Zwitterionic hydrophobic modified guar gum and preparation method thereof

An anionic guar gum and hydrophobic modification technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of unfavorable rapid liquid preparation, reduced solubility, singleness, etc., and achieve increased viscosity and durability Temperature and salt resistance, good dispersibility, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

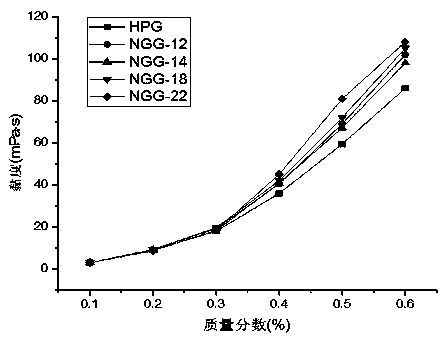

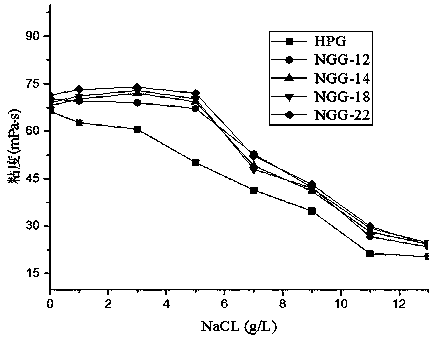

Embodiment 1

[0041] (1) 85% ethanol aqueous solution is packed in the flask; 20g guar gum is added in the flask under stirring state, and the temperature is set as 60 ℃, add 1.2g triethylamine, stir 20-30min evenly; 4.8g Slowly add maleic anhydride into the flask, stir evenly, and react for 3-5 hours to obtain anionic guar gum.

[0042] (2) In the three-necked flask, nitrogen gas was passed for 10min; n-dodecanoic acid and 3-dimethylaminopropylamine were added to the flask according to the molar ratio of 1:1.1; in the flask, 0.5wt% KOH solution was added dropwise, and the temperature increased After reacting for 6 hours at 120°C, unreacted amine and generated water were distilled off under reduced pressure to obtain a tertiary amine product. Add absolute ethanol as solvent to a single-necked flask, raise the temperature to 70°C, then add the hydrophobic chain to epichlorohydrin in a molar ratio of 1:1.1 to the flask, install a reflux tube, react for 10 hours, and then remove the solvent by...

Embodiment 2

[0045] (1) The preparation method of anionic guar gum is as in Example 1.

[0046] (2) Nitrogen 5min is passed in the three-necked flask, and n-tetradecanoic acid and 3-dimethylaminopropylamine are added into the flask according to a molar ratio of 1:1.1; 0.5wt% KOH solution is added dropwise in the flask, and the temperature rises After reacting for 6 hours at 170°C, unreacted amine and generated water were distilled off under reduced pressure to obtain a tertiary amine product. Add absolute ethanol as solvent to a single-necked flask, raise the temperature to 70°C, then add the hydrophobic chain to epichlorohydrin in a molar ratio of 1:1.1 to the flask, install a reflux tube, react for 10 hours, and then remove the solvent by rotary distillation. Intermediate N-14 was obtained as a brown paste.

[0047] (3) Take an appropriate amount of 85% ethanol water 4 solution and put it into a flask, weigh 40 g of guar gum maleate derivative, add it into the flask, stir evenly, and wa...

Embodiment 3

[0049] (1) The preparation method of anionic guar gum is as in Example 1.

[0050] (2) In the three-necked flask, nitrogen gas was passed for 10min; oleic acid and 3-dimethylaminopropylamine were added to the flask according to the molar ratio of 1:1.1; in the flask, 0.5wt% KOH solution was added dropwise, and the temperature was raised to 160 °C, after reacting for 6 hours, unreacted amine and generated water were distilled off under reduced pressure to obtain a tertiary amine product. Add absolute ethanol as solvent to a single-necked flask, raise the temperature to 70°C, then add the hydrophobic chain to epichlorohydrin in a molar ratio of 1:1.1 to the flask, install a reflux tube, react for 10 hours, and then remove the solvent by rotary distillation. Intermediate N-18 was obtained as a brown paste.

[0051] (3) Take an appropriate amount of 85% ethanol aqueous solution and put it into a flask, weigh 40 parts of guar gum maleate, add it into the flask, stir evenly, and wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com