Al-Si-Mg-Er rare earth casting aluminium alloy

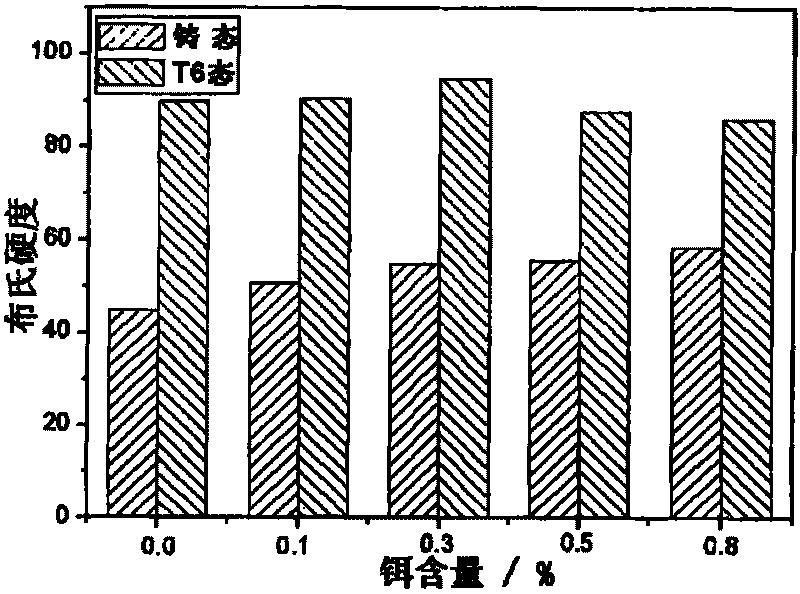

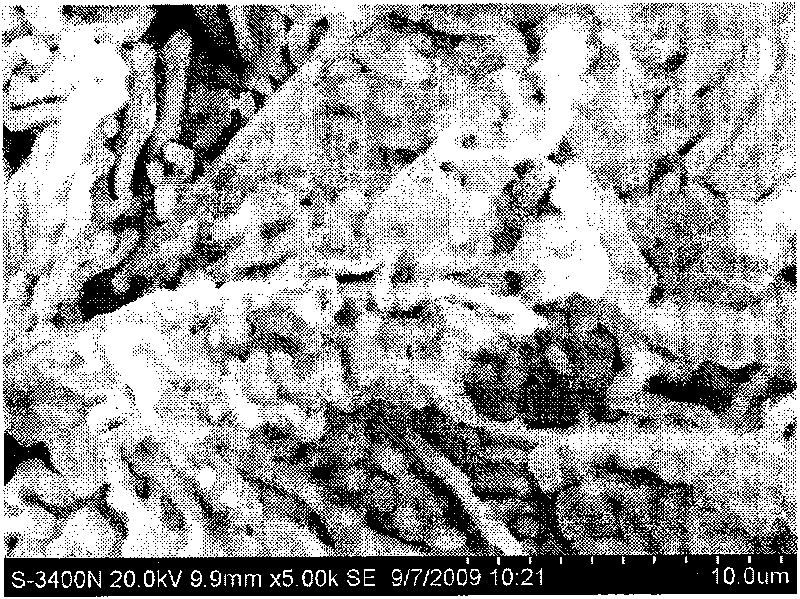

An al-si-mg-er, casting aluminum alloy technology, applied in the field of metal alloys, can solve the problems that the mechanical properties research has not been reported yet, and the modification effect of rare earth element Er has not been studied, and achieves comprehensive performance improvement, tensile strength. and the effect of increasing yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: adopt conventional gravity casting to prepare Al-Si-Mg-Er alloy, used raw material is high-purity Al (purity is 99.99%), industrial pure Mg (purity is 99.9%), Al-12% Si master alloy and Al-6% Er master alloy. Firstly, 631.7g of high-purity aluminum and 838.4g of Al-12% Si master alloy were added into a graphite clay crucible, and the alloy was melted in a resistance furnace at a melting temperature of 750°C. After the metal is completely melted, press 6.4g of pure Mg into the metal melt with a bell jar, and the alloy is heated at 720°C with C 2 Cl 6 Degassing and refining. After standing for 20 minutes, raise the temperature to 750°C and add 25g Al-6% Er master alloy. After standing still, it is poured into an iron mold to obtain an Al-7%Si-0.4%Mg-0.1%Er alloy ingot, and the pouring temperature is 720°C.

Embodiment 2

[0015] Embodiment 2: adopt conventional gravity casting to prepare Al-Si-Mg-Er alloy, used raw material is high-purity Al (purity is 99.99%), industrial pure Mg (purity is 99.9%), Al-12% Si master alloy and Al-6% Er master alloy. Firstly, 581.7g of high-purity aluminum and 838.4g of Al-12% Si master alloy were added into a graphite clay crucible, and the alloy was melted in a resistance furnace at a melting temperature of 750°C. After the metal is completely melted, press 6.4g of pure Mg into the metal melt with a bell jar, and the alloy is heated at 720°C with C 2 Cl 6 Degassing and refining. After standing still for 20 minutes, the temperature was raised to 750° C. and 75 g of Al-6% Er master alloy was added. After standing still, it is poured into an iron mold to obtain an Al-7%Si-0.4%Mg-0.3%Er alloy ingot, and the pouring temperature is 720°C.

Embodiment 3

[0016] Embodiment 3: adopt conventional gravity casting to prepare Al-Si-Mg-Er alloy, used raw material is high-purity Al (purity is 99.99%), industrial pure Mg (purity is 99.9%), Al-12% Si master alloy and Al-6% Er master alloy. Firstly, 531.7g of high-purity aluminum and 838.4g of Al-12% Si master alloy were added into a graphite clay crucible, and the alloy was melted in a resistance furnace at a melting temperature of 750°C. After the metal is completely melted, press 6.4g of pure Mg into the metal melt with a bell jar, and the alloy is heated at 720°C with C 2 Cl 6 Degassing and refining. After standing still for 20 minutes, raise the temperature to 750°C and add 125g Al-6% Er master alloy. After standing still, it is poured into an iron mold to obtain an Al-7%Si-0.4%Mg-0.5%Er alloy ingot, and the pouring temperature is 720°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com