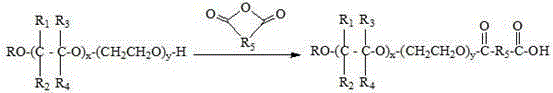

Carbon dioxide soluble zwitterionic surfactant and preparation method thereof

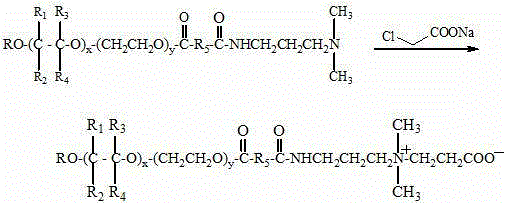

ActiveCN106606993AImprove featuresImprove hard water resistanceOrganic compound preparationTransportation and packagingSolubilityBetaine

The invention belongs to the field of special surfactants and particularly relates to a carbon dioxide soluble zwitterionic surfactant and a preparation method thereof. The surfactant is structurally characterized in that a carbon dioxide-philic branched alkylene oxide group, an ester group characteristic group and a hydrophilic glycine betaine group are introduced into a hydrophobic chain, so that the surfactant has good carbon dioxide-philic and hydrophilic properties and also has high-salinity hard water resistance. According to the preparation method of the surfactant disclosed by the invention, alkyl alcohol serves as an initiator to cause epoxyalkane aggregation, and the final product is obtained through the anhydride esterification, amidation of N,N-dimethylaminopropylamine and sodium chloroacetate quaterisation reaction. The surfactant has the following advantages that (1) the synthetic route is mature and easy to implement, and (2) the surfactant has high solubleness in supercritical or liquid-phase carbon dioxide.

Owner:CHINA PETROCHEMICAL CORP +1

Raspberry amido amines and betaines as a delivery system for natural antioxidants

The present invention relates to raspberry seed oil derivatives derived by the reaction of dimethyl amino propyl amine and cold pressed raspberry seed oil. This intermediate is subsequently reacted with sodium monochloroacetic acid to make a raspberry betaine. The choice of cold pressed raspberry seed oil as a raw material in the preparation of the compounds of the present invention is critical, since it has been found that the cold pressed raspberry seed oil contains antioxidants, antimicrobial compounds and which when reacted with a DMAPA result in products that deliver said actives to the skin and hair, resulting in protection of the skin and hair from environmental factors such as acid rain, ozone attack and UV degradation.

Owner:T C U S A

Reactive amine catalysts for use in pucb foundry binder

InactiveUS20050004257A1Eliminate the problemEliminate wasteOrganic-compounds/hydrides/coordination-complexes catalystsFoundry mouldsChemistryDimethylaminopropylamine

The present invention relates a reactive tertiary amine catalyst used in a phenolic urethane cold box process. Through the use of a reactive tertiary amine, the problems associated with vaporous amine waste streams can be eliminated. Some typical reactive tertiary amine catalysts that are useful in the present invention include 1-dimethylamino-2-propanol (DMA-2P), monoethanolamine and dimethylaminopropylamine (DMAPA).

Owner:ARKEMA INC

High-hardness corrugated pipe

InactiveCN103554614AImprove mechanical propertiesImprove anti-friction performanceRigid pipesPotassiumMechanical property

The invention discloses a high-hardness corrugated pipe. The high-hardness corrugated pipe is characterized by consisting of the following raw materials in parts by weight: 96-100 parts of high-density polyethylene, 2-3 parts of potassium feldspar powder, 1-2 parts of tung oil, 1-2 parts of sodium hydrogen phosphate, 2-3 parts of montmorillonite powder, 0.3-0.6 part of dimethylaminopropylamine, 0.3-1 part of antiscorching agent CTP, 2-3 parts of polytetrafluoroethylene, 1-2 parts of polylactic acid, 2-3 parts of aluminum nitride, 0.1-1 part of cuprous chloride, 0.1-0.2 part of fenbutatin oxide and 6-10 parts of composite fillers. The corrugated pipe disclosed by the invention has high mechanical property and friction resistance, high hardness, good impact resistance and ring stiffness, excellent pressure resistance and good stability.

Owner:SINOMACH GENERAL MACHINERY SCIENCE & TECHNOLOGY CO LTD

High-dispersion stable rubber material

The invention discloses a high-dispersion stable rubber material composed of the following raw materials, by weight: 3-4 parts of an anti-aging agent D, 2-3 parts of a vulcanizing agent MOCA, 1-2.4 parts of phytosterol, 40-46 parts of white clay, 6-8 parts of propylene glycol alginate, 1-3 parts of dimethylaminopropylamine, 3-4 parts of chlorinated paraffin, 0.3-1 parts of potassium bisulfate, 0.2-0.6 parts of 8-10% sulfuric acid, 26-30 parts of melamine, 5-8 parts of a 37% formaldehyde solution, 7-10 parts of urea, 6-10 parts of microcrystalline cellulose, 1-1.2 parts of isopropyl alcohol, 3-4 parts of maleic anhydride, and 210-230 parts of neoprene S40V. According to the invention, under the crosslinking effect of maleic anhydride, microcrystalline cellulose can form a closer network structure in melamine resin formed by melamine, urea and formaldehyde. With an added dispersing agent, the dispersion effect of cellulose in resin can be effectively promoted; compatibility can be improved; resin viscosity and tensile deformation resistance can be greatly improved; and certain reinforcement and tackification effects are performed in the rubber material. Therefore, flexure cracking resistance, hot air aging resistance and stability of the material are improved.

Owner:FUYANG ANGU BOILER PRESSURE VESSEL MFG

Low pressure process for manufacture of 3-dimethylaminopropylamine (DMAPA)

InactiveUS6951959B2Speed up the processOrganic compound preparationAmino compound preparation3-DimethylaminopropylamineHydrogenation process

An improved process for the production of 3-dimethylaminopropylamine in high purity from N,N-dimethylaminopropionitrile utilizing a low pressure hydrogenation process is described. The basic process comprises contacting the nitrile with hydrogen at low pressure in the presence of a catalyst under conditions sufficient to effect the conversion of the nitrile to the primary amine product.

Owner:ASCEND PERFORMACE MATERIALS OPERATIONS LLC

Water-soluble anti-dandruff compounds and compositions thereof

InactiveUS7518005B2Cosmetic preparationsCationic surface-active compoundsPersonal careWater dispersible

Water-soluble and water dispersible undecylenic amido propyl dimethyl hydroxyl ethoxy ethyl ammonium undecylenate compounds of formula I having anti-dandruff, preservative and sunscreen activity wherein R1, R2 are from C1-C6 carbon atoms, R3 is undecylenic acid, amino group is selected from dimethyl amino propyl amine. Personal care compositions comprising compounds of formula I

