Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Not afraid of moths" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wear-resistant wood plastic floor and its production technology

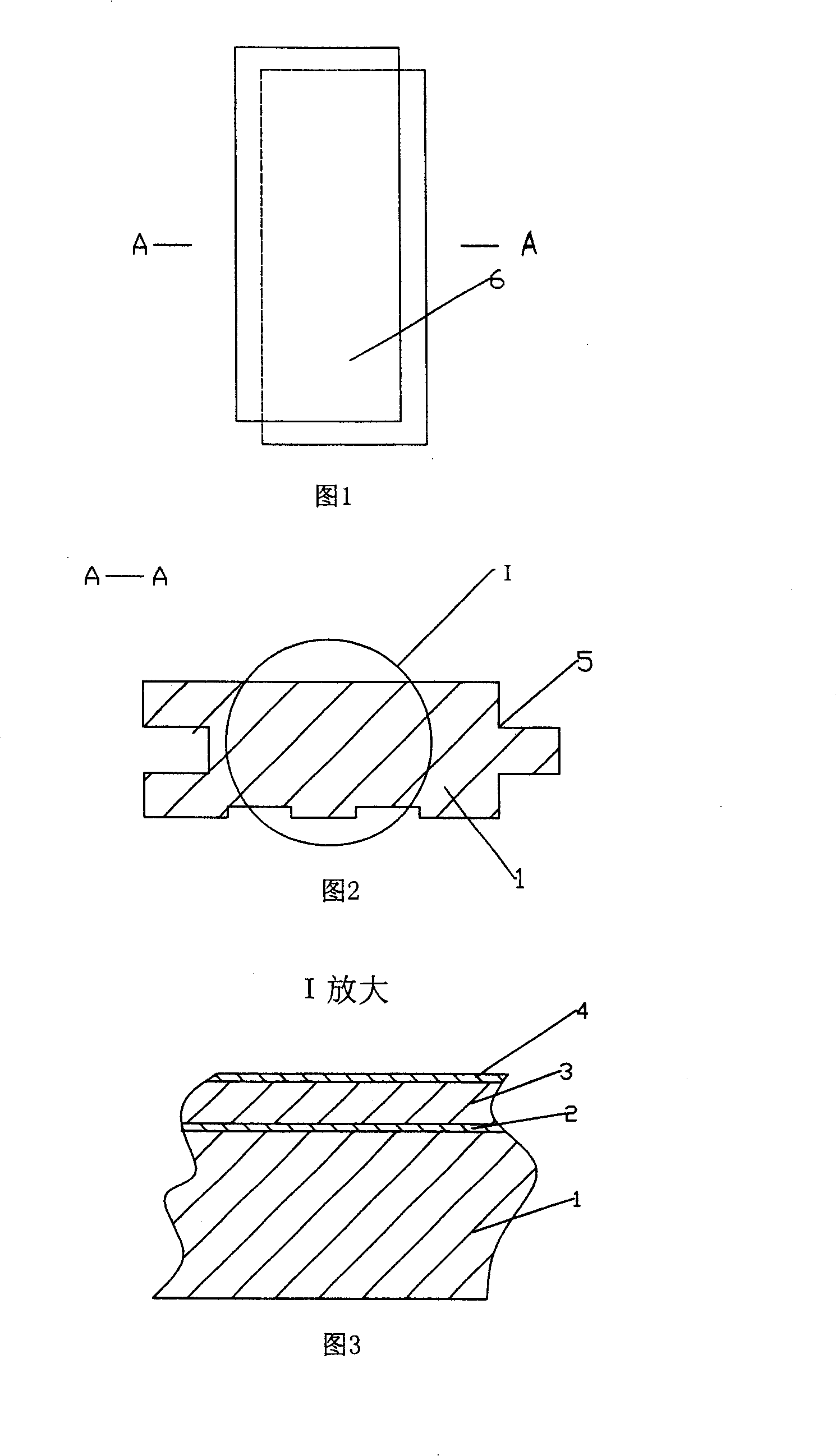

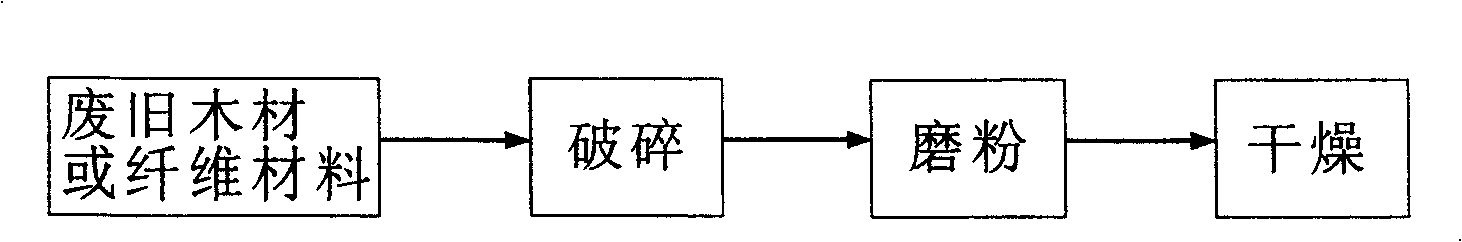

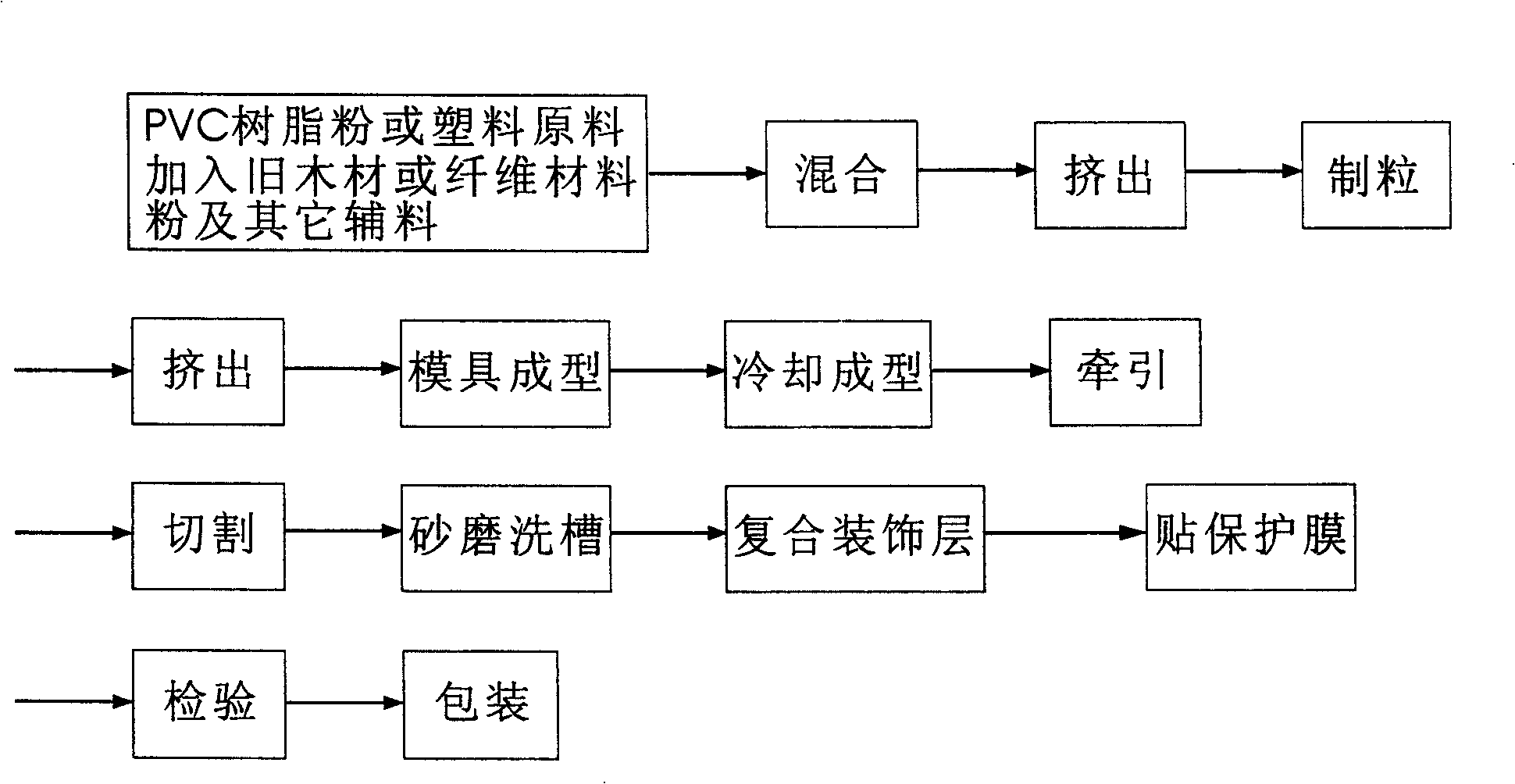

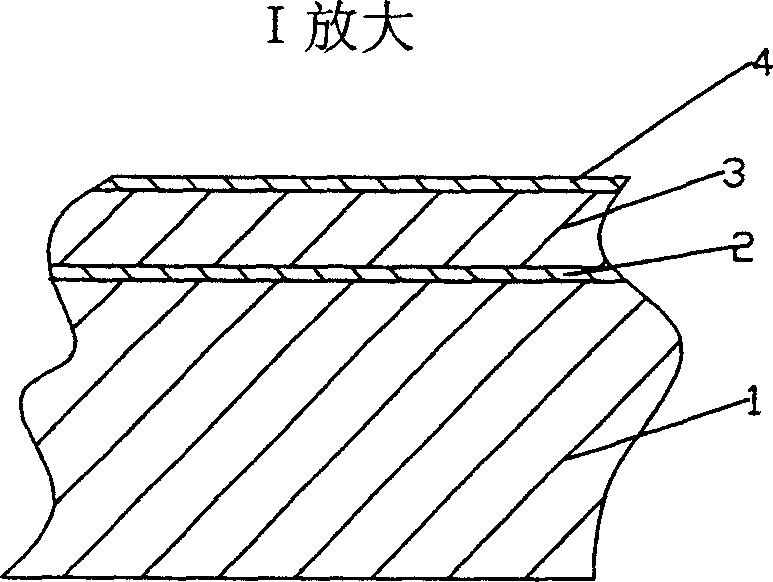

The present invention is wear-resistant wood-plastic floor board and its production process, and belongs to the field of decoration material technology. Polyvinyl chloride resin or plastic material is added with waste wood powder or fiber material powder, active calcium carbonate, assistant, stuffer, etc, and the mixture is pelletized, and further treated through extruding, molding, vacuum cooling, settling, drawing and cutting to form the basic wood-plastic board. The basic wood-plastic board is polished, groove milled and covered with surface decoration layer to form the wear resistant wood-plastic floor board product. The wear resistant wood-plastic floor board is beautiful, wear resistant, fireproof, waterproof, non-skid, anticorrosive and environment friendly and has high strength, heat insulation, electrical insulation and other advantages.

Owner:无锡市中德装饰新材料有限公司

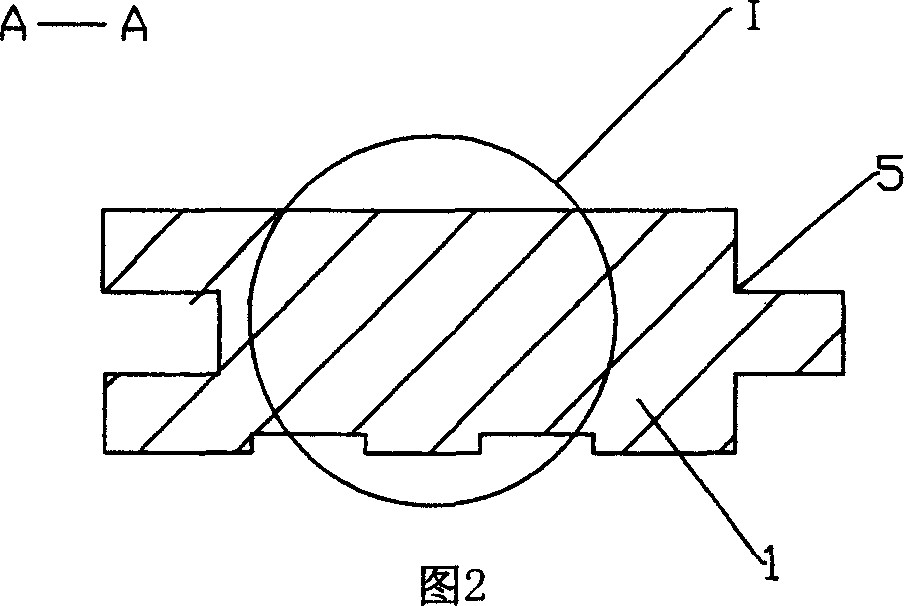

Wear-resistant wood plastic floor and its production technology

The present invention is wear-resistant wood-plastic floor board and its production process, and belongs to the field of decoration material technology. Polyvinyl chloride resin or plastic material is added with waste wood powder or fiber material powder, active calcium carbonate, assistant, stuffer, etc, and the mixture is pelletized, and further treated through extruding, molding, vacuum cooling, settling, drawing and cutting to form the basic wood-plastic board. The basic wood-plastic board is polished, groove milled and covered with surface decoration layer to form the wear resistant wood-plastic floor board product. The wear resistant wood-plastic floor board is beautiful, wear resistant, fireproof, waterproof, non-skid, anticorrosive and environment friendly and has high strength, heat insulation, electrical insulation and other advantages.

Owner:无锡市中德装饰新材料有限公司

Wear resistant type plastic floor and its production technology

ActiveCN1903926AGood mechanical propertiesExcellent weather and corrosion resistanceFlat articlesSpecific gravityWear resistant

The present invention relates to an abrasion-resistant plastic floor board and its production process. Said process includes the following steps: using waste and old plastic powder as main raw material, adding active calcium carbonate and plastic filling agent as auxiliary raw material, mixing them and extruding them to obtain plastic foamed granules, die-pressing and forming, cooling, setting, drawing and cutting so as to obtain the invented plastic base plate, then sticking plastic protection film on its surface, so that the invented plastic floor board finished product can be made up.

Owner:无锡市中德装饰新材料有限公司

Method for producing wear resistant type plastic floor

ActiveCN100462398CImprove wear resistanceStrong fire resistanceFlat articlesTectorial membraneAdhesive

