Fabricated thermal-insulation energy-saving building T-shaped die wall and assembling method thereof

A prefabricated, wall technology, applied in thermal insulation, construction, building components, etc., can solve the inconvenient extension of the horizontal and vertical walls of the T-shaped wall, the complicated assembly process of the T-shaped wall, and the inconvenience of the wall Handling and assembly problems, to achieve the effect of convenient and fast splicing, good chemical stability, and good insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

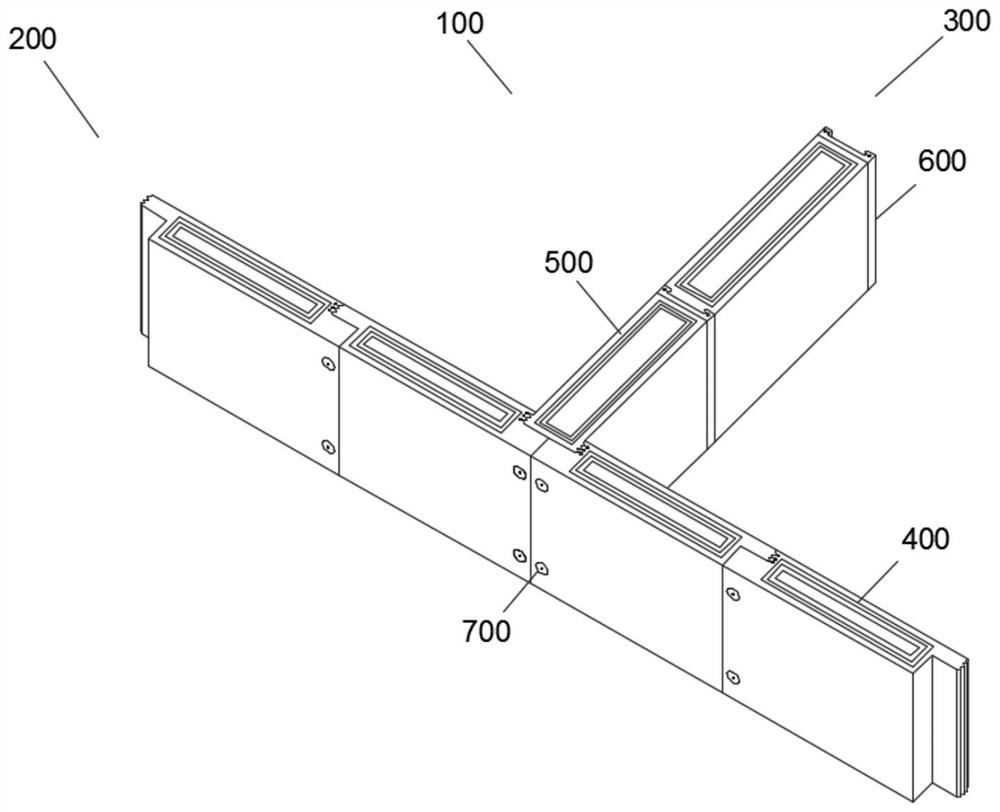

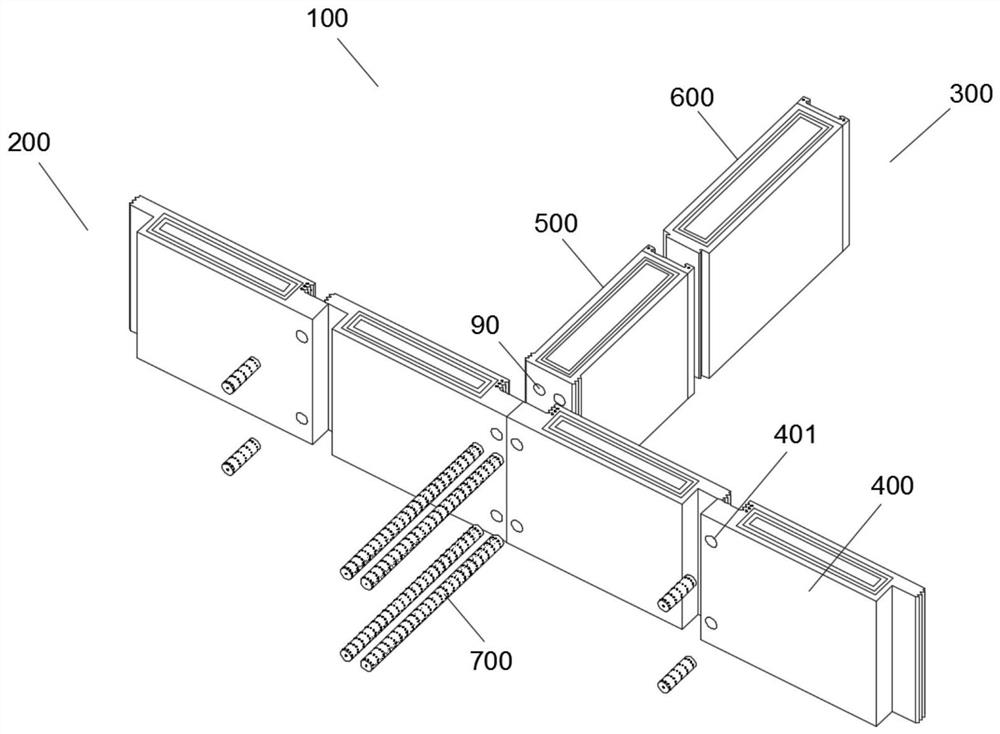

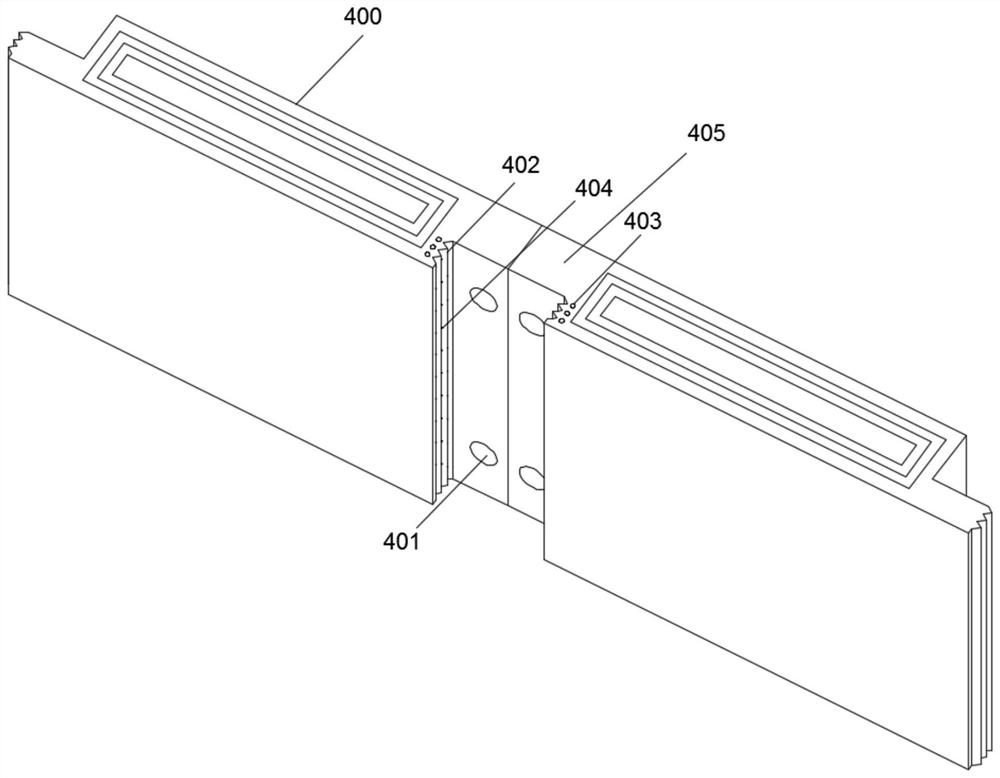

[0039] Refer to the attached Figure 1-9 In order to achieve the above purpose, the present invention provides a T-shaped wall of an assembled thermal insulation and energy-saving building, the present invention provides the following technical solutions: The wall body 200, the vertical wall body 300, the assembled wall body 1 400, the assembled wall body 2 500 and the assembled wall body 3 600, the T-shaped wall body 100 also includes a horizontal wall body 200 and a vertical wall body 300. 200 is assembled by two groups of assembled walls one 400, the vertical wall 300 is assembled by two assembled walls 500 and three 600 assembled walls, one end of the assembled wall 400 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com