Wear-resistant wood plastic floor and its production technology

A technology of wood-plastic flooring and production technology, which is applied in the field of decoration and decoration materials, can solve the problems of low mechanical properties, short service life, poor water resistance, and poor wear resistance, and achieve the effect of excellent weather resistance, corrosion resistance, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

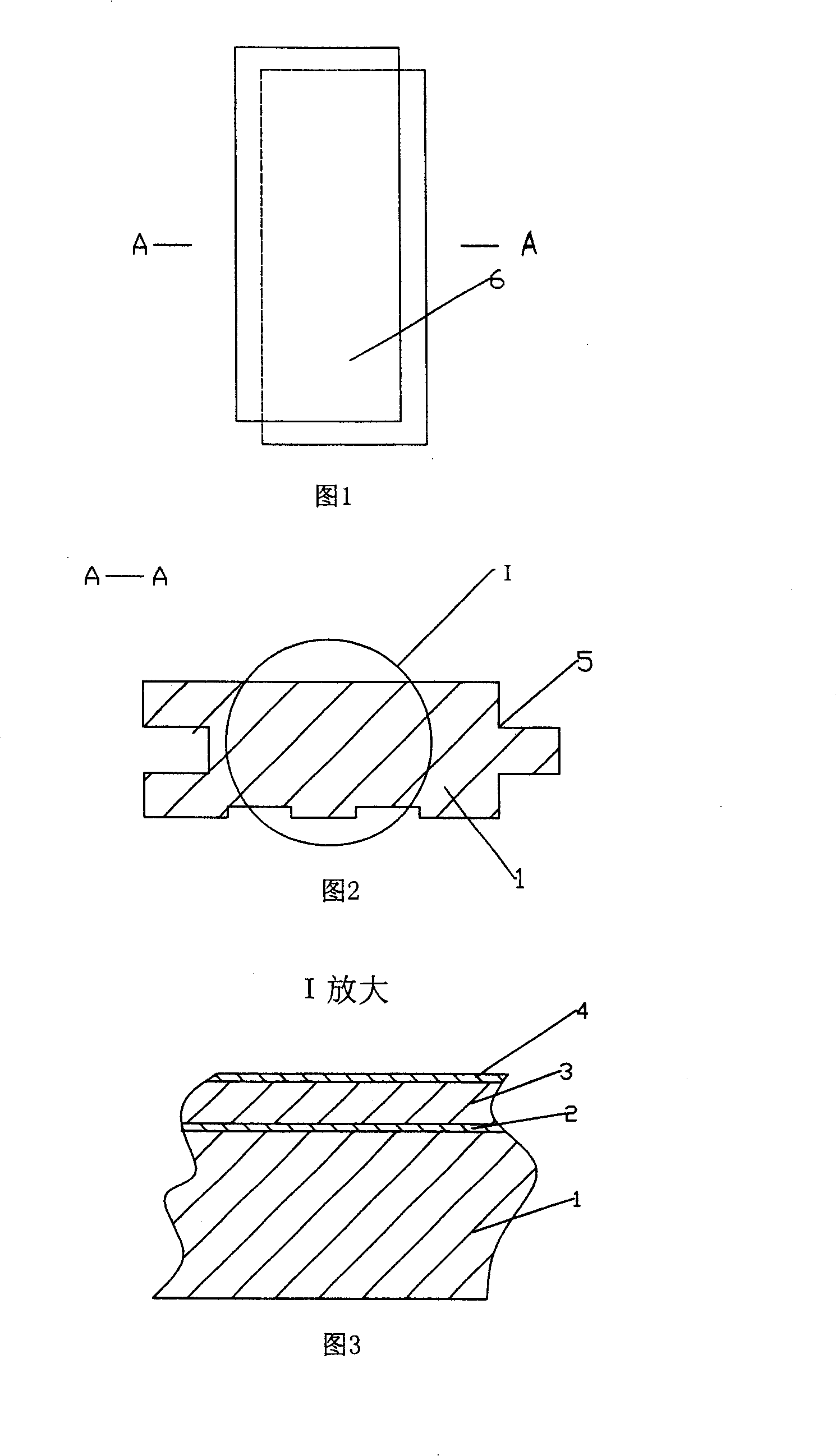

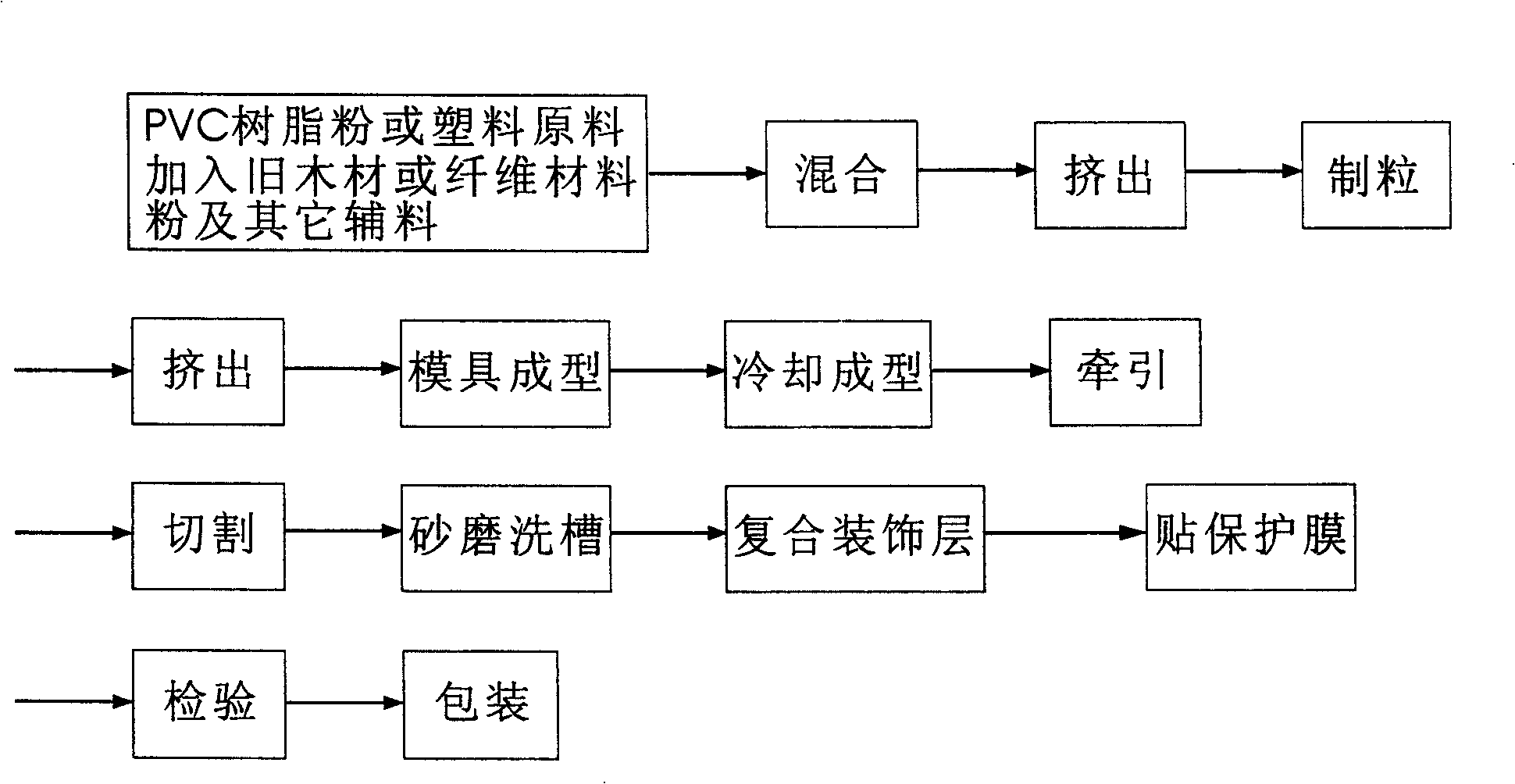

[0038] Embodiment 1: The production process steps of the wear-resistant wood-plastic floor in the embodiment of the present invention are as follows:

[0039] 1. Mixing and granulation of main and auxiliary materials of wood-plastic floor substrate:

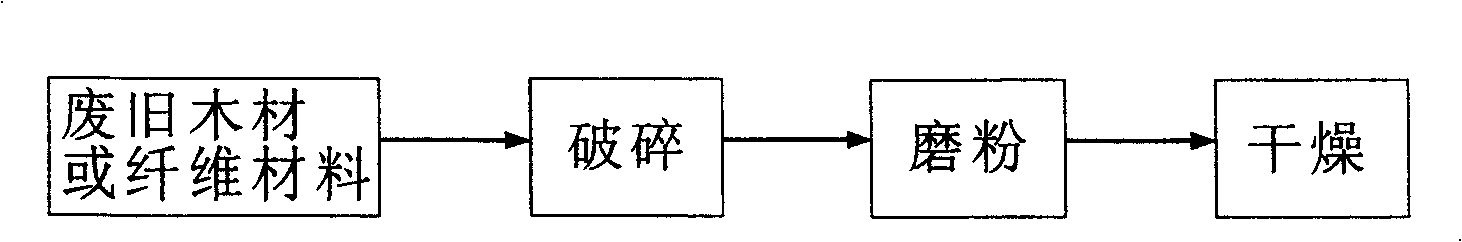

[0040] First, the waste wood is crushed with sawdust and ground into waste wood sawdust powder with a fineness of 200 mesh; it is naturally dried and ready for use;

[0041] Get polyvinyl chloride (PVC) resin powder: 35% by weight, add waste wood sawdust powder: 40% by weight, active calcium carbonate (stone powder): 11% by weight, plastic reinforcing agent selects chlorinated polyethylene (CPE) for use Azodicarbonamide: 5% by weight, calcium carbonate (stone powder) as plastic filler: 3% by weight, AC foaming agent as plastic processing aid: 6% by weight, mixed at high speed, mixing temperature: 100°C , mixing time, 10 minutes, speed: 100 rpm; extruded into wood plastic granules through an extrusion mixer, temperature: 160 ° C,...

Embodiment 2

[0048] 1. Mixing and granulation of main and auxiliary materials of wood-plastic floor substrate:

[0049] First, the waste fiber material is crushed with grain straw (water content reaches 12-14%), and ground into waste grain straw powder with a fineness of 350 mesh; it is naturally dried and ready for use;

[0050] Get plastic raw material PE in the embodiment of the present invention: 45% by weight, add waste grain stalk powder: 30% by weight, active calcium carbonate (stone powder): 13% by weight, plastic reinforcing agent selects methyl methacrylate copolymer ( ACR) is: 4% by weight, calcium carbonate (stone powder) is selected as plastic filler: 2% by weight, foam regulator is selected as plastic processing aid: 6% by weight, mixed at high speed, mixing temperature: 110 ° C, mixing time , 13 minutes, speed: 110 rpm; extruded into wood plastic pellets through the extrusion mixer, temperature: 190 ° C, screw speed: 35 rpm;

[0051] 2. Production of wood-plastic floor substr...

Embodiment 3

[0056] 1. Mixed granulation of main and auxiliary materials of wood-plastic floor substrate:

[0057] First, the waste wood is crushed with wood twigs (water content reaches 12-14%), and ground into waste wood twig powder, the fineness reaches 500 mesh; natural drying, stand-by;

[0058] Get the plastic raw material PP in the embodiment of the present invention: 55% by weight, add wood branch powder: 20% by weight, active calcium carbonate (stone powder): 15% by weight, plastic reinforcing agent selects chlorinated polyethylene (CPE) as: 3% by weight, wood fiber powder as plastic filler: 1% by weight, calcium stearate as 6% by weight as plastic processing aid, mixed at high speed, mixing temperature: 120°C, mixing time, 15 minutes, rotating speed: 120 revolutions per minute; extruded into wood-plastic granules through the extrusion mixer, the temperature is: 200 ° C, the screw speed is: 40 revolutions per minute;

[0059] 2. Production of wood-plastic floor substrate:

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com