The present invention relates to an abrasion-resistant plastic floor board and its production process. Said process includes the following steps: using waste and old plastic powder as main raw material, adding active calcium carbonate and plastic filling agent as auxiliary raw material, mixing them and extruding them to obtain plastic foamed granules, die-pressing and forming, cooling, setting, drawing and cutting so as to obtain the invented plastic base plate, then sticking plastic protection film on its surface, so that the invented plastic floor board finished product can be made up.

Owner:无锡市中德装饰新材料有限公司

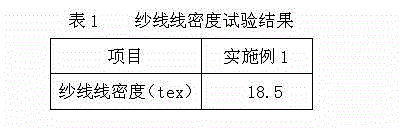

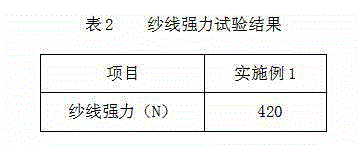

Blended yarn of terylene, rabbit hair and silkworm pupa protein fiber

The invention provides blended yarn of terylene, rabbit hair and silkworm pupa protein fiber. The blended yarn comprises the following components: 65-75 weight parts of terylene, 25-35 weight parts of rabbit hair and 10-20 weight parts of silkworm pupa protein fiber. The blended yarn provided by the invention enables the characteristics of terylene, rabbit hair and silkworm pupa protein fiber to be complementary and brings the advantages thereof into play.

Owner:HAIAN COUNTY BROS SYNTHETIC FIBER

Terylene, bamboo fiber and milk protein fiber blended yarn

The invention provides a terylene, bamboo fiber and milk protein fiber blended yarn which comprises the following components in parts by weight: 55-65 parts of terylene, 20-30 parts of bamboo fiber, and 10-20 parts of milk protein fiber. According to the blended yarn provided by the invention, the characteristics of the terylene, the bamboo fiber and the milk protein fiber are integrated, so as to play the advantages of the the terylene, the bamboo fiber and the milk protein fiber.

Owner:HAIAN COUNTY BROS SYNTHETIC FIBER

Bamboo fiber, viscose and polyester fiber blended yarn

The invention provides a bamboo fiber, viscose and polyester fiber blended yarn. The bamboo fiber, viscose and polyester fiber blended yarn comprises, by weight percent, 30% of bamboo fiber, 15% of viscose and 55% of polyester fiber. The bamboo fiber, viscose and polyester fiber blended yarn has the advantages that the viscose is high in moisture absorption and soft to touch, has wet strength larger than dry strength, and is fine in dyeing property, soft in gloss, naturally attractive and alkali-proof; the bamboo fiber is antibacterial and capable of absorbing and releasing damp, removing peculiar odor and adsorbing, removing oil and dirt and preserving heat, and is soft, comfortable, fine in whiteness, bright in color, high in ductility and wear resistance, unique in rebound, high in longitudinal and transverse strength, uniform in stability and fine in drapability; the polyester fiber is high in strength and elastic recovery, solid and durable, anti-wrinkle and non-ironing, and is easy to dry after being washed, thermally plastic, fine in light fastness, sunlight resistance and chemicals resistance, and resistant to mould and insects; the blended yarn has complentary characteristics and advantages of the bamboo fiber, the viscose and the polyester fiber.

