Bamboo fiber, viscose and polyester fiber blended yarn

A technology of bamboo fiber and blended yarn, which is applied in the field of viscose and polyester blended yarn and bamboo fiber to achieve strong longitudinal and transverse strength, good washability and wearability, and good dyeing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] The blended yarn of bamboo fiber, viscose and polyester in this embodiment includes the following components according to weight percentage: 30% bamboo fiber, 15% viscose and 55% polyester. Said viscose is 1.5D×38mm viscose, and said polyester is 1.5D×38mm polyester.

[0012] The production method steps are as follows:

[0013] (1) Cleaning: the mixed raw materials are rolled into rolls through the cleaning machine;

[0014] (2) Carding: the rolls are made into raw sliver through the carding machine;

[0015] (3) Drawing: the raw sliver is merged with the mature sliver through the drawing frame;

[0016] (4) Roving: through the roving frame, the combined cooked sliver is under-stretched and thinned into a roving sliver;

[0017] (5) Spinning: The roving is understretched into a certain number of yarns through the spinning frame;

[0018] (6) Winding: the spun yarn is wound into a conical cheese through the winder;

[0019] (7) Weigh and pack the finished blend...

Embodiment 2

[0021] The yarn properties of the blended yarn of bamboo fiber, viscose and polyester in Example 1 were detected.

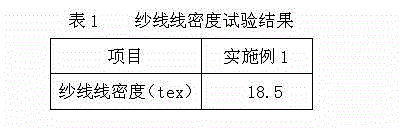

[0022] 1) Yarn linear density test

[0023] The linear density of the yarn is one of the most important characteristic indicators of the yarn, which directly affects the performance and appearance of the fabric, such as stiffness, gloss, texture, wear resistance, etc.

[0024] The blended yarn of the bamboo fiber of embodiment 1, viscose glue and polyester is carried out yarn linear density test. The test results are as follows:

[0025]

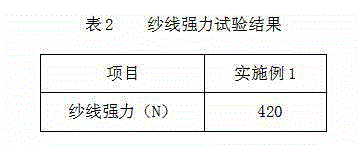

[0026] 2) Yarn strength test

[0027] Yarn strength is closely related to the breakage rate of this process and the next process, and it is an important reference index for product grading and spun yarn quality assessment.

[0028] The blended yarn of bamboo fiber, viscose glue and polyester of embodiment 1 is carried out yarn strength test. The test results are as follows:

[0029]

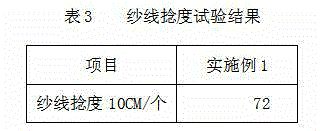

[0030] 3) Yarn twist ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com