Owner:GALAXY SURFACTANTS LTD

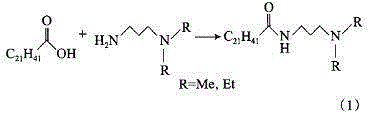

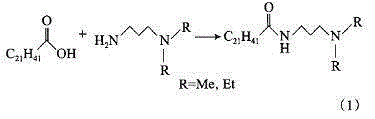

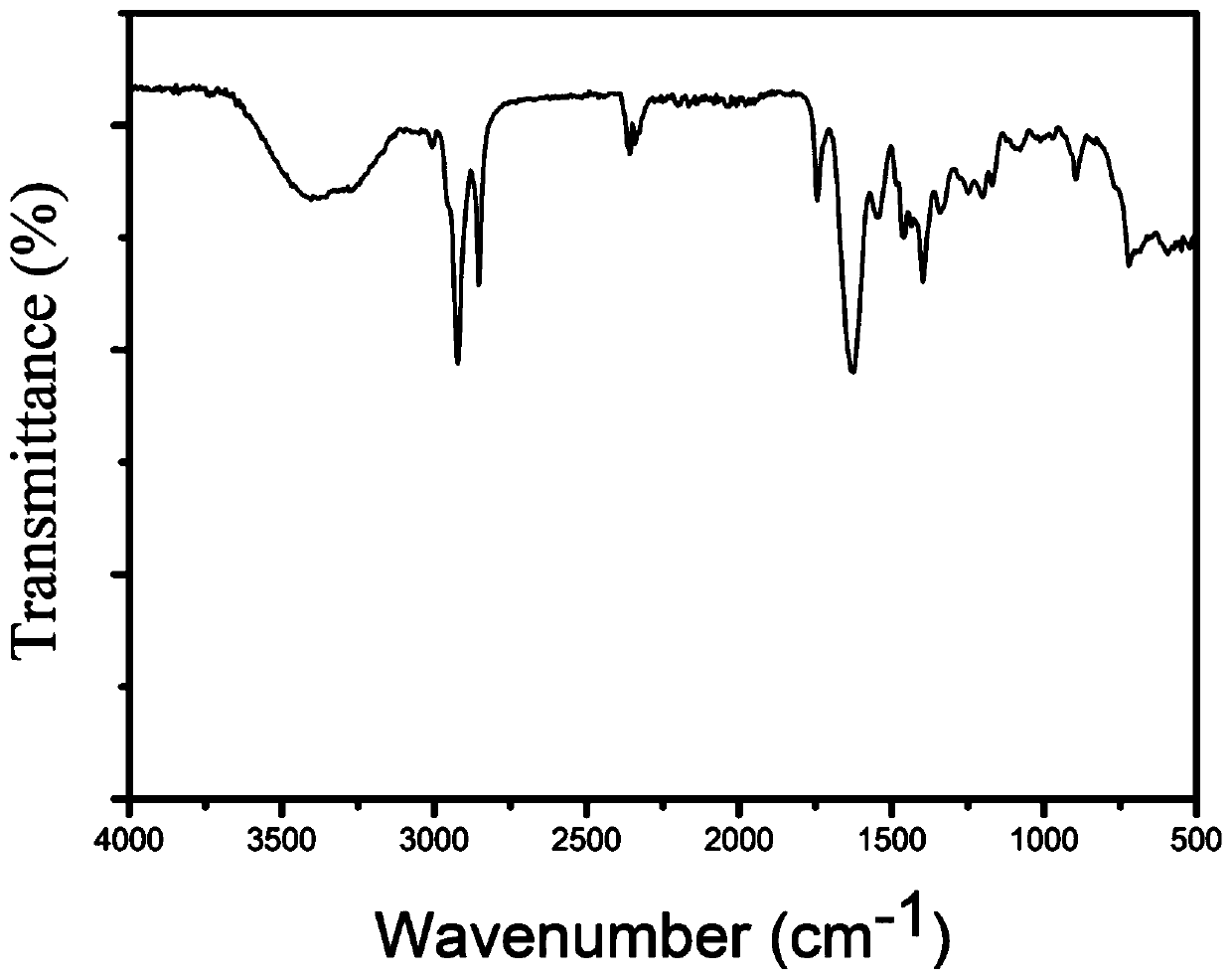

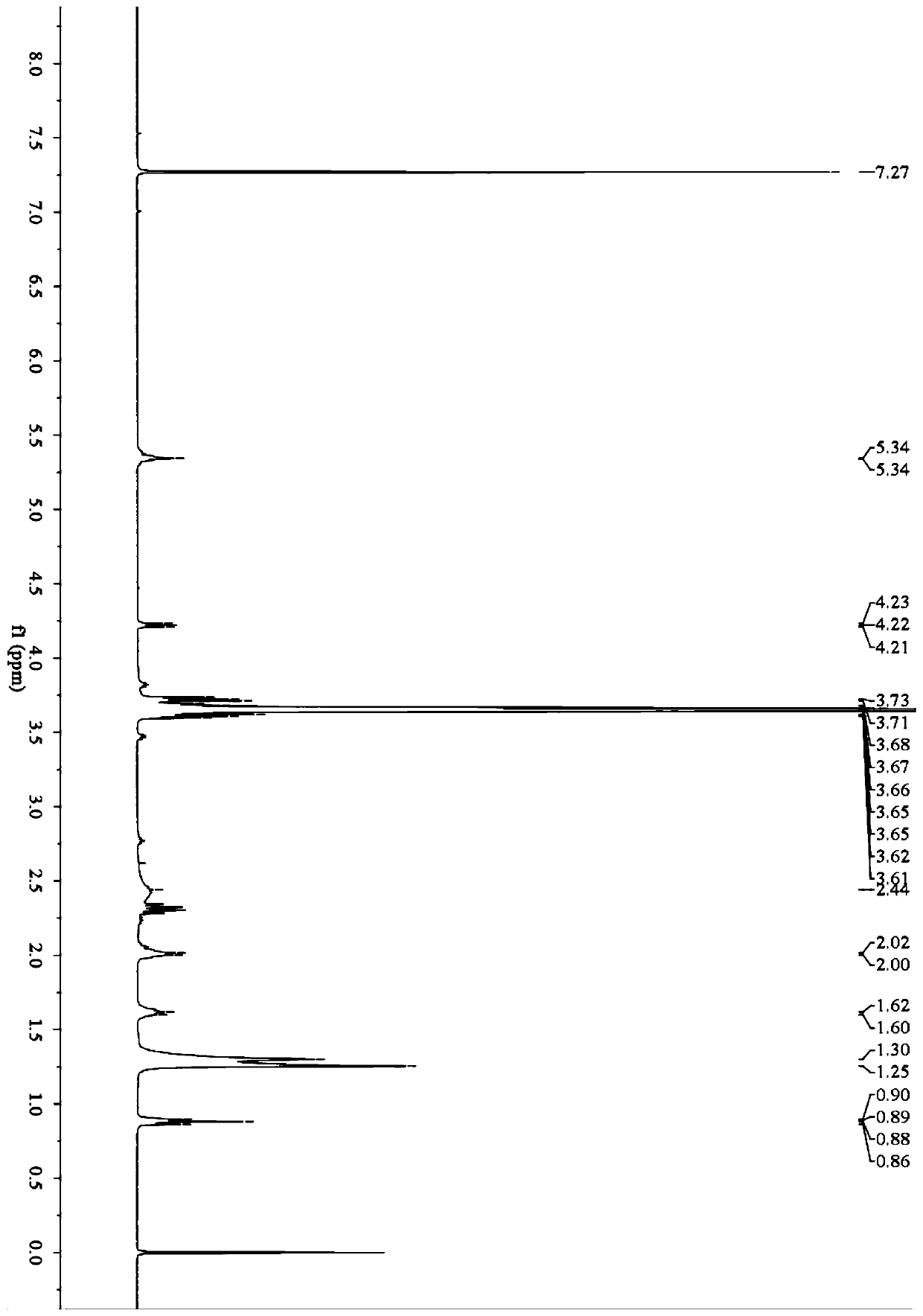

Synthesis method of erucylamidopropyl dimethylamine (diethylamine)

InactiveCN105566144AEasy to operateEasy to prepare on siteOrganic compound preparationCarboxylic acid amides preparationSynthesis methodsPotassium hydroxide

The invention relates to a synthesis method of erucylamidopropyl dimethylamine (diethylamine). The synthesis method of the erucylamidopropyl dimethylamine (diethylamine) includes the steps of firstly, adding erucic acid and N,N-dimethylaminopropylamine (or N,N-ethylaminopropylamine) into a three-necked bottle with a reflux condensing tube and a stirring device; secondly, adding potassium hydroxide under the protection of argon gas and reacting at the temperature of 160 DEG C for 12 hours; thirdly, after reaction is completed, performing rotary evaporation to remove unreacted N,N-dimethylaminopropylamine (or N,N-ethylaminopropylamine) so as to obtain the erucylamidopropyl dimethylamine (diethylamine). The synthesis method of the erucylamidopropyl dimethylamine (diethylamine) has the advantages of simplicity in operation, easiness in field compounding and few required equipment.