Owner:NANTONG SUZHONG TEXTILE

Blended yarn of terylene and glass fiber

The invention provides blended yarn of terylene and glass fiber. The blended yarn comprises the following components: 80-90 weight parts of terylene and 10-20 weight parts of glass fiber. The blended yarn enables the characteristics of terylene and glass fiber to be complementary and brings the advantages thereof into play.

Owner:HAIAN COUNTY BROS SYNTHETIC FIBER

Terylene and carbon fiber blended yarn

The invention provides a terylene and carbon fiber blended yarn which comprises the following components in parts by weight: 85-90 parts of terylene, and 10-15 parts of carbon fiber. According to the blended yarn provided by the invention, the characteristics of the terylene and the carbon fiber are integrated, so as to play the advantages of the terylene and the carbon fiber.

Owner:HAIAN COUNTY BROS SYNTHETIC FIBER

Reed plywood and its processing method

InactiveCN1552557ASimple processHigh strengthCane mechanical workingWood veneer joiningEngineeringWater soluble

A ply-reed used for building shuttering, non-bearing partition, packing material, or furniture is prepared from reed stalks through rolling for longitudinal breaking, cutting by needed size, automatically braiding reed curtain, immersing in water-soluble resin solution, removing excessive solution, baking, alternative laminating, and hot pressing.

Owner:褚宝顺

Method for manufacturing environment-friendly waterproof fiber board

InactiveCN105522638AGood processing performanceOvercoming poor durabilityFlat articlesDomestic articlesWater contentEmulsion

The invention discloses a method for manufacturing an environment-friendly waterproof fiber board. The method is technologically characterized in that prehydrolysis treatment is not conducted on raw materials, and hydrolysis and hot pressing of the raw materials are completed at a time in a hot pressing machine; the weight ratio of an activating agent is optimally set as 1.5%, the water content of a plate blank reaches 20%, the hot pressing temperature reaches 180 DEG C, hot pressing pressure reaches 5 Mpa, hot pressing time is 6 min, the quantity of paraffin emulsion reaches 1.0%, and limiting performance meets the national standard of medium-density fiber boards in GBT11718-2009. The product obtained by implementing the method can be sawn and nailed and is good in machinability, and the defects that natural wood is poor in durability, prone to combustion, damping, corrosion and moth biting and the like are overcome. The shortcomings of pure plastic are overcome. Compared with wood, the environment-friendly waterproof fiber board is good in isotropy, weather resistance and dimensional stability and has the advantages of being firm, tough, durable, resistant to abrasion and the like. In addition, the surface of the environment-friendly waterproof fiber board is easily decorated, the materials of the product can be degraded and recycled, and the product is good in environmental friendliness.

Owner:于金峰 +2

Production process of base cloth of polyester abrasive belt

The invention discloses a production process of a base cloth of a polyester abrasive belt. The production process comprises the following steps: firstly, carrying out a spinning process on polyester staple fibers to obtain polyester filament yarns; secondly, stretching a semi-finished base cloth, drying and sizing; and at last, cutting edges of the semi-finished base cloth, humidifying, pressurizing, heating and calendaring to obtain a finished product. According to the production process provided by the invention, cotton can be replaced by artificial chemical fiber polyester, and the polyester is subjected to special surface treatment, so that slashing and desizing processes in the conventional process are avoided, the size is saved, the manpower and material resources are saved, and meanwhile, the environmental pollution is reduced.

Owner:JIANGSU HUAYUE TEXTILE NEW MATERIAL TECH

Sealing braided base material for foodstuff processing machinery and method for preparing same

The invention discloses a sealing braided base material for foodstuff processing machinery. The base material comprises a core layer and a skin layer; the core layer employs continuous nylon fiber bundles; the skin layer employs nylon fiber yarn having a S-twist structure with the twist being 80-100; the skin layer is clockwise wound around the outer surface of the core layer; and the core layer is provided with a silane coupling agent and an antistatic agent. The invention also discloses a method for preparing the sealing braided base material for foodstuff processing machinery. The method comprises following steps: preparing a compound molding agent by the use of the silane coupling agent and the antistatic agent with the ratio being 1:1; soaking the continuous nylon fiber bundles in the compound molding agent for 3-5 minutes; preparing the nylon fiber yarn by the use of nylon fibers based on the S-twist structure with the twist being 80-100; and clockwise winding the nylon fiber yarn around the outer surface of the continuous nylon fiber bundles after the continuous nylon fiber bundles are soaked in the compound molding agent. According to the invention, a problem that nylon fibers are difficult to mold as the nylon fibers are high in elasticity is solved, and the sealing braided base material is ageing resistant, and is high in sealing performance and antibacterial performance.

Owner:DONGTAI HUAYANG GLASS FIBER

Dacron, coconut fiber and copper ammonia fiber blended yarn

The invention provides dacron, coconut fiber and copper ammonia fiber blended yarn comprising the following components in parts by weight: 50-60 parts of dacron, 10-20 parts of coconut fiber and 10-20 parts of copper ammonia fiber. According to the invention, the characteristics of the dacron, the coconut fiber and the copper ammonia fiber are complementary, and the advantages of the dacron, the coconut fiber and the copper ammonia fiber are exerted.

Owner:HAIAN COUNTY BROS SYNTHETIC FIBER

Preparation method of composite board

The invention relates to a preparation method of a composite board required by manufacturing industry of desks / chairs and furniture. The method comprises the steps of extrusion and hard compression at constant temperature. The method comprises the following steps: compositely and uniformly stirring and dehydrating PVC (polyvinyl chloride), wood meal, calcium powder and related materials in a high speed machine, sending into an extruding machine, heating to 180-230 DEG C in the extruding machine, carrying out foaming and extrusion, sending into a thermal insulation cabinet, and sending into a hydraulic machine mold, wherein a mold with required shape is arranged in the hydraulic machine, the mold pressure of the hydraulic machine is 300-2400 tons and is determined by the size of the product, and a quick refrigerating plant is arranged in the mold, so that the extruded mixture can be quickly cooled, molded and demolded. The composite board has the characteristics of high toughness, high hardness, worm resistance, corrosion resistance, moisture absorption resistance and no deformation, can be nailed or punched, can not be influenced when being put outdoors for three years, can be reutilized, is free of formaldehyde, can be used in middle and small desks / chairs and household kitchens, and has the advantages low cost, beautiful appearance and high quality.

Owner:GUANGZHOU LIANGJIAN STATIONERY CO LTD

Blended yarn of terylene and metal fiber

The invention provides blended yarn of terylene and metal fiber. The blended yarn comprises the following components: 85-95 weight parts of teylene and 5-15 weight parts of metal fiber. The blended yarn provided by the invention enables the characteristics of terylene and metal fiber to be complementary and brings the advantages thereof into play.

Owner:HAIAN COUNTY BROS SYNTHETIC FIBER

Dacron, aupoz fiber and acetate fiber blended yarn

The invention discloses a dacron, aupoz fiber and acetate fiber blended yarn which comprises, by weight, 45 to 55 parts of dacron, 15 to 25 parts of aupoz fibers and 15 to 25 parts of acetate fibers. According to the blended yarn, characteristics of dacron, aupoz fibers and acetate fibers are complementary and advantages are fully developed.

Owner:HAIAN COUNTY BROS SYNTHETIC FIBER

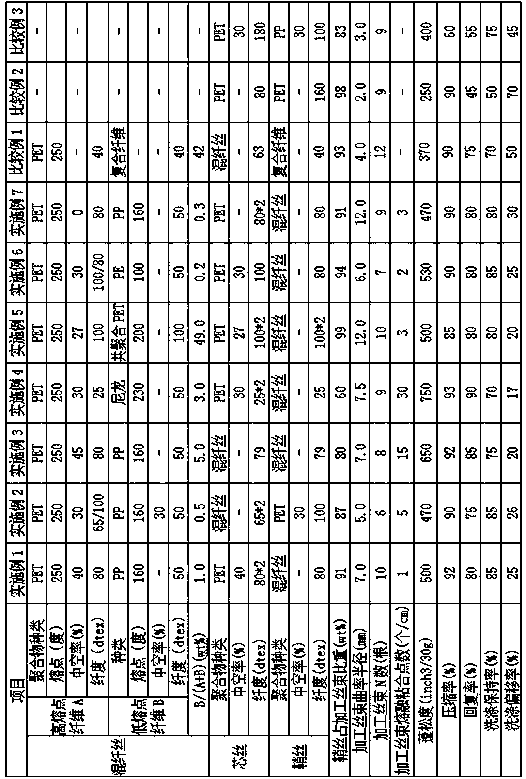

Core-sheath type bulked tow and preparation method thereof

The invention discloses a core-sheath type bulked tow. The tow contains N bulked yarns each of which is formed by a core yarn and a sheath yarn through air interlacing processing integration; at leastone of the core yarn and sheath yarn of the bulked yarn is combined yarn formed by high-melting-point fiber and low-melting-point fiber; and the bulked tow contains disperse melt bonding points, andN is greater than 1.The bulked tow disclosed by the invention has the advantages of good bulkiness, light weight and warmth keeping, soft and smooth handfeel and excellent resistance to machine washing, and can replace down to serve as filler.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Synthetic-wood board for decoration

The invention relates to a synthetic-wood board for decoration, which constitutes the following raw materials of 40-60 parts of wood powder, 12-16 parts of foaming agent, 0.8-1.3 parts of stearic acid, 1.1-1.6 parts of Tissuemat E, 100 parts of PVC resin, 26-32 parts of calcium powder, and 1.8-2.5 parts of colourment. According to the synthetic-wood board for decoration, continuous and stable microcellular foam can be achieved, high-speed extrusion is realized, the foam can be carried out at the lower temperature, therefore, the production cost is reduced, and the production efficiency is improved. The synthetic-wood board provided by the invention is economical, practical and environmentally-friendly, conforms to the requirements of the country on tensile strength, bending strength and the like of materials, and further has better performances of flame retardance, wear resistance and ageing resistance.

