Preservative wood-plastic chopping board

A cutting board and wood-plastic technology, applied in the field of daily utensils, can solve the problems of easy loss of cutting boards, easy sliding of cutting boards, easy breeding of bacteria, etc., and achieves excellent comprehensive mechanical properties, no maintenance, and strong plasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

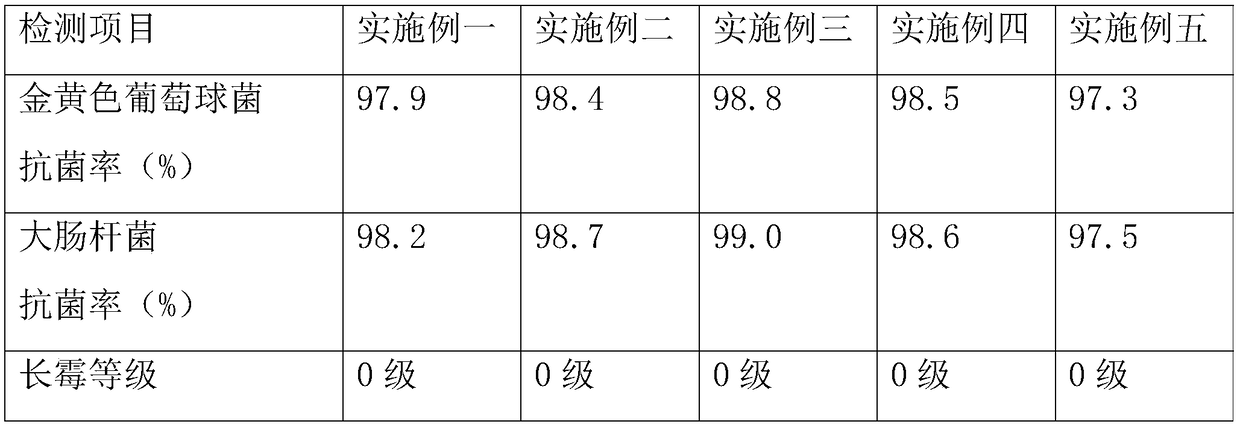

Examples

Embodiment 1

[0020] The antiseptic wood-plastic cutting board provided by the present embodiment, the raw materials of the wood-plastic cutting board include the following components by weight: 50 parts of polyvinyl chloride, 30 parts of ABS resin, 15 parts of TPU, 50 parts of wood powder (80 mesh) , 18 parts of nano jade powder, 17 parts of talc powder (1250 mesh), 5 parts of boron nitride (800 mesh), 2 parts of mugwort leaf powder, 1 part of garlic powder, 1 part of onion powder, 0.4 part of vinyltrimethylsilane, 0.3 parts of zinc stearate.

[0021] In the present embodiment, the preparation method of described chopping board comprises the following steps:

[0022] (1) Add polyvinyl chloride, ABS resin, TPU, zinc stearate, and vinyltrimethylsilane to the mixer, heat up to 160°C, mix and stir at a speed of 300r / min for 15min, then add wood powder and mugwort leaf powder , garlic powder and onion powder, adjust the rotation speed to 800r / min, heat up to 175°C, continue to stir for 12min, ...

Embodiment 2

[0028] The antiseptic wood-plastic cutting board provided in this embodiment, the raw materials of the wood-plastic cutting board include the following components by weight: 65 parts of polyvinyl chloride, 28 parts of ABS resin, 17 parts of TPU, 48 parts of wood powder (80 mesh) , 19 parts of nano jade powder, 16 parts of talc powder (800 mesh), 4 parts of boron nitride (1250 mesh), 2 parts of mugwort leaf powder, 2 parts of garlic powder, 1 part of onion powder, 0.4 part of vinyltrimethylsilane, 0.3 parts of zinc stearate.

[0029] In the present embodiment, the preparation method of described chopping board comprises the following steps:

[0030] (1) Add polyvinyl chloride, ABS resin, TPU, zinc stearate, and vinyltrimethylsilane into the mixer, heat up to 160°C, mix and stir at a speed of 300r / min for 18min, then add wood powder and mugwort leaf powder , garlic powder and onion powder, adjust the speed to 800r / min, heat up to 175°C, continue to stir for 13min, finally add n...

Embodiment 3

[0036] The antiseptic wood-plastic cutting board provided in this embodiment, the raw materials of the wood-plastic cutting board include the following components by weight: 75 parts of polyvinyl chloride, 30 parts of ABS resin, 18 parts of TPU, 50 parts of wood powder (100 mesh) , 20 parts of nano jade powder, 17 parts of talc powder (1000 mesh), 5 parts of boron nitride (800 mesh), 3 parts of mugwort leaf powder, 2 parts of garlic powder, 2 parts of onion powder, 0.5 part of vinyltrimethylsilane, 0.5 parts of zinc stearate.

[0037] In the present embodiment, the preparation method of described chopping board comprises the following steps:

[0038] (1) Add polyvinyl chloride, ABS resin, TPU, zinc stearate, and vinyltrimethylsilane to the mixer, heat up to 160°C, mix and stir at a speed of 300r / min for 20min, then add wood powder and mugwort leaf powder , garlic powder and onion powder, adjust the speed to 800r / min, heat up to 175°C, continue to stir for 15min, finally add n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending failure load | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Bending failure load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com