A kind of imitation wood grain wallboard coated with anti-ultraviolet coating and preparation method thereof

An anti-ultraviolet coating and imitation wood grain technology, applied in the field of building boards, can solve the problems of complicated procedures, long construction period, complicated operation, etc., and achieve the effect of light weight, great flexibility and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

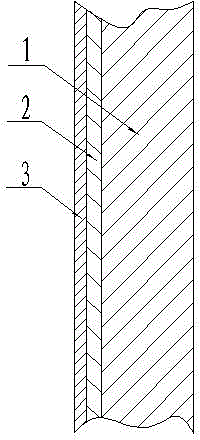

[0028] An imitation wood-grain wallboard coated with an anti-ultraviolet coating, which includes an imitation wood-grain base 1, an imitation wood-grain forming layer 2 and an anti-ultraviolet coating 3, the outer surface of the imitation wood-grain base 1 contains an imitation wood-grain forming layer 2, A layer of anti-ultraviolet coating 3 is sprayed on the imitation wood grain forming layer 2;

[0029] The imitation wood grain forming layer 2 is a texture layer imitating the texture of pine logs; the anti-ultraviolet coating 3 is a commercially available anti-ultraviolet coating; the imitation wood base layer 1 is composed of 50% (weight) coal gangue fiber Granules, 35% (weight) of polymer fire-resistant modified materials, 10% (weight) of silicon-aluminum clinker and 5% (weight) of stearic acid are mixed and then added with pigments imitating the color of pine logs.

[0030] A kind of preparation method of the imitation wood-grain wallboard that is coated with anti-ultrav...

Embodiment 2

[0038] An imitation wood-grain wallboard coated with an anti-ultraviolet coating, which includes an imitation wood-grain base 1, an imitation wood-grain forming layer 2 and an anti-ultraviolet coating 3, the outer surface of the imitation wood-grain base 1 contains an imitation wood-grain forming layer 2, A layer of anti-ultraviolet coating 3 is sprayed on the imitation wood grain forming layer 2;

[0039] The imitation wood grain forming layer 2 is a texture layer imitating the texture of ebony wood; the described anti-ultraviolet coating 3 is a commercially available anti-ultraviolet coating; the described imitation wood base layer 1 is composed of 75% (weight) coal gangue Fiber particles, 15% (weight) polymer fire-resistant modified materials, 8% (weight) silicon-aluminum clinker and 2% (weight) stearic acid are mixed and then added with pigments imitating the color of ebony wood.

[0040] A kind of preparation method of the imitation wood-grain wallboard that is coated wit...

Embodiment 3

[0048] An imitation wood-grain wallboard coated with an anti-ultraviolet coating, which includes an imitation wood-grain base 1, an imitation wood-grain forming layer 2 and an anti-ultraviolet coating 3, the outer surface of the imitation wood-grain base 1 contains an imitation wood-grain forming layer 2, A layer of anti-ultraviolet coating 3 is sprayed on the imitation wood grain forming layer 2;

[0049] The imitation wood grain forming layer 2 is a texture layer imitating the texture of Fraxinus mandshurica; the described anti-ultraviolet coating 3 is a commercially available anti-ultraviolet coating; the described imitation wood base layer 1 is made of 60% (weight) coal gangue Fiber particles, 20% (weight) polymer fireproof modified material, 15% (weight) silicon-aluminum clinker and 5% (weight) stearic acid are mixed and then added with pigment imitating the color of ash.

[0050] A kind of preparation method of the imitation wood-grain wallboard that is coated with anti-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com