Owner:濮阳市东宝科技发展有限公司

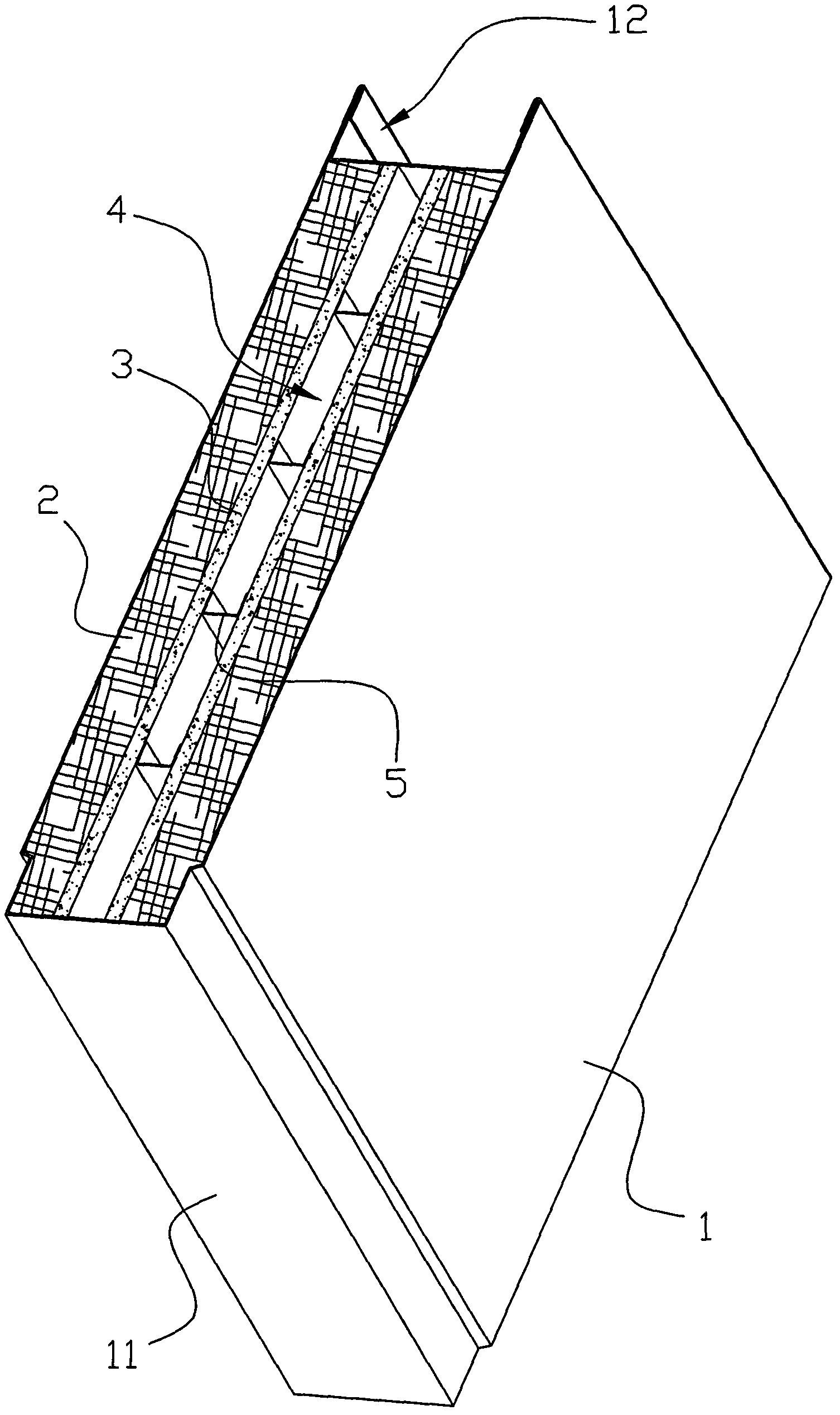

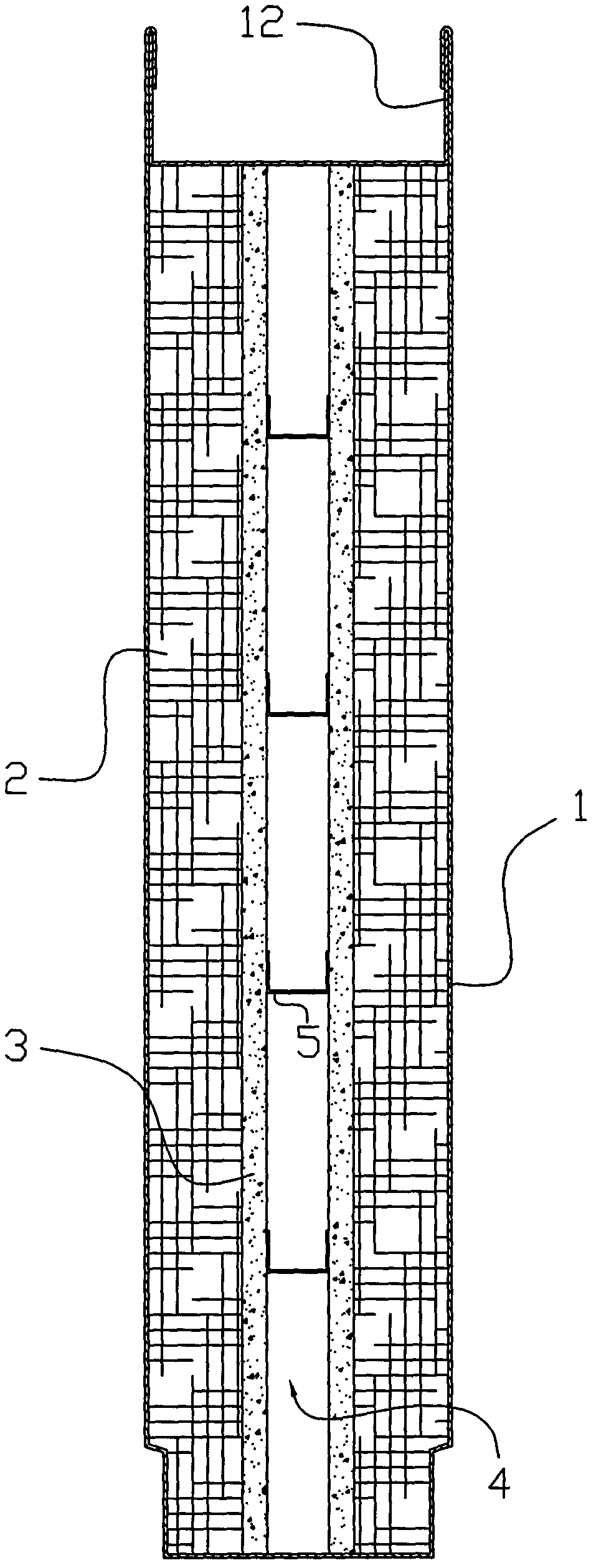

Decorative board with heat-insulating and sound-insulating performance

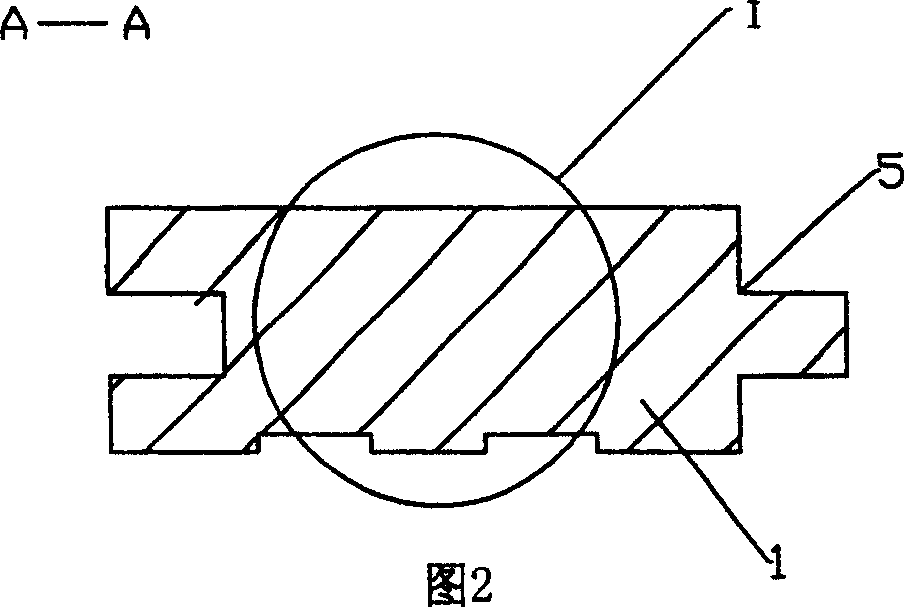

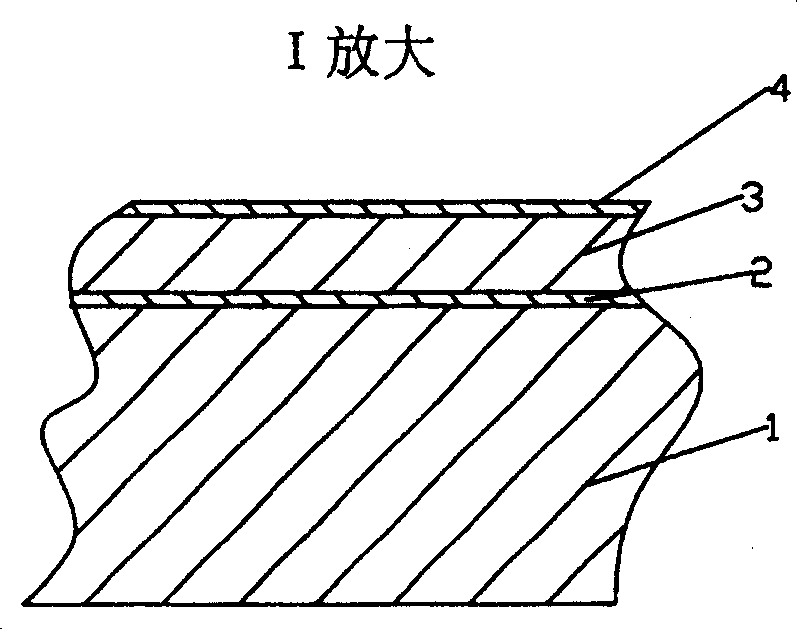

A decorative board with heat-insulating and sound-insulating performance comprises a board body which comprises an outer wrapping layer (1), rock wool board layers (2), carbonate silicon board layers (3) and a cavity layer (4). The carbonate silicon board layers (3) are arranged in the middle of the board body in a left-right interval manner, a spacing portion between the carbonate silicone board layers (3) on the left and on the right forms the cavity layer (4), the rock wool board layers (2) are arranged on the outer surfaces of the carbonate silicone board layers (3) on the left and on the right respectively , and the rock wool board layers (2) positioned on two sides of the cavity layer (4) are wrapped in the outer wrapping layer (1). The decorative board with the heat-insulating sound-insulating performance has the advantages that rock wool boards and carbonate silicon boards are adopted, so that the decorative board is light in weight, moistureproof, good in fireproof performance, convenient to construct, good in processing performance, capable of being sawed and nailed, less prone to warping and cracking, mothproof and free of heat generation, has good heat-insulating and sound-insulating performance and can meet using requirements of buildings and related decorative places. Especially due to good fireproof performance, under the circumstance of accidents, the decorative board can effectively prevent flame from spreading, so that good safety effect is realized.

Owner:舟山市金海舟船舶设备有限公司

Preparation procedure of high-strength environment-friendly polyester abrasive belt base cloth

InactiveCN105386202AControl the quality of the weaving beamUniform tensionWoven fabricsYarnPolyesterFiber

The invention discloses a preparation procedure of high-strength environment-friendly polyester abrasive belt base cloth and relates to the technical field of textiles. A preparation method comprises the steps of classifying, cleaning and pulverizing waste drink bottles through a crusher, heating the waste drink bottles to the melting point for preparing melt, extruding the melt out of spinneret orifices with a metering pump through a screw extrusion machine, condensing the melt in air for forming fine strips, processing polyester staple fibers through a spinning procedure, obtaining polyester yarn, adopting a blowing carding machine for