Core-sheath type bulked tow and preparation method thereof

A core-sheath type, fluffy technology, applied in the field of fluffy processing tow, can solve the problems of not easy to machine wash, price change, difficult to wash, etc., and achieve the effect of high bulkiness, light quality and stable price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

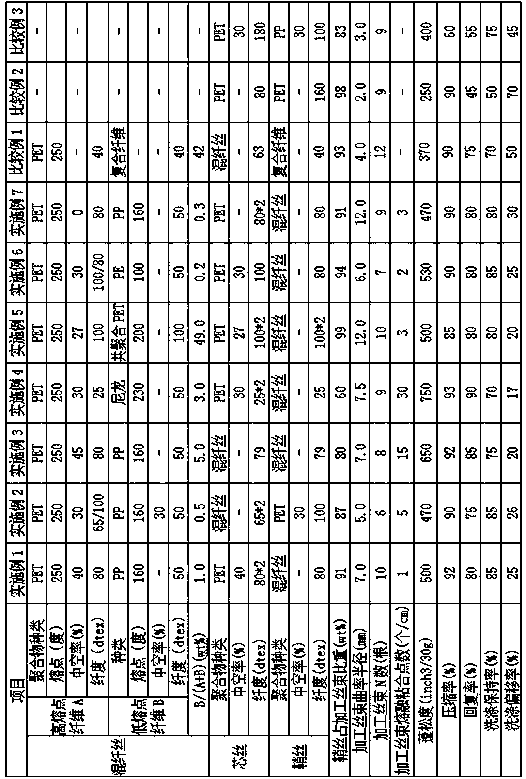

Embodiment 1

[0107] The core filament is high-melting point hollow polyester PET fiber with a fineness of 160.0dtex; the sheath filament is a blended filament composed of the above-mentioned high-melting point hollow polyester fiber and low-melting point solid polypropylene PP fiber with a fineness of 80.0dtex and a low melting point The weight ratio of PP to the mixed filament is 1.0wt%. The weight ratio of sheath filaments to processed filaments is 91wt%. The high-melting point hollow polyester PET fiber is a three-dimensional curled shape in a natural state.

[0108] The sheath fiber and the core fiber are respectively fed into the interlacer through different feeding rollers, the feeding speed of the core fiber is 20m / min, and the feeding speed of the sheath fiber is 400m / min. The flow rate of the air in the nozzle is set to be 70 L / min, and the sheath fiber and the core fiber pass through the air nozzle to form a fluffy processed yarn. Then the obtained bulky processed yarns were pr...

Embodiment 2

[0112] The core filament is a blended filament composed of high-melting point hollow polyester fiber and low-melting point hollow polypropylene PP fiber, with a fineness of 130.0dtex; the sheath filament is made of high-melting point hollow polyester fiber, with a fineness of 100.0dtex, and low-melting point PP fiber The mass fraction of mixed filaments is 0.5wt%. The weight ratio of sheath filaments to processed filaments is 87wt%. The high melting point hollow polyester PET fiber and the low melting point hollow polypropylene PP fiber are three-dimensional curled shapes in the natural state.

[0113] The sheath fiber and the core fiber are respectively fed into the interlacer through different feeding rollers, the feeding speed of the core fiber is 20m / min, and the feeding speed of the sheath fiber is 180m / min.

[0114] Other steps are the same as in Example 1, and the specific values are shown in Table 1.

Embodiment 3

[0116] The core filament is a blended filament composed of high melting point hollow polyester PET fiber and low melting point solid polypropylene PP fiber, with a fineness of 79.0dtex; the sheath filament is made of high melting point hollow polyester PET fiber and low melting point medium solid polypropylene The mixed fiber yarn composed of PP fiber has a fineness of 79.0dtex, and the mass fraction of the low melting point PP fiber in the mixed fiber yarn is 5.0wt%. The mass fraction of sheath filaments in processed filaments is 80wt%.

[0117] The sheath fiber and the core fiber are respectively fed into the interlacer through different feeding rollers, the feeding speed of the core fiber is 20m / min, and the feeding speed of the sheath fiber is 80m / min.

[0118] Other steps are the same as in Example 1, and the specific values are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| compression ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com