Owner:SHAANXI JUJIEHAN CHEM CO LTD

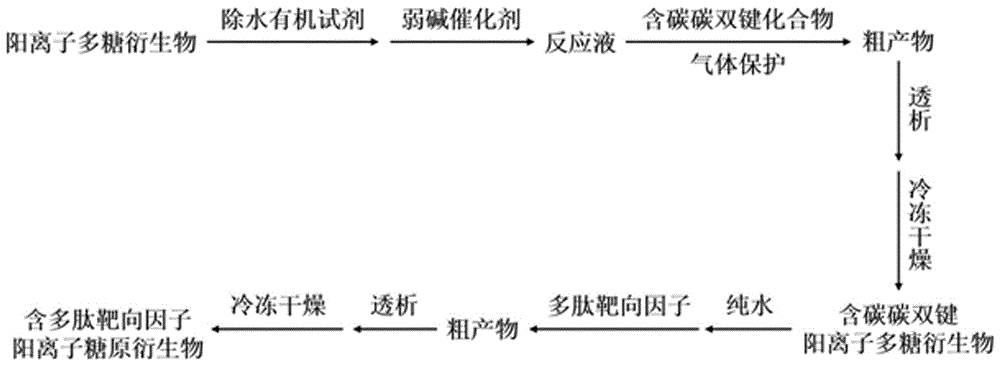

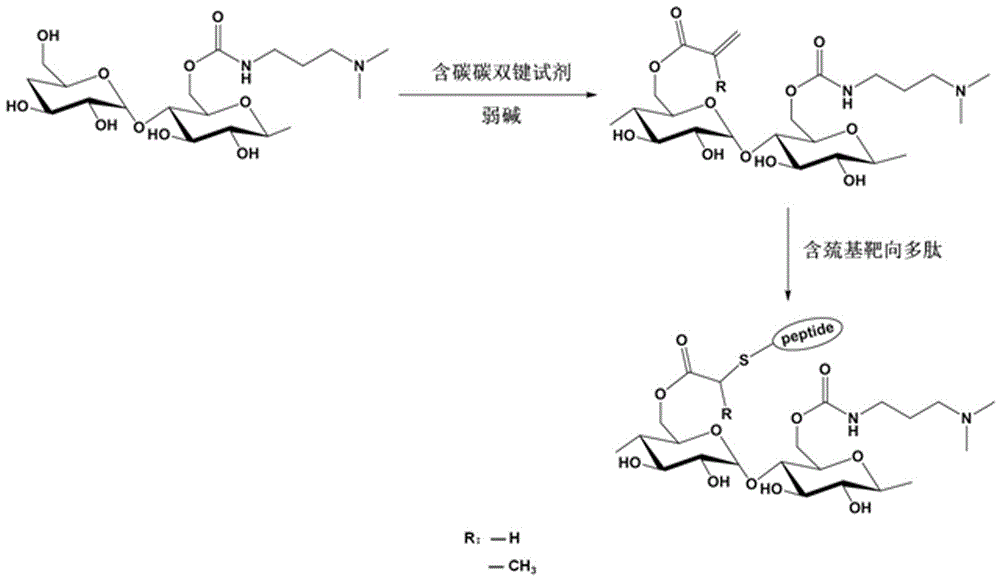

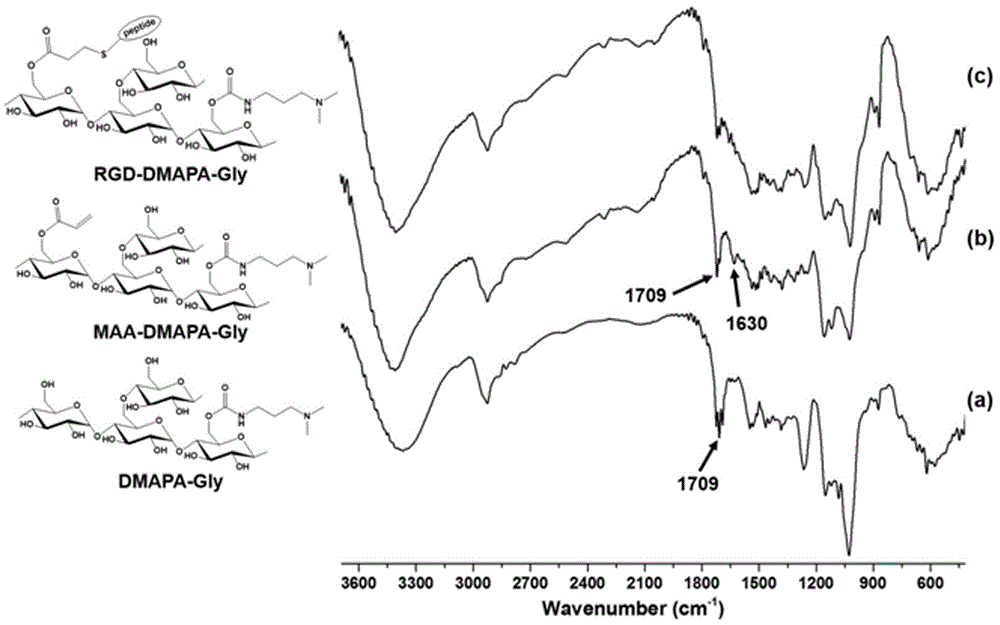

Polysaccharide derivative containing polypeptide targeting factor and preparation method thereof

ActiveCN106749517ASimple processEasy to operateSomatostatinsDepsipeptidesChemical reactionStrong acids

The invention discloses a polysaccharide derivative containing a polypeptide targeting factor and a preparation method thereof. The preparation method comprises that a polypeptide targeting factor and a polysaccharide derivative containing a 3-dimethylaminopropylamine group as a raw material undergo a mercapto-alkene click chemical reaction at the room temperature. The preparation method has mild reaction conditions, is free of strong acid and strong alkali reagents and maximally keeps the biological activity of the polypeptide and the polysaccharide. The preparation method has simple processes, is easy to operate and needs cheap equipment and raw materials. The polysaccharide derivative containing a polypeptide targeting factor can be used as a drug or a gene carrier having performances of targeted transport to a lesion location and thus the polysaccharide derivative has a certain application prospect in the field of biomedicine.