conducting blowing carding treatment on warp yarn and weft yarn mixed fabrics, adopting a drawing frame for conducting drawing on polyester fibers, the warp yarn and weft yarn mixed fabrics and double-strand cotton fibers, then using a roving frame for conducting spinning, then making the fabrics and the fibers enter a spinning frame for being spun into spun yarn, conducting spooling, after spooling is ended, conducting beaming, after beaming is ended, conducting slashing, subsequently, making the spun yarn enter an air-jet loom, obtaining the base cloth, conducting finishing and packing, and then warehousing the base cloth. Advanced spinning equipment such as the roving frame is under automatic control of a computer in the preparation process, light-ration and smooth-drafting processes are adopted, resultant yarn quality is improved, a pure starch sizing agent containing no PVA is adopted in the formula, and environmental pollution caused by desizing is reduced.

Owner:张玮

Preservative wood-plastic chopping board

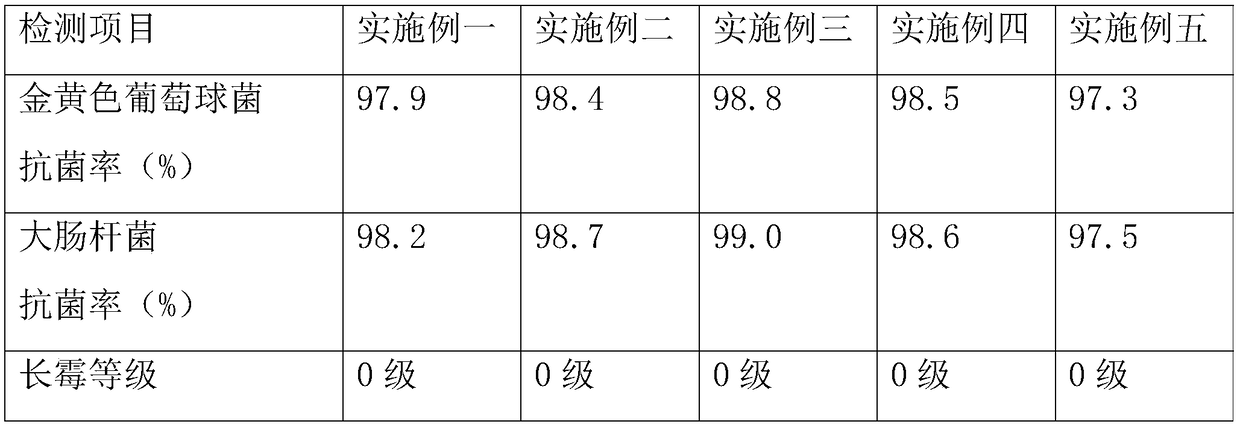

InactiveCN109438882AImprove overall performanceGood comprehensive mechanical propertiesZincBoron nitride

The invention provides a preservative wood-plastic chopping board. The preservative wood-plastic chopping board is prepared from the following components in parts by weight: 50 to 75 parts of polyvinyl chloride, 25 to 30 parts of ABS resin, 15 to 18 parts of TPU, 45 to 50 parts of wood flour, 18 to 20 parts of nano jade powder, 15 to 17 parts of talcum powder, 3 to 5 parts of boron nitride, 2 to 3parts of folium artemisiae argyi powder, 1 to 2 parts of garlic powder, 1 to 2 parts of onion powder, 0.3 to 0.5 parts of vinyl trimethylsilane and 0.3 to 0.5 part of zinc stearate. According to thepreservative wood-plastic chopping board, by adoption of proper components in reasonable amounts and combination with a preferred preparation method, the various raw material components are promoted to realize mutual synergy and mutual cooperation in a process of preparing the chopping board, thereby greatly improving the comprehensive performance of the chopping board. The prepared preservative wood-plastic chopping board which combines the dual characteristics of wood and plastic solves the problems that an existing wooden chopping board is easy to wear, easy to crack and easy to mold and easily produces bacteria, so that the prepared preservative wood-plastic chopping board has excellent comprehensive mechanical properties, can prevent damages by worms and molds, cannot absorb water, and is long in service life and high in stability.

