Acrylic resin paint for ultraviolet-resistant copper sculptures

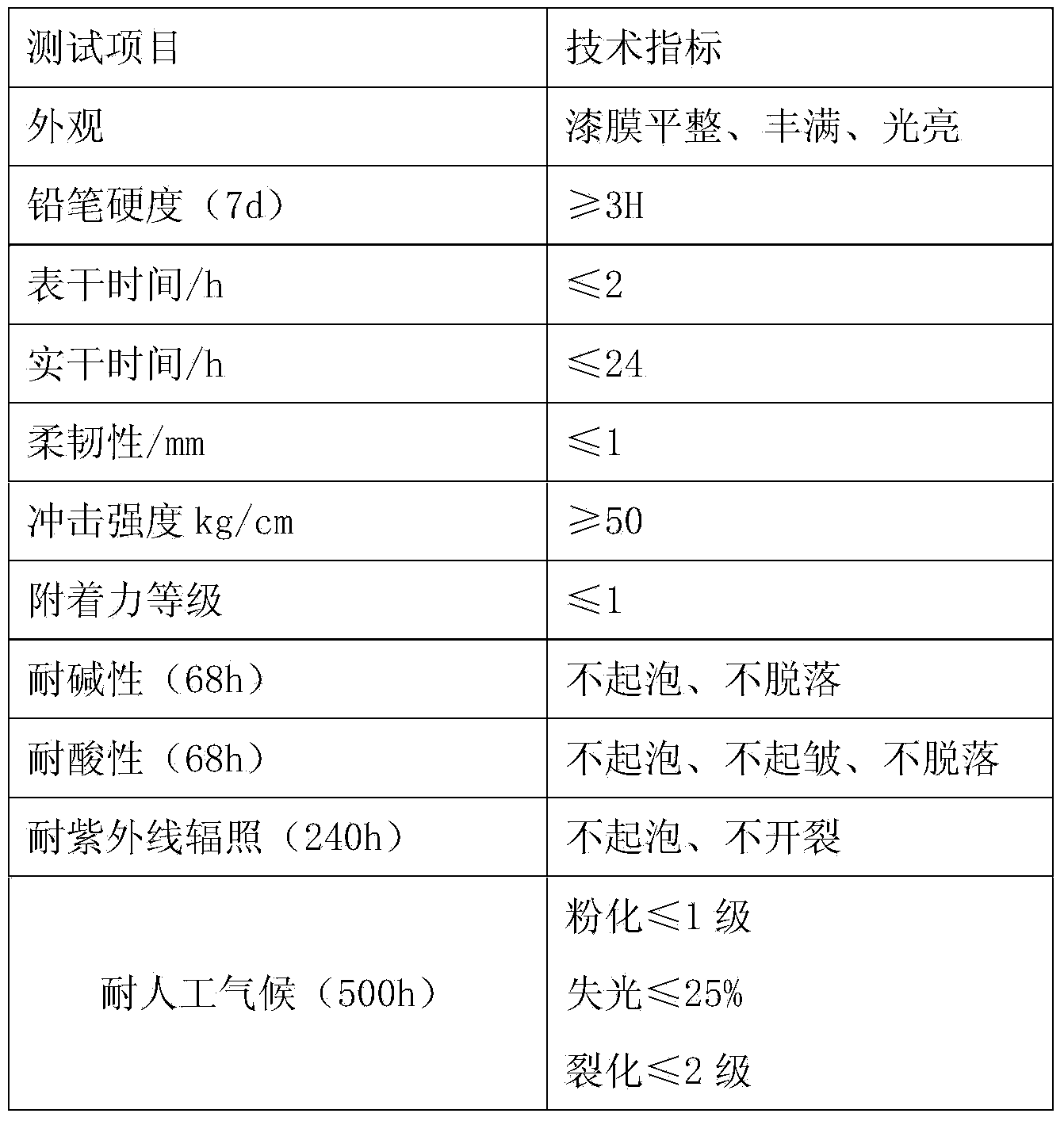

An acrylic resin and UV-resistant technology, applied in the field of paint, can solve the problems of easy oxidation and corrosion, affecting the appearance and service life, etc., and achieve the effects of UV aging resistance, stable properties and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0012] The paint of this embodiment is made of the following raw materials in parts by weight: nano cerium dioxide 3, potassium silicate 4, lithium silicate 2, acrylic resin 34, copper citrate 2, 2-aminoethyl heptadecenyl imidazoline 2, Tripropylene glycol diacrylate 12, phenyl glycidyl ether 2, propenyl glycidyl ether 6, vinyl triethoxysilane 3, accelerator Na-221, tetrabutyl titanate 3, isophorone 2 Amine 2, trimethylolpropane triacrylate 12, dicumyl peroxide 2, dimethylaminopropylamine 6, additive 6, xylene 12, butyl acetate 12.

[0013] The auxiliary agent is made of the following raw materials in parts by weight: clay 12, diatomite 4, jade 3, sepiolite 3, accelerator DTDM2, crosslinking agent TAC3, sodium sebacate 2, alkylphenol polyoxygen Vinyl ether 5, sodium tripolyphosphate 2, glycerol triacetate 40, vanadium diboride 2, propyl gallate 2, barley oil 3, epicatechin 2; the preparation method is to mix clay, diatomaceous earth, jade 1. Put the sepiolite into the calcina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com