Owner:SUN YAT SEN UNIV

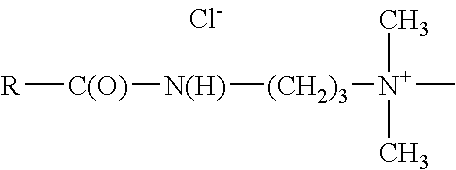

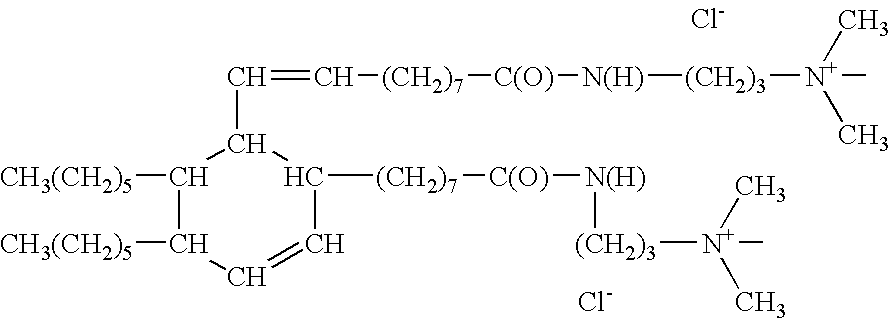

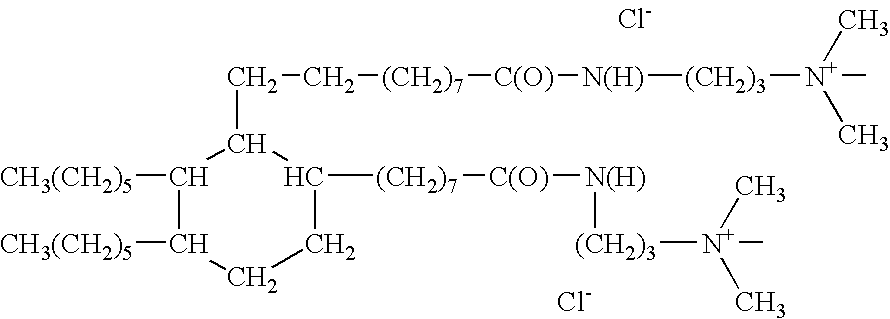

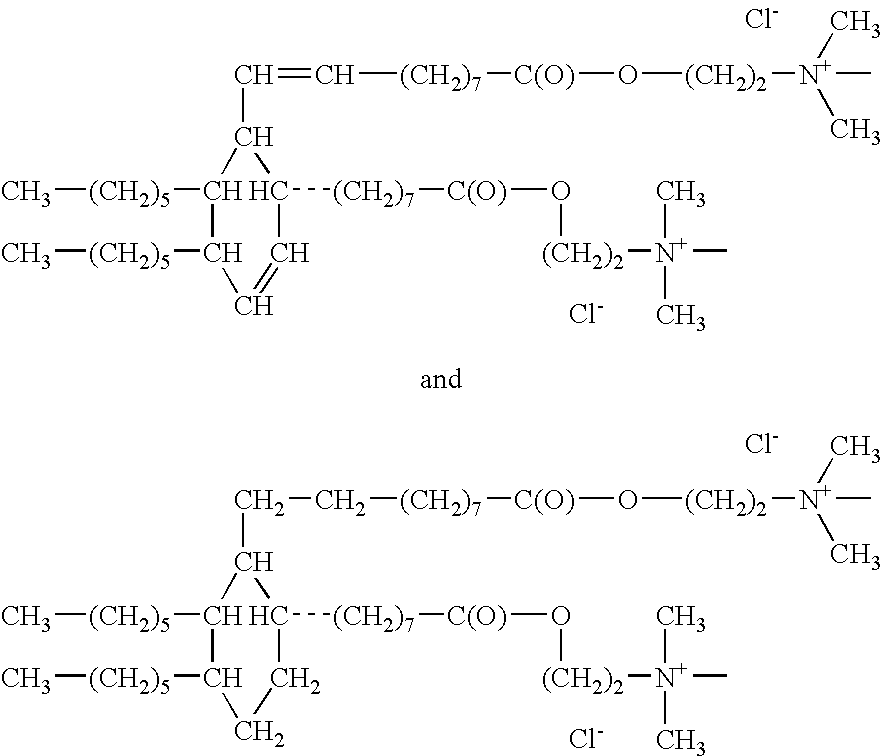

Dimer poly-quaternary compounds

The present invention relates to a novel class of polymeric compounds having specific quaternized amine based upon a dimer acid reacted with an dimethyl amino propyl amine to make an amido amine, which is subsequently reacted to make a polymeric quaternary compound. Dimer acid is a C-36 diacid having a cyclic structure and two amine groups that allow for the synthesis of a high molecular weight cationic compound which is extremely substantitive to human skin and are well tolerated by human tissue making them suitable for use preparation of barrier products for personal care applications.

Owner:SURFATECH

Antibacterial pharmaceutical packaging material and preparation method thereof

The invention discloses an antibacterial pharmaceutical packaging material and a preparation method thereof. The antibacterial pharmaceutical packaging material is prepared from the following raw materials in parts by weight: 20 to 45 parts of polyvinyl chloride, 12 to 25 parts of permethrin, 8 to 18 parts of polyethylene terephthalate, 3 to 10 parts of nanometer titania, 2 to 8 parts of nano-silver, 12 to 25 parts of polyimide, 10 to 22 parts of polyglycolic acid, 3 to 8 parts of zinc oxide, 5 to 12 parts of acrylamide, 3 to 10 parts of ammonium dihydrogen phosphate, 6 to 14 parts of polyester fiber, 1 to 2.5 parts of trichlorofluoromethane, 2.5 to 7 parts of polyethersulfone, 4 to 11 parts of diphenyldichlorosilane, 2 to 7 parts of calcium carbonate, 2 to 6 parts of titanate coupling agent, 5 to 12 parts of dicumyl peroxide, 3 to 9 parts of calcium alkylbenzene sulfonate, 2 to 8 parts of dimethylaminopropylamine, and 3 to 13 parts of ethylene-vinyl acetate copolymer. Compared with the prior art, the antibacterial pharmaceutical packaging material provided by the invention has the advantages of high strength, simple preparation method and the like, and has a good antibacterial effect, can effectively inhibit the microbial activity, and is particularly suitable for the medical field.

Owner:ANHUI SHUNTONG PACKAGING MATERIAL

Improved ultraviolet-light ultralow-temperature-curable powdery paint

InactiveCN103497628AStrong impact resistanceStrong weather resistancePowdery paintsEpoxy resin coatingsEpoxyUltraviolet lights

The invention discloses an improved ultraviolet-light ultralow-temperature-curable powdery paint composed of the raw materials of, by weight: 50-60 parts of E-12 epoxy resin, 4-6 parts of polysiloxane resin, 1-2 parts of white carbon black, 25-30 parts of montmorillonite powder, 4.5-5.5 parts of activated carbon powder, 0.1-0.3 parts of cobalt oxide, 2-3 parts of molybdenum boride, 10-16 parts of dimethylaminopropylamine, 0.2-0.4 parts of dimethyl isooctyl thioglycolate tin, 0.8-1 part of 2-hydroxy-4-n-octyloxy benzophenone, and 10-20 parts of a composite filling material. The powdery paint provided by the invention has good impact strength and high weatherability, and can be applied in the coating fields of heat sensitive substrates such as plastics, wood, paper, and various heat sensitive electronic elements. The paint can also be used in the fields such as hardware, electrical appliances, household appliances, automobiles, furniture, decoration, machinery equipment, and the like.

Owner:BENGBU DEMO FILTRATION TECH

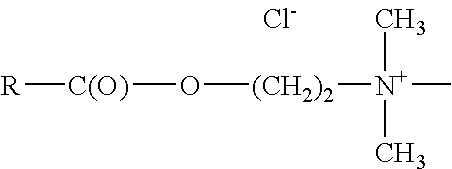

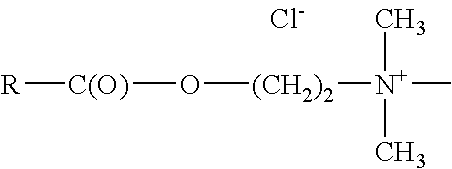

Dimer poly-quaternary ester compounds

The present invention relates to a novel class of polymeric compounds having specific quaternized amine based upon a dimer acid reacted with an alkanolamine to make an ester quaternary compound. Dimer acid is a C-36 diacid having a cyclic structure and two amine groups that allow for the synthesis of a high molecular weight cationic compound which is extremely substantitive to human skin and are well tolerated by human tissue making them suitable for use preparation of barrier products for personal care applications. These materials are dimethylaminopropyl amine free, which is highly desirable in personal care applications.

Owner:SURFATECH

Acrylic resin paint for ultraviolet-resistant copper sculptures

ActiveCN103666156AHigh hardnessGood optical performanceAnti-corrosive paintsTripropylene glycolCerium oxide

The invention relates to paint and in particular relates to acrylic resin paint for ultraviolet-resistant copper sculptures. The paint is prepared from the following raw materials in parts by weight: 2-3 parts of nano cerium oxide, 3-4 parts of potassium silicate, 1-2 parts of lithium silicate, 30-34 parts of acrylic resin, 1-2 parts of copper citrate, 1-2 parts of 2-aminoethylheptadecenylimidazoline, 10-12 parts of tripropylene glycol diacrylate, 1-2 parts of phenyl glycidyl ether, 4-7 parts of allyl glycidyl ether, 2-3 parts of vinyltriethoxysilane, 0.5-1.2 parts of accelerator Na-22, 2-3 parts of tetrabutyl titanate, 1-2 parts of isophorone diamine, 10-12 parts of trimethylolpropane triacrylate, 1-2 parts of dicumyl peroxide, 4-6 parts of dimethylaminopropylamine, 5-6 parts of auxiliary, 10-12 parts of xylene and 10-12 parts of butyl acetate. The paint contains nano cerium oxide. The paint prepared from nano cerium oxide in combination with other raw materials has high hardness, good optical properties, stable properties and long service life, and is resistant to ultraviolet radiation aging and environment corrosion.

Owner:TONGLING XINJIUDING COPPER CULTURE IND

Polypropylene composite material for vehicle door decoration plate

The present invention discloses a polypropylene composite material for a vehicle door decoration plate. The polypropylene composite material comprises the following raw materials by weight: 4-7 parts of hydroxyl-terminated polybutadiene, 2-3 parts of lithium silicate, 0.5-1 part of sodium mercaptobenzothiazole, 1-2 parts of diacetone alcohol, 0.7-1 part of calcium ascorbate, 2-4 parts of hexanedioic acid propanediol polyester, 0.1-0.3 part of 1-hydroxyethylidene-1,1-diphosphonic acid, 10-16 parts of graphite powder, 3-5 parts of polyamide wax micro-powder, 4-6 parts of tricresyl phosphate, 0.4-1 part of dimethylaminopropylamine, 4-6 parts of a modification auxiliary agent, 100-105 parts of polypropylene, and 0.7-1 part of an antioxidant 168. The polypropylene composite material of the present invention is mainly used for producing the vehicle door decoration plate, and has characteristics of excellent impact resistance, excellent toughness, excellent rigidity, excellent scratching resistance, excellent processing performance, and simple production process.

Owner:ANHUI HAINA SICHUAN PLASTICS TECH

Water-based environment-friendly wear-resistant paint

InactiveCN105038540AReduce volatilityImprove dustproof effectFireproof paintsPolyester coatingsWater basedMethacrylate

The invention discloses water-based environment-friendly wear-resistant paint. The water-based environment-friendly wear-resistant paint consists of the following raw materials in parts by weight: 90-100 parts of alkyd resin, 1-2 parts of 1,2-dimethoxyethane, 3-5 parts of aluminum borate whisker, 1-2 parts of volcanic ash, 3-4 parts of expanded perlite, 2-3 parts of polyvinyl alcohol, 0.6-1 part of dimethylaminopropylamine, 0.5-1 part of naphthenic acid, 2-4 parts of iso-octyl methacrylate, 1-3 parts of magnesium stearate, 0.5-1 part of manganese sulfate, 1-2 parts of aluminum sulfate, 0.7-1 part of stearic acid, 8-12 parts of wollastonite in powder, 2-4 parts of a flame retardant agent, 1-2 parts of sodium tripolyphosphate and 80-100 parts of deionized water. Compared with solvent type paint, the paint disclosed by the invention is more environment-friendly and scratch-resistant, and is low in volatilization, good in dustproof effect, and lasting in protective effect; and a coating formed by the paint is stable, and is high in adhesive force, good in surface wear resistance, not liable to age and drop, and high in impact resistance.

Owner:ANHUI OS BUILDING MATERIAL

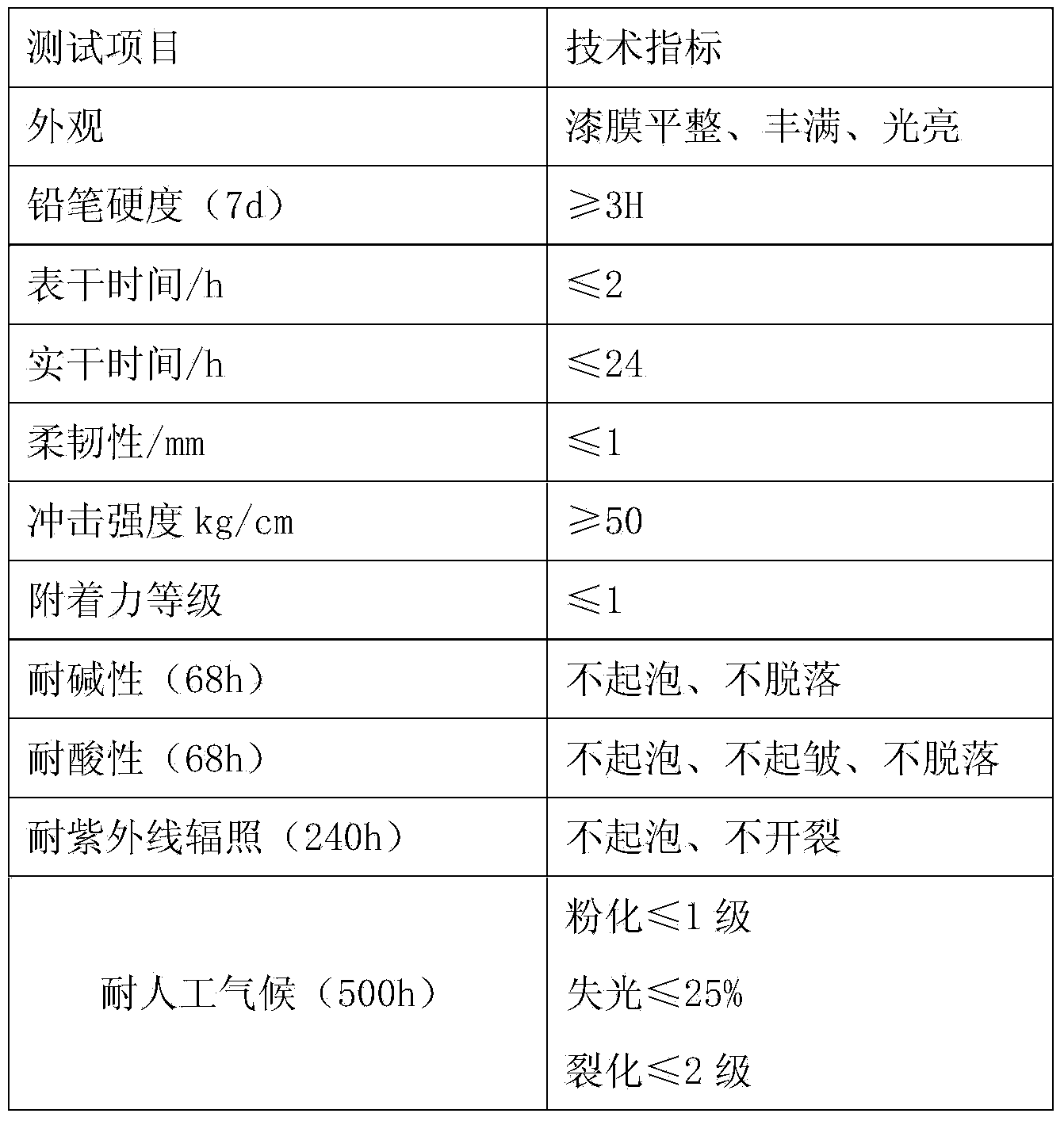

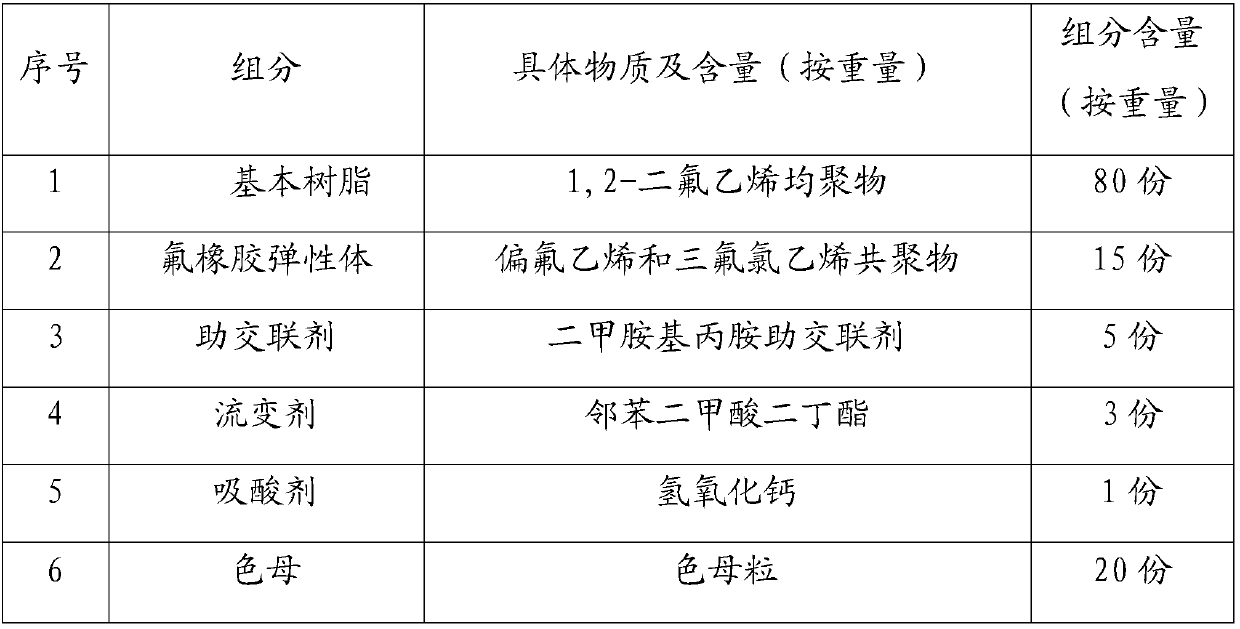

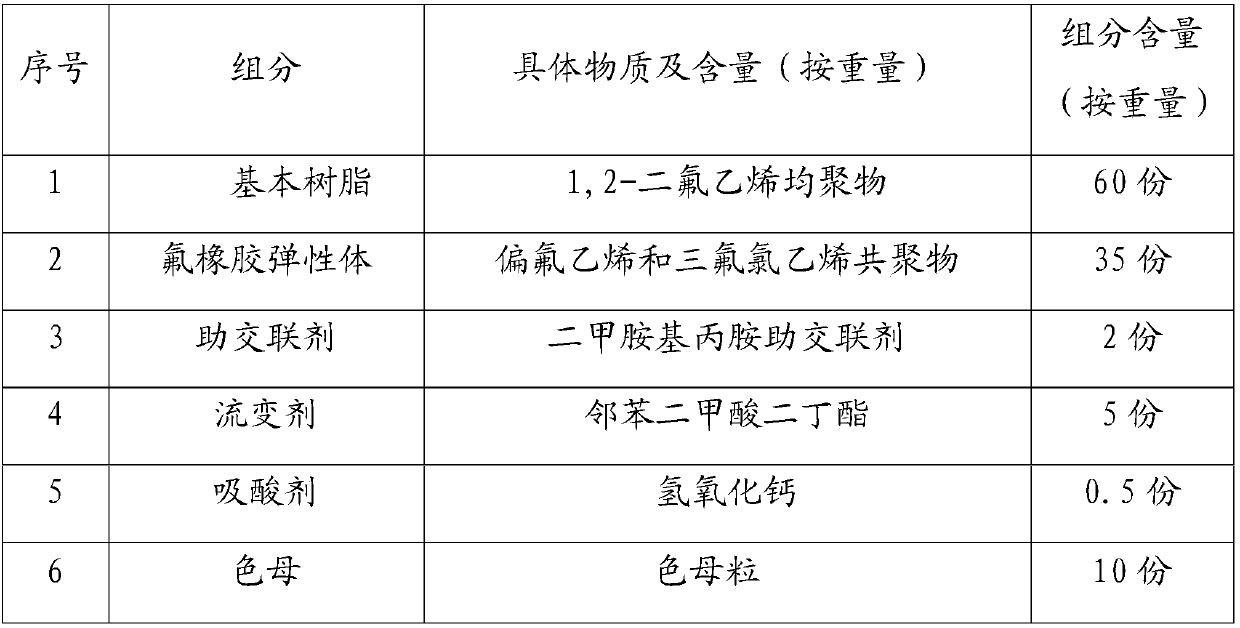

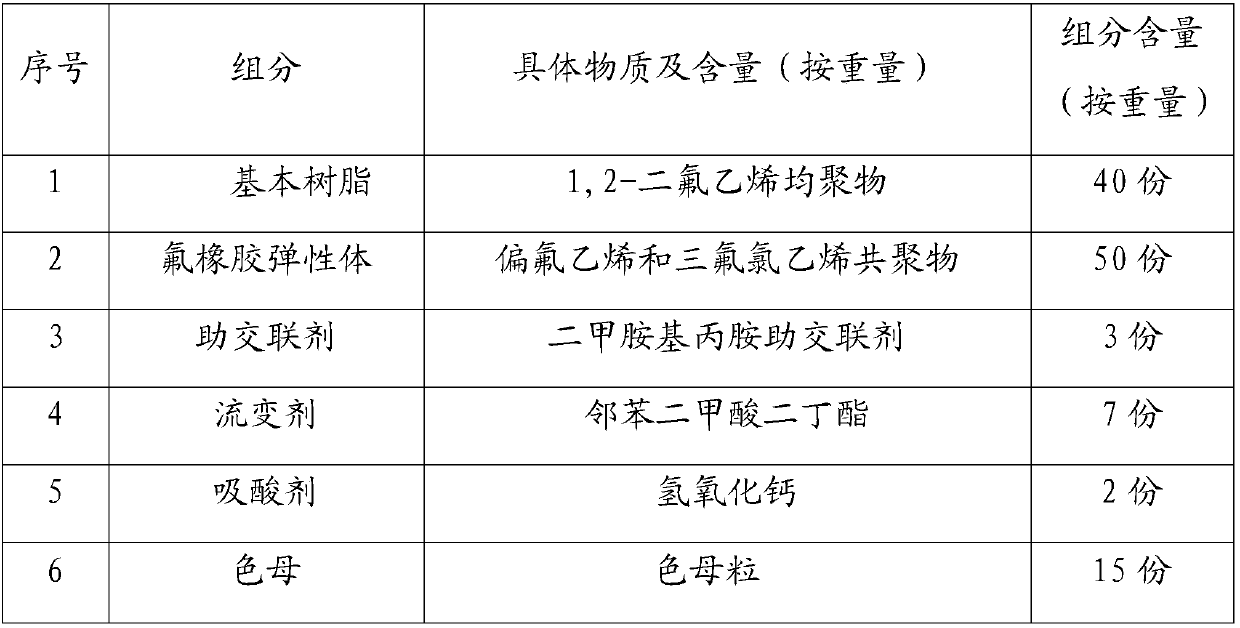

Fluoroplastic electric wire and cable and preparation method thereof

InactiveCN108047612AGood flame retardantImprove corrosion resistancePlastic/resin/waxes insulatorsElastomerHexafluoropropylene

The invention provides a fluoroplastic electric wire and cable. The fluoroplastic electric wire and cable is prepared from the following components in parts by weight: 30 to 80 parts of basic resin, 15 to 50 parts of a fluororubber elastomer, 2 to 5 parts of an auxiliary crosslinking agent, 3 to 8 parts of a rheological agent, 0.5 to 2 parts of an acid absorption agent and 5 to 20 parts of color master batch, wherein the basic resin is one or a mixture of two of the following substances: a 1,2-difluoroethylene homopolymer and a 1,2 difluoroethylene-hexafluoropropylene copolymer; the fluororubber elastomer is one or a mixture of more of the following substances: a vinylidene fluoride and chlorotrifluoroethylene copolymer, a vinylidene fluoride and hexafluoropropylene copolymer, and a tetrafluoroethylene, vinylidene fluoride and hexafluoropropylene terpolymer; the auxiliary crosslinking agent is one or a mixture of more of the following substances: tetrahydrophthalic anhydride, hexahydrophthalic anhydride, triethylenetetramine, dimethylaminopropylamine and diethylaminopropylamine. The fluoroplastic electric wire and cable, provided by the invention, is applicable to adverse environments with corrosive gas, heat engine cycle and mechanical stress effects.

Owner:CHANGYUAN ELECTRONICS DONGGUAN +4

High-strength carbon fiber enhanced boron nitride ceramic matrix composite and preparation method thereof

The invention discloses high-strength carbon fiber enhanced boron nitride ceramic matrix composite and a preparation method thereof. The high-strength carbon fiber enhanced boron nitride ceramic matrix composite is characterized by being prepared from raw materials in parts by weight as follows: 60-70 parts of boron nitride, 5-8 parts of iridium trioxide, 5-8 parts of hafnium carbide, 8-12 parts of manganese powder, 10-14 parts of modified high-elastic carbon fiber, 0.03-0.05 parts of ammonium persulfate, 5-7 parts of acrylic acid, 0.3-0.5 parts of dimethylaminopropylamine, 10-12 parts of light calcium carbonate, 2-3 parts of chitosan, 20-30 parts of ethanol and 40-60 parts of deionized water. With modified high-strength carbon fiber as an enhancing phase, the high-strength carbon fiber enhanced boron nitride ceramic matrix composite has the advantages of excellent oxidation resistance, improvement of ceramic toughness and strength, high-temperature and low-temperature resistance, good thermal conductivity and small expansion coefficient; the surface of a blank body is coated with the added iridium trioxide and hafnium carbide, and accordingly, the sintering performance is improved.

Owner:安徽省含山瓷业股份有限公司

Mink oil betaine surfactant and preparation method thereof

InactiveCN111569775AChange structureExpand the types of surfactantsOrganic compound preparationTransportation and packagingSodium chloroacetateActive agent

The invention discloses a mink oil betaine surfactant and a preparation method thereof, and belongs to the technical field of surfactants, colloids and interface chemistry. The preparation method of the betaine type surfactant comprises the following steps of: (1) carrying out amidation reaction on mink oil and 3-dimethylaminopropylamine to obtain mink oil amide propyl dimethyl tertiary amine; and(2) carrying out quaternization reaction on the mink oil amide propyl dimethyl tertiary amine and sodium chloroacetate to obtain the mink oil betaine surfactant. The molecular structure of the surfactant disclosed by the invention takes long-chain alkyl of mink oil as a hydrophobic group and a betaine characteristic group, so that the performance of the mink oil is improved; the surfactant has better foam stability and mild performance; the emulsifying property of the surfactant is obviously superior to that of a dodecyl betaine surfactant; and the surfactant has good biocompatibility. The preparation method is simple; and the raw materials are natural and green.

Owner:JIANGNAN UNIV +1

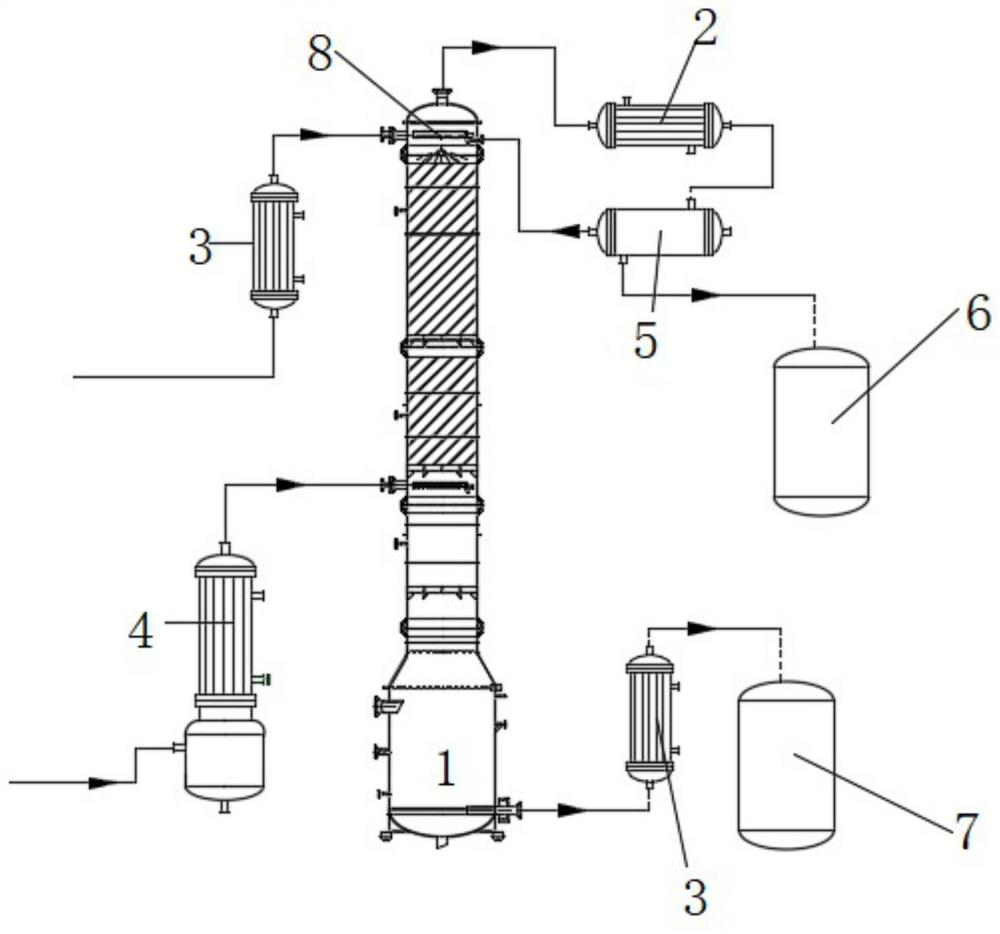

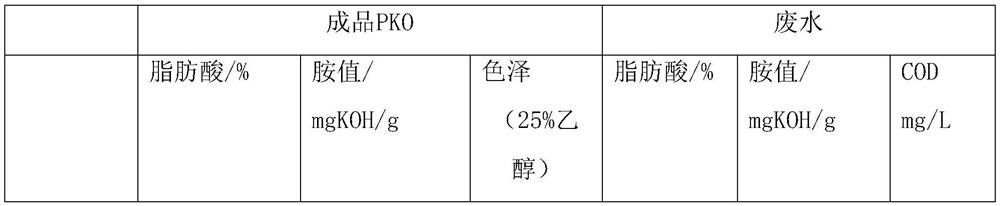

Low-impurity fatty acid amide propyl tertiary amine production process and device

PendingCN112495315ALow fatty acid contentWell mixedOrganic compound preparationDistillation regulation/controlPropylamineFatty acid amide

The invention relates to a low-impurity fatty acid amide propyl tertiary amine production process and device capable of reducing cost and shortening the production cycle. Gas dimethylaminopropylamineand liquid fatty acid are subjected to a gas-liquid two-phase reaction and sequentially pass through a heater and an atomizer to become mist; dimethylaminopropylamine is used for uniformly distributing gas in the rectifying tower through the porous distributor, methylaminopropylamine gas penetrates through the rectifying tower from bottom to top and is in rapid contact with atomized fatty acid, the gas-liquid two-phase continuous countercurrent contact strengthens the mass transfer process, and the amidation reaction is greatly promoted. According to the invention, the materials in the rectifying tower depend on the special structures of the units and the fluid motion, so that the fluids are respectively dispersed and mutually mixed, a good mixing effect is achieved, the production periodis obviously shortened, and the production of PKO products with low fatty acid content is facilitated; the problem of dimethylaminopropylamine wastewater discharge is avoided, clean production of fatty acid amide propyl tertiary amine is truly realized, the production period is shortened, the production cost is reduced, and the like.

Owner:ZANYU TECH GRP CO LTD +1

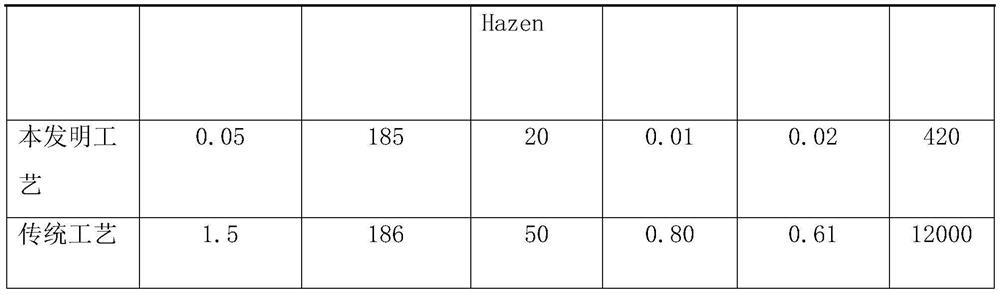

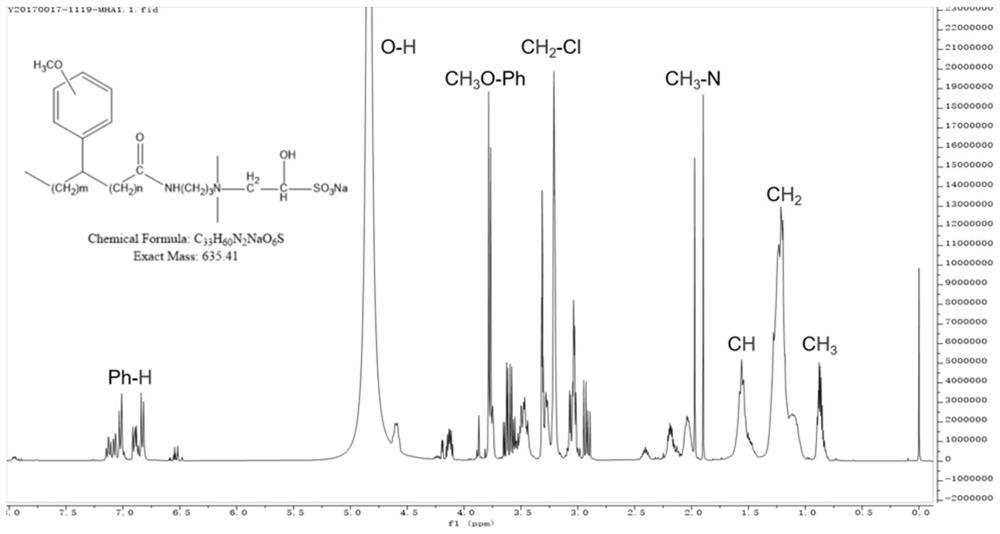

Benzyl methoxy-oleoyl quaternary ammonium surfactant as well as preparation method and application thereof

ActiveCN113930249AImprove salt resistanceGreat application potentialOrganic compound preparationTransportation and packagingActive agentAqueous ethanol

The invention relates to a benzyl methoxy-oleoyl quaternary ammonium surfactant as well as a preparation method and application thereof, wherein the structural formula of the surfactant is represented by a formula (I) or a formula (II), m is equal to 0-11, n is equal to 4-15, and m+n is equal to 15. The preparation method comprises the steps: firstly, mixing fatty acid, anisole and FeCl3, and carrying out alkylation reaction; then mixing the product with 3-dimethylaminopropylamine, and carrying out amidation reaction; and finally, mixing the obtained intermediate product with chlorinated organic acid salt and sodium carbonate in an ethanol / aqueous solution, and carrying out quaternization reaction to obtain the surfactant. Compared with the prior art, oleic acid obtained from animals and plants and anisole extracted from fennel are adopted to replace benzene as raw materials, traditional phenyl octadecanoic acid is subjected to structure optimization, and after alkylation reaction, amidation reaction and quaternization reaction are sequentially carried out, the minimum oil-water interfacial tension of the obtained surfactant can reach 5*10 <-4> mN / m, and the surfactant has great application potential in the tertiary oil recovery industry.

Owner:EAST CHINA UNIV OF SCI & TECH

Anti-oxidation bonding copper wire and preparation method thereof

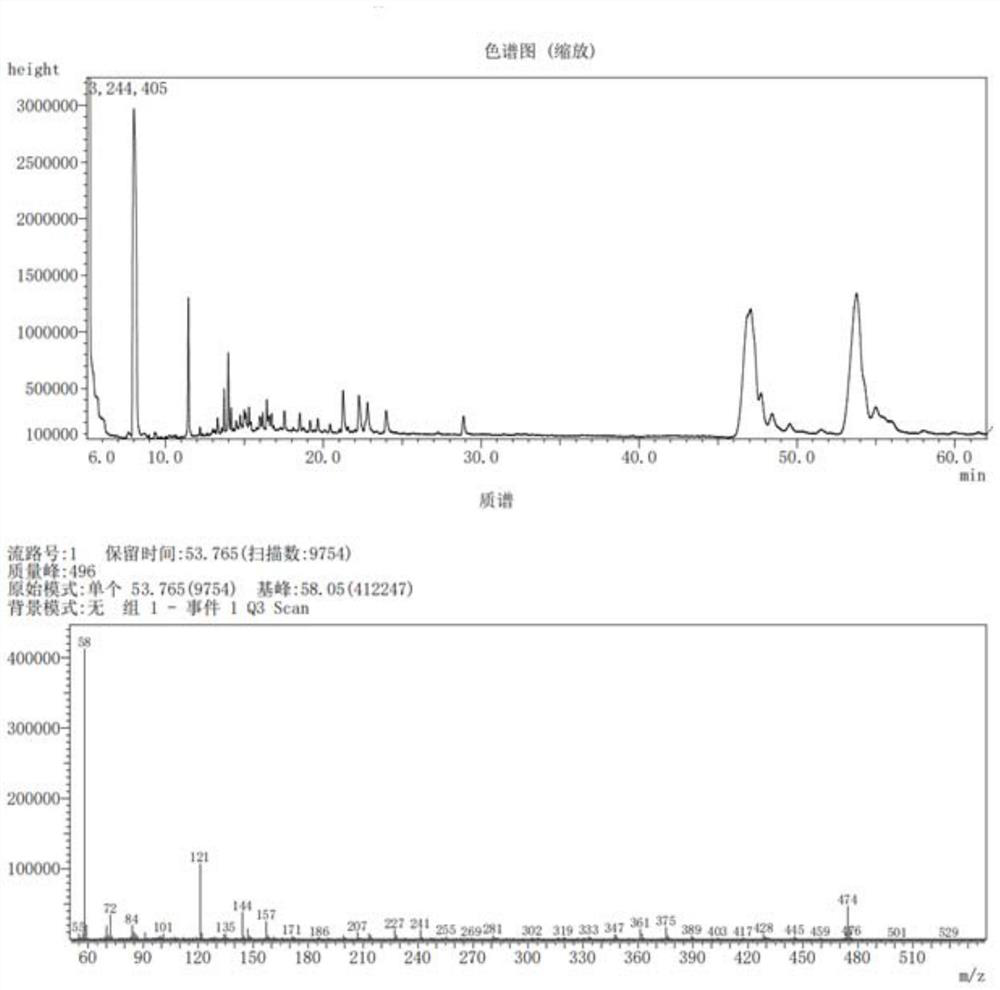

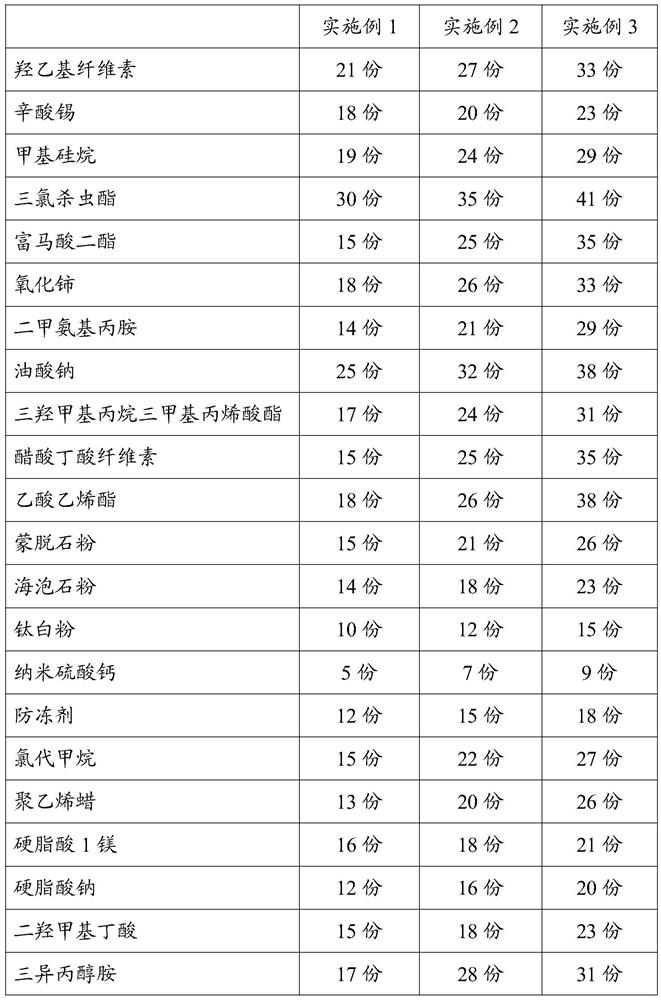

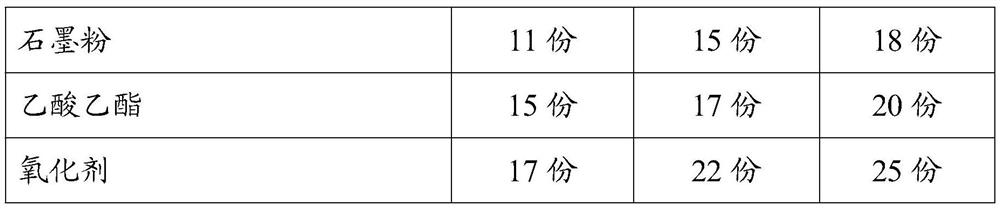

The invention discloses an anti-oxidation bonding copper wire, wherein the anti-oxidation bonding copper wire comprises a bonding copper wire and an anti-oxidation coating layer coated on the outer wall of the bonding copper wire. A formula of the anti-oxidation coating layer comprises the components in parts by weight: 21 to 33 parts of hydroxyethyl cellulose, 18 to 23 parts of tin octanoate, 19 to 29 parts of methylsilane, 30 to 41 parts of trichloro insecticidal ester, 15 to 35 parts of diester fumarate, 18 to 33 parts of cerium oxide, 14 to 29 parts of dimethylaminopropylamine, 25 to 38 parts of sodium oleate, 17 to 31 parts of trimethylolpropane trimethacrylate, 15 to 35 parts of cellulose acetate butyrate, 18 to 38 parts of vinyl acetate, 15 to 26 parts of montmorillonite powder, 14 to 23 parts of sepiolite powder, 10 to 15 parts of titanium dioxide, 5 to 9 parts of nano calcium sulfate, 12 to 18 parts of an anti-freezing agent, 15 to 27 parts of chloromethane, 13 to 26 parts of polyethylene wax, 16 to 21 parts of magnesium stearate and 12 to 20 parts of sodium stearate. The surface of the bonding copper wire is coated with the anti-oxidation coating layer through a laser melting method, the anti-oxidation performance of the bonding copper wire is further improved, and thus it is guaranteed that the bonding copper wire is not prone to oxidation in the storage, transportation and use processes.

Owner:SHENZHEN ZHONGBAO NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com