Owner:CHONGQING JIALI LIQUOR IND

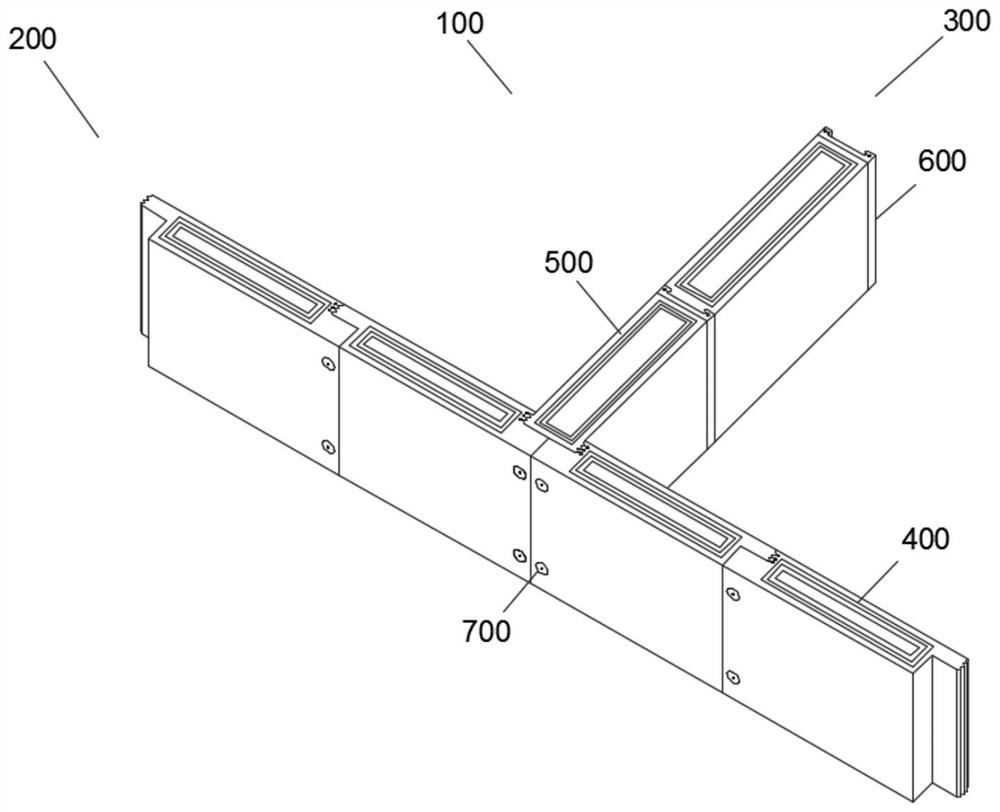

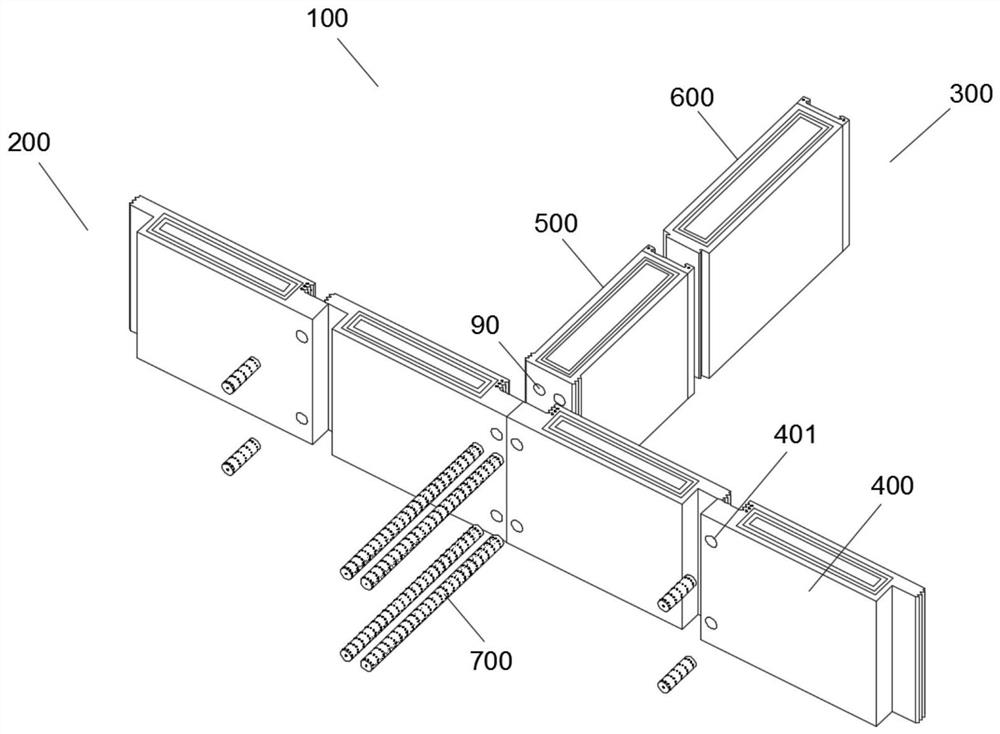

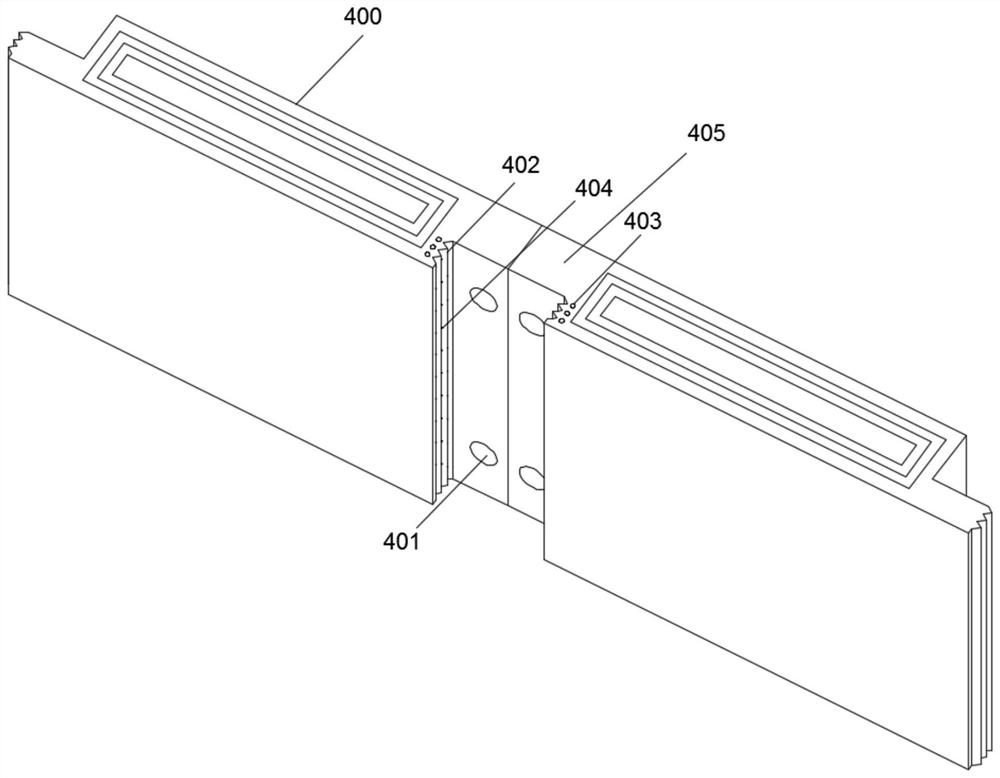

Fabricated thermal-insulation energy-saving building T-shaped die wall and assembling method thereof

ActiveCN114562067AImprove insulation performanceImprove waterproof performanceWallsPassive housesStructural engineeringMechanical engineering

The invention discloses a fabricated thermal-insulation and energy-saving building T-shaped die wall and an assembling method thereof, and relates to the technical field of constructions.The fabricated thermal-insulation and energy-saving building T-shaped die wall comprises a T-shaped die wall body, a transverse wall body, a vertical wall body, a first assembling wall body, a second assembling wall body and a third assembling wall body, and the T-shaped die wall body further comprises the transverse wall body and the vertical wall body; the transverse wall body is formed by splicing two groups of spliced wall bodies I, the vertical wall body is formed by splicing a spliced wall body II and a spliced wall body III, a lengthening plate is mounted at one end of each spliced wall body I, an insertion hole is formed in the outer surface of one side of each lengthening plate, a tooth groove I is formed in one end of each spliced wall body I, and a tooth groove II is formed in the other end of each spliced wall body II. The T-shaped die wall has the advantages of being simple in structure, low in cost, easy to machine and high in installation flexibility, and the yield of the T-shaped die wall is increased; in addition, the T-shaped mold wall has the advantages of being light in weight, convenient to assemble, good in wall heat preservation performance, capable of being rapidly assembled according to needs, capable of lengthening the transverse length and the vertical length of the T-shaped mold wall and capable of improving practicability and stability.

Owner:新疆澳地建设工程有限公司

Blended yarn of dacrons, wools and soybean protein fibers

The invention provides a blended yarn of dacrons, wools and soybean protein fibers, which comprises the following components: 60-70 weight parts of dacrons, 20-30 weight parts of wools and 15-25 weight parts of soybean protein fibers. The characteristics of the dacrons, the wools and the soybean protein fibers are mutually complemented and the advantages of the three components are utilized by the blended yarn provided by the invention.

Owner:HAIAN COUNTY BROS SYNTHETIC FIBER

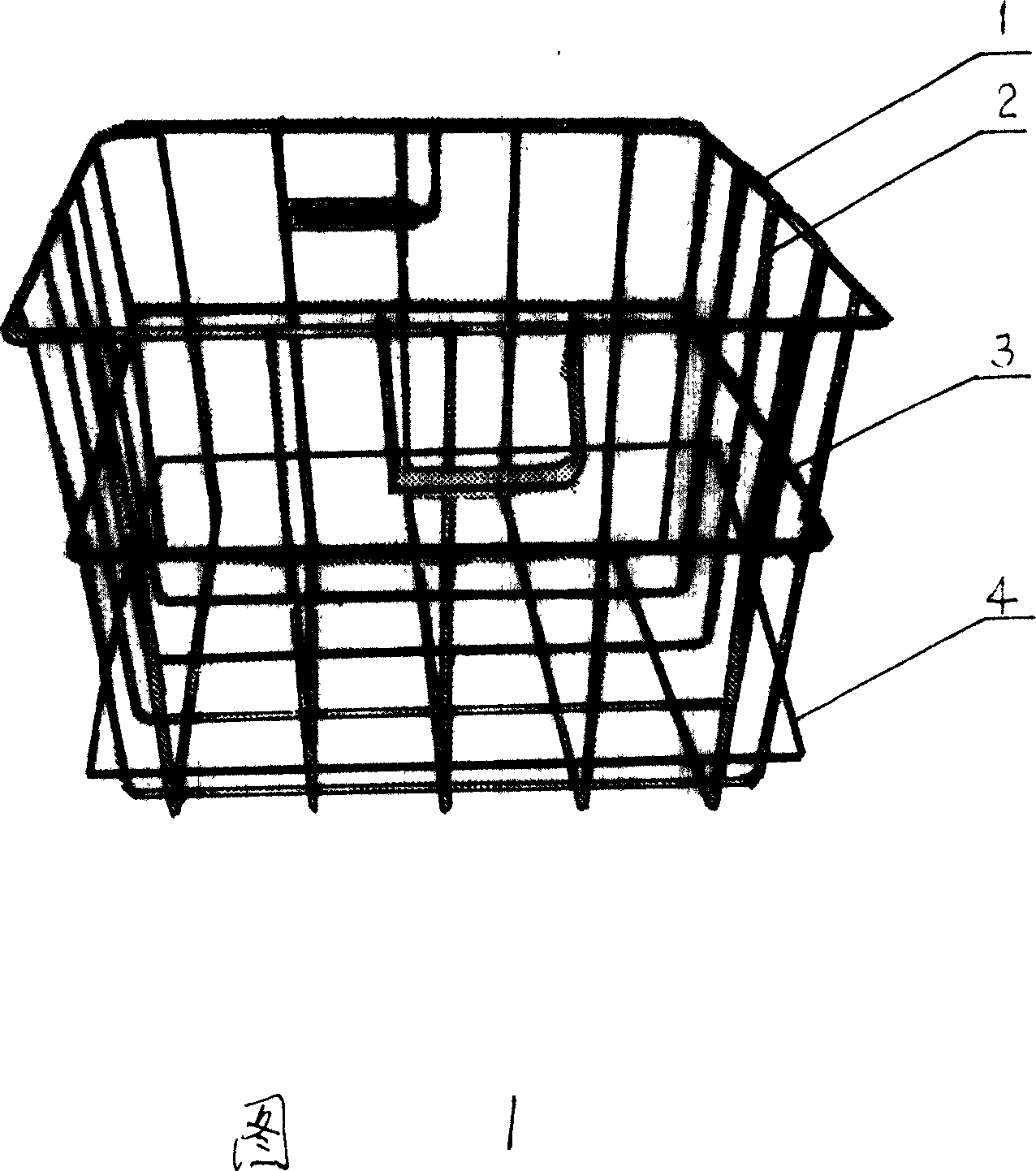

Metal basket

The invention is concerned with the gabion, it is: the top port (-) is the closure metal rectangle frame; several vertical strips (-) are bended metal strips, both sides of each vertical strip fixes on the top port (-); the bottom of the top port (-) is set one or more fixing strip (-), the fixing strip (-) rounds the vertical strips (-) and fixing connects with each vertical strip (-). The invention is uses the metal strips as the material, and spaces a distance, which is low cost and long using life.

Owner:王新光

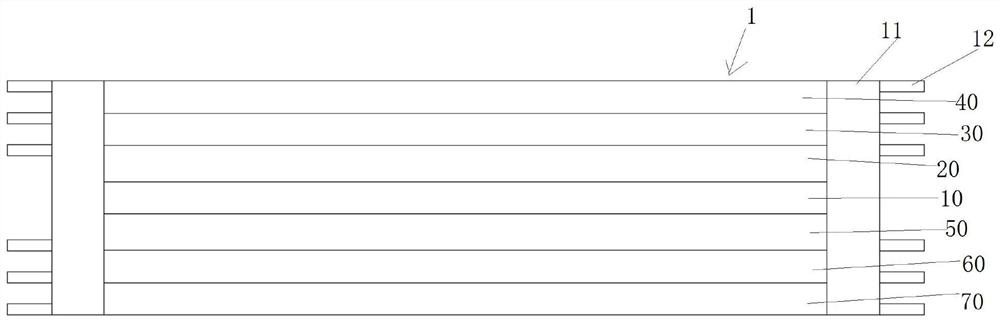

Improved scarf structure

InactiveCN114259097AImprove comfortGood warmth retentionSynthetic resin layered productsScarvesPolyesterFiber

The invention discloses an improved scarf structure which comprises a scarf body, the scarf body comprises a pure cotton layer, a chiffon fiber layer, a polyester layer and a pattern layer are sequentially arranged on the pure cotton layer, the chiffon fiber layer is fixedly connected to the upper portion of the pure cotton layer, the polyester layer is fixedly connected to the upper portion of the chiffon fiber layer, and the pattern layer is fixedly connected to the lower portion of the pure cotton layer. The pattern layer is fixedly connected to the upper surface of the polyester layer, a double-thread woven layer, a cashmere layer and an inner pattern layer are sequentially arranged below the pure cotton layer, the double-thread woven layer is fixedly connected to the lower portion of the pure cotton layer, the cashmere layer is fixedly connected to the lower portion of the double-thread woven layer, and the inner pattern layer is fixedly connected to the lower portion of the double-thread woven layer. The inner grain layer is fixedly connected to the lower surface of the cashmere layer, outer wrapping edges are arranged at the two ends of the pure cotton layer, and tassels are arranged on the outer sides of the outer wrapping edges.

Owner:溆浦县多爱申服饰有限公司

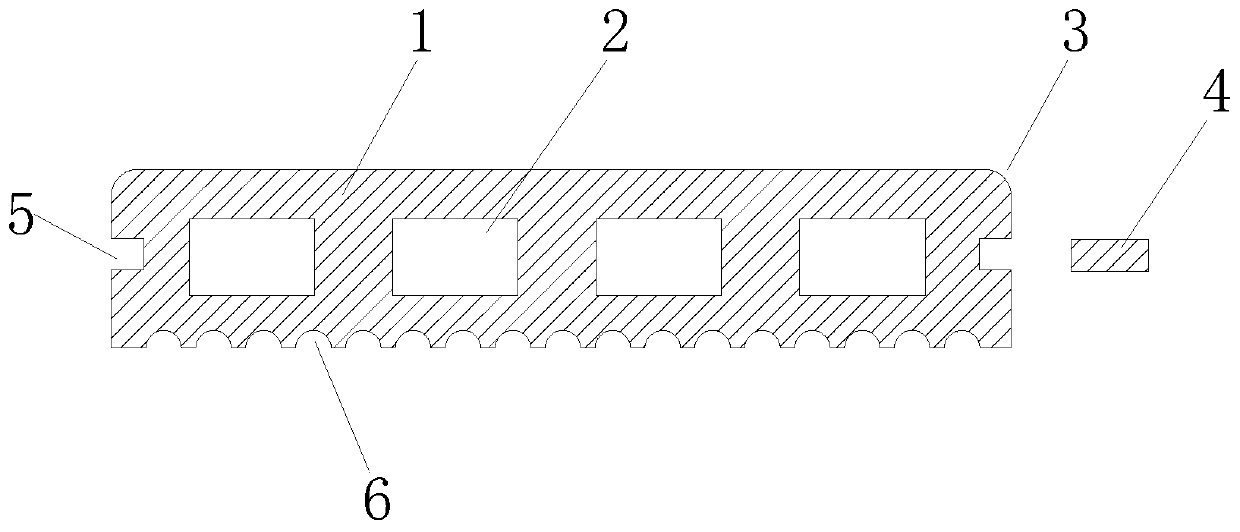

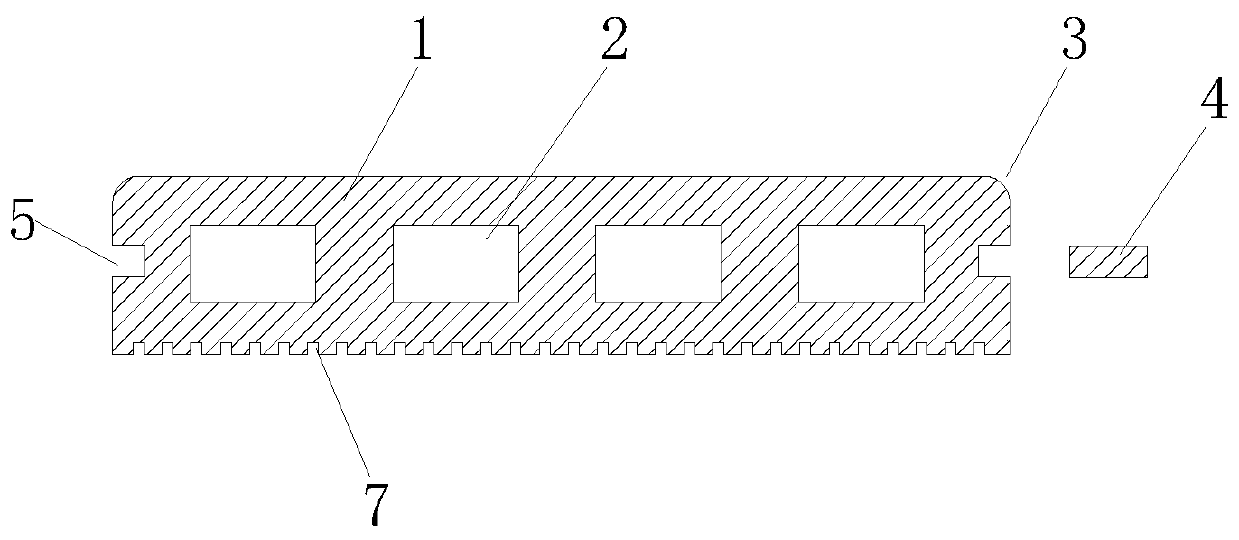

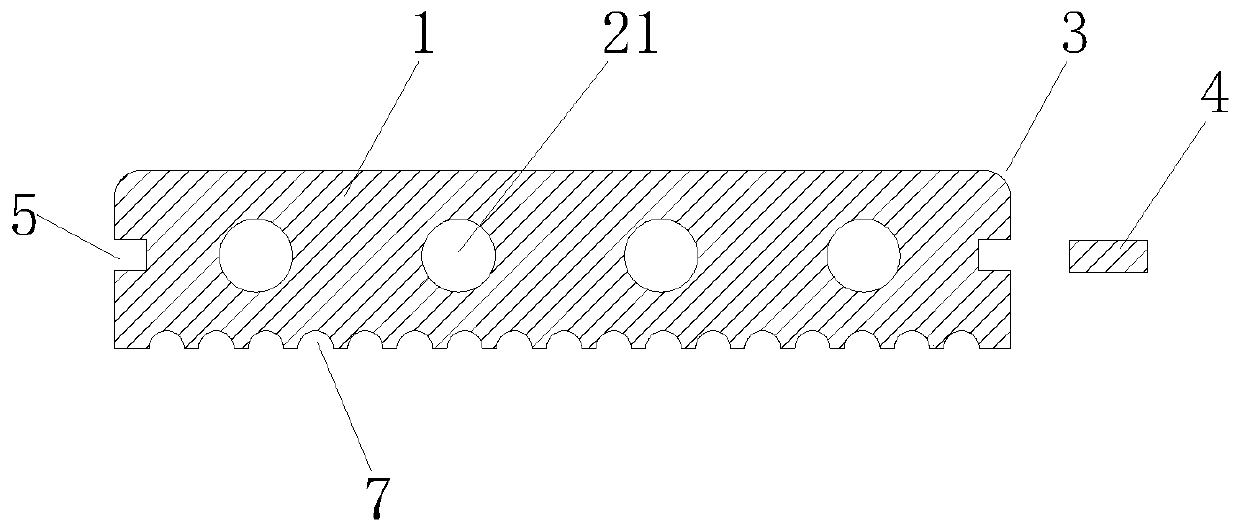

Outdoor insect preventing and aging resisting wood plastic floor and processing method

The invention discloses an outdoor insect preventing and aging resisting wood plastic floor and a processing method. The outdoor insect preventing and aging resisting wood plastic floor comprises a floor body, wherein the floor body is in a rectangular shape, and rounded corner structures are arranged at corner positions of the top surface of the floor body; weight reducing cavities are formed inthe floor body side by side; the height of the weight reducing cavities is two-thirds of the thickness of the floor body; anti-slip grooves are formed in the bottom surface of the floor body; the depth of the anti-slip grooves is one-tenth of the thickness of the floor body; an anti-corrosion layer is arranged on the surface of the floor body, and the thickness of the anti-corrosion layer is 1-2mm; the processing method is simple in steps; a wood plastic composite material has durability, a long service life, a soil-wood-like appearance and high hardness; excellent physical properties and better stability than wood are achieved, no cracks and warpage are caused, no bamboo wood scar and cross grains are caused, and a coloring agent, a film or a composite surface is added to prepare variouscolorful products; and an electrostatic spraying anti-corrosion coating is adopted to increase the corrosion resistance of the wood plastic floor.

Owner:重庆市久三建材有限公司

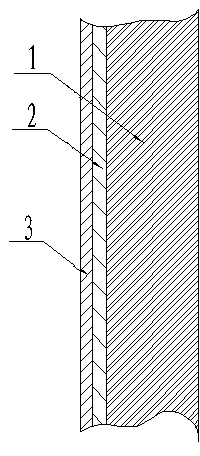

Simulated aluminum sheet wallboard coated with ultraviolet-resistant coating and preparation method thereof

The invention relates to a simulated aluminum sheet wallboard coated with an ultraviolet-resistant coating and a preparation method thereof. The simulated aluminum sheet wallboard comprises a simulated aluminum sheet base layer (1), a simulated aluminum sheet fluorocarbon lacquer coating (2) and an ultraviolet-resistant coating (3), wherein the external surface of the simulated aluminum sheet base layer (1) comprises the simulated aluminum sheet fluorocarbon lacquer coating (2); and the ultraviolet-resistant coating (3) is sprayed on the simulated aluminum sheet fluorocarbon lacquer coating (2). The preparation method comprises the following steps: mixing coal gangue fiber particles, high-polymer fireproof modified material, silicon aluminum clinker and stearic acid, drying at 150 DEG C, stirring for 20 minutes, extruding into a mold with simulated aluminum sheet grains, molding, spraying the fluorocarbon lacquer on the external veneer of the product, drying, and spraying the ultraviolet-resistant paint. The preparation method is simple to operate and simplifies the procedure; and the simulated aluminum sheet wallboard has the advantages of beautiful appearance, environmental protection and energy saving.

Owner:王东彬

Polyester and carbon fiber blended yarn

The invention provides a polyester and carbon fiber blended yarn which comprises the following components in parts by weight: 85-90 parts of polyesters and 10-15 parts of carbon fibers. The blended yarn provided by the invention complements the characteristics of the polyesters and the carbon fibers and has the advantages of the polyesters and the carbon fibers.

Owner:绍兴柯桥中兴化纤原料有限公司

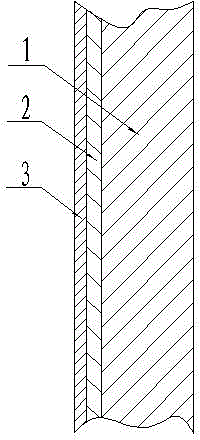

A kind of imitation wood grain wallboard coated with anti-ultraviolet coating and preparation method thereof

ActiveCN103741868BReduce weightArbitrary assemblySolid waste managementBuilding componentsFiberStearic acid

The invention relates to an imitation wood grain wallboard coated with an anti-ultraviolet coating and a preparation method thereof, which comprises an imitation wood base layer (1), an imitation wood grain forming layer (2) and an anti-ultraviolet coating (3). The outer surface of the base (1) includes an imitation wood grain forming layer (2), and a layer of anti-ultraviolet coating (3) is sprayed on the imitation wood grain forming layer (2); the imitation wood base (1) is added with imitation Paints for wood color. The process steps are: mix coal gangue fiber particles, polymer fire-resistant modified materials, silicon-aluminum clinker and stearic acid, then add wood-like color pigments according to production needs, dry and stir at 150°, and mix for 20 minutes. It is injected into a mold with imitation wood grain texture, and the outer decorative surface of the formed product is sprayed with anti-ultraviolet paint. The invention has the advantages of simple and convenient operation, simplified process, beautiful appearance, environmental protection and energy saving.

Owner:王